Abstract

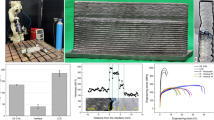

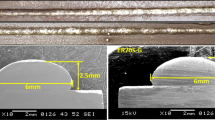

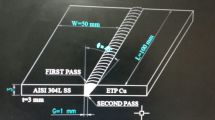

This paper proposes a novel and efficient preparation method for copper-steel bimetallic materials. A transition welding wire for copper-steel gradient connections was designed, and then gas metal arc welding (GMAW) additive manufacturing processes were explored. The effects of the process and material on the microstructure, interface characteristics, and mechanical properties of copper-steel bimetallic materials were systematically studied. The results show that copper-steel bimetallic thin-walled parts can be well formed, which confirms the possibility of the arc additive manufacturing of copper-steel bimetallic parts. With the direct deposition of silicon bronze on the surface of low-alloy steel, the melting unmixed zone (MUZ) appears at the bonding interface of low-alloy steel and silicon bronze, which is prone to produce microcracks, leading to fracture failure of the joint. However, with the addition of the Cu-Ni interlayer, the Fe, Ni, and Cu elements in the bronze interface between the low-alloy steel and silicon were continuously diffused, which improved the nonuniformity of the Fe-rich phase in silicon bronze matrix, and realized the gradient connection at the welding joint. Comparing the tensile properties and microhardness of the joints, it can be found that the tensile strength of the low-alloy steel/Cu-Ni/silicon bronze joint was 66.36 pct higher than that of the alloy steel/silicon bronze joint, which can reach approximately 345.2 MPa and shows a typical ductile fracture mechanism. Additionally, the microhardness of the transition zone in the low-alloy steel/Cu-Ni/silicon bronze joint was more uniform.

Similar content being viewed by others

References

Y.R. Wang, Y.M. Gao, Y.F. Li, W.Y. Zhai, L. Sun, and C. Zhang: Emerg. Mater. Res., 2019, vol. 8(4), pp. 538–51. .

J.N. Yang, L.J. Zhang, J. Ning, Q.L. Bai, X.Q. Yin, J.J. Zhang, and L.X. Zhang: Appl. Therm. Eng., 2017, vol. 126, pp. 867–83. .

Z. Cheng, J.H. Huang, Z. Ye, Y. Chen, J. Yang, and S.H. Chen: J. Mater. Process. Technol., 2019, vol. 265, pp. 87–98. .

A.V. Müller, B. Böswirth, V. Cerri, H. Greuner, R. Neu, U. Siefken, E. Visca, and J.H. You: Phys. Scr., 2020, vol. T171, pp. 014–5. .

M.H. Zhu, P.F. Tian, R. Kurtz, T. Lunkenbein, J. Xu, R. Schlögl, and I.E. Wachs: Ange. Chem., 2019, vol. 131(27), pp. 9181–5. .

K. Shaheen, Z. Shah, A. Asad, T. Arshad, S.B. Khan, and H.L. Suo: ACS Omega., 2020, vol. 5(26), pp. 15992–6002. .

Y.Y. Poo-arporn, S. Duangnil, D. Bamrungkoh, and P. Klangkaew: J. Mater. Process. Technol., 2020, vol. 277, p. 116490. .

B.X. Liu, J.Y. Wei, M.X. Yang, F.X. Yin, and K.C. Xu: Vacuum., 2018, vol. 154, pp. 250–8. .

W.D. Chen, Y.G. Li, Q. Zou, J.C. Xiong, Z.C. Lou, and Z.J. Jiao: Int. J. Adv. Manuf. Technol., 2021, vol. 112(3), pp. 1–13. .

P. Jakupi, P.G. Keech, I. Barker, S. Ramamurthy, R.L. Jacklin, and D.W. Shoesmith: J. Nucl. Mater., 2015, vol. 466, pp. 1–11. .

