Abstract

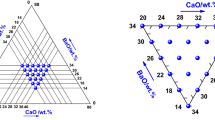

A series of steel-flux reaction experiments was conducted to elucidate the reaction mechanism between high Mn-high Al steel and CaO-\({\text{SiO}}_2\)-type molten mold flux of low MgO content \((({\text{pct MgO}})_0 = 0\) to 1.8) at 1723 K (\(1450\,^\circ \text {C}\)). Composition evolutions in the liquid steel and the molten flux during the reaction and microstructure change in the flux near the steel-flux interface were investigated by employing different experimental techniques. \(4{\underline{{\text{Al}}}} + 3({\text{SiO}}_2) = 3{\underline{\text{Si}}} + 2({{\text{Al}}_2} {{\text{O}}_3}\)) was confirmed as a major reaction in the system. It was found that rate of \({{\text{Al}}_2} {{\text{O}}_3}\) accumulation in the flux was retarded as the initial Al content in the steel (\([{\text{pct Al}}]_0\)) increased from 1 to 5 or 11, approximately. Moreover, keeping the initial content of MgO in the flux (\(({\text{pct MgO}})_0\)) < 1.8) resulted in a slower reaction rate than that with the normal MgO content (\(({\text{pct MgO}})_0 = \sim 2.5\)) reported previously, even at high Al content (\([{\text{pct Al}}]_0 = 4.6 {\text{to}} 5.8\)). From the microstructure analysis in the flux, the \({{\text{Al}}_2} {{\text{O}}_3}\)-rich zone and calcium aluminate layer were observed near the interface. A rapid increase of \({{\text{Al}}_2} {{\text{O}}_3}\) in the flux near the interface was found at the early stage of the reaction. As the reaction proceeded, however, the concentration gradients in the flux did not show noticeable changes. This suggests that mass transport in the flux was hindered by accumulation of the reaction products near the interface. The formation mechanism of the calcium aluminate layer was discussed by considering the measured flux compositions and phase diagram analysis calculated using the CALPHAD technique. Several kinetic analyses indicated that mass transport in the flux significantly affects the overall reaction rate in the high Mn-high Al steel and CaO-\({\text{SiO}}_2\)-type molten mold flux system with high Al \(([{\text{pct Al}}]_0 \ge 5\)) and low MgO content \((({\text{pct MgO}})_0 \le 1.8\)). The formation of a calcium aluminate layer in the low-MgO flux was beneficial to retarding the reaction rate.

Similar content being viewed by others

Notes

The present study employed an alumina crucible, which could even increase (pct \({{\text{Al}}_2} {{\text{O}}_3}\)) compared to that of the previous study which employed a magnesia crucible.[12]

References

S.-H. Kim, H. Kim, and N. J. Kim: Nature, 2015, vol. 518, pp. 77–79.

S.-W. Park, J. Y. Park, K. M. Cho, J. H. Jang, S.-J. Park, J. Moon, T.-H. Lee, and J.-H. Shin: Met. Mater. Int., 2019, vol. 25, pp. 683–696.

J. Lee, S. Park, H. Kim, S.-J. Park, K. Lee, M.-Y. Kim, P. P. Madakashira, and H. N. Han: Met. Mater. Int., 2018, vol. 24, pp. 702–710.

H. Kim, D.-W. Suh, and N. J. Kim: Sci.Tech. Adv. Mater., 2013, vol. 14, p. 014205.

S. Kim, D. Jeong, and H. Sung: Met. Mater. Int., 2018, vol. 24, pp. 1–14.

K. Blazek, H. Yin, G. Skoczlas, M. McClymonds, and M. Frazee: Proc. of AISTech 2011, Association for Iron and Steel Technology, 2011 pp. 1577–86.

J.-W. Cho, K. Blazek, M. Frazee, H. Yin, J. H. Park, and S.-W. Moon: ISIJ Int., 2013, vol. 53, pp. 62–70.

