Abstract

The melting behavior of BOF slag (CaO-SiO2-FeOx) is one of the key factors for dephosphorization during the converter process. Laboratory experiments using mixed chemical reagents and pre-melted slags were carried out to study the effect of the slag compositions on its hemispheric melting point, and the phases in the slag system were observed at high temperatures. The results reveal that only a small amount of CaCl2 can decrease the hemispheric melting points of low basicity slags (w(CaO)/w(SiO2) ≤ 1.0); while an excessive amount of CaCl2 will increase the hemispheric melting point of the slag system. In the case of higher basicity slag (w(CaO)/w(SiO2) ≥ 1.5), the addition of CaCl2 will increase the ratio of solid phase in slag, which results in the rise of hemispheric melting point. Even though, the positive effect of CaCl2 on the dissolution of CaO is still obvious, higher slag basicity generally leads to a higher hemispheric melting point of the CaCl2-added slags except for a few cases, and the content of FeOx has an evident impact on the hemispheric melting point of this slag system. A certain amount of FeOx in BOF slag is very necessary.

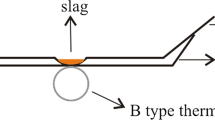

Adapted from Ref. [30] (Color figure online)

Similar content being viewed by others

References

N. Maruoka, A. Ishikawa, H. Shibata, S. Kitamura: High Temp. Mater. Process., 2013, vol. 32 (1), pp. 15-24.

T. Deng, D. Sichen: Metall. Mater. Trans. B, 2012, vol. 43 (3), pp. 578-586.

S. Kakimoto, A. Kiyose, R. Murao: ISIJ Int., 2017, vol. 57 (10), pp. 1710-1717.

Y. S. Lee, D. J. Min, S. M. Jung, S. H. Yi: ISIJ Int., 2007, vol. 44 (8), pp. 1291-1297.

J. B. Kim, I. Sohn: Metall. Mater. Trans. B, 2017, vol. 49 (1), pp. 291-303.

F. Z. Ji: Metall. Mater. Trans. B, 2001, vol. 32 (1), pp. 181-186.

H. C. Chuang, W. S. Hwang, S. H. Liu: Mater. Trans., 2009, vol. 50 (6), pp. 1448-1456.

F. Shahbazian, D. Sichen, S. Seetharaman: ISIJ Int., 2002, vol. 42 (2), pp. 155-162.

J. Yang, Q. Wang, J. Q. Zhang, O. Ostrovski, C. Zhang, D. X. Cai: Metall. Mater. Trans. B, 2019, vol. 50 (6), pp. 2794-2803.

G. Li, T. Hamano, Tsukihashi F: ISIJ Int., 2005, vol. 45 (1), pp. 12-18.

Z. L. Piao, L. G. Zhu, X. J. Wang, Z.X. Liu, B. Wang, P. C. Xiao, Z. P. Yuan: Metall. Mater. Trans. B, 2020, vol. 51(6), pp. 2119-2130.

