Abstract

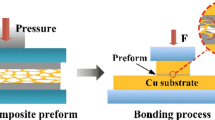

A copper foam–silver composite for large-area interconnections of power modules is proposed, which is prepared by homogeneously mixing a solid copper foam skeleton with a micro-silver paste. The shear strength of the composite was increased to 52.46 MPa by optimizing the preparation and sintering processes. The influence of the primary parameters of the copper foam material on the quality of the sintered joints was discussed, and the morphology and distribution of the sintered silver in the sintered layer of the composite were elucidated and the fracture mode was described. With the increase in copper foam thickness, the deformation rate of the joints increased from 3.13% to 20.23%, the porosity of sintered silver in the composite sintered joints decreased from 23.05% to 2.42%, and the shear strength increased from 34.8 MPa to 59.7 MPa, compared with the sintered silver joints under the same process, the shear strength increased by 4.61% (50.04 MPa for sintered silver joints). The thermal conductivity of the fabricated copper foam–silver composites was tested using a laser thermal conductivity meter. The thermal resistance of a double-sided cooling power module using the copper foam–silver composite as the interconnection layers were evaluated.

Similar content being viewed by others

References

S. Jahdi, O. Alatise, J.A. Ortiz Gonzalez, R. Bonyadi, L. Ran, and P. Mawby, Temperature and switching rate dependence of crosstalk in Si-IGBT and SiC power modules. IEEE Trans. Ind. Electron. 63(2), 849–863 (2016).

L. Zhang, X. Yuan, X. Wu, C. Shi, J. Zhang, and Y. Zhang, Performance evaluation of high-power SiC MOSFET modules in comparison to Si IGBT modules. IEEE Trans. Power Electron. 34(2), 1181–1196 (2019).

E. Lon, Bell, cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 321, 1457–1461 (2008).

J. Broughton, V. Smet, R.R. Tummala, and Y.K. Joshi, Review of thermal packaging technologies for automotive power electronics for traction purposes. ASME J. Electron. Packag. 140(4), 040801 (2018).

M.C. Shaw, J.R. Waldrop, S. Chandrasekaran, B. Kagalwala, X. Jing, E.R. Brown, V.J. Dhir, M. Fabbeo, Enhanced thermal management by direct water spray of high-voltage, high power devices in a three-phase, 18-hp AC motor drive demonstration, in ITherm 2002. Eighth Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (Cat. No. 02CH37258). IEEE, pp. 1007–1014 (2002)

G. Tang, L.C. Wai, S. Boon Lim, B.L. Lau, Y. Kazunori, X.W. Zhang, Thermal analysis, characterization and material selection for SiC device based intelligent power module (IPM), in 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 2020, pp 2078–2085 (2020)

S. Gao, S. Yuki, H. Osanai, W. Sun, K.D. Ngo, G.-Q. Lu, Thermo-mechanical reliability of high-temperature power modules with metal-ceramic substrates and sintered silver joints, in 2016 International Conference on Electronics Packaging (ICEP), Hokkaido, Japan, 2016, pp 395–399 (2016).

H. Yan, Y.-H. Mei, X. Li, C. Ma, and G.-Q. Lu, A multichip phase-leg IGBT module using nanosilver paste by pressureless sintering in formic acid atmosphere. IEEE Trans. Electron Devices 65(10), 4499–4505 (2018).

H. Ogura, M. Maruyama, R. Matsubayashi, T. Ogawa, S. Nakamura, T. Komatsu, H. Nagasawa, A. Ichimura, and S. Isoda, Carboxylate-passivated silver nanoparticles and their application to sintered interconnection: a replacement for high temperature lead-rich solders. J. Electron. Mater. 39, 1233–1240 (2010).

Y.-S. Tan, X. Li, X. Chen, G.-Q. Lu, and Y.-H. Mei, Low-pressure-assisted large-area (> 800 mm2) sintered-silver bonding for high-power electronic packaging. IEEE Trans. Compon. Packag. Manuf. Technol. 8(2), 202–209 (2018).

T.G. Lei, J.N. Calata, G.-Q. Lu, X. Chen, and S. Luo, Low-temperature sintering of nanoscale silver paste for attaching large-area (> 100 mm2) chips. IEEE Trans. Compon. Packag. Technol. 33(1), 98–104 (2010).

K. Xiao, K. Ngo, and G. Lu, A diffusion-viscous analysis and experimental verification of defect formation in sintered silver bond-line. J. Mater. Res. 29(8), 1006–1017 (2014).

Y. Tan, X. Li, X. Chen, Z. Yang, and G.Q. Lu, Feasibility investigation and characterization of low-pressure-assisted sintered-silver bonded large-area DBA plates. Solder. Surf. Mount Technol. 32(3), 129–136 (2020).

A.A. Wereszczak, M.C. Modugno, B.R. Chen, and W.M. Carty, Contact drying of printed sinterable-silver paste. IEEE Trans. Compon. Packag. Manuf. Technol. 7(12), 2079–2086 (2017).

Z. Lv, J. Wang, F. Wang, J. Wang, F. Duan, W. Zhang, C. Hang, and H. Chen, Interconnection method based on Cu-foam/Sn composite preform for high-temperature applications. J. Mater. Sci. Mater. Electron. 33, 25964–25975 (2022).

