Abstract

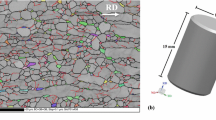

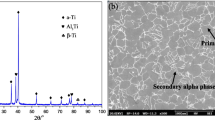

Ti-6Al-4V alloy is often preferred for high-performance components such as aerospace components due to its superior material properties and thermal resistance. In order to produce these components in the desired geometry, it is very important to determine the high-temperature thermomechanical properties of Ti-6Al-4V. In order to define these properties, uniaxial tensile tests at strain rates of 0.001, 0.01 and 0.1 s−1 at 700, 750 and 800 °C were applied in this study. In tests performed at a strain rate of 0.001 s−1 at 800 °C, an elongation at break above 0.8 representing a dominant ductile behavior is observed. It is clearly demonstrated that the initial 17.32% β phase reaches 31.02% at 800 °C, and the α grain size increases with temperature. Existence of dimples and voids in the fracture surfaces are an indicator of increased ductility behavior. In addition to the Modified Johnson–Cook model, which is widely used for modeling flow stress, the use of the extended Ludwik equation is suggested in this study. According to the correlation coefficient (R), it is claimed that the Extended Ludwik model is a more suitable approach for modeling the mechanical behavior for the studied forming temperature range.

Similar content being viewed by others

References

E.O. Ezugwu, J. Bonney and Y. Yamane, An Overview of the Machinability of Aeroengine Alloys, J. Mater. Process. Technol., 2003, 134(2), p 233–253. https://doi.org/10.1016/S0924-0136(02)01042-7

Hadavi, M. (2009): Advanced Materials in Aircraft İndustry. Materials. Malek Ashtar Univ. Technol

M.H. Yoo, J.R. Morris, K.M. Ho and S.R. Agnew, Nonbasal Deformation Modes of HCP Metals and Alloys: Role of Dislocation Source and Mobility, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2002, 33(3), p 813–822. https://doi.org/10.1007/s11661-002-0150-1

M. Vanderhasten, L. Rabet and B. Verlinden, Ti-6Al-4V: Deformation Map and Modelisation of Tensile Behaviour, Mater. Des., 2008, 29(6), p 1090–1098. https://doi.org/10.1016/j.matdes.2007.06.005

P.E. Markovsky, J. Janiszewski, V.I. Bondarchuk, O.O. Stasyuk, D.G. Savvakin, M.A. Skoryk and S.V. Prikhodko, Effect of Strain Rate on Microstructure Evolution and Mechanical Behavior of Titanium-based Materials, Metals, 2020, 10(11), p 1404.

G. Chen, C. Ren, X. Qin and J. Li, Temperature Dependent Work Hardening in Ti-6Al-4V Alloy Over Large Temperature and Strain Rate Ranges: Experiments and Constitutive Modeling, Mater. Des., 2015, 83, p 598–610. https://doi.org/10.1016/j.matdes.2015.06.048

B. Valoppi, S. Bruschi and A. Ghiotti, High-Temperature Mechanical Properties and Constitutive Modelling of Ti6Al4V Sheets, Mater. Sci. Forum, 2017, 879, p 1980–1986. https://doi.org/10.4028/www.scientific.net/MSF.879.2020

S. Gao et al., Anisotropic Behavior and Mechanical Properties of Ti-6Al-4V Alloy in High Temperature Deformation, J. Mater. Sci., 2022, 57(1), p 651–670. https://doi.org/10.1007/s10853-021-06569-8

S. Dineshkumar, S. Sriram, R. Surendran and V. Dhinakaran, Experimental Investigation of Tensile Properties of Ti-6Al-4V Alloy at Elevated Temperature, Int. J. Recent Technol. Eng., 2019, 8(1), p 103–107.

R. Pederson, R. Gaddam and M.L. Antti, Microstructure and Mechanical Behavior of Cast Ti-6Al-4V with Addition of Boron, Cent. Eur. J. Eng., 2012, 2(3), p 347–357. https://doi.org/10.2478/s13531-012-0004-6

H. Zhan, G. Wang, D. Kent and M. Dargusch, Constitutive Modelling of the Flow Behaviour of a β Titanium Alloy at High Strain Rates and Elevated Temperatures Using the Johnson-Cook and Modified Zerilli-Armstrong Models, Mater. Sci. Eng. A, 2014, 612, p 71–79. https://doi.org/10.1016/j.msea.2014.06.030

G. Kang, Y. Dong, Y. Liu and H. Jiang, Macroscopic and Microscopic Investigations on Uniaxial Ratchetting of two-phase Ti-6Al-4V Alloy, Mater. Charact., 2014, 92, p 26–35. https://doi.org/10.1016/j.matchar.2014.02.014

J. Cai, K. Wang, P. Zhai, F. Li and J. Yang, A Modified Johnson-Cook Constitutive Equation to Predict Hot Deformation Behavior of Ti-6Al-4V Alloy, J. Mater. Eng. Perform., 2015, 24(1), p 32–44. https://doi.org/10.1007/s11665-014-1243-x

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32(4), p 1733–1759. https://doi.org/10.1016/j.matdes.2010.11.048