E. J. Jung, D. J. Min: Steel Res. Int., 2012, vol. 83 (7), pp. 705-711.

S. Wang, Y. Guo, T. Jiang, F. Chen, F. Zheng, L. Yang: JOM, 2019, 71(5), pp. 1858-1865.

H. M. Wang, P. S. Li, G. R. Li, M. Zhang, Z. Zhao, Y. Zhao: Appl. Mech. Mater., 2012, vol. 217-219, pp. 35-38.

C. Liu, S. Huang, B. Blanpain, M. Guo: Metall. Mater. Trans. B, 2018, vol. 50 (1), pp.271-281.

B. Yan, Y. Liu, Q. Shu, B. Glaser: Metall. Mater. Trans. B, 2018, vol. 50 (1), pp. 376-384.

S. Wright, L. Zhang, S. Shouyi: J. Non-Cryst. Solids, 2001, vol. 282 (1), pp. 15-23.

E. Andersson, D. Sichen: Steel Res. Int., 2009, vol. 80 (8), pp. 544-551.

C. Wang, J. Zhang, Z. Liu, K. Jiao, G. Wang, J. Yang, K. Chou: Metall. Mater. Trans. B, 2017, vol. 48 (1), pp. 328-334.

J. H. Park, K. Y. Ko, T. S. Kim: Metall. Mater. Trans. B, 2015, vol. 46 (2), pp. 741-748.

R. C. Behera, U. K. Mohanty: ISIJ Int., 2001, vol. 41 (8), pp. 834-843.

J. Zhou, X. Bi, R. Yue,F. Yang: ISIJ Int., 2017, vol. 57 (4), pp. 706-712.

F. Li, X. Li, S. Yang, Y. Zhang: Metall. Mater. Trans. B, 2017, vol. 48 (5), pp. 2367-2378.

N. Sano, F. Tsukihashi, A. Tagaya: ISIJ Int., 1991, vol. 31 (11), pp. 1345-1347.

H. Nakamura, Y. Kawai, K. Kawakami: Tetsu-to-Hagané, 1981, vol. 67 (4), pp.186.

A. Ishizaka, T. Toyoda, K. Takuchi, H. Nakamura: Tetsu-to-Hagané, 1983, vol. 69 (12), 242.

G. J. W. Kor: Metall. Mater. Trans. B, 1977, vol. 8 (1), pp. 107-113.

J. L. Yu: Gangtie, 1988, vol. 23 (5), pp. 19-23.

K. Shimauchi, S. Kitamura, H. Shibata: ISIJ Int., 2009, vol. 49 (4), pp. 505–511.

V.D. Eisenhüttenleute: Slag Atlas. 2nd Edition. Verlag Stahleisen GmbH, Germany. 1995, pp 126-127.

C. Su, N. Lv, J. Yang, L. Wu, H. Wang, Y. Dong: J. Iron. Steel. Res. Int., 2009, vol. 26 (1), pp. 42-51.

L. Lin, Y. Bao, C. Gu, W. Wu, J. Zeng: High Temp. Mater. Proc., 2018, vol. 37 (7), pp. 655-663.

C. Du, X. Gao, S. Ueda, S. Kitamura: Metall. Mater. Trans. B, 2018, vol. 49 (1), pp. 181-189.

H. M. Wang, G. R. Li, B. Li, X. J. Zhang, Y. Q. Yan: Steel Res. Int., 2010, vol. 17 (10), pp. 18-22.

S. Ueda, T. Kon, T. Miki, S.J. Kim, H. Nogami: Metall. Mater. Trans. B, 2016, vol. 47 (4), pp. 2371-2377.

W. Gutt, G. J. Osborne: Tran. J. Br. Ceram. Soc, 1966, 65 (9): 521-535.

W. Gutt, G. J. Osborne: Tran. J. Br. Ceram. Soc, 1968, 67, pp. 125-133.

W. Gutt, G. J. Osborne: Tran. J. Br. Ceram. Soc, 1970, 69, pp. 125-139.

P. Patnaik: Handbook of Inorganic Chemicals. The McGraw-Hill Companies, Inc., New York, 2019, p. 162.

D. A. Wenz, I. Johnson, R. D. Wolson: J. Chem. Eng. Data, 1969, 14(2), 250-252.

D. G. Kim, M. A. Van Ende, C. Van Hoek, C. Liebsk, S. Van Der Laan, I. H. Jung: Metall. Mater. Trans. B, 2012, vol. 43(6), pp. 1315-1325.

S. Y. Kitamura, K. Yonezawa, Y. Ogawa, N. Sasaki: Ironmak. Steelmak., 2002, vol. 29 (2), pp. 121-124.

X. Yang, H. Matsuura, F. Tsukihashi: ISIJ Int., 2010, vol. 50 (5), pp. 702-711.

S. Xie, W. Wang, Z. Luo, D. Huang: Metall. Mater. Trans. B, 2016, vol. 47 (3), pp. 1583-1593.

J. Im, K. Morita, N. Sano: ISIJ Int., 1996, vol. 36 (5), pp. 517-521.

M. Zhong, H. Matsuura, F. Tsukihashi: ISIJ Int., 2015, vol. 55 (11), pp. 2283-2288.

Acknowledgments

The Natural Science Foundation of China (51804068, 52074073) and the Fundamental Research Funds for the Central Universities (N182504016) as well as Liaoning Revitalization Talents Program (XLYC1802032) are acknowledged for the financial support of the present study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 26, 2020; accepted January 14, 2021.

Rights and permissions

About this article

Cite this article

Yan, Z., Deng, Z., Zhu, M. et al. Effect of CaCl2 Addition on the Melting Behaviors of CaO-SiO2-FeOx Steelmaking Slag System. Metall Mater Trans B 52, 1142–1153 (2021). https://doi.org/10.1007/s11663-021-02088-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02088-8