Abstract

A phase-field model is proposed to simulate coherency loss coupled with microstructure evolution. A special field variable is employed to describe the degree of coherency loss of each particle and its evolution is governed by a Ginzburg-Landau type kinetic equation. For the sake of computational efficiency, a flood-fill algorithm is introduced that can drastically reduce the required number of field variables, which allows the model to efficiently simulate a large number of particles sufficient for characterizing their statistical features during Ostwald ripening. The model can incorporate size dependence of coherency loss, metastability of coherent particles, and effectively incorporate the underlying mechanisms of coherency loss by introducing a so-called differential energy criterion. The model is applied to simulate coarsening of Al3Sc precipitates in aluminum alloy and comprehensively compared with experiments. Our results clearly show how the particle size distribution is changed during coherency loss and affects the coarsening rate.

Similar content being viewed by others

Introduction

Loss of interfacial coherency is common during the growth of precipitates in a multiphase material system1. When precipitates start to nucleate, they are typically coherent with the matrix material (or called parent phase) maintaining small interfacial energy. However, the lattice mismatch between the parent and product phases leads to coherency strain to keep the lattice correspondence. The coherency strain causes elastic energy that is in general proportional to the volume of the particle thus the cube of particle size, according to Eshelby’s ellipsoidal inclusion solution2. Since the surface energy scales with the square of particle size, when the particle grows, at a certain threshold size, the elastic energy will outweigh the surface energy so that it is thermodynamically favorable if the particle loses its coherency with the matrix.

In general coherency loss (CL) is accompanied by relief of elastic energy and increase of interfacial energy due to interfacial defects, which then can change the shape of precipitates and has a profound influence on the microstructure evolution and mechanical performance of precipitation strengthened alloys3,4,5,6. Iwamura & Miura (hereafter called IM) have performed a comprehensive experimental study on the Ostwald ripening (coarsening) of Al3Sc precipitates in aluminum alloy and reported that both the growth law of particle size and the particle size distribution (PSD) are changed during CL owing to the change of interfacial energy7. The different coarsening rate during CL is also reported for γ” in nickel-base Alloy 7188. The coherency state also has a significant influence on the performance of oxide dispersion strengthened alloys9,10.

At atomic level, however, CL may result from distinct mechanisms. Three well-documented mechanisms are: (a) attraction of matrix dislocations to the particle/matrix interface followed by climb and interaction of dislocations at the interface11; (b) nucleation of dislocation loops within the precipitate11; (c) prismatic punching of dislocation loops12,13 for plate-shaped coherent precipitate. The third mechanism proposed by Weatherly12 is usually considered to correspond to the situation that the lattice misfit is severe (~5% or more) so that the stress at the interfacial region approaches the theoretical shear strength of the matrix. In principle, the third mechanism also means CL is independent of particle size as the stress level of an isolate ellipsoidal particle does not depend on the particle size but mainly on the misfit strain according to Eshelby’s solution2. This is a ‘upper limit’ in terms of the misfit strain for CL to occur without any nucleation barrier required14. Except for the dislocation punching mechanism, the other mechanisms predict a ‘threshold size’ below which CL cannot occur11.

CL is often predicted by thermodynamics, i.e., the transition is expected to occur at a critical particle size when the reduction of elastic energy equals the increase of interfacial energy1. Calculation of the elastic energy change during CL needs identification of the eigenstrains associated with both the coherent and the semi-coherent precipitates. A method for calculating the eigenstrains, by considering the lattice correspondence, orientation relation and various defects involved during CL, has been developed by Shi et al.3, and the method has been applied to study CL of γ” in nickel-base Alloy 71815. In most existing models, CL is treated as an abrupt change, i.e., a precipitate particle is either coherent, or semi-coherent/incoherent with reduced/zero eigenstrains, without considering the intermediate state. In experiments, it is frequently found that CL occurs later or much later than the thermodynamic predictions, and CL occurs within a broad range instead of at a critical particle size7,8,11,16,17 (e.g., Al3Sc in Al 15–40 nm7, θ’ in Al-Cu 25–50 nm11, and γ” in Alloy 718 40–180 nm8). In an Al-Cu-Mg alloy, it is found that most precipitate particles remain coherent at 260 °C for 25 days, but they lose coherency within 20 min when a creep load is applied, which indicates the rate of CL highly depends on the availability of matrix dislocations in the Al-Cu-Mg system11. Owing to these facts, and since CL is not a martensitic (diffusionless) process, it should be natural to consider CL as a continuous process instead of an abrupt transformation, which is the hypothesis of the current model. Weatherly and Nicholson also observed that for network dislocations that require two different Burgers vectors those dislocations are often formed in sequence rather than simultaneously11, and such an effect can only be included by taking the process of CL into account.

Quek et al. have studied the process of CL by level set-based discrete dislocation dynamics18, which is also in agreement with the experiment of Weatherly and Nicholson. However, at mesoscale there lacks a general and efficient model that can incorporate CL as a continuous kinetic process and couple CL with microstructure evolution. A dislocation density-based crystal plasticity model has been developed to study the punching mechanism19, which corresponds to the aforementioned mechanism (c) and thus does not predict the size dependence of CL. It is noted that the change of eigenstrain of a precipitate associated with CL is not necessarily deviatoric (it can involve volumetric strain)3, as CL can occur by nucleation of a stacking fault within the precipitate (addition or loss of an atomic plane) through vacancy diffusion11, which corresponds to the aforementioned mechanism (b). This means unless in special situations CL may not be modeled by classical plasticity or crystal plasticity models as plastic strain is just deviatoric20,21.

Here we propose a phase-field approach where a special field variable is introduced to describe the coherency state of precipitate particles, with its value continuously varying from 0 to 1 to represent the transition from coherent to the final semi-coherent state of particles (see the schematic of Fig. 1). A similar idea to use a field variable to represent the degree of CL has been proposed by Appolaire et al.22. Appolaire’s model treats CL as the release of shear stress at the interface and unfortunately, it does not predict any size dependence of CL. A major advantage in our approach is that the total interfacial energy and elastic energy of a precipitate are linked to this special field variable so that the model can predict the size dependence of CL. In addition, our model fully couples microstructure evolution and CL, and CL is controlled by a differential energy criterion incorporated via a Ginzburg-Landau type equation that can also effectively incorporate atomic level kinetic mechanisms. To facilitate large-scale simulation, a flood-fill algorithm is introduced to identify each individual particle from one phase-field profile, which can significantly reduce the number of field variables so as to drastically improve the computational efficiency.

