Abstract

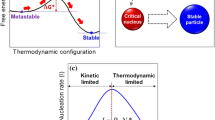

For the Kampmann–Wagner numerical (KWN) model, to accurately describe the microstructure evolution in a solid-state precipitation reaction requires a good evaluation of the Gibbs–Thomson effect and an appropriate nucleus size to be used. In the present work, it is found that there exists a big discrepancy between the nucleation thermodynamics and growth thermodynamics when adopting the widely used Gibbs–Thomson equation to evaluate the Gibbs–Thomson effect. This discrepancy can reduce the computational accuracy of the KWN model. When adopting the numerical method, “the equivalence of nucleation thermodynamics and growth thermodynamics” can be achieved. But due to the relatively large value of the critical size, some waves can be formed in the PSD function if the nucleus size is not carefully selected. Based on the analysis of formation mechanism of waves in the PSD function, it is suggested that, when adopting the numerical method to evaluate the Gibbs–Thomson effect, the most appropriate nucleus size should be the one derived from Zeldovich’s theory.

Similar content being viewed by others

References

D.L. McDowell and R.A. LeSar: MRS Bull., 2016, vol. 41, pp. 587–93.

A. Deschamps and C.R. Hutchinson: Acta Mater., 2021, vol. 220, p. 117338.

M. Perez, M. Dumont, and D. Acevedo-Reyes: Acta Mater., 2008, vol. 56, pp. 2119–32.

R. Wagner, and R. Kampmann: in Materials science and technology: a comprehensive treatment, R.W. Cahn ed., John Wiley, Weinheim, 1991, pp. 381–94.

Q. Zhang, S.K. Makineni, J.E. Allison, and J.C. Zhao: Scr. Mater., 2019, vol. 160, pp. 70–74.

J.P. Sanhueza, D. Rojas, O. Prat, J. Garcia, R. Espinoza, C. Montalba, and M.F. Melendrez: Mater. Chem. Phys., 2017, vol. 200, pp. 342–53.

W. Cao, S.L. Chen, F. Zhang, K. Wu, Y. Yang, Y.A. Chang, R. Schmid-Fetzer, and W.A. Oates: Calphad, 2009, vol. 33, pp. 328–42.

R. Schmid-Fetzer and F. Zhang: Calphad, 2018, vol. 61, pp. 246–63.

C. Zhang, W. Cao, S.L. Chen, J. Zhu, F. Zhang, A.A. Luo, and R. Schmid-Fetzer: JOM, 2014, vol. 66, pp. 389–96.

O.R. Myhr and Ø. Grong: Acta Mater., 2000, vol. 48, pp. 1605–15.

J.D. Robson, M.J. Jones, and P.B. Prangnell: Acta Mater., 2003, vol. 51, pp. 1453–68.

J.D. Robson: Acta Mater., 2004, vol. 52, pp. 4669–76.

D. den Ouden, F.J. Vermolen, L. Zhao, C. Vuik, and J. Sietsma: Comp. Mater. Sci., 2011, vol. 50, pp. 2397–2410.

D. den Ouden, L. Zhao, C. Vuik, J. Sietsma, and F.J. Vermolen: Comp. Mater. Sci., 2013, vol. 79, pp. 933–43.

Q. Du, W.J. Poole, and M.A. Wells: Acta Mater., 2012, vol. 60, pp. 3830–39.

Q. Du, K. Tang, C.D. Marioara, S.J. Andersen, B. Holmedal, and R. Holmestad: Acta Mater., 2017, vol. 122, pp. 178–86.

Q. Shu, V.V. Visuri, T. Alatarvas, and T. Fabritius: Metall. Mater. Trans. B, 2020, vol. 51, pp. 2905–16.

J.Z. Zhao, L. Ratke, and B. Feuerbacher: Model. Simul. Mater. Sci. Eng., 1998, vol. 6, pp. 123–39.

J.Z. Zhao, H.L. Li, Q.L. Wang, and J. He: Comp. Mater. Sci., 2008, vol. 44, pp. 400–03.

J.Z. Zhao, T. Ahmed, H.X. Jiang, J. He, and Q. Sun: Acta Metall. Sin. (Engl. Lett.), 2017, vol. 30, pp. 1–28.

