Abstract

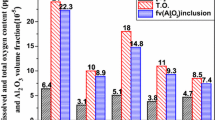

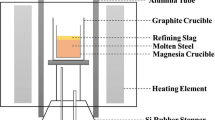

The effect of physicochemical properties of iron-bearing calcium aluminate (Ruhrstahl–Heraeus, RH-type) slag on the removal rate of alumina inclusions in Al-killed steel melts has been investigated by considering the interfacial reaction between steel melts and the slag layer at high temperature. The total oxygen content in the steel decreases as soon as the Fe–Al alloy is added to the steel melts. The apparent rate constant of oxygen removal reaction increases with increasing content of iron oxide and CaO/Al2O3 ratio in the slag due to a decrease in the viscosity of the slag. However, the apparent rate constant of oxygen removal reaction is not fully proportional to the physicochemical properties of the slag because the oxygen is continuously transferred from slag to bulk steel melts due to the reoxidative interfacial reaction between steel and slag melts. Alumina-rich inclusions in the steel sample were observed using scanning electron microscopy combined with automatic feature analysis to characterize the inclusions based on reaction time and slag composition. It was revealed that the inclusion removal rate, which is obtained from the decrease in the mass pct of alumina inclusion, is strongly proportional to the physicochemical properties of the slag. Furthermore, the oxygen behavior in the steel has been investigated using a computational simulation considering the inclusion removal rate as well as metal–slag chemical reaction kinetics in a commercial RH operation scale.

Similar content being viewed by others

References

A. Ghosh: Secondary Steelmaking: Principles and Applications, CRC Press, Boca Raton, 2000, pp. 255–57.

S.H. Lee, C. Tse, K.W. Yi, P. Misra, V. Chevrier, C. Orrling, S. Sridhar, and A.W. Cramb: J. Non-Cryst. Solids, 2001, vol. 282, pp. 41–48.

M. Valdez, G.S. Shannon, and S. Sridhar: ISIJ Int., 2006, vol. 46, pp. 450–57.

K.H. Sandhage and G.J. Yurek: J. Am. Ceram. Soc., 1988, vol. 71, pp. 478–89.

K.H. Sandhage and G.J. Yurek: J. Am. Ceram. Soc., 1990, vol. 73, pp. 3643–49.

S. Taira, K. Nakashima, and K. Mori: ISIJ Int., 1993, vol. 33, pp. 116–23.

J.Y. Choi, H.G. Lee, and J.S. Kim: ISIJ Int., 2002, vol. 42, pp. 852–60.

Y.Q. Liu, L.J. Wang, and K.C. Chou: ISIJ Int., 2014, vol. 54, pp. 728–33.

S. Sridhar and A.W. Cramb: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 406–10.

M. Valdez, K. Prapakorn, A.W. Cramb, and S. Sridhar: Ironmaking Steelmaking, 2002, vol. 29, pp. 47–52.

K.W. Yi, C. Tse, J.H. Park, M. Valdez, A.W. Cramb, and S. Sridhar: Scand. J. Metall., 2003, vol. 32, pp. 177–84.

B.J. Monaghan, L. Chen, and J. Sorbe: Ironmaking Steelmaking, 2005, vol. 32, pp. 258–64.

B.J. Monaghan and L. Chen: Ironmaking Steelmaking, 2006, vol. 33, pp. 323–30.

J.H. Park, I.H. Jung, and H.G. Lee: ISIJ Int., 2006, vol. 46, pp. 1626–34.

W.D. Cho and P. Fan: ISIJ Int., 2004, vol. 44, pp. 229–34.

W. Yang, X. Wang, L. Zhang, Q. Shan, and X. Liu: Steel Res. Int., 2013, vol. 84, pp. 473–89.

B.H. Reis, W.V. Bielefeldt, and A.C.F. Vilela: ISIJ Int., 2014, vol. 54, pp. 1584–91.

J.S. Park and J.H. Park: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 3225–30.

Y.J. Park, Y.M. Cho, W.Y. Cha, and Y.B. Kang: J. Am. Ceram. Soc., 2020, vol. 103, pp. 2210–24.

T.S. Kim and J.H. Park: ISIJ Int., 2021, vol. 61, pp. 724–33.

Y. Chung: Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, 1999.

D.C. Park, I.H. Jung, P.C.H. Rhee, and H.G. Lee: ISIJ Int., 2004, vol. 44, pp. 1669–78.

T. Tanaka, H. Goto, M. Nakamoto, M. Suzuki, M. Hanao, M. Zeze, H. Yamamura, and T. Yoshikawa: ISIJ Int., 2016, vol. 56, pp. 944–52.

T.S. Kim, Y. Chung, L. Holappa, and J.H. Park: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 1736–47.

P. Ni, T. Tanaka, M. Suzuki, M. Nakamoto, and P.G. Jönsson: ISIJ Int., 2019, vol. 59, pp. 737–48.

T.S. Kim, L. Holappa, and J.H. Park: Ironmaking Steelmaking, 2020, vol. 47, pp. 84–92.

Y. Ji, C. Liu, Y. Lu, H. Yu, F. Huang, and X. Wang: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 3127–36.

Y. Ji, C. Liu, H. Yu, X. Deng, F. Huang, and X. Wang: J. Iron Steel Res. Int., 2020, vol. 27, pp. 402–08.

Y. M. Cho, W. Y. Cha and Y. B. Kang: Metall. Mater. Trans. B, 2021.

J.S. Park and J.H. Park: Steel Res. Int., 2014, vol. 85, pp. 1303–09.

S.K. Kwon, J.S. Park, and J.H. Park: ISIJ Int., 2015, vol. 55, pp. 2589–96.

N. Choi, K.R. Lim, Y.S. Na, U. Glatzel, and J.H. Park: J. Alloys Compd., 2018, vol. 763, pp. 546–57.

K.R. Lee and H. Suito: Metall. Mater. Trans. B, 1994, vol. 25B, pp. 893–902.

V. Espejo and M. Iwase: Metall. Mater. Trans. B, 1995, vol. 26B, pp. 257–64.

I. Sunagawa: Morphology of Crystals, Terra Scientific Publishing Company, Tokyo, 1987.

R. Dekkers, B. Blanpain, and P. Wollants: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 161–71.

R.L. Fullman: JOM, 1953, vol. 5, pp. 447–52.

A. Karasev and H. Suito: Metall. Mater. Trans. B, 1999, vol. 30, pp. 259–70.

H. Ohta and H. Suito: ISIJ Int., 2006, vol. 46, pp. 14–21.

J.H. Shin, Y. Chung, and J.H. Park: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 46–59.

J.H. Shin and J.H. Park: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2820–25.

J.H. Shin and J.H. Park: ISIJ Int., 2018, vol. 58, pp. 88–97.

Acknowledgments

This research was partly supported by Korea Evaluation Institute of Industrial Technology (KEIT, with Grant No. 20009956), funded by the Ministry of Trade, Industry & Energy (MOTIE), Korea.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 10, 2021; accepted April 29, 2022.

Rights and permissions

About this article

Cite this article

Kim, T.S., Yang, J. & Park, J.H. Effect of Physicochemical Properties of Slag on the Removal Rate of Alumina Inclusions in the Ruhrstahl–Heraeus (RH) Refining Conditions. Metall Mater Trans B 53, 2523–2533 (2022). https://doi.org/10.1007/s11663-022-02548-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02548-9