Abstract

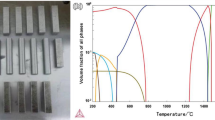

17-4 PH stainless steel (SS) is a precipitation-hardening (PH) type of steel manufactured by selective laser melting (SLM) and known for high strength and corrosion resistance. The selection of process parameters plays an important role to reduce defects and improve mechanical properties. This study investigated the effect of hexagonal and chessboard scan strategies on relative density and residual stress of SLM-printed 17-4 PH SS samples. Relative density decreased as the scan strategy changed from hexagonal to chessboard due to insufficient melting, which causes pores in the samples and the residual stress was lower in the chessboard scan strategy due to lower thermal gradient. In this study, the hexagonal scan strategy was chosen based on higher relative density. The microstructure and mechanical properties of as-built and heat-treated (SA, SA + H900, SA + H1150) samples for optimized scan strategy were studied. The microstructure of 17-4 PH SS contains austenite and martensite. Austenite in as-built samples was retained due to nitrogen inert atmosphere, which acts as an austenite stabilizer and this can be further reduced by heat treatments, which is confirmed by EBSD and XRD. Precipitates were formed during aging heat treatments, which effects the mechanical properties. Mechanical properties depended on martensitic phase fraction and grain size. Grain size decreased from as-built to heat treatments. The increase in martensitic phase fraction and decrease in grain size resulted in high hardness and high strength. In this study, SA + H1150 samples were completely converted into martensite and showed higher mechanical properties.

Similar content being viewed by others

References

J. Butt, Exploring the interrelationship between additive manufacturing and Industry 4.0, Designs, 2020, 4(2), p 13. https://doi.org/10.3390/DESIGNS4020013

C.Y. Yap, C.K. Chua, Z.L. Dong et al., Review of Selective Laser Melting: Materials and Applications, Appl. Phys. Rev., 2015, 2, p 041101. https://doi.org/10.1063/1.4935926

L. Zai, C. Zhang, Y. Wang et al., Laser Powder Bed Fusion of Precipitation-Hardened Martensitic Stainless Steels: A Review, Metals, 2020, 10, p 255. https://doi.org/10.3390/MET10020255

A.K. Singla, M. Banerjee, A. Sharma et al., Selective Laser Melting of Ti6Al4V Alloy: Process Parameters, Defects and Post-treatments, J. Manuf. Process., 2021, 64, p 161–187. https://doi.org/10.1016/J.JMAPRO.2021.01.009

N. Limbasiya, A. Jain, H. Soni et al., A Comprehensive Review on the Effect of Process Parameters and Post-process Treatments on Microstructure and Mechanical Properties of Selective Laser Melting of AlSi10Mg, J. Market. Res., 2022, 21, p 1141–1176. https://doi.org/10.1016/J.JMRT.2022.09.092

I. Koutiri, E. Pessard, P. Peyre et al., Influence of SLM Process Parameters on the Surface Finish, Porosity Rate and Fatigue Behavior of As-Built Inconel 625 Parts, J. Mater. Process. Technol., 2018, 255, p 536–546. https://doi.org/10.1016/J.JMATPROTEC.2017.12.043

E. Liverani, S. Toschi, L. Ceschini, and A. Fortunato, Effect of Selective Laser Melting (SLM) Process Parameters on Microstructure and Mechanical Properties of 316L Austenitic Stainless Steel, J. Mater. Process. Technol., 2017, 249, p 255–263. https://doi.org/10.1016/J.JMATPROTEC.2017.05.042

S. Bai, N. Perevoshchikova, Y. Sha, and X. Wu, The Effects of Selective Laser Melting Process Parameters on Relative Density of the AlSi10Mg Parts and Suitable Procedures of the Archimedes Method, Appl. Sci., 2019, 9, p 583. https://doi.org/10.3390/APP9030583

A.K. Dutt, G.K. Bansal, S. Tripathy et al., Optimization of Selective Laser Melting (SLM) Additive Manufacturing Process Parameters of 316L Austenitic Stainless Steel, Trans Indian Inst Met, 2023, 76, p 335–345. https://doi.org/10.1007/s12666-022-02687-2

M. Elsayed, M. Ghazy, Y. Youssef, and K. Essa, Optimization of SLM Process Parameters for Ti6Al4V Medical Implants, Rapid Prototyp J, 2019, 25, p 433–447. https://doi.org/10.1108/RPJ-05-2018-0112

Z. Xiao, C. Chen, H. Zhu et al., Study of Residual Stress in Selective Laser Melting of Ti6Al4V, Mater. Des., 2020, 193, 108846. https://doi.org/10.1016/J.MATDES.2020.108846