Q.L. Wang and J.Z. Zhao: Mater. Sci. Eng. A, 2010, vol. 528, pp. 268–72.

J.Z. Zhao, Q.L. Wang, H.L. Li, and J. He: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3200–07.

Q.L. Wang and H. Xiong: Metall. Mater. Trans. A, 2021, vol. 52A, pp. 4987–96.

H.B. Aaron, D. Fainstein, and G.R. Kotler: J. Appl. Phys., 1970, vol. 41, pp. 4404–10.

I.V. Markov: Crystal Growth for Beginners: Fundamentals of Nucleation, Crystal Growth, and Epitaxy, 3rd ed. World Scientific, New Jersey, 2016.

S. Shahandeh and S. Nategh: Mater. Sci. Eng. A, 2007, vol. 443, pp. 178–84.

M. Hillert: Phase Equilibria, Phase Diagrams and Phase Transformations, 2nd ed. Cambridge University Press, Cambridge, 2008.

M. Qian: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1283–87.

M. Perez: Scr. Mater., 2005, vol. 52, pp. 709–12.

Q. Du, M. Perez, W.J. Poole, and M. Wells: Scr. Mater., 2012, vol. 66, pp. 419–22.

B. Rheingans and E.J. Mittemeijer: Calphad, 2015, vol. 50, pp. 49–58.

B. Rheingans and E.J. Mittemeijer: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 3423–39.

R.W. Hyland Jr.: Metall. Trans. A, 1992, vol. 23, pp. 1947–55.

C. Watanabe, T. Kondo, and R. Monzen: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3003–08.

E. Clouet, A. Barbu, L. Lae, and G. Martin: Acta Mater., 2005, vol. 53, pp. 2313–15.

E. Clouet and M. Nastar: Phys. Rev. B, 2007, vol. 75, p. 132102.

G.M. Novotny and A.J. Ardell: Mater. Sci. Eng. A, 2001, vol. 318, pp. 144–54.

E.A. Marquis and D.N. Seidman: Acta Mater., 2001, vol. 49, pp. 1909–19.

J. Røyset and N. Ryum: Int. Mater. Rev., 2005, vol. 50, pp. 19–44.

S. Iwamura and Y. Miura: Acta Mater., 2004, vol. 52, pp. 591–600.

H.I. Aaronson, M. Enomoto, and J.K. Lee: Mechanisms of Diffusional Phase Transformations in Metals and Alloys, CRC Press, Boca Raton, 2010.

A. Harten: J. Comput. Phys., 1983, vol. 49, pp. 357–93.

P.K. Sweby: SIAM J. Numer. Anal., 1984, vol. 21, pp. 995–1011.

R.J. LeVeque: SIAM J. Numer. Anal., 1996, vol. 33, pp. 627–65.

R.J. LeVeque: Finite Volume Methods for Hyperbolic Problems, Cambridge University Press, Cambridge, 2003.

S.V. Patankar: Numerical Heat Transfer and Fluid Flow, McGraw-Hill, New York, 1980.

S.I. Fujikawa: Defect Diffus. Forum, 1997, vol. 143–47, pp. 115–20.

J.L. Murray: J. Phase Equilibria, 1998, vol. 19, pp. 380–84.

H. Bo, L.B. Liu, and Z.P. Jin: J. Alloys Compd., 2010, vol. 490, pp. 318–25.

H. Bo, L.B. Liu, J.L. Hu, and Z.P. Jin: Comput. Mater. Sci., 2017, vol. 133, pp. 82–92.

A.T. Dinsdale, SGTE Pure elements (unary) database, v4.4, 2001.

M. Perez, M. Dumont, and D. Acevedo-Reyes: Acta Mater., 2009, vol. 57, p. 1318.

Acknowledgment

The authors gratefully acknowledge the financial support from Natural Science Foundation of Hebei Province (E2023203125).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, QL., Liu, HR. On Evaluation of the Gibbs–Thomson Effect and Selection of Nucleus Size for the Kampmann–Wagner Numerical Model. Metall Mater Trans A (2024). https://doi.org/10.1007/s11661-024-07380-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11661-024-07380-1