Abstract

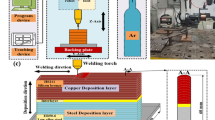

A bimetallic GCr15/45 carbon steel has been produced by the newly developed electroslag remelting cladding (ESRC) technique. Based on the solidified precipitates characteristics of the bimetallic materials and the relationship of temperature varying with time at the bimetallic interface during the ESRC process, the one-phase model in DICTRA was selected to calculate the element diffusion behavior at the bimetallic interface in the present study. The calculated result illustrates that the diffusion distance of C (3720 μm) is much larger than that of Cr (42 μm), Si (30 μm), and Mn (34 μm) due to the small atomic size, while the experimental result of the bimetallic interface shows that the transition width of Cr is 1140 μm which is much larger than that of the calculated values by diffusion model. The difference between the above calculated and experimental results illustrates that a fusion bonding with obvious element migration has occurred between the bimetallic metals in addition to the diffusion bonding. Affected by the element migration and diffusion, a good metallurgical bonding with no defects is formed between the bimetallic materials and the microstructure as well as the corresponding properties at the interface change significantly.

Similar content being viewed by others

References

L. Rao, S.J. Wang, J.H. Zhao, M.P. Geng, and G. Ding: J. Iron Steel Res. Int., 2014, vol. 21, pp. 869–77.

D.J. Lee, D.H. Ahn, E.Y. Yoon, S.I. Hong, S. Lee, and H.S. Kim: Scripta Mater., 2013, vol. 68, pp. 893–96.

K. Ichino, Y. Kataoka, and T. Koseki: Kawasaki Steel Tech. Rep., 1997, vol. 37, pp. 13–18.

H.G. Fu, A.M. Zhao, J.D. Xing, and D.M. Fu: J. Iron Steel Res. Int., 2002, vol. 9, pp. 32–35.

C.K. Kim, J.I. Par, S. Lee, Y.C. Kim, N.J. Kim, and J.S. Yang: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 87–97.

M. Hashimoto, T. Tanaka, T. Inoue, M. Yamashita, R. Kurahashi, and R. Terakado: ISIJ Int., 2002, vol. 42, pp. 982–89.

G.J. Li and M.J. Feng: J. Cent. South Univ., 2014, vol. 21, pp. 849–56.

A. Yamamoto, Y. Ishii, H.G. Kang, F. Sakata, A. Sonoda, and M. Hashimoto: Mater. Trans., 2019, vol. 60, pp. 770–76.

M. Shimizu, O. Shitamura, S. Matsuo, T. Kamata, and Y. Kondo: ISIJ Int., 1992, vol. 32, pp. 1244–49.

B.I. Medovar, L.B. Medovar, A.V. Chernets, B.B. Fedorovskii, I.A. Lantsman, A.P. Beloglazov, V.E. Shevchenko, V.I. Ous, J. Shutey, and T. Nylen: 38th Mech. Working Steel Process. Conf. Proc., 1997, Cleveland, Ohio, pp. 83–87.

L.B. Medovar, A.P. Stovpchenko, V.Y. Saenko, G.V. Noshchenko, B.B. Fedorovskii, V.L. Petrenko, I.A. Lantsman, and V.M. Zhuravel: Russ. Metall. (Met.), 2011, vol. 2011, pp. 1118–23.

Z.H. Jiang, Y.L. Cao, Y.W. Dong, D. Hou, H.B. Cao, and J.X. Fan: Steel Res. Int., 2016, vol. 87, pp. 699–711.

Y.L. Cao, Z.H. Jiang, Y.W. Dong, X. Deng, L. Medovar, and G. Stovpchenko: ISIJ Int., 2018, vol. 58, pp. 1052–60.

G. Polishko, G. Stovpchenko, L. Medovar, and L. Kamkina: Ironmak. Steelmak., 2019, vol. 46, pp. 789–93.

Y.L. Cao, Z.H. Jiang, Y.W. Dong, G.Q. Li, Z.W. Hou, and Q. Wang: Ironmak. Steelmak., 2020, vol. 47, pp. 686–92.

Y.L. Cao, Y.W. Dong, Z.H. Jiang, G.Q. Li, and Z.R. Zhao: ISIJ Int., 2021, vol. 61, pp. 2127–34.

X.L. Shi, Y.H. Jiang, R. Zhou, and Y.Q. Zhang: The 12th China–Russia Symp. Adv. Mater. Technol., The Nonferrous Metals Society of China, Kunming, China, 2013, pp. 402–6.

S.Y. Jiao, J.X. Dong, M.C. Zhang, and X.S. Xie: J. Mater. Eng., 2009, vol. 54, pp. 10–16.

A. Borgenstam, A. Engstrom, L. Höglund, and J. Ågren: J. Phase Equilib., 2000, vol. 21, pp. 269–80.

Y.P. Zhao, J.M. Gong, X.W. Wang, L.M. Shen, and Q.N. Li: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 2218–23.

J.O. Andersson, T. Helander, L. Höglund, P.F. Shi, and B. Sundman: CALPHAD, 2002, vol. 26, pp. 273–312.

P.D. Jablonski and C.J. Cowen: Metall. Mater. Trans. B, 2009, vol. 40B, pp. 182–86.

Y.L. Cao, G.Q. Li, Z.H. Jiang, Y.W. Dong, Z.R. Zhao, and C.R. Niu: Mater. Trans., 2022, vol. 61, pp. 2228–35.

Z.H. Jiang: Physical Chemistry and Transport Phenomena of Electroslag Remelting, Northeastern University Press, Shenyang, 2000, p. 223.

Q.F. Hou and K. Li: NISCO Technol. Manag, 2015, vol. 41, pp. 28–32.

Y.L. Cao, G.Q. Li, Z.H. Jiang, Y.W. Dong, Z.R. Zhao, and C.R. Niu: High Temp. Mater. Process., 2020, vol. 39, pp. 270–80.

T. Gietzelt, V. Toth, and A. Huell: Adv. Eng. Mater., 2018, vol. 20, pp. 1–10.

E. Akca and A. Gursel: Period. Eng. Nat. Sci., 2015, vol. 3, pp. 12–16.

C.Y. Sun, L. Li, M.W. Fu, and Q.J. Zhou: Mater. Des., 2016, vol. 94, pp. 433–43.

B. Kurt, N. Orhan, and A. Hasçalık: Mater. Des., 2007, vol. 28, pp. 2229–33.

A. Laik, P.S. Gawde, K. Bhanumurthy, and G.B. Kale: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 733–41.

Acknowledgments

The authors are very grateful to the financial support of the National Natural Science Foundation of China (52004188).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cao, Y., Ma, C., Jiang, Z. et al. Element Migration and Diffusion at the Bonding Interface of the Bimetallic Composite Billet Produced by the ESRC Method. Metall Mater Trans B 53, 2398–2406 (2022). https://doi.org/10.1007/s11663-022-02538-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02538-x