H. Jia, H. Sun, H. Wang et al., Scanning Strategy in Selective Laser Melting (SLM): A Review, Int. J. Adv. Manuf. Technol., 2021, 113, p 2413–2435. https://doi.org/10.1007/S00170-021-06810-3

Hy. Chen, Dd. Gu, Q. Ge et al., Role of laser scan strategies in defect control, microstructural evolution and mechanical properties of steel matrix composites prepared by laser additive manufacturing, Int. J. Miner. Metall. Mater., 2021, 28, p 462–474. https://doi.org/10.1007/s12613-020-2133-x

W. Abd-Elaziem, S. Elkatatny, A.E. Abd-Elaziem et al., On the Current Research Progress of Metallic Materials Fabricated by Laser Powder bed Fusion Process: A Review, J. Market. Res., 2022, 20, p 681–707. https://doi.org/10.1016/J.JMRT.2022.07.085

S. Giganto, S. Martínez-Pellitero, J. Barreiro et al., Impact of the laser scanning strategy on the quality of 17-4PH stainless steel parts manufactured by selective laser melting, J. Market. Res., 2022, 20, p 2734–2747. https://doi.org/10.1016/J.JMRT.2022.08.040

P. Bian, J. Shi, Y. Liu, and Y. Xie, Influence of Laser Power and Scanning Strategy on Residual Stress Distribution in Additively Manufactured 316L Steel, Opt. Laser Technol., 2020, 132, 106477. https://doi.org/10.1016/J.OPTLASTEC.2020.106477

X. Miao, X. Liu, P. Lu et al., Influence of Scanning Strategy on the Performances of GO-Reinforced Ti6Al4V Nanocomposites Manufactured by SLM, Metals, 2020, 10, p 1379. https://doi.org/10.3390/MET10101379

L. Mugwagwa, D. Dimitrov, S. Matope, and I. Yadroitsev, Evaluation of the Impact of Scanning Strategies on Residual Stresses in Selective Laser Melting, Int. J. Adv. Manuf. Technol., 2019, 102, p 2441–2450. https://doi.org/10.1007/s00170-019-03396-9

Y. Lu, S. Wu, Y. Gan et al., Study on the Microstructure, Mechanical Property and Residual Stress of SLM Inconel-718 Alloy Manufactured by Differing Island Scanning Strategy, Opt Laser Technol, 2015, 75, p 197–206. https://doi.org/10.1016/j.optlastec.2015.07.009

T. Bhardwaj and M. Shukla, Effect of Laser Scanning Strategies on Texture, Physical and Mechanical Properties of Laser Sintered Maraging Steel, Mater. Sci. Eng., A, 2018, 734, p 102–109. https://doi.org/10.1016/J.MSEA.2018.07.089

M.K. Gupta, A.K. Singla, H. Ji et al., Impact of Layer Rotation on Micro-Structure, Grain Size, Surface Integrity and Mechanical Behaviour of SLM Al-Si-10Mg Alloy, J. Market. Res., 2020, 9, p 9506–9522. https://doi.org/10.1016/J.JMRT.2020.06.090

Z. Wang, Z. Yang, F. Liu, and W. Zhang, Influence of the Scanning Angle on the Grain Growth and Mechanical Properties of Ni10Cr6W1Fe9Ti1 HEA Fabricated Using the LPBF–AM Method, Mater. Sci. Eng., A, 2023, 864, 144596. https://doi.org/10.1016/J.MSEA.2023.144596

S. Pasebani, M. Ghayoor, S. Badwe et al., Effects of Atomizing Media and Post Processing on Mechanical Properties of 17-4 PH Stainless Steel Manufactured Via Selective Laser Melting, Addit. Manuf., 2018, 22, p 127–137. https://doi.org/10.1016/J.ADDMA.2018.05.011

L.E. Murr, E. Martinez, J. Hernandez et al., Microstructures and Properties of 17-4 PH Stainless Steel Fabricated by Selective Laser Melting, J. Market. Res., 2012, 1, p 167–177. https://doi.org/10.1016/S2238-7854(12)70029-7

H.K. Rafi, D. Pal, N. Patil et al., Microstructure and Mechanical Behavior of 17-4 Precipitation Hardenable Steel Processed by Selective Laser Melting, J. Mater. Eng. Perform., 2014, 23, p 4421–4428. https://doi.org/10.1007/S11665-014-1226-Y