J. Porntadawit, V. Uthaisangsuk and P. Choungthong, Modeling of Flow Behavior of Ti-6Al-4V Alloy at Elevated Temperatures, Mater. Sci. Eng. A, 2014, 599, p 212–222. https://doi.org/10.1016/j.msea.2014.01.064

S. Seo, O. Min and H. Yang, Constitutive Equation for Ti-6Al-4V at High Temperatures Measured using the SHPB Technique, Int. J. Impact Eng., 2005, 31(6), p 735–754. https://doi.org/10.1016/j.ijimpeng.2004.04.010

W.M. Van Haaften, B. Magnin, W.H. Kool and L. Katgerman, Constitutive Behavior of as-cast AA1050, AA3104, and AA5182, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2002, 33(7), p 1971–1980. https://doi.org/10.1007/s11661-002-0030-8

A. Soni and A. Alankar, Analyses of Constitutive Behavior of As-Cast Aluminum Alloys AA3104, AA5182, and AA6111 During Direct Chill Casting Using Physically Based Models, J. Eng. Mater. Technol., 2019 https://doi.org/10.1115/1.4042869

W.M. Van Haaften, W.H. Kool and L. Katgerman, Effect of Strain Rate and Thermal History on the Constitutive Behaviour of Al-Mg alloy AA 5182, Mater. Sci. Technol., 2004, 20(10), p 1233–1236. https://doi.org/10.1179/026708304225022151

G. Wei et al., Constitutive Modeling of Mg-9Li-3Al-2Sr-2Y at Elevated Temperatures, Mech. Mater., 2015, 89, p 241–253. https://doi.org/10.1016/j.mechmat.2015.05.006

ASTM B348/B348M-21 Standard Specification for Titanium and Titanium Alloy Bars and Billets

ASTM E8/E8M-11 Standard Test Methods For Tension Testing Of Metallic Materials, 2011.

G. Deng, X. Zhao, L. Su, P. Wei, L. Zhang, L. Zhan and N. Tsuji, Effect of High Pressure Torsion Process on the Microhardness, Microstructure and Tribological Property of Ti6Al4V Alloy, J. Mater. Sci. Technol., 2021, 94, p 183–195.

F. Ozturk, R.E. Ece, N. Polat, A. Koksal, Z. Evis and J.Y. Sheikh-Ahmad, Application of Electric Resistance Heating Method on Titanium Hot Forming at Industrial Scale, Arab. J. Sci. Eng., 2016, 41(11), p 4441–4448.

Mahdavi, R., Emadoddin, E., & Abbasi, S. M. (2022). Effect of Initial Microstructure and Strain Rate on the Hot Deformation Behavior of ATI425 Alloy in Two-Phase α/β Region. J. Mater. Eng. Perform., 1–12

V. Anil Kumar, A. Sarkar, R.K. Gupta, M.J.N.V. Prasad and S.V.S.N. Murty, Microstructure Evolution During High-temperature Deformation of Ti-5Al-5V-2Mo-1Cr-1Fe Alloy Under Compression, J. Mater. Eng. Perform., 2021, 30(5), p 3258–3272.

Y. Zhou, J. Zhou, Q. Shu, S. Li, F. Gongye, S. Long and H. Deng, Deformation Mechanism and Constitutive Consideration for Ti-5Al-5Mo-5V-3Cr-1Zr Alloy Compressed at Elevated Temperatures, J. Mater. Eng. Perform., 2020, 29(8), p 5104–5113.

A.O. Mosleh, A.V. Mikhaylovskaya, A.D. Kotov, J.S. Kwame and S.A. Aksenov, Superplasticity of Ti-6Al-4V Titanium Alloy: Microstructure Evolution and Constitutive Modelling, Materials (Basel), 2019, 12(11), p 1756. https://doi.org/10.3390/ma12111756

J.I. Qazi, J. Rahim, O.N. Senkov, A. Genc and F.H. Froes, Phase Transformations in Ti-6Al-4V-xH Alloys, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2001, 32(10), p 2453–2463. https://doi.org/10.1007/s11661-001-0035-8

J. Luo, M. Li and W. Yu, Microstructure Evolution During High Temperature Deformation of Ti-6Al-4V Alloy, Rare. Met. Mater. Eng., 2010, 39(8), p 1323–1328. https://doi.org/10.1016/s1875-5372(10)60114-2

T. Zhang, Y. Liu, D.G. Sanders, B. Liu, W. Zhang and C. Zhou, Development of Fine-Grain Size Titanium 6Al-4V Alloy Sheet Material for Low Temperature Superplastic Forming, Mater. Sci. Eng. A, 2014, 608, p 265–272. https://doi.org/10.1016/j.msea.2014.04.098

S. Gao, Y. Sang, Q. Li, Y. Sun, Y. Wu and H. Wang, Constitutive Modeling and Microstructure Research on the Deformation Mechanism of Ti-6Al-4V Alloy Under Hot Forming Condition, J. Alloys Compd., 2022, 892, 162128. https://doi.org/10.1016/j.jallcom.2021.162128

