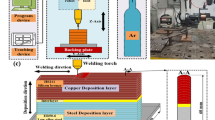

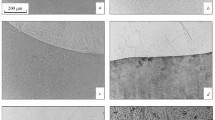

In the present paper, the microstructure of heterogeneous material bimetal compound fabricated by wire-feed electron-beam additive technology from CrNiTi stainless steel and С11000 copper has been investigated. The bimetallic compound is characterized by the well-defined interface between the two materials and possesses two-phase transition areas on both sides of the interface. The heterogeneity of strength properties (microhardness) in the transition zones is associated with a solid solution hardening of the bimetal basis components and formation of composite structures in the transition zone of the bimetal: spherical inclusions of steel in the copper part and copper inclusions in the steel section. In the copper part of the bimetal sample, a heterogeneous grain structure is formed – areas with macroscale non-equiaxed grain structure and zones with spherical grains were observed. The heterogeneity of grain structure does not have significant influence on the yield strength, but affects the macroscopic deformation pattern of the bimetal copper part, as has been revealed by microstructural analysis of slip traces and grain structure calculated using the Hall–Petch relationship.

Similar content being viewed by others

References

S. Yu. Tarasov, A. V. Filippov, N. L. Savchenko, et al., Int. J. Adv. Manuf. Tech., 99, 2353–2363 (2018).

H. D. Carlton, A. Haboub, G. F. Gallegos, et al., Mater. Sci. Eng. A, 651, 406–414 (2016).

K. Schmidtke, F. Palm, and A. Hawkins, Phys. Procedia, 12, 369–374 (2011).

E. Louvis, P. Fox, and C. J. Sutcliffe, Proc. Tech., 211, 275–284 (2011).

K. Yamanaka, W. Saito, M. Mori, et al., Addit. Manuf., 8, 105–109 (2015).

A. Yu. Nikonov, A. M. Zharmukhambetova, A. V. Ponomareva, et al., Phys. Mesomech., 21, 43–50 (2018).

Y. Zhai, H. Galarraga, D. A. Lados, et al., Procedia Eng., 114, 658–666 (2015).

P. Nie, O. A. Ojo, and Z. Li, Acta Mater., 77, 85–95 (2014).

X. Z. Xin, N. Xiang, J. Chen, et al., Mater. Lett., 88, 101–103 (2012).

T. Abe and H. Sasahara, Precis Eng., 45, 387–395 (2016).

S. Meco, G. Pardal, and S. Ganguly, Opt. Lasers Eng., 67, 22–30 (2015).

J. Kar, S. K. Roy, G. G. Roy, et al., Mater. Process. Technol., 233, 174–185 (2016).

O. M. Al-Jamal, S. Hinduja, and L. Li, CIRP Ann., 57, 239–242 (2008).

C. Tana, K. Zhoua, W. Ma, et al., Mater. Design, 155, 77–85 (2018).

S. V. Shukhardin, ed., Bi- and Multicomponent Copper-Based Systems [in Russian], Nauka, Moscow (1979).

P. Åkerfeldt, M.-L. Antti, and R. Pederson, Mater. Sci. Eng. A, 674, 428–437 (2016).

É. V. Kozlov, N. A. Konev, A. N. Zhdanov, et al., Fizich. Mesomekh., 4, 93–113 (2004).

É. V. Kozlov, A. N. Zhdanov, L. N. Ignatenko, et al., in: Ultrafine Grained Materials II, Warrendale, TMS (2012), pp. 419–428.

T. H. Johnston and C. E. Feltner, Metall. Trans., 1, 1161–1167 (1970).

A. M. Glezer, Principles of Plastic Deformation of Nanostructural Materials [in Russian], Fizmatlit, Moscow (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 8, pp. 166–174, August, 2019.

Rights and permissions

About this article

Cite this article

Osipovich, K.S., Chumaevskii, A.V., Eliseev, A.A. et al. Peculiarities of Structure Formation in Copper/Steel Bimetal Fabricated by Electron-Beam Additive Technology. Russ Phys J 62, 1486–1494 (2019). https://doi.org/10.1007/s11182-019-01867-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-019-01867-w