W. Wang, B. Lu, and D. Xiao: Metall. Mater. Trans. B, 2016, vol. 47, pp. 384–389.

S. He, Z. Li, Z. Chen, T. Wu, and Q. Wang: Steel Res. Int., 2019, vol. 90, p. 1800424.

X. Fu, G. Wen, Q. Liu, P. Tang, J. Li, and W. Li: Steel Res. Int., 2015, vol. 86, pp. 110–120.

H. Shao, E. Gao, W. Wang, and L. Zhang: J. Am. Ceram. Soc., 2019, vol. 102, pp. 4440–4449.

M.-S. Kim, S.-W. Lee, J.-W. Cho, M.-S. Park, H.-G. Lee, and Y.-B. Kang: Metall. Mater. Trans. B, 2013, vol. 44, pp. 299–308.

Y.-B. Kang, M.-S. Kim, S.-W. Lee, J.-W. Cho, M.-S. Park, and H.-G. Lee: Metall. Mater. Trans. B, 2013, vol. 44, pp. 309–316.

M.-S. Kim, M.-S. Park, S.-E. Kang, J.-K. Park, and Y.-B. Kang: ISIJ Int., 2018, vol. 58, pp. 686–695.

M.-S. Kim and Y.-B. Kang: Calphad, 2018, vol. 61, pp. 105–115.

M.-S. Kim, M.-S. Park, and Y.-B. Kang: Metall. Mater. Trans. B, 2019, vol. 50, pp. 2077–2082.

J. Yang, J. Zhang, O. Ostrovski, C. Zhang, and D. Cai: Metall. Italiana, 2019, vol. 1, pp. 12–19.

C. Bale, E. Bélisle, P. Chartrand, S. Decterov, G. Eriksson, K. Hack, I. Jung, Y. Kang, J. Melançon, A. Pelton, C. Robelin, and S. Petersen: Calphad, 2009, vol. 33, pp. 295–311.

C. W. Bale, E. Bélisle, P. Chartrand, S. A. Decterov, G. Eriksson, A. E. Gheribi, K. Hack, I. H. Jung, Y. B. Kang, J. Melançon, A. D. Pelton, S. Petersen, C. Robelin, J. Sangster, P. Spencer, and M.-A. Van Ende: Calphad, 2016, vol. 54, pp. 35–53.

S. and K. Hack

Q. Wang, S. Qiu, and P. Zhao: Metall. Mater. Trans. B, 2012, vol. 43, pp. 424–430.

Y. Chung and A. Cramb: Metall. Mater. Trans. B, 2000, vol. 31, pp. 957–971.

M. A. Rhamdhani, K. S. Coley, and G. A. Brooks: Metall. Mater. Trans. B, 2005, vol. 36, pp. 219–227.

M. A. Rhamdhani, G. A. Brooks, and K. S. Coley: Metall. Mater. Trans. B, 2006, vol. 37, pp. 1087–1091.

A. N. Assis, J. Warnett, S. Spooner, R. J. Fruehan, M. A. Williams, and S. Sridhar: Metall. Mater. Trans. B, 2015, vol. 46, pp. 568–576.

R. Roscoe: British J. Applied Phys., 1952, vol. 3, pp. 267- 269.

L. Thu Hoai and J. Lee: Metall. Mater. Trans. B, 2011, vol. 42, pp. 925–927.

Acknowledgments

This work was financially supported by POSCO, Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 25, 2020, accepted September 6, 2020.

Rights and permissions

About this article

Cite this article

Kim, MS., Park, MS., Jung, SH. et al. Reaction Between High Mn-High Al Steel and CaO-SiO\(_2\)-Type Molten Mold Flux: Retardation of \({{\text{Al}}_2} {{\text{O}}_3}\) Accumulation at High Al Content \(([{\text{pct Al}}]_0\) \(\ge \) 5) in Steel and Low MgO Content \((({\text{pct MgO}})_0\) \(\le \) 1.8) in Flux. Metall Mater Trans B 51, 3067–3078 (2020). https://doi.org/10.1007/s11663-020-01972-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01972-z