The blue and green bands represent interfacial dislocation loops with different Burgers vectors. Note that the two sets of dislocations may appear in sequence according to Weatherly and Nicholson11, not necessarily the same as what is shown in this schematic.

Results

Without loss of generality, a multi-phase-field model is developed to describe an alloy system with multiple precipitation phases and grains. A set of order parameters {ƞ} is employed to describe each grain in each phase. A set of composition fields {x} is used to represent the molar fraction of each component in the alloy. A special field variable ξ(r) is introduced to represent the degree of coherency loss (dCL) of precipitate particles. ξ = 0 means coherent state and ξ = 1 indicates completion of the CL process.

The total free energy of the system (Ω) is assumed to be a sum of chemical, elastic, and interfacial energies, i.e.,

dCL linked to surface energy and elastic energy

The interfacial energy density is defined as

where the interfacial energy density for coherent precipitate phase is given by23

Δγ is a factor to account for the increase of interfacial energy during CL and ƞαi is the order parameter for the ith grain of phase α. q(ξ) is a function that satisfies q(0) = 0 and q(1) = 1. The dCL parameter ξ can be linked to the physical property such as the effective interfacial dislocation density, and then q(ξ) can be obtained from lower-length-scale simulations such as microscopic phase-field approach24 or dislocation dynamics based methods13,18 to link the interfacial energy to defect density. q(ξ) could also be approximated by a Read-Shockley (RS) type relation25 to account for the interfacial energy caused by misfit dislocations, as is done in refs. 3,15. Nevertheless, in this work for simplicity, a hyperbolic tangent function is assumed with a profile that to some extent resembles the RS relation,

where k is a constant. The formulation leads to an interfacial energy increase of Δγ tanh(kξ) fcoh after CL. This formulation is simpler than the RS relation for code implementation, and more importantly it has finite first derivative at ξ = 0 of q′(0) = k, while the first derivative is infinity at θ = 0 in the original RS relation (θ is the misorientation angle at a grain boundary which is proportional to the dislocation density). The infinite value of q′(0) will inhibit CL to initiate by the differential energy criterion that will be introduced in the following text. The RS relation is an analytical model for low angle grain boundaries that considers defect density can be infinitesimal. For a particle of tens of nanometers, however, there are typically a limited amount of dislocations on its surface, so the first dislocation loop should be associated with a finite increment of dislocation density, which leads to a finite q′(0).

The form of q(ξ) offers an opportunity for defining the effect of the kinetic pathway during CL, which will be further discussed in the Discussion. From an atomistic viewpoint, if ξ is linked to the defect density the first derivative of free energy with respect to ξ at ξ = 0 corresponds to the energy change associated with the first dislocation loop, which has been discussed in the theoretical model of Brown and Woolhouse26. Therefore, it is not sufficient for CL to start and proceed when only the final semi-coherent particle is energetically more favorable than the coherent predecessor. Each addition of defect (dislocation loop for example) needs to be energetically favorable and especially the first one that marks the onset of CL. Namely, the onset and proceeding of CL require the condition of

where γ is the interfacial energy and Eel the elastic energy. We call this condition a differential energy criterion, which is in contrast to the conventional thermodynamic criterion that only considers the coherent and the final semicoherent states1. Figure 2 is a schematic showing how CL is possible by the differential energy criterion. In Fig. 2, CL will spontaneously occur in case (b) but not in case (a) even if case (a) also satisfies the conventional thermodynamic criterion, so case (a) is a metastable state. Note that the schematic surface energy curves in Fig. 2 are plotted as concave down as the RS relation is in this shape, but it is not necessarily the general situation. Integration of the differential energy criterion leads to \(E_{\mathrm{coh}}^{\mathrm{el}} - E^{\mathrm{el}} > \gamma - \gamma _{\mathrm{coh}}\), the conventional thermodynamic criterion, where subscript ‘coh’ denotes a coherent system. Therefore, if the differential energy criterion is satisfied throughout the CL process, the conventional thermodynamic criterion is automatically satisfied.

a A coherent precipitate is metastable when \(E_{\mathrm{coh}}^{\mathrm{el}} - E^{\mathrm{el}} > \gamma - \gamma _{\mathrm{coh}}\) but −∂Eel/∂ξ < ∂γ/∂ξ; b a coherent precipitate is unstable when \(E_{\mathrm{coh}}^{\mathrm{el}} - E^{\mathrm{el}} > \gamma - \gamma _{\mathrm{coh}}\) and −∂Eel/∂ξ < ∂γ/∂ξ (CL will spontaneously occur).

Assume small strain and for precipitation phase α the eigenstrain associated with CL is

where \(^\circ \varepsilon _{ij}^{L(\alpha )}\) is the eigenstrain of the α phase semi-coherent precipitate (we mean the final stable semi-coherent state typically with elastic energy significantly reduced) minus that of its coherent predecessor. This equation, combining with Eqs. (2) and (4), defines the physical meaning of ξ in this model. Namely, it reflects the degree of reduction of the coherent eigenstrain and in the meanwhile is linked to the increase of interfacial energy owing to the interfacial defects. The degree of reduction of coherent eigenstrain is assumed to be proportional to the density of interfacial dislocations, and thus ξ is also linked to the normalized density of interfacial dislocation (in reference to the density for the final semicoherent state).

The elastic energy density is given by

where the stress-free strain (eigenstrain) \(\varepsilon _{ij}^0\) is

The eigenstrain associated with each coherent precipitate phase is \(\mathop {\sum}\nolimits_{\alpha = 1}^M {g_\alpha ({\boldsymbol{\eta }})\varepsilon _{ij}^{00(\alpha )}}\) and g(ƞ) is an interpolation function defined by27

This interpolation function strictly satisfies \(\mathop {\sum}\nolimits_{\alpha = 1}^M {g_\alpha ({\boldsymbol{\eta }})} = 1\). Generally, \(\varepsilon _{ij}^{00(\alpha )}\) depends on the lattice correspondence between the product (precipitate) and parent phases, as well as the orientation relationship between the two lattices3,28. The term \(\varepsilon _{ij}^L\) stands for the change of eigenstrain during the loss of coherency, which can be determined by accounting for the misfit dislocations and structural ledges associated with CL3. Therefore, when ξ = 1, this model would conform to the model of Shi et al.3 for predicting the equilibrium shape of semicoherent precipitates.