J.S. Weaver, J. Whiting, V. Tondare et al., The Effects of Particle Size Distribution on the Rheological Properties of the Powder and the Mechanical Properties of Additively Manufactured 17-4 PH Stainless Steel, Addit. Manuf., 2021, 39, 101851. https://doi.org/10.1016/J.ADDMA.2021.101851

M.A. Aripin, Z. Sajuri, N.H. Jamadon et al., Effects of Build Orientations on Microstructure Evolution, Porosity Formation, and Mechanical Performance of Selective Laser Melted 17-4 PH Stainless Steel, Metals, 2022, 12, p 1968. https://doi.org/10.3390/MET12111968

M. Mahmoudi, A. Elwany, A. Yadollahi et al., Mechanical Properties and Microstructural Characterization of Selective Laser Melted 17-4 PH Stainless Steel, Rapid Prototyp J, 2017, 23, p 280–294. https://doi.org/10.1108/RPJ-12-2015-0192

C. Garcia-Cabezon, C.G. Hernández, M.A. Castro-Sastre et al., Heat Treatments of 17-4 PH SS Processed by SLM to Improve Its Strength and Biocompatibility in Biomedical Applications, J. Market. Res., 2023, 26, p 3524–3543. https://doi.org/10.1016/J.JMRT.2023.08.104

S. Cheruvathur, E.A. Lass, and C.E. Campbell, Additive Manufacturing of 17-4 PH Stainless Steel: Post-processing Heat Treatment to Achieve Uniform Reproducible Microstructure, JOM, 2016, 68, p 930–942. https://doi.org/10.1007/s11837-015-1754-4

Y. Sun, R.J. Hebert, and M. Aindow, Effect of Heat Treatments on Microstructural Evolution of Additively Manufactured and Wrought 17-4PH Stainless Steel, Mater. Des., 2018, 156, p 429–440. https://doi.org/10.1016/j.matdes.2018.07.015

A.D. Akessa, W.M. Tucho, H.G. Lemu, and J. Grønsund, Investigations of the Microstructure and Mechanical Properties of 17-4 PH ss Printed Using a MarkForged Metal X, Materials, 2022, 15, p 6898. https://doi.org/10.3390/MA15196898

D. Dong, J. Wang, C. Chen et al., Influence of Aging Treatment Regimes on Microstructure and Mechanical Properties of Selective Laser Melted 17-4 PH Steel, Micromachines (Basel), 2023, 14, p 871. https://doi.org/10.3390/mi14040871

K. Li, J. Zhan, T. Yang et al., Homogenization Timing Effect on Microstructure and Precipitation Strengthening of 17-4PH Stainless Steel Fabricated by Laser Powder Bed Fusion, Addit. Manuf., 2022, 52, 102672. https://doi.org/10.1016/J.ADDMA.2022.102672

H.R. Lashgari, E. Adabifiroozjaei, C. Kong et al., Heat Treatment Response of Additively Manufactured 17-4PH Stainless Steel, Mater Charact, 2023, 197, 112661. https://doi.org/10.1016/J.MATCHAR.2023.112661

S. An, D.R. Eo, I. Sohn, and K. Choi, Homogenization on Solution Treatment and Its Effects on the Precipitation-Hardening of Selective Laser Melted 17-4PH Stainless Steel, J. Mater. Sci. Technol., 2023, 166, p 47–57. https://doi.org/10.1016/J.JMST.2023.04.055

H. Eskandari, H.R. Lashgari, L. Ye et al., Microstructural Characterization and Mechanical Properties of Additively Manufactured 17-4PH Stainless Steel, Mater Today Commun, 2022, 30, 103075. https://doi.org/10.1016/J.MTCOMM.2021.103075

T. LeBrun, T. Nakamoto, K. Horikawa, and H. Kobayashi, Effect of Retained Austenite on Subsequent Thermal Processing and Resultant Mechanical Properties of Selective Laser Melted 17-4 PH Stainless Steel, Mater. Des., 2015, 81, p 44–53. https://doi.org/10.1016/J.MATDES.2015.05.026

C. Li, Y. Chen, X. Zhang et al., Effect of Heat Treatment on Microstructure and Mechanical Properties of 17-4PH Stainless Steel Manufactured by Laser-Powder Bed Fusion, J. Market. Res., 2023, 26, p 5707–5715. https://doi.org/10.1016/J.JMRT.2023.08.283

B. AlMangour and J.M. Yang, Improving the Surface Quality and Mechanical Properties by Shot-Peening of 17-4 Stainless Steel Fabricated by Additive Manufacturing, Mater. Des., 2016, 110, p 914–924. https://doi.org/10.1016/J.MATDES.2016.08.037

