Abstract

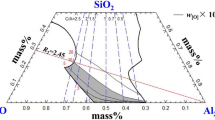

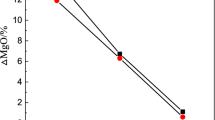

Industrial experiments were performed to improve the cleanliness of 95CrMo drill rod steel by slag refining. Higher steel cleanliness, lower corrosion, and small inclusions were obtained using the optimal slag composition (pctCaO/pctSiO2 = 3.7 to 4, pctCaO/pctAl2O3 = 6 to 8). Layered composite inclusions formed during vacuum decarburizing refining. CaS first precipitated around the spinel and subsequently formed inclusions in which solid CaS-CaO wrapped around the Al2O3-MgO-SiO2-CaO system as the modification and diffusion progressed. The thermodynamic equilibrium between slag and liquid 95CrMo steel at 1873 K (1600 °C) was also studied to understand the effect of slag composition on the oxygen content and absorption capacity for Al2O3. A mathematical model based on an investigation of slag viscosity and the interfacial tension between slag and inclusions was used to predict the size of critical inclusions for different slags. The evolution of typical inclusions is discussed in terms of the study of reactions between slag and steel.

Similar content being viewed by others

References

McGregor K (1967) The Drilling of Rock. Books Ltd., London.

L. Zhang and B. G. Thomas: ISIJ Int., 2003, vol. 43, pp. 271-91.

P. Juvonen: D.D. Thesis, Helsinki University of Technology, 2004.

M. Jiang and X. H. Wang and W. J. Wang: Steel Res. Int., 2010, vol. 81, pp 759–65.

C.J. Cai, S.B. Zheng, J. Chen, Z.Y. Ye, H.G. Li, and J.M. Yang: Mater. Sci. Forum, 2014, pp. 289–97.

Yoon B, Heo K, Kim J, Sohn H (2002) Ironmak. Steelmak 29:214–17.

S. Chen, M. Jiang, X. He, and X. Wang: Int. J. Met. Mater., 2012, vol.19, pp. 490–98.

S. Yang, J. Li, C. Liu, L. Sun, and H. Yang: Metall. Mater. Trans. B, 2014, pp. 1–11.

M. Valdez and G. S. Shannon and S. Sridhar: ISIJ Int., 2006, vol. 46, pp. 450–57.

J. H. Park and S. Lee and H. R. Gaye: Metall. Mater. Trans. B, 2008, vol. 39, pp. 853–86.

H. Ohta and H. Suito: ISIJ Int.,1996, vol. 36, 983–90.

M. Andersson, M. Hallberg, L. Jonsson, and P. A. R. J O Nsson: Ironmak. Steelmak. 2002, vol.29, pp. 224–32.

M. Jiang and X. Wang and J. Pak: Metall. Mater. Trans. B, 2014, vol. 45, pp. 1248–59.

J. W. Kim, S. K. Kim, D. S. Kim, Y. D. Lee, and P. K. Yang: ISIJ Int., 1996, vol. 36S, pp.140–43.

J. H. Park and D. S. Kim: Metall. Mater. Trans. B, 2005, vol.36, pp. 495–502.

W. Ma, Y. Bao, M. Wang, and D. W. Zhao: Ironmak. Steelmak, 2014, vol. 41, pp. 26–30.

P. Yan, S. Huang, L. Pandelaers, J. Van Dyck, M. Guo, and B. Blanpain: Metall. Mater. Trans. B, 2013, vol 44, pp. 1105–19.

W. Yang, X. Wang, L. Zhang, Q. Shan, and X. Liu: Steel Res. Int., 2013, vol.84, pp. 473–89.

M. Jiang: D.D. Thesis, University of Sicence and Technology Beijing, 2008.

J. Strandh, K. Nakajima, R. Eriksson, and P. A. R. J O Nsson: ISIJ Int. 2005, vol. 45, pp. 1838–47.

J. Strandh, K. Nakajima, R. Eriksson, and P. A. R. J O Nsson: ISIJ Int. 2005, vol. 45, pp. 1597–1606.

G. Zhang, K. Chou, Q. Xue, and K. C. Mills: Metall. Mater. Trans. B, 2012, vol. 43, pp. 64–72.

G. Zhang and K. Chou and K. Mills: ISIJ Int., 2012, vol. 52, pp. 355–62.

J. Choi and H. Lee: ISIJ Int., 2003, vol. 43, pp. 1348–s55.

T. Lis: Metalurgija. 2009, vol. 48, pp. 95.

N. Verma, P. C. Pistorius, R. J. Fruehan, M. Potter, M. Lind, and S. Story: Metall. Mater. Trans. B, 42B, 2011, vol. 42, 711–19.

N. Verma, P. C. Pistorius, R. J. Fruehan, M. Potter, M. Lind, and S. R. Story: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 720–29.

Acknowledgment

This research is supported by the National Science Foundation of China (Nos. 51474085 and 51304016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 24, 2014.

Rights and permissions

About this article

Cite this article

Wang, L., Yang, S., Li, J. et al. Improving Cleanliness of 95CrMo Drill Rod Steel by Slag Refining. Metall Mater Trans B 47, 99–107 (2016). https://doi.org/10.1007/s11663-015-0481-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0481-0