The chemical-free energy fchem is detailed in the Supplementary Method 1 of this paper. A thin-interface approach, following Kim, Kim, and Suzuki (KKS)29, is adopted. The thin-interface approach allows the phase-field model to converge with a relaxed restriction on the ratio of interface width to the characteristic structural length, which makes the phase-field model more efficient while maintaining accuracy.

Governing equations

For simplicity first assume there is no overlapping particles and each precipitate particle has only one grain. It is assumed that the dCL parameter is piecewise uniform, i.e., it has uniform value ξαp over a specific particle αp region (Ωαp) although this value evolves over time, i.e.,

where the delta function δαp(r) is 1 when r∈Ωαp and 0 elsewhere. Subsequently, by Eqs. (1–2) and Eqs. (6–8) the derivative of system free energy with respect to ξαp is given by

The equilibrium condition of Eq. (11) is ∂F / ∂ξαp = 0. For a single particle if \(^\circ \varepsilon _{ij}^{L(\alpha )} = - \varepsilon _{ij}^{00(\alpha )}\) (This means elastic eigenstrain of the coherent precipitate is completely removed after CL) and q′(ξ) = 2, then it is obtained that

The right hand side of the above equation is exactly the elastic energy of a system containing a coherent precipitate in the absence of body force and external load30, and the left hand side is the increase of interfacial energy due to CL. It is clear that this is equivalent to the conventional thermodynamic criteria used for CL1. Obviously, the value of q′(ξ) is not necessarily 2 (and it depends on the definition of ξ). A coefficient k > 2 here would lead to ‘supersaturation’ and the particle needs to over-grow to trigger CL. From viewpoint at atomic level the specific form of q(ξ) depends on the detailed atomic process (mechanism) of CL.

The evolution of the dCL parameter of particle αp is governed by the equation proposed below,

in the spirit of the time-dependent Ginzburg-Landau (TDGL) equation. In a simple form Kξ can be defined as \(K^\xi = K_0^\xi H\left( { - \frac{{\partial F}}{{\partial \xi ^\alpha }}} \right)\), where \(K_0^\xi\) is a constant and H(x) is a Heaviside step function that satisfies [H(x) = 0, when x < 0 and H(x) = 1 when x ≥ 0]. This makes CL an irreversible process (note that this is not necessarily the general situation and without the Heaviside step function CL will be reversible). It is reported in the experiments7 that with respect to Al3Sc-Al system at a certain stage of coarsening all precipitates lose coherency, which indicates CL is an irreversible process in this system because otherwise during coarsening there will always be particles shrinking till disappearance and if CL is reversible those particles should recover the coherency before their disappearance. It is noted that Brown et al.26 studied the stability of a semi-coherent precipitate by considering a single dislocation loop at the interface of spherical precipitate. Their conclusion is that below a critical size (rcrit) the semi-coherent precipitate is thermodynamically unstable so the interfacial dislocation will climb through the particle and disappear. Since rcrit is relatively small, it is probably not important to consider this reverse process of CL during coarsening, but it can be incorporated in our model if necessary.

If CL is predicted to occur but the theoretical equilibrium dislocation spacing is larger than the particle size, likely the particle needs to grow up until its size is larger than the required spacing before CL can proceed. If this is true the CL becomes virtually a one-step process (appearance of the first interfacial defect means the completion of the CL). This situation can be handled by setting a large coefficient k (k > 2). With a large k the particle needs to over-grow before the first interfacial defect is in place so that the onset of CL will be later than prediction by the conventional thermodynamic criterion. This one-step CL process can also be treated simply by allowing the coefficient Kξ to be dependent on the particle size/volume. Kξ needs to be zero when the particle size is smaller than the calculated equilibrium dislocation spacing. In general, if the attraction of matrix dislocations is the major CL mechanism and there are scarce matrix dislocations Kξ should be small.

TDGL equations are applied to the evolution of order parameters, and Cahn-Hilliard equation is applied to the conserved composition fields. These combined with the dCL evolution equation lead to the governing equations

Mk is chemical mobility for component k. In general, it is in the form of \(M_k^{(\alpha )} = \tilde D_k^{(\alpha )}/V_m\frac{{\partial ^2f^{(\alpha )}}}{{\partial x_k^2}}\), so the diffusivity of component k is \(\tilde D_k^{(\alpha )} = 2M_k^{(\alpha )}V_mc_k\). The above formula is developed for general situations. It is noted that for the Al3Sc system per se, the elastic constant is set isotropic and the eigenstrain of Al3Sc is dilatational7, which leads to spherical particle shape.

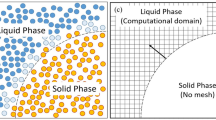

Using the flood fill algorithm

For simulation of coarsening of N particles, it would be straightforward to directly use N order parameters, which is convenient for identifying each particle and tracking its dCL value. However, the computational cost and memory demand surge when N is large. To obtain statistically reliable PSD in coarsening, N is required to be several hundred or above, and thus the starting N for coarsening simulation needs to reach at least ~1000. Consider situation where there is only one precipitation phase and a matrix phase. To reduce the computational cost, by Eq.(11), the integration over the region Ωαp can be approximated by region Ωαp′ bounded by ƞ = ƞcutoff, where ƞcutoff is a cutoff value. Consequently, we can employ only two order parameters to represent the precipitate phase and the matrix phase (without considering the grain boundaries), respectively, with all particles are represented by order parameter ƞ1. Then, the identification of Ωαp′ can be achieved by a flood-fill algorithm31. More details on the algorithm are given in Supplementary Method 2. The field variable, ξ(r), maps the dCL value of each precipitation particle ξαp, and ξ(r) is updated every time step when each ξαp is updated by Eq. (13). When two particles begin to merge and coalesce during coarsening, in this work the dCL of the merged particle is defined as the volume average of the two (in other words the two particles are taken as one). This is only for numerical convenience of coarse-grained modeling, as the physical meaning of the average dCL of two particles just beginning to coalesce is difficult to define. It is noted that the application of the flood-fill algorithm is not mandatory. It is just a practical way for the phase-field model to handle CL of thousands of particles during coarsening with reasonable computational cost.