B. AlMangour and J.-M. Yang, Integration of Heat Treatment with Shot Peening of 17-4 Stainless Steel Fabricated by Direct Metal Laser Sintering, JOM, 2017, 69, p 2309–2313. https://doi.org/10.1007/s11837-017-2538-9

M. Yakout, M.A. Elbestawi, and S.C. Veldhuis, A Study of Thermal Expansion Coefficients and Microstructure During Selective Laser Melting of Invar 36 and Stainless Steel 316L, Addit. Manuf., 2018, 24, p 405–418. https://doi.org/10.1016/J.ADDMA.2018.09.035

J. Rodriguez, A. Zuriarrain, A. Madariaga et al., Mechanical Properties and Fatigue Performance of 17-4 PH Stainless Steel Manufactured by Atomic Diffusion Additive Manufacturing Technology, J. Manuf. Mater. Process., 2023, 7, p 172. https://doi.org/10.3390/JMMP7050172

M.E. Fitzpatrick, A.T. Fry, P. Holdway et al., Determination of residual stresses by X-ray diffraction, 2005

W.H. Kan, L.N.S. Chiu, C.V.S. Lim et al., A Critical Review on the Effects of Process-Induced Porosity on the Mechanical Properties of Alloys Fabricated by Laser Powder Bed Fusion, J. Mater. Sci., 2022, 57, p 9818–9865. https://doi.org/10.1007/S10853-022-06990-7

N. Guennouni, A. Barroux, C. Grosjean et al., Comparative Study of the Microstructure Between a Laser Beam Melted 17-4PH Stainless Steel and Its Conventional Counterpart, Mater. Sci. Eng., A, 2021, 823, 141718. https://doi.org/10.1016/j.msea.2021.141718

A.K. Bhaduri, T.P.S. Gill, G. Srinivasan, and S. Sujith, Optimised Post-Weld Heat Treatment Procedures and Heat Input for Welding 17-4PH Stainless Steel, Sci. Technol. Weld. Joining, 1999, 4, p 295–301. https://doi.org/10.1179/136217199101537905

A. Yadollahi, N. Shamsaei, S.M. Thompson, and D.W. Seely, Effects of Process Time Interval and Heat Treatment on the Mechanical and Microstructural Properties of Direct Laser Deposited 316L Stainless Steel, Mater. Sci. Eng. A, 2015, 644, p 171–183. https://doi.org/10.1016/J.MSEA.2015.07.056

A. Yadollahi, N. Shamsaei, S.M. Thompson et al., Effects of Building Orientation and Heat Treatment on Fatigue behavior of Selective Laser Melted 17-4 PH Stainless Steel, Int. J. Fatigue, 2017, 94, p 218–235. https://doi.org/10.1016/J.IJFATIGUE.2016.03.014

E.J. Pavlina and C.J. Van Tyne, Correlation of Yield Strength and Tensile Strength with Hardness for Steels, J. Mater. Eng. Perform., 2008, 17, p 888–893. https://doi.org/10.1007/s11665-008-9225-5

D. Kong, C. Dong, S. Wei et al., About Metastable Cellular Structure in Additively Manufactured Austenitic Stainless Steels, Addit. Manuf., 2021, 38, 101804. https://doi.org/10.1016/J.ADDMA.2020.101804

D. Kong, C. Dong, X. Ni et al., Mechanical Properties and Corrosion Behavior of Selective Laser Melted 316L Stainless Steel After Different Heat Treatment Processes, J. Mater. Sci. Technol., 2019, 35, p 1499–1507. https://doi.org/10.1016/J.JMST.2019.03.003

B. AlMangour and J.-M. Yang, Understanding the Deformation Behavior of 17-4 Precipitate Hardenable Stainless Steel Produced by Direct Metal Laser Sintering Using Micropillar Compression and TEM, Int. J. Adv. Manuf. Technol., 2017, 90, p 119–126. https://doi.org/10.1007/s00170-016-9367-9

R. Colaço and R. Vilar, Stabilisation of Retained Austenite in Laser Surface Melted Tool Steels, Mater. Sci. Eng. A, 2004, 385, p 123–127. https://doi.org/10.1016/J.MSEA.2004.06.069

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Asapu, S., Y, R., Gupta, A. et al. Microstructural and Mechanical Characterization of Selective Laser Melted 17-4 PH Stainless Steel: Effect of Laser Scan Strategy and Heat Treatment. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09470-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09470-y