M. Teimouri, W.Q. Gao, and A. Godfrey: Mater. Sci. Technol., 2020, vol. 36(12), pp. 1364–71. .

A. Durgutlu, B. Gülenç, and F. Findik: Mater. Des., 2005, vol. 26(6), pp. 497–507. .

H. Zhang, K.X. Jiao, J.L. Zhang, and J.P. Liu: Mater. Sci. Eng. A., 2019, vol. 756, pp. 430–41. .

H. Zhang, K.X. Jiao, J.L. Zhang, and J.P. Liu: Mater. Des., 2018, vol. 154, pp. 140–52. .

H. Zhang, K.X. Jiao, and J.L. Zhang: Mater. Sci. Eng. A., 2018, vol. 731, pp. 278–87. .

S. Ramachandran and A.K. Lakshminarayanan: Trans. Nonferrous. Met. Soc. China., 2020, vol. 30(3), pp. 727–45. .

Y.F. Meng, X.W. Li, M. Gao, and X.Y. Zeng: Opt. Laser Technol., 2019, vol. 111, pp. 140–5. .

C.W. Yao, B.S. Xu, X.C. Zhang, J. Huang, J. Fu, and Y.X. Wu: Opt. Lasers Eng., 2009, vol. 47(78), pp. 807–14. .

Z. Shen, Y. Chen, M. Haghshenas, T. Nguyen, J. Galloway, and A.P. Gerlich: Mater. Charact., 2015, vol. 104, pp. 1–9. .

T.H. Wang, S. Shukla, S.S. Nene, and M. Frank: Metall. Mater. Trans. A., 2018, vol. 49A(7), pp. 2578–82. .

N. Switzner, H. Queiroz, and J. Duerst: Mater. Sci. Eng. A., 2018, vol. 709, pp. 55–64. .

W.Y. Li, K. Yang, S. Yin, X.W. Yang, Y.X. Xu, and R. Lupoi: J. Mater. Sci. Technol., 2018, vol. 34(3), pp. 440–57. .

C. Zhang, F. Chen, and Z.F. Huang: Mater. Sci. Eng. A., 2019, vol. 764, p. 138209. .

N. Li, S. Huang, G.D. Zhang, R.Y. Qin, W. Liu, H.P. Xiong, and G.Q. Shi: J. Mater. Sci. Technol., 2019, vol. 35(2), pp. 242–69. .

Y.H. Wang, X.Z. Chen, S. Konovalov, C.C. Su, A.N. Siddiquee, and N. Gangil: Appl. Surf. Sci., 2019, vol. 487, pp. 1366–75. .

G.Q. Chen, X. Shu, J.P. Liu, B.G. Zhang, and J.C. Feng: Vacuum., 2020, vol. 171, p. 109009. .

X. Shu, G.Q. Chen, J.P. Liu, B.G. Zhang, and J.C. Feng: Mater. Lett., 2018, vol. 213, pp. 374–7. .

I. Magnabosco, P. Ferro, and F. Bonollo: Mater. Sci. Eng. A., 2006, vol. 424(1–2), pp. 163–73. .

L.M. Liu, Z.L. Zhuang, F. Liu, and M.L. Zhu: Int. J. Adv. Manuf. Technol., 2013, vol. 69(9–12), pp. 2131–7. .

Q.W. Guo, G.S. Wang: Chemical Industry Press, 2010, pp. 61–117.

M. Velu and S. Bhat: Mater. Des., 2013, vol. 47, pp. 793–809. .

H.Q. Hu, F.N. Shen, Z.D. Wang: Machine Press, 2000, pp. 41–47.

K.S. Osipovich, E.G. Astafurova, and A.V. Chumaevskii: J. Mater. Sci., 2020, vol. 55(22), pp. 9258–72. .

Acknowledgments

This research was funded by National Natural Science Foundation of China, Grant Number 51904243; Natural Science Foundation of Shaanxi Provincial Department of Education, Grant Number 19JK0573; and Natural Science Foundation of Shaanxi Province, Grant Numbers 2019JQ-284 and 2019JZ-31.

Conflict of interest

The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 10, 2021, accepted July 26, 2021.

Rights and permissions

About this article

Cite this article

Zhang, M., Zhang, Y., Du, M. et al. Experimental Characterization and Microstructural Evaluation of Silicon Bronze-Alloy Steel Bimetallic Structures by Additive Manufacturing. Metall Mater Trans A 52, 4664–4674 (2021). https://doi.org/10.1007/s11661-021-06418-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06418-y