Computational settings

Some technical details and parameter setting of the computational model are provided in the Supplementary Method 3, including the normalization and rescaling of the phase-field model. The aluminum alloy system is assumed to be elastically isotropic with shear modulus μ = 26.2 GPa and Poisson’s ratio ν = 1/3. The parameter Kƞ is set sufficiently large so that the rate-limiting process of coarsening is the diffusion. In IM’s experiment, the samples are cold-worked prior to the aging, so plenty of matrix dislocations are expected. Thus, the parameter Kξ is set large on assumption that attraction of matrix dislocation is easy for CL to proceed when it is energetically favorable. The eigenstrain for the coherent Al3Sc is set to \(\varepsilon _{11}^ \ast = \varepsilon _{22}^ \ast = \varepsilon ^ \ast = 0.013\)(dilatational) with all other components of \(\varepsilon _{ij}^ \ast\) set to zero. The eigenstrain associated with CL is set to \(^\circ \varepsilon _{ij}^L = - \varepsilon _{ij}^ \ast\). The dimensionless coefficients χ = 2 and Δγ = 0.5. The values of all the parameters are chosen to best match the Al3Sc/Al system in IM’s experiment (at temperature 703 K). The exceptions are Al3Sc volume fraction and the solubility of scandium in the matrix phases which are enlarged for the sake of numerical efficiency. Our model is formulated in 3D. Because coarsening involving thousands of particles is still computational expensive, we adopt 2D simulations and how it is different from 3D models will be discussed in the Discussion. A uniform 1024 × 1024 mesh is employed in this work to study the coarsening kinetics of Al3Sc. Random noise is added to the initial x1 field to facilitate the nucleation of precipitates. After simulation starts, phase separation (the growth stage) is rapidly completed (~100t0) with the volume fraction of α phase (Al3Sc) grows to ~8% and keeps constant. This volume fraction, though low, is higher than that in IM’s experiments7. The latter is <1%, which is inconvenient for the phase-field model in consideration of the numerical efficiency. After phase separation the remaining parts of the simulations are coarsening accompanied by CL.

Antiphase boundaries (APBs) could exist in this system. Unfortunately, in the IM’s experiments information on APBs is not reported. For simplicity APBs are not included in this work. The APB energy is usually high, and if it is greater than twice the interfacial energy of the precipitate, ‘out-of-phase’ particles can be prevented from directly coalescing together32,33. Since in IM’s experiments the particle volume fraction is low, the chance of particle coalescence events is small and such an effect by APBs is expected to be insignificant to the coarsening kinetics.

Baseline simulations

Three sets of baseline simulations are conducted to calibrate the model. In the first set, the elastic energy is excluded on purpose so the coarsening is under the full scope of conventional LSW theory except that the volume fraction is finite here. In the second set, elastic energy is included while all precipitates are forced to maintain coherency (ξ = 0) throughout the coarsening simulation. In the third set, all precipitates are set semi-coherent (ξ = 1.0) throughout the simulation (relieved elastic energy but higher interface energy). In each set, 10 simulation runs are conducted with different initial random noise with respect to the composition fields. In the baseline simulations, the length unit is l0 = 3.5 nm and time unit t0 = 3.2 s. The simulated growth curves are shown in Fig. 3a. The steady-state PSD for the three cases are shown in Fig. 3b. It is clear that all three cases lead to cubic growth kinetics and very similar PSDs at a steady state. The cubic constant for all semi-coherent precipitates is about 1.5 times of that of all coherent precipitates, which is due to that the interfacial energy is 1.5 times higher, as is expected from the LSW theory.

a Without elastic energy, with elastic energy and coherent interface, and with relieved elastic energy and semi-coherent interface. Each data point is the averaged value of the 10 simulations in each set and the error bar is set to the standard error of \(\bar r/l_0\). b Particle size distribution in steady-state (at time 2500 t0), where the solid magenta line is the fitted PSD profile from steady-state coarsening of all-coherent precipitates, and it is used as a reference in other situations as a reference. The error bar is set to the standard deviation of particle density in each bin over the 10 simulation runs.

The steady-state PSD for coherent precipitates is fitted by a 10th order polynomial (by software Tecplot 360), shown as a solid curve line in Fig. 3b. The shape of the steady-state PSD resembles the LSW theory prediction, while the peak is broader34,35, because the volume fraction of precipitates in our simulation is 8%. The LSW theory is accurate only in the zero volume fraction limit, owing to the long-range Coulombic nature of diffusion field36.

Earlier phase-field simulations show that the growth of coherent precipitates also follows \(\bar r^3 \propto t\) law, even when elastic energy is present and in 2D situations37,38. For coherent precipitates, if inter-particle interaction is negligible, Eshelby’s solution shows that the elastic energy of an ellipsoid precipitate depends only on its volume. Consequently, one particle and two particles with the same volume has the same elastic energy if the particle shape is unchanged. Our results show that the contribution of elastic energy to the coarsening rate of Al3Sc at the coherent stage is small (Fig. 3). This could be due to: (a) the elastic interaction between precipitate particles is small due to the low volume fraction, and (b) for dilatational eigenstrain the elastic energy does not change the spherical shape of particles.

In the baseline simulations, the three sets for semi-coherent, coherent and coherent without elastic energy cases all show steady-state PSDs conforming to one another. This PSD will be used as a reference for comparison of the PSD during the following CL simulations. The semi-coherent precipitates coarsen faster than the other two cases due to the higher surface energy.

Coarsening of Al3Sc precipitates in Al-Sc alloy

Phase-field simulations are performed to capture the coherent to semi-coherent transition of Al3Sc precipitates in aluminum alloy that has been systematically studied in the IM’s work. Figure 4a shows the simulated \(\bar r^3 - t\) law. Similarly, each data point is averaged over 10 simulation runs at the same simulation time that has different random noise of the initial composition. The solid line shows the average dCL value of all particles as a function of time. The average dCL changes from 0 to ~0.93 when most particles have completed the CL process. The dCL distribution at three representative stages (point A, B and C in Fig. 4a) are shown in Fig. 4b–d, respectively. In Fig. 4b most particles are coherent, with only a couple of particles started to lose coherency. At point B (Fig. 4c), most bigger particles have lost their coherency, and most smaller particles still maintain coherency, which is expected by simple energy analysis. At point C (Fig. 4d), almost all particles have lost their coherency. It is interesting that some particles in Fig. 4d (the one in the dash-line box is an example) are smaller than part of particles in Fig. 4c but with a higher dCL, which is because these particles lost coherency during growth but maintained semi-coherent state while shrinking (As has been mentioned, the reversal of CL is prohibited regardless of particle size.). This could contribute to the range of semi-coherent particle sizes observed in the CL experiments.

a Growth kinetics with spontaneous loss of coherency. The red line represents the cube of mean particle radius and the blue line represents the average dCL. The shadow zone represents the main period of loss of coherency. The error bar for dCL is set to the standard deviation of average dCL from 10 simulation runs at the time. The error bar for \(\bar r^3\) is set to \((\bar r + s_r)^3 - \bar r^3 \approx 3\bar r^2s_r\) where sr is the standard error of \(\bar r\) from the 10 runs. b–d Distribution of dCL (from 1 out of the 10 simulation runs), corresponding to A, B, and C points in a.

