Abstract

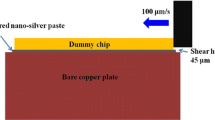

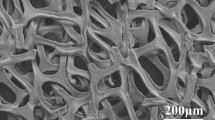

In this study, a silver paste has been introduced for attaching chips onto bare Cu substrates (without coating) without applying pressure. Small nano-thickness Ag flakes, measuring 1 μm–5 μm length, were embedded uniformly in Ag nanoparticles for improving the density of the material. The presence of silver flakes in the silver paste affected the joining process and its microstructure. Microstructure characterization revealed that densification of the silver layer was affected by the presence of silver flakes as the flakes coarsened and formed reactive in situ nanoparticles, which facilitated the sintering between the flakes and the incorporated nanoparticles. Coarsening of silver flakes depended on the sintering temperature, time, and the atmosphere, which affected the decomposition and burning out of organics presented on the surface of the flakes. A high-density silver layer was obtained due to the presence of compact silver flakes. With an increase in the microstructure density, a higher bonding strength and a lower thermal impedance of the sintered joints were achieved. On performing pressureless sintering at 270°C for 30 min under 99.99% N2 or 4% H2/N2, the bonding strength and thermal impedance for 11 × 11 mm2 chips were excellent, measuring approximately 21.9 MPa and 0.077°C/W, respectively.

Similar content being viewed by others

References

K.S. Siow, J. Alloys. Compd. 514, 15 (2012).

Z. Pešina, V. Vykoukal, M. Palcut, and J. Sopoušek, Electron. Mater. Lett. 10, 1 (2014).

R. Khazaka, L. Mendizabal, and D. Henry, J. Electron. Mater. 43, 7 (2014).

J.G. Bai, J.N. Calata, and G.Q. Lu, IEEE Trans. Eelctron. Packag. Manu. 30, 4 (2007).

W. Sabbah, R. Riva, S. Hascoët, C. Buttay, S. Azzopardi, E. Woirgard D. Planson, B. Allard and R. Meuret, in 7th International Conference on Integrated Power Electronics Systems (CIPS). IEEE pp. 1–7. (2012)

F. Le Henaff, S. Azzopardi, J.Y. Deletage, E. Woirgard, S. Bontemps, and J. Joguet, Microelectron. Reliability. 52, 9 (2012).

G. Chen, X.H. Sun, P. Nie, Y.H. Mei, G.Q. Lu, and X. Chen, J. Electron. Mater. 41, 4 (2012).

T.G. Lei, J.N. Calata, G.Q. Lu, X. Chen, and S. Luo, IEEE Trans. Compon. Packag. Technol. 33, 1 (2010).

H.G. Zheng, D. Berry, J.N. Calata, K.D.T. Ngo, S. Luo, and G.Q. Lu, IEEE Trans. Compon. Packag. Technol. 3, 6 (2013).

T. Wang, X. Chen, G.Q. Lu, and G.Y. Lei, J. Electron. Mater. 36, 10 (2007).

Z.Y. Zhang, J.N. Calata, J.G. Bai, G.Q. Lu, in Materials Processing and Manufacturing Division Fifth Global Symposium, TMS, pp. 129–135, (2004)

S. Wang, H.J. Ji, M.Y. Li, and C.Q. Wang, Mater. Lett. 85, 61 (2012).

S.C. Fu, Y.H. Mei, G.Q. Lu, X. Li, G. Chen, and X. Chen, Mater. Lett. 128, 42 (2014).

A. Sharif, M.N. Islam, and Y.C. Chan, Mater. Sci. Eng., B 113, 3 (2004).

S.K. Kang, W.K. Choi, D.Y. Shih, P. Lauro, D.W. Henderson, T. Gosselin, D.N. Leonard, in Proceedings of the 52nd Electronic Components and Technology Conference, (2002) p. 146

P.G. Kim, J.W. Jang, T.Y. Lee, and K.N. Tu, J. Appl. Physics. 86, 12 (1999).

D.W. Henderson, J.J. Woods, T.A. Gosselin, J. Bartelo, D.E. King, T.M. Korhonen, M.A. Korhonen, L.P. Lehman, E.J. Cotts, S.K. Kang, P. Lauro, D.Y. Shih, C. Goldsmith, and K.J. Puttlitz, J. Mater. Res. 19, 6 (2004).

E. Ide, A. Angata, A. Hirose, and K.F. Kobayashi, Acta Mater. 53, 8 (2005).

A. Hu, J.Y. Guo, H. Alarifi, G. Patane, Y. Zhou, G. Compagnini, and C.X. Xu, Appl. Phys. Let. 97, 15 (2010).

G. Chen, D. Han, Y.H. Mei, X. Cao, T. Wang, X. Chen, and G.Q. Lu, IEEE Trans. Device. Mater. Rel. 12, 1 (2012).

N. Chawla and X. Deng, Mater. Sci. Eng., A 390, 1–2 (2005).

T.G. Lei, J.N. Calata, and G.Q. Lu, IEEE Trans. Compon. Packag. Technol. 33, 1 (2010).

R.W. Zhang, W. Lin, K.S. Moon, and C.P. Wong, J. Am. Chem. Soc. 2, 9 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, SY., Li, X., Mei, YH. et al. Effect of Silver Flakes in Silver Paste on the Joining Process and Properties of Sandwich Power Modules (IGBTs Chip/Silver Paste/Bare Cu). J. Electron. Mater. 45, 5789–5799 (2016). https://doi.org/10.1007/s11664-016-4739-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4739-3