Abstract

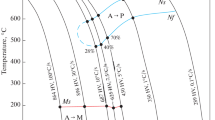

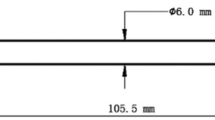

This investigation aims to explore the formation mechanism of abnormal martensite in the bainitic rail welding process by combining numerical simulation and physical experiment. For this purpose, the continuous cooling transformation (CCT) diagram of bainitic steel was measured to determine the transformation temperature and cooling rate range of bainite and martensite during phase transformation. Besides, the Eulerian multiphase solidification model was also used to accurately design the experimental plan of the thermosimulated test. The higher cooling rate and microsegregation of the welded joint are important factors affecting the formation of abnormal martensite. The effects of cooling rate and microsegregation on the microstructure during the welding process of the bainitic rail were examined against the martensite fraction and bainite fraction. When the cooling rate is greater than or equal to 1 K/s, abnormal martensite will appear in bainite after the thermosimulated test, regardless of whether there is microsegregation in the sample. The cooling rate, not the microsegregation, is the main factor promoting the formation of abnormal martensite. The reasonable postwelding treatment process has excellent potential for improving the mechanical properties of the welded joint of the bainitic rail.

Similar content being viewed by others

Abbreviations

- ρ l, ρ e, ρ c :

-

Density, kg/m3

- f l, f e, f c :

-

Volume fraction

- f ie , f ic :

-

Volume fraction of interdendritic melt phase

- t :

-

Time, s

- \( \vec{v}_{l} \), \( \vec{v}_{e} \), \( \vec{v}_{c} \) :

-

Velocity vector, m/s

- S le :

-

The liquid-equiaxed net mass transfer rate, kg/s/m3

- S lc :

-

The liquid-columnar net mass transfer rate, kg/s/m3

- S ce :

-

Columnar-equiaxed net mass transfer rate, kg/s/m3

- S sc , S se :

-

Interdendritic net mass transfer rate, kg/s/m3

- P:

-

Pressure, Pa

- μ l :

-

Viscosity, kg/m/s

- μ t,k :

-

Turbulent viscosity, kg/m/s

- \( \vec{F}_{T}^{l} \), \( \vec{F}_{T}^{e} \) :

-

Stress–strain tensors caused by thermal buoyancy, kg/m/s2

- \( \vec{F}_{C}^{l} \), \( \vec{F}_{C}^{e} \) :

-

Stress–strain tensors caused by solutal buoyancy, kg/m/s2

- \( \vec{F}_{u} \) :

-

Discriminatory function

- \( \vec{V}_{cl} \) :

-

The liquid-columnar momentum exchange rate, kg/m2/s2

- \( \vec{V}_{ce} \) :

-

The columnar-equiaxed momentum exchange rate, kg/m2/s2

- \( \vec{V}_{el} \) :

-

The liquid-equiaxed momentum exchange rate, kg/m2/s2

- H l, H e, H c :

-

Enthalpy, J/kg

- k * :

-

Effective thermal conductivity, W/m/K

- T l, T e, T c :

-

Temperature, K

- H :

-

Phase transition enthalpy, J/kg

- H * :

-

Diffusional heat exchange coefficient

- c l, c e, c c :

-

Solute concentration

- c ie , c ic :

-

The solute concentration of interdendritic melt phase

- C Ple , C Plc , C Pce , C sPc , C sPe :

-

Solute transfer rates with respect to phase change, kg/m3/s

- C Dle , C Dlc , C Dce , C sDc , C sDe :

-

Solute transfer rates with respect to diffusion, kg/m3/s

- c 0 :

-

Initial concentration

- c mix :

-

Concentration of the liquid-columnar-equiaxed mixture

- \( \Delta T \) :

-

Undercooling, K

- l :

-

Columnar dendrite length, m

- a 1, a 2 :

-

Fitting coefficient

- n e :

-

Nucleation density of the equiaxed crystal, m−3

- n max :

-

Maximum nucleation density of the equiaxed crystal, m−3

- ∆T σ :

-

Standard deviation, K

- ∆T N :

-

Average nucleation undercooling, K

- l :

-

Mark liquid

- c :

-

Columnar dendrite

- e :

-

Equiaxed crystal

References

Z. Shao, Z. Ma, J. Sheu, and H.O. Gao: Transport. Res. E-Log., 2018, vol. 117, pp. 40–57.

D.T. Eadie, D. Elvidge, K. Oldknow, R. Stock, P. Pointner, J. Kalousek, and P. Klauser: Wear, 2008, vol. 265, pp. 1222–30.

H.K.D.H. Bhadeshia and J. Vijay: Patent No. WO 96/22396, July 25, 1996.