Multiscale simulation of coherent to semi-coherent transition

The simulations above have shown the essential feature of the coherent to the semi-coherent transition of Al3Sc. However, in Fig. 4a at point A there are about ~1000 particles, while at point C there are only ~100 particles, which leads to significant scattering on the PSD and uncertainty in the growth kinetics. The coherent stage and semi-coherent stage (outside the shaded zone in Fig. 4a, where the criteria for the onset of CL is defined as that at least one bin in PSD has an average dCL more than 0.05, and the criteria for completion of CL is all bins in PSD have average dCL more than 0.1) are short to perform more quantitative analysis such as the correlation between the growth law and PSDs. To resolve this issue, the phase-field model is rescaled to two different length scales for a refined study on the transition from all coherent to the coexistence of coherent/semi-coherent precipitates, and transition from the latter to all semi-coherent stage, respectively. In one case the grid size of the computational domain is halved (l0 → 0.5l0) to allow the simulation to focus on the earlier stage (Fig. 5a and Fig. 6a–c); and in the other case the grid size is doubled (l0 → 2l0) to focus on the later stage of the transition (Figs. 5b and 6e, f), and Fig. 6d is from the simulation with original grid size l0. As has been stated, during rescaling, the major physical properties, including interfacial energy, diffusivities, and solubilities are maintained constant. Similar scheme has been applied in the simulation of oxidation kinetics in our earlier work39. In both rescaled models, the number of particles is above ~300 till the end of the simulation, which keeps the statistics reliable.

a Using l0’ = 0.5l0 focusing on the transition from coherent to semi-coherent (onset of CL), and b l0’=2.0l0, focusing on the completion of the CL. The error bars are set similar to Fig. 4a.

From \(\bar r^3 - t\) curve and the dCL evolution in Fig. 5a, it is interesting to observe that the steady-state linear \(\bar r^3 - t\) relation is mildly deviated at the two ends. At the very beginning it takes time for the nucleation stage PSD to evolve into the steady-state one, which is reflected by the change of profile from Fig. 6a, b. If this period is included to fit the coefficient of the cubic growth the slope would be affected. Instead, the solid line in Fig. 5a is fitted from the segment after PSD starts to coincide with the reference one and before the average dCL = 0.05 (~500<t/t0 < 1200 in Fig. 5a). Similar strategy for Fig. 5b the solid line is fitted from the segment when the PSD coincide with the reference one. It is observed that although the onset of CL occurs at \(\bar r \approx 3.7l_0\), the deviation of particle growth law from the linear \(\bar r^3 - t\) relation is not obvious until \(\bar r \approx 5.2l_0\).

When CL occurs bigger particles that lose coherency further decrease the chemical potential of the species scandium by releasing elastic energy. As a result, part of intermediate-sized particles that originally neither grow nor shrink now have higher potential than the average chemical potential so that they begin to shrink. As a result, the peak of the original PSD gradually shrinks and the PSD profile becomes broadened during CL, and at some stage there are apparently two humps (one around \(r/\bar r = 0.7\) and one around \(r/\bar r = 1.2\) in Fig. 6d) instead of one hump (around 1.0 in the reference PSD). The broadening of the PSD has been reported in the experiment of IM. Note that in the IM’s experiments, the PSDs are processed only by 10 bins, which is probably not enough to resolve the fine detail in the PSD, but they performed a theoretical analysis that also supports two humps in PSD during CL7.

Figure 7 demonstrates the contour profile of the chemical potential of scandium (normalized by μ0, c.f. the Supplementary Method 3) over a group of particles in the simulation before and after one of the particles loses coherency when the size of all the particles is nearly unchanged. The chemical potential is defined by μ1 = δF/δx1 = ∂fchem/∂xi, and the elastic energy plays a role indirectly by the coupled TDGL and Cahn-Hilliard Eq. (14) under the total free energy (linked through the order parameters {ƞ}). It is clear that the chemical potential in the semicoherent particle is decreased after CL, which is due to that the release of elastic energy of the particle outweighs the influence of the increase of interfacial energy (an increase of interfacial energy alone will lead to an increase of the chemical potential). Consequently, this big semicoherent particle will become a deeper sink for surrounding particles during coarsening so that originally some intermediate-size particles that neither grow nor shrink will become to shrink. The physics revealed in Fig. 7 might be counterintuitive. By intuition, one might assume that semi-coherent particles have higher interfacial energy so they should have higher tendency to shrink than coherent particles (with the same size). In fact, when a particle loses coherency it is energetically more favorable for it to grow as compared to a coherent one with the same size. Consequently, the fraction of small particles in the system is increased since more particles begin to shrink after the biggest particles lose coherency. The mean particle size then becomes smaller as compared to all-coherent-particle situation. As a result, there is apparent slowdown of coarsening at the beginning stage of CL (Fig. 5a). When all particles complete CL, they all have higher interfacial energy and the PSD gradually approaches the reference one again. And the growth rate goes up as if the particles are all coherent but with higher interfacial energy (equivalent to the all-semicoherent case in Fig. 3).