M.A. Wahed, A.K. Gupta, V. Sharma, K. Mahesh, S.K. Singh and N. Kotkunde, Material Characterization, Constitutive Modelling, and Processing Map for Superplastic Deformation Region in Ti-6Al-4V Alloy, Int. J. Adv. Manuf. Technol., 2019, 104(9–12), p 3419–3438. https://doi.org/10.1007/s00170-019-03956-z

P. Hu, Y. Liu, Y. Zhu and L. Ying, Crystal Plasticity Extended Models based on Thermal Mechanism and Damage Functions: Application to Multiscale Modeling of Aluminum Alloy Tensile Behavior, Int. J. Plast., 2016, 86, p 1–25. https://doi.org/10.1016/j.ijplas.2016.07.001

H. Chen, L. Zhang, J. Bao, H. Guo, X. Tao and Y. Ouyang, The Effect of Grain Boundary Energy on the Amorphous Forming Composition Range of Zr–Fe–Al Ternary System, J. Non. Cryst. Solids, 2016, 432, p 277–284. https://doi.org/10.1016/j.jnoncrysol.2015.10.020

A.J.W. Johnson, C.W. Bull, K.S. Kumar and C.L. Briant, The İnfluence of Microstructure and Strain Rate on the Compressive Deformation Behavior of Ti-6Al-4V, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2003, 34(2), p 295–306. https://doi.org/10.1007/s11661-003-0331-6

Y. Han, S. Yan, B. Yin, H. Li and X. Ran, Effects of Temperature and Strain Rate on the Dynamic Recrystallization of a Medium-High-Carbon High-Silicon Bainitic Steel During Hot Deformation, Vacuum, 2018, 148, p 78–87. https://doi.org/10.1016/j.vacuum.2017.11.007

Giuliano, G., (2011): Superplastic Forming of Advanced Metallic Materials, Methods and Applications. Woodhead Publishing Series in Metals and Surface Engineering

Y.C. Lin et al., Effects of İnitial Microstructures on Hot Tensile Deformation Behaviors and Fracture Characteristics of Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2018, 711, p 293–302. https://doi.org/10.1016/j.msea.2017.11.044

Plastic Deformation and Ductile Fracture of Ti-6Al-4V under Various Loading Conditions. Ohio State University, 2012

U. Bathini, T.S. Srivatsan, A. Patnaik and T. Quick, A Study of the Tensile Deformation and Fracture Behavior of Commercially Pure Titanium and Titanium Alloy: Influence of Orientation and Microstructure, J. Mater. Eng. Perform., 2010, 19(8), p 1172–1182. https://doi.org/10.1007/s11665-010-9613-5

F.Q. Li, J.H. Mo, J.J. Li, L. Huang and H.Y. Zhou, Formability of Ti-6Al-4V Titanium Alloy Sheet in Magnetic Pulse Bulging, Mater. Des., 2013, 52, p 337–344. https://doi.org/10.1016/j.matdes.2013.05.064

A. Orozco-Caballero, F. Li, D. Esque-De Los Ojos, M.D. Atkinson and J.Q. da Fonseca, On the Ductility of Alpha Titanium: The Effect of Temperature and Deformation Mode, Acta Mater, 2018, 149, p 1–10. https://doi.org/10.1016/j.actamat.2018.02.022

S.V. Sajadifar and G.G. Yapici, Workability Characteristics and Mechanical Behavior Modeling of Severely Deformed Pure Titanium at High Temperatures, Mater. Des., 2014, 53, p 749–757.

E. Alabort, D. Putman and R.C. Reed, Superplasticity in Ti-6Al-4V: Characterisation, Modelling and Applications, Acta Mater., 2015, 95, p 428–442. https://doi.org/10.1016/j.actamat.2015.04.056

Ludwik, P. (1909): Elemente der Technologischen Mechanik. Jul. Springer, Berlin

van Haaften, L. K. W.M., Magnin, B., Kool, W.H. (1999): Thermomechanical Behaviour of an AA3004 Alloy at Low Strain Rate. Light Met.

Fracture Characteristics of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures. G. R. Johnson W. H. Cook, vol. Eng. Fract, 1985

H.Y. Li, Y.H. Li, X.F. Wang, J.J. Liu and Y. Wu, A comparative Study on modified Johnson Cook, modified Zerilli-Armstrong and Arrhenius-type Constitutive Models to Predict the Hot Deformation Behavior in 28CrMnMoV Steel, Mater. Des., 2013, 49, p 493–501. https://doi.org/10.1016/j.matdes.2012.12.083

Acknowledgements

This study was supported by the Scientific and Technological Research Council of Turkey (Turkish Aerospace Industries-Yıldız Technical University 2244—Industrial PhD Fellowship Program/project number: 118C071) and the Scientific Research Program of Turkish Aerospace Industries. Partial support of the Ozyegin University Research Fund is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Uz, M.M., Hazar Yoruç, A.B., Aydoğan, C.S. et al. A Comparative Study on the High-Temperature Forming and Constitutive Modeling of Ti-6Al-4V. J. of Materi Eng and Perform 32, 4376–4390 (2023). https://doi.org/10.1007/s11665-022-07426-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07426-8