Y. Liu, Z. Li, H. Zhang, and F. Sun, Microstructure and mechanical properties of nano-Ag sintered joint enhanced by Cu foam. J. Mater. Sci. Mater. Electron. 30, 15795–15801 (2019).

K. Mohan, N. Shahane, P.M. Raj, A. Antoniou, V. Smet, R. Tummala, Low-temperature, organics-free sintering of nanoporous copper for reliable, high-temperature and high-power die-attach interconnections, in 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 2017, pp. 3083–3090 (2017)

C. Chen, S. Nagao, K. Suganuma, J. Jiu, T. Sugahara, H. Zhang, T. Iwashige, K. Sugiura, and K. Tsuruta, Macroscale and microscale fracture toughness of microporous sintered Ag for applications in power electronic devices. Acta Mater. 129, 41–51 (2017).

B. Park, D.L. Han, M. Saito, J. Mizuno, and H. Nishikawa, Effect of various parameters on the shear strength of solid-state nanoporous Cu bonding in Cu–Cu disks for power device packaging. J. Electron. Mater. 51, 3851–3862 (2022).

K. Qi, X. Chen, and G.Q. Lu, Effect of interconnection area on shear strength of sintered joint with nano-silver paste. Solder. Surf. Mount Technol. 20(1), 8–12 (2008).

T. Herboth, M. Guenther, A. Fix, J. Wilde, Failure mechanisms of sintered silver interconnections for power electronic applications, in 2013 IEEE 63rd electronic components and technology conference. IEEE, pp. 1621–1627 (2013)

H.-Y. Zhang, X. Li, H.-N. Jiang, Y.-H. Mei, and G.-Q. Lu, Large-area substrate bonding with single-printing silver paste sintering for power modules. IEEE Trans. Compon. Packag. Manuf. Technol. 11(1), 11–18 (2021).

S.K. Bhogaraju, F. Conti, H.R. Kotadia, S. Keim, U. Tetzlaff, and G. Elger, Novel approach to copper sintering using surface enhanced brass micro flakes for microelectronics packaging. J. Alloy. Compd. 844, 156043 (2020).

Y.J. Kim, B.H. Park, S.K. Hyun, and H. Nishikawa, The influence of porosity and pore shape on the thermal conductivity of silver sintered joint for die attach. Mater. Today Commun. 29, 102772 (2021).

S.T. Chua, and K.S. Siow, Microstructural studies and bonding strength of pressureless sintered nano-silver joints on silver, direct bond copper (DBC) and copper substrates aged at 300 C. J. Alloy. Compd. 687, 486–498 (2016).

W. Schmitt, L.M. Chew, Silver sinter paste for SiC bonding with improved mechanical properties, in 2017 IEEE 67th Electronic Components and Technology Conference (ECTC). IEEE, pp. 1560–1565 (2017)

C.J. Du, X. Li, Y.H. Mei, and G.Q. Lu, An explanation of sintered silver bonding formation on bare copper substrate in air. Appl. Surf. Sci. 490, 403–410 (2019).

A. Hu, J.Y. Guo, H. Alarifi, G. Patane, Y. Zhou, G. Compagnini, and C.X. Xu, Low temperature sintering of Ag nanoparticles for flexible electronics packaging. Appl. Phys. Lett. 97(15), 153117 (2010).

S.T. Feng, Y.H. Mei, G. Chen, X. Li, and G.Q. Lu, Characterizations of rapid sintered nanosilver joint for attaching power chips. Materials 9(7), 564 (2016).

Y. Chen, G. Lei, G.Q. Lu, and Y.H. Mei, High-temperature characterizations of a half-bridge wire-bondless SiC MOSFET module. IEEE J. Electron Devices Soc. 9, 966–971 (2021).

Z. Zhang, J. Zhang, J. Xu, K.D. Ngo, G.Q Lu, E. Cousineau, S. Narumanchi, Packaging of an 8-kV silicon carbide diode module with double-side cooling and sintered-silver joints, in 2021 IEEE Electric Ship Technologies Symposium (ESTS). IEEE, pp. 1–7 (2021).

N. Langmaack, S. Balasubramanian, R. Mallwitz, M. Henke, Comparative analysis of high speed drive inverter designs using different wide-band-gap power devices, in 2021 23rd European Conference on Power Electronics and Applications (EPE'21 ECCE Europe), Ghent, Belgium, 2021, pp. 1–10 (2021). https://doi.org/10.23919/EPE21ECCEEurope50061.2021.9570649.

K.S. Tan, Y.H. Wong, and K.Y. Cheong, Thermal characteristic of sintered Ag–Cu nanopaste for high-temperature die-attach application. Int. J. Therm. Sci. 87, 169–177 (2015).

Acknowledgments

This research was supported by the National Natural Science Foundation of China (No. 51967005), the Science and Technology Planning Project of Guangxi (No. AD20159081), and the Innovation Project of GUET Graduate Education (No. 2021YCXS012).

Funding

The research received no outside funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest declared by the authors.

Human or Animal Rights

There are no studies using human or animal subjects in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fan, Y., Yan, H., Li, J. et al. Prefabrication and Characterization of Copper–Silver Foam Composites for Low-Temperature Interconnection of Power Modules. J. Electron. Mater. 53, 1360–1373 (2024). https://doi.org/10.1007/s11664-023-10785-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10785-0