When CL is mostly completed \(\left( {\bar r \approx 15.9l_0} \right)\), it is shown that the PSD still needs a certain time to evolve into the shape of the reference PSD (Fig. 6e, f). From the \(\bar r^3 - t\) curve, the slight deviation of PSD appears to deviate the power-law growth but very mildly till \(\bar r \approx 17l_0\) (Fig. 5b). The transition period required for PSD to evolve from a perturbated state to the steady-state may depend on the volume fraction of the precipitates, further study is needed for a systematic investigation on what factors affect the transition period for the evolution of PSD into the steady-state one. In IM’s experiments, it is also observed that there is certain transition time following completion of CL before the power-law growth enters a steady state, which agrees with our simulations. From the onset of CL to the completion of CL, in our simulations the average particle size spans from 3.7l0 to 15.9l0, which translates to 13 nm to 56 nm as l0 = 3.5 nm, and it is in line with the reported value of 15–40 nm in IM’s experiments. IM also gives a thermodynamic analysis for CL that predicts CL to occur at an average particle size of 12.3 nm which is close to the predicted onset of CL in this work.

It needs to be clarified that the simulations of Fig. 5a, b are not connected (simulation set for Fig. 5b also starts with random noise fields and zero dCL), although it is possible to perform a connected multi-scale-relay simulation by mapping the simulation result of the smaller-length-scale simulation (Fig. 5a) to the larger-length-scale one (Fig. 5b) as the initial condition. The purpose here is mainly to demonstrate the correlation between PSD and particle growth law at the later stage, which is assumed to be not sensitive to the starting PSD.

Discussion

In the previous simulations, the coefficient k in Eq. (4) is chosen to be 2.0. As a result, the differential energy criterion (Eq. (5)) coincides with the conventional thermodynamic criterion in terms of the onset of CL. The simulation results agree with the experiments of IM in terms of the range of mean particle size as well as the evolution of PSD during CL. Now k is changed to 3.0 and 4.0, respectively, to study the effect of this coefficient. The simulated growth curve is shown in Fig. 8a. It is shown that with a larger k, onset of CL becomes harder and more particles become metastable (overgrown) prior to the loss of coherency as discussed in Fig. 2. The ranges of mean particle size during CL are 6.1l0−16.8l0 (21~59 nm), and 7.6l0−18.6l0 (27~65 nm), corresponding to k = 3, and 4, respectively, which is compared to 3.7l0−15.9l0 (13~56 nm) for the previous case k = 2. It is clear that the case k = 2 matches best with the 15~40 nm observation in IM’s experiments. From the \(\bar r^3 - t\) curves, the k = 3 case exhibits smaller mean particle size than k = 2 case (starting from t/t0 ≈ 5000) and then larger (from t/t0 ≈ 10,000). Similarly, the k = 4 case exhibits a smaller mean particle size (starting from t/t0 ≈ 6000) than the k = 3 case, and then larger (starting from t/t0 ≈ 18,000). These are due to the fact that CL is delayed from k = 2 to k = 3, and further delayed from k = 3 to k = 4.

The larger k is, the later CL occurs, but the PSDs and growth curves are changed more profoundly due to more particles are in a deep metastable state in larger k cases. Figure 8b shows the PSDs at mean dCL = 0.5, which corresponds to \(\bar r \approx 8.0l_0,\;10.3l_0,\;13.2l_0\), for the k = 2, k = 3, and k = 4 cases, respectively. In all three cases the height of the original peak at \(r/\bar r \approx 1\) is lowered down, and the larger k is, the lower particle density is at \(r/\bar r \approx 1\)(more obvious two humps). It seems the profile of PSD in the bottom panel of Fig. 8b is too far from what is reported in IM’s experiments, which also indicates for Al3Sc, the coefficient k should not be far from 2.

Treating CL as a continuous process allows for the incorporation of the kinetic pathway and atomistic mechanism of CL, at least to a first-order approximation, in a mesoscale model in which the behavior of individual defects is not tracked. This provides an interface to link the mesoscale model for Ostwald ripening to atomistic models that can predict defect motions during CL. One can define the dCL parameter proportional to the eigenstrain linked to the transition to the final semi-coherent precipitate. Such a kinetic pathway can also be defined as one or multiple steps. For example, in the work of Shi3, the equivalent eigenstrain associated with interfacial misfit dislocations and structural ledges in the α/β titanium alloy is derived from experimental observation of the spacing/density of the defects. If dislocation level modeling shows the CL process is composed of two steps in which the dislocations at broad face and ledges on the terrace face are formed sequentially, one may define a piecewise function of q(ξ), with ξ in ranges [0,ξ1] and [ξ1,1], defined respectively (0 < ξ1 < 1), to distinguish the two steps of CL.

For the punching of prismatic dislocation loop mechanism, as has been stated in the introduction that it does not involve size dependence and a stress criterion will work. The crystal plasticity approach proposed by Oum19 can be included in our model, while at mesoscale a phenomenological constitutive law21 instead of the dislocation-density-based one for crystal plasticity may be more appropriate. CL by this mechanism is not size dependent and is not the focus of the current work.

It is interesting that our 2D model predicts the range of the mean particle size for CL in good agreement with IM’s experiment, which is analyzed as follows. First let us estimate the threshold particle size for CL of Al3Sc precipitates by the conventional thermodynamic criterion. For an isolated 3D sphere with dilatational eigenstrain of \(\varepsilon _{11}^ \ast = \varepsilon _{22}^ \ast = \varepsilon _{33}^ \ast = \varepsilon _0\), the elastic energy caused by the coherency strain is \(\frac{{8\pi r^3\mu }}{{45(1 - \nu )}}(13 + 5\nu )\varepsilon _0^2\)30. After CL, the increase of interfacial energy is \(4\pi r^2{\Delta} \gamma\). Thus, assuming the elastic energy is completely released after CL the critical radius for CL is \(\hat r_{3D} = \frac{{45(1 - \nu ){\Delta} \gamma }}{{(26 + 10\nu )\mu \varepsilon _0^2}}\). On the other hand, for an isolated 2D cylinder with eigenstrain \(\varepsilon _{11}^ \ast = \varepsilon _{22}^ \ast = \varepsilon _0\), the elastic strain energy is \(\frac{3}{2}\pi r^2\mu \varepsilon _0^2\) per unit length30, and the increase of interfacial energy 2πrΔγ, which gives the critical radius for CL to be \(\hat r_{2D} = \frac{{4{\Delta} \gamma }}{{3\mu \varepsilon _0^2}}\). For this Al3Sc system, ν = 1/3, the 2D model (\(\hat r_{2D} \approx 1.33{\Delta} \gamma /\mu \varepsilon _0^2\)) would only overestimate the critical particle radius by about ~30% as compared to the 3D model (\(\hat r_{3D} \approx 1.02{\Delta} \gamma /\mu \varepsilon _0^2\)).

