Abstract

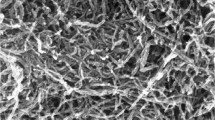

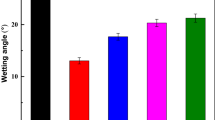

The microstructure and tensile creep behavior of plain Sn-58Bi solder and carbon nanotubes (CNTs)-reinforced composite solder joints were investigated. The stress exponent n under different stresses and the creep activation energy Q c under different temperatures of solder joints were obtained by an empirical equation. The results reveal that the microstructure of the composite solder joint is refined and the tensile creep resistance is improved by CNTs. The improvement of creep behavior is due to the microstructural change of the composite solder joints, since the CNTs could provide more obstacles for dislocation pile-up, which enhances the values of the stress exponent and the creep activation energy. The steady-state tensile creep rates of plain solder and composite solder joints are increased with increasing temperature and applied stress. The tensile creep constitutive equations of plain solder and composite solder joints are written as \( \dot{\varepsilon }_{s1} = 14.94\left( {\sigma /G} \right)^{3.7} \exp \left( { - \frac{81444}{RT}} \right) \) and \( \dot{\varepsilon }_{s2} = 2.5\left( {\sigma /G} \right)^{4.38} \exp \left( { - \frac{101582}{RT}} \right) \), respectively. The tensile creep mechanism of the solder joints is the effects of lattice diffusion determined by dislocation climbing.

Similar content being viewed by others

References

P. Lall, D. Zhang, and V. Yadav, Microelectron. Reliab. 62, 4 (2016).

L. Yang, J.G. Ge, Y.C. Zhang, J. Dai, H.X. Liu, and J.C. Xiang, J. Electron. Mater. 45, 3766 (2016).

S. Xu, Y.C. Chan, K.L. Zhang, and K.C. Yung, J. Alloys Compd. 595, 92 (2014).

G. Chen, H. Peng, V.V. Silberschmidt, Y.C. Chan, C.Q. Liu, and F.S. Wu, J. Alloys Compd. 685, 680 (2016).

L. Shen, P. Lu, S.J. Wang, and Z. Chen, J. Alloys Compd. 574, 98 (2013).

Q.K. Zhang and Z.F. Zhang, Mater. Sci. Eng. A 528, 2686 (2011).

L.Z. Yang, W. Zhou, Y.H. Liang, W.Q. Cui, and Mater PingWu, Sci. Eng. A. 642, 7 (2015).

A.K. Gain and L.C. Zhang, J. Mater. Sci.: Mater. Electron. 27, 781 (2017).

T.W. Hu, Y. Li, Y.C. Chan, and F.S. Wu, Microelectron. Reliab. 55, 1226 (2015).

Y.W. Shi, Y.F. Yan, J.P. Liu, Z.D. Xia, Y.P. Lei, F. Guo, and X.Y. Li, J. Electron. Mater. 38, 1866 (2009).

Y.W. Shi, J.P. Liu, Y.F. Yan, Z.D. Xia, Y.P. Lei, F. Guo, and X.Y. Li, J. Electron. Mater. 37, 507 (2008).

A.A. El-Daly, A.E. Hammada, G.S. Al-Ganainy, and M. Ragab, Mater. Sci. Eng. A 608, 130 (2014).

A.E. Hammad, Mater. Des. 52, 663 (1963).

L. Yang, Y.C. Zhang, J. Dai, Y.F. Jing, J.G. Ge, and N. Zhang, Mater. Des. 67, 209 (2015).

S.M.L. Nai, J. Wei, and M. Gupta, J. Alloys Compd. 473, 100 (2009).

Y.D. Han, L. Chen, H.Y. Jing, S.M.L. Nai, and J. Wei, J. Electron. Mater. 42, 3559 (2013).

Y.D. Han, H.Y. Jing, S.M.L. Nai, L.Y. Xu, C.M. Tan, and J. Wei, J. Mater. Sci.: Mater. Electron. 23, 315 (2011).

F.J. Wang, L.L. Zhou, X.J. Wang, and P. He, J. Alloys Compd. 688, 639 (2016).

X.Z. Li, Y. Ma, W. Zhou, and P. Wu, Mater. Sci. Eng. A 684, 328 (2017).

P. Yao, X.Y. Li, X.B. Liang, and B. Yu, Mater Sci Semi. Pro. 58, 39 (2017).

Y.M. Zhang, H.L. Zhu, M. Fujiwara, J.Q. Xua, and M. Dao, Scrip. Mater. 68, 607 (2013).

A.A. El-Daly, A.M. El-Taher, and T.R. Dalloul, J. Alloys Compd. 55, 309 (2014).

L. Shen, P. Septiwerdani, and Z. Chen, Mater. Sci. Eng. A 558, 253 (2012).

Y.C. Zhang, L. Yang, J. Dai, J.G. Ge, G.L. Guo, and Z. Liu, Mater. Sci. Eng. A 63, 309 (2014).

S. Jadhav, K.N. Subramanian, T.R. Bieler, and J.P. Lucas, J. Electron. Mater. 30, 1197 (2001).

Y.K. Kwon, S. Berber, and D. Tomanek, Phys. Rev. Lett. 92, 95 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Liu, H. & Zhang, Y. Study on the Tensile Creep Behavior of Carbon Nanotubes-Reinforced Sn-58Bi Solder Joints. J. Electron. Mater. 47, 662–671 (2018). https://doi.org/10.1007/s11664-017-5741-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5741-0