Y. Satoh, M. Tatsumi, K. Kasiwaya, M. Ueda, and H. Yokoyama: Q. Rep. Railw. Tech. Res. Inst., 1999, vol. 40, pp. 86–91.

V.V. Pavlov, L.A. Godik, L.V. Korneva, N.A. Kozyrev, and E.P. Kuznetsov: Metallurgist, 2007, vol. 51, pp. 209–12.

S. Parzych and J. Krawczyk: Arch. Metall. Mater., 2012, vol. 57, pp. 261–64.

P. Clayton and N. Jin: Wear, 1996, vol. 200, pp. 74–82.

Pettersen: U.S. Patent No. 6899261B2, May 31, 2005.

L. Hou, Y. Dai, Y. Fautrelle, Z. Li, Z. Ren, C. Esling, and X. Li: Scripta Mater., 2018, vol. 156, pp. 95–100.

P.M. Ossi: Z. Phys. B, 1985, vol. 62, pp. 71–77.

T.F. Majka, D.K. Matlock, and G. Krauss: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1627–37.

T. Sourmail and V. Smanio: Mater. Sci. Technol., 2013, vol. 29, pp. 883–88.

W. Maziarz, P. Czaja, M.J. Szczerba, L. Lityńska-Dobrzyńska, T. Czeppe, and J. Dutkiewicz: J. Alloys Compd., 2014, vol. 615, pp. 173–77.

W. Ding, L. Li, G. Zhao, H. Song, and X. Zhang: Hot Work. Technol., 2015, vol. 44, pp. 209–12.

S.R. Babu, D. Ivanov, and D. Porter: ISIJ Int., 2019, vol. 59, pp. 169–75.

D.A. Mirzaev, M.M. Shtejnberg, T.N. Ponomareaa, and V.M. Schastlivtsev: Fiz. Met. Metalloved., 1979, vol. 47, pp. 125–35.

L. Cui, H. Fujii, N. Tsuji, and K. Nogi: Scripta Mater., 2007, vol. 56, pp. 637–40.

S.M.C. Van Bohemen and J. Sietsma: Mater. Sci. Eng. A, 2010, vol. 527, pp. 6672–76.

M. Nikravesh, M. Naderi, and G.H. Akbari: Mater. Sci. Eng. A, 2012, vol. 540, pp. 24–29.

B.S. Taysom and C.D. Sorensen: Int. J. Mach. Tool. Manu., 2020, vol. 150, p. 103512.

R. Guan, C. Ji, and M. Zhu: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 1137–53.

R. Guan, C. Ji, C. Wu, and M. Zhu: Int. J. Heat Mass Transfer, 2019, vol. 141, pp. 503–16.

M.C. Schneider and C. Beckermann: ISIJ Int., 1995, vol. 35, pp. 665–72.

S. Nabeshima, H. Nakato, T. Fujii, T. Fujimura, K. Kushida, and H. Mizota: ISIJ Int., 1995, vol. 35, pp. 673–79.

C. Celada-Casero, J. Sietsma, and M.J. Santofimia: Mater. Des., 2019, vol. 167, p. 107625.

J.J. Sun, Y.J. Wang, S.W. Guo, and Y.N. Liu: Mater. Lett., 2020, vol. 266, p. 127495.

A. García-Junceda, C. Capdevila, F.G. Caballero, and C.G. De Andres: Scripta Mater., 2008, vol. 58, pp. 134–37.

C. García-Mateo and F.G. Caballero: Mater. Trans., 2005, vol. 46, pp. 1839–46.

Y. Shen, J. Leng, and C. Wang: J. Mater. Sci. Technol., 2019, vol. 35, pp. 1747–52.

Acknowledgments

The present work was financially supported by the National Key Research and Development Program of China (Grant No. 2017YFB0304502-01), National Natural Science Foundation of China (Grant No. 51974078), Fundamental Research Funds for the Central Universities of China (Grant Nos. N2025012 and N2125018), and Liaoning Revitalization Talents Program (Grant Nos. XLYC1802032 and XLYC1907176). Special thanks are due to the instrumental or data analysis from the Analytical and Testing Center, Northeastern University. We also acknowledge financial support from the China Scholarship Council (Grant No. 201906080127).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted January 23, 2021; accepted June 3, 2021.

Rights and permissions

About this article

Cite this article

Guan, R., Ji, C., Chen, T. et al. Formation Mechanism of Abnormal Martensite in the Welded Joint of the Bainitic Rail. Metall Mater Trans B 52, 3220–3234 (2021). https://doi.org/10.1007/s11663-021-02250-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02250-2