Our model treats the CL as a continuous process and the criterion for the onset of CL is defined as that at least one bin in PSD has an average dCL larger than 0.05, and the criterion for completion of CL is that all bins in PSD have average dCL more than 0.1. It is difficult to accurately correspond these threshold numbers to IM’s experiment, which may lead to some uncertainty with respect to the simulated range of mean particle size during CL. Otherwise, since the particles are with relatively low volume fraction, mostly isolated without strong interaction with each other, the 2D simulation is able to capture the characteristics associated with the interaction between CL and the coarsening process. The formulation of the model is developed in three-dimensional but we use 2D simulations to save some computational cost for these long-time coarsening simulations. The absolute rate of coarsening, controlled by matrix diffusion, may also be affected by employing a 2D simulation, which is however not the focus of this study.

The current model focuses on the transition from coherent to semi-coherent precipitates but not fully incoherent interfaces. A fully incoherent interface cannot withstand any shear stress (under quasi-static load) and behaves similarly to a sliding grain boundary or a shear crack40. Such behavior has been modeled in a phase-field (diffuse interface) model by applying a J2 type viscosity to the interfacial region21. One might ask if it is possible to derive a fully variational approach with respect to the interfacial shear eigenstrain to capture the transition from a fully coherent to a fully incoherent interface. The problem is that the variation of the total free energy with respect to any dimensionless quantity (such as eigenstrain) will have the dimension of stress. Therefore, the thermodynamic driving force for the evolution of CL in such a variational approach would solely depend on the stress level. Such a process could be consistent with the prismatic dislocation punching mechanism as we have mentioned in the introduction. Under this mechanism, theoretically the occurrence of CL mainly depends on the magnitude of eigenstrain and it occurs at large coherency strain12,14. However, per Eshelby’s solution2, the stress level of a coherent precipitate is independent of its size. Therefore, such a direct variational approach will not be able to predict the size-dependence of the coherency state of a precipitate that is more general in many precipitation-hardened materials, which is the case in Appolaire’s work22. The ‘efficiency of coherency loss’ parameter defined in Appolaire’s model is position-dependent along with the particle interface. In contrast, in our model the counterpart dCL parameter is piecewise uniform. Consequently, the variational approach is reduced to a differential approach in our model and the integral of energy across the particle volume leads to the size dependence of CL.

In the current model when dCL equals one, even if the eigenstrain of particle becomes zero (i.e., \(^\circ \varepsilon _{ij}^L = - \varepsilon _{ij}^ \ast\) which is not necessarily true3), the precipitate-matrix interface could still withstand shear stress caused by an external load. Therefore, strictly speaking, in this model dCL = 1 combined with \(^\circ \varepsilon _{ij}^L = - \varepsilon _{ij}^ \ast\) is not yet corresponding to a fully incoherent interface. However, without external load, they can be equivalent, at least for the purpose of coarsening simulation.

From the viewpoint of kinetics, it is possible in principle to have \(E_{coh}^{el} - E^{el} < \gamma - \gamma _{coh}\) but −∂Eel/∂ξ > ∂γ/∂ξ at ξ = 0, which means complete transition to semi-coherent is not thermodynamically favorable but partial CL can occur. From atomistic viewpoint, this means introduction of the first one (or a few) dislocation loop(s) lowers down the system energy, but more dislocation loops increase it. The loss of coherency of γ” in IN 718 alloy has shown this possibility per the work of Ji et al.15. Nevertheless, the experimental data concerning CL of γ”8,41 is very scattered and the reported critical radius is the mean radius, not the radius for an individual particle that loses coherency. Refined experimental study is required on the CL of γ”, and the current model could be applied to bridge atomistic modeling and experimental measurements on the coarsening kinetics and evolution of PSD of γ” for a comprehensive study.

In this model, if the CL process is sluggish and the mechanism is due to scarcity of matrix dislocations, then the coefficient Kξ in the Eq. (13) should be small. If the ‘sluggishness’ is due to that the energy of the first interfacial dislocation is particularly high, the coefficient k in Eq. (4) should be set higher. The two situations can be distinguished, although in our application to the coarsening of Al3Sc Kξ is set large due to abundance of matrix dislocations and k = 2 is found to be reasonable. The Al3Sc precipitate is studied in detail because of the comprehensive study and statistical data reported by Iwamura and Miura, but our modeling approach is general for simulation of CL processes in other systems.

Methods

Methods

The phase-field governing equations are discretized with respect to space and time by using the finite difference and explicit forward Euler scheme. The elastic field in each time step is solved by using the phase-field-microelasticity approach by Khachaturyan28 using the Fast Fourier Transform technique.

Data availability

The data and codes supporting the findings of this study are available from the corresponding author on reasonable request.

References

Porter, D. A., Easterling, K. E. & Sherif, M. Phase Transformations in Metals And Alloys, (revised reprint) (CRC press, 2009).

Eshelby, J. D. The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. Math. Phys. Eng. Sci. 241, 376–396 (1957).

Shi, R., Ma, N. & Wang, Y. Predicting equilibrium shape of precipitates as function of coherency state. Acta Mater. 60, 4172–4184 (2012).

Ali, M. A., Görler, J. V. & Steinbach, I. Role of coherency loss on rafting behavior of ni-based superalloys. Comput. Mater. Sci. 171, 109279 (2020).

Tang, S. et al. Precipitation strengthening in an ultralight magnesium alloy. Nat. Commun. 10, 1–8 (2019).

Hu, Y. et al. Study of θ’precipitation behavior in al-cu-cd alloys by phase-field modeling. Mater. Sci. Eng. A 746, 105–114 (2019).

Iwamura, S. & Miura, Y. Loss in coherency and coarsening behavior of al3sc precipitates. Acta Mater. 52, 591–600 (2004).

Devaux, A. et al. Gamma double prime precipitation kinetic in alloy 718. Mater. Sci. Eng. A 486, 117–122 (2008).

Karnesky, R. A., Meng, L. & Dunand, D. C. Strengthening mechanisms in aluminum containing coherent al3sc precipitates and incoherent al2o3 dispersoids. Acta Mater. 55, 1299–1308 (2007).

Schobel, M., Pongratz, P. & Degischer, H. P. Coherency loss of al-3(sc,zr) precipitates by deformation of an al-zn-mg alloy. Acta Mater. 60, 4247–4254 (2012).

Weatherly, G. C. & Nicholson, R. B. An electron microscope investigation of interfacial structure of semi-coherent precipitates. Philos. Mag. 17, 801 (1968). &.

Weatherly, G. C. Loss of coherency of growing particles by prismatic punching of dislocation loops. Philos. Mag. 17, 791 (1968). &.

Geslin, P. A., Appolaire, B. & Finel, A. Investigation of coherency loss by prismatic punching with a nonlinear elastic model. Acta Mater. 71, 80–88 (2014).

Ashby, M. F. & Johnson, L. On generation of dislocations at misfitting particles in a ductile matrix. Philos. Mag. 20, 1009 (1969).

Ji, Y. Z. et al. Predicting coherency loss of precipitates in in718 superalloy. Metal. Mater. Trans. A 47A, 3235–3247 (2016).

Watanabe, D. Z., Watanabe, C. & Monzen, R. Effect of coherency on coarsening of second-phase precipitates in cu-base alloys. J. Mater. Sci. 43, 3946–3953 (2008).

Rajagopalan, M. et al. Microstructural evolution in a nanocrystalline cu-ta alloy: A combined in-situ tem and atomistic study. Mater. Des. 113, 178–185 (2017).

Quek, S. S., Xiang, Y. & Srolovitz, D. J. Loss of interface coherency around a misfitting spherical inclusion. Acta Mater. 59, 5398–5410 (2011).

Oum, G., Thuinet, L. & Legris, A. A 3d crystal plasticity model for coherency loss during precipitation. Model. Simul. Mater. Sci. Eng. 26, 065008 (2018).

Lemaitre, J. & Chaboche, J. L. Mechanics of Solid Materials (Cambridge University Press, 1990).

Cheng, T.-L., Wen, Y.-H. & Hawk, J. A. Diffuse interface approach to modeling crystal plasticity with accommodation of grain boundary sliding. Int. J. Plast. 114, 106–125 (2019).

Appolaire, B., Aeby-Gautier, E., Teixeira, J. D. C., Dehmas, M. & Denis, S. Non-coherent interfaces in diffuse interface models. Philos. Mag. 90, 461–483 (2010).

Moelans, N., Blanpain, B. & Wollants, P. Quantitative analysis of grain boundary properties in a generalized phase field model for grain growth in anisotropic systems. Phys. Rev. B 78, 024113 (2008).

Wang, Y. Z. & Li, J. Phase field modeling of defects and deformation. Acta Mater. 58, 1212–1235 (2010).

Read, W. T. & Shockley, W. Dislocation models of crystal grain boundaries. Phys. Rev. 78, 275–289 (1950).

Brown, L. & Woolhouse, G. The loss of coherency of precipitates and the generation of dislocations. Philos. Mag. 21, 329–345 (1970).

Moelans, N. A quantitative and thermodynamically consistent phase-field interpolation function for multi-phase systems. Acta Mater. 59, 1077–1086 (2011).

Khachaturyan, A. G. Theory of Structural Transformations in Solids (Wiley, 1983).

Kim, S. G., Kim, W. T. & Suzuki, T. Phase-field model for binary alloys. Phys. Rev. E 60, 7186–7197 (1999).

Mura, T. Micromechanics of Defects in Solids, 2nd, revised edn. (Martinus Nijhoff, 1987).

Torbert, S. Applied Computer Science, 2nd edn. (Springer, 2016).

Wang, Y. & Khachaturyan, A. Microstructural evolution during the precipitation of ordered intermetallics in multiparticle coherent systems. Philos. Mag. A 72, 1161–1171 (1995).

Wang, Y., Banerjee, D., Su, C. C. & Khachaturyan, A. G. Field kinetic model and computer simulation of precipitation of ll(2) ordered intermetallics from fcc solid solution. Acta Mater. 46, 2983–3001 (1998).

Wagner, C. Z. Theory of precipitate change by redissolution (owtwald ripening). Z. Elektrochem. 65, 581–591 (1961).

Lifshitz, I. M. & Slyozov, V. V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 19, 35–50 (1961).

Baldan, A. Review progress in ostwald ripening theories and their applications to nickel-base superalloys - part i: Ostwald ripening theories. J. Mater. Sci. 37, 2171–2202 (2002).

Zhou, N. et al. Computer simulation of phase transformation and plastic deformation in in718 superalloy: microstructural evolution during precipitation. Acta Mater. 65, 270–286 (2014).

Vaithyanathan, V. & Chen, L. Q. Coarsening of ordered intermetallic precipitates with coherency stress. Acta Mater. 50, 4061–4073 (2002).

Cheng, T.-L., Wen, Y.-H. & Hawk, J. A. Diffuse-interface modeling and multi-scale-relay simulation of metal oxidation kinetics - with revisit on wagner’s theory. J. Phys. Chem. C 118, 1269–1284 (2014).

Mori, T., Okabe, M. & Mura, T. Diffusional relaxation around a 2nd phase particle. Acta Metall. 28, 319–325 (1980).

Slama, C., Servant, C. & Cizeron, G. Aging of the inconel 718 alloy between 500 and 750 c. J. Mater. Res. 12, 2298–2316 (1997).

Acknowledgements

This technical effort was performed in support of the Cross-Cutting Technologies Program of the National Energy Technology Laboratory (NETL) under the RSS contract 89243318CFE000003. The research was executed through NETL Research & Innovation Center’s project coordinated by David E. Alman and was specifically under the advanced alloy development FWP led by Drs. David Alman and Jeffrey A. Hawk and in part through the XMAT project. This work partially used the Extreme Science and Engineering Discovery Environment (XSEDE), which is supported by National Science Foundation grant number ACI-1548562. Disclaimer: This work was funded by the Department of Energy, National Energy Technology Laboratory, an agency of the United States Government, through a support contract with Leidos Research Support Team (LRST). Neither the United States Government nor any agency thereof, nor any of their employees, nor LRST, nor any of their employees, makes any warranty, expressed or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Author information

Authors and Affiliations

Contributions

T.C. developed the model, performed the simulations, and wrote the manuscript. Y.W. contributed to analyzing the results and revising the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cheng, TL., Wen, YH. Phase-field model of precipitation processes with coherency loss. npj Comput Mater 7, 36 (2021). https://doi.org/10.1038/s41524-021-00503-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41524-021-00503-x

- Springer Nature Limited