Abstract

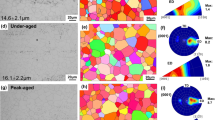

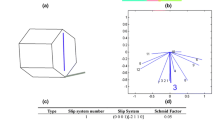

To understand the reversed tension–compression asymmetry (TCA), i.e. compressive yield strength > tensile yield strength, in an extruded Mg-10Y sheet, quasi-in-situ grain-scale slip activity and plastic heterogeneity were studied statistically using slip trace analysis and EBSD. No twins were found in present study, while notable TCA slip behavior was observed and analyzed in detail. The overall slip activity, in terms of the fraction of the grains exhibiting slip traces, for compression (79.5 pct) was higher than that of tension (64.6 pct). Besides, basal < a > and prismatic < a > slips always exhibited higher activity during tension than compression, while the opposite was true for pyramidal slips. Further analysis of the critical resolved shear stress (CRSS) ratio, based on 1185 sets of observed slip traces, revealed that CRSSpyr II/CRSSbas and CRSSpyr I/CRSSbas for tension was ~ 3 times larger than that for compression, while CRSSpri/CRSSbas was symmetric. Statistical investigation on the angle between active pyramidal slip plane normal and loading direction indicated that pyramidal slip was more active when the slip plane was under tension compared to compression, which was consistent with the asymmetric CRSS ratios. More inhomogeneous deformation, in terms of higher intragranular misorientation angle (IGM) and geometrically necessary dislocation (GND) density, was found during compression.

Similar content being viewed by others

References

J. Song, J. She, D. Chen, and F. Pan: J. Magnes. Alloy, 2020, vol. 8, pp. 1–41.

W.J. Joost and P.E. Krajewski: Scr. Mater., 2017, vol. 128, pp. 107–12.

W. Yang, G.F. Quan, B. Ji, Y.F. Wan, H. Zhou, J. Zheng, and D.D. Yin: J. Magnes. Alloy, 2022, vol. 10, pp. 195–208.

T. Wang, M. Zha, C. Du, H. Jia, C. Wang, K. Guan, Y. Gao, and H. Wang: Mater. Res. Lett., 2023, vol. 11, pp. 187–95.

Z. Jiang, D. Yin, Y. Wan, R. Ni, H. Zhou, J. Zheng, and Q. Wang: T. Nonferr. Metal. Soc., 2023, vol. 33, pp. 79–94.

Z. Zeng, N. Stanford, C.H.J. Davies, J. Nie, and N. Birbilis: Int. Mater. Rev., 2018, vol. 64, pp. 27–62.

U.M. Chaudry, K. Hamad, and J. Kim: J. Alloy Compd., 2019, vol. 792, pp. 652–64.

Z. Yang, A. Ma, B. Xu, J. Jiang, and J. Sun: J. Alloy Compd., 2021, vol. 868, p. 159238.

J. Robson: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 5226–35.

W. Ren, R. Xin, J. Xu, B. Song, L. Zhang, and Q. Liu: J. Alloy Compd., 2019, vol. 792, pp. 610–16.

S.H. Park, J.H. Lee, B.G. Moon, and B.S. You: J. Alloy Compd., 2014, vol. 617, pp. 277–80.

M.R. Barnett, N. Stanford, P. Cizek, A. Beer, Z. Xuebin, and Z. Keshavarz: JOM-US, 2009, vol. 61, pp. 19–24.

L. Xiao, G. Yang, H. Qin, J. Ma, and W. Jie: Mater. Sci. Eng. A, 2021, vol. 801, p. 140439.

J.W. Lu, D.D. Yin, L.B. Ren, and G.F. Quan: J. Mater. Sci., 2016, vol. 51, pp. 10464–77.

C.M. Cepeda-Jiménez, C. Prado-Martínez, and M.T. Pérez-Prado: Acta Mater., 2018, vol. 145, pp. 264–77.

X. Wang, L. Jiang, D. Zhang, I.J. Beyerlein, S. Mahajan, T.J. Rupert, E.J. Lavernia, and J.M. Schoenung: Acta Mater., 2018, vol. 146, pp. 12–24.

P. Hidalgo-Manrique, J.D. Robson, and M.T. Pérez-Prado: Acta Mater., 2017, vol. 124, pp. 456–67.

E. Vasilev, N.C. Ferreri, R. Decker, I.J. Beyerlein, and M. Knezevic: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 3858–68.

A.E. Davis, J.D. Robson, and M. Turski: Mater. Sci. Eng. A, 2019, vol. 744, pp. 525–37.

S.A. Habib, A.S. Khan, T. Gnäupel-Herold, J.T. Lloyd, and S.E. Schoenfeld: Int. J. Plast., 2017, vol. 95, pp. 163–90.

J. Bohlen, S. Yi, D. Letzig, and K.U. Kainer: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7092–98.

Y. Chai, D. Yin, S. Hua, G. Huang, H. Zhou, J. Zheng, and Q. Wang: T. Nonferr. Metal. Soc., 2022, vol. 32, pp. 3534–49.

D.D. Yin, C.J. Boehlert, L.J. Long, G.H. Huang, H. Zhou, J. Zheng, and Q.D. Wang: Int. J. Plast., 2021, vol. 136, p. 102878.

L.J. Long, G.H. Huang, D.D. Yin, B. Ji, H. Zhou, and Q.D. Wang: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 2738–51.

K. Luo, L. Zhang, G.H. Wu, W.C. Liu, and W.J. Ding: J. Magnes. Alloy., 2019, vol. 7, pp. 345–54.

G.H. Huang, D.D. Yin, J.W. Lu, H. Zhou, Y. Zeng, G.F. Quan, and Q.D. Wang: Mater. Sci. Eng. A, 2018, vol. 720, pp. 24–35.

A. Imandoust, C.D. Barrett, T. Al-Samman, K.A. Inal, and H. El Kadiri: J. Mater. Sci., 2017, vol. 52, pp. 1–29.

S.R. Agnew, M.H. Yoo, and C.N. Tomé: Acta Mater., 2001, vol. 49, pp. 4277–89.

S. Hua, Z.W. Jiang, Y.F. Wan, G.H. Huang, H. Zhou, J. Zheng, Q.D. Wang, and D.D. Yin: Mater. Sci. Eng. A, 2021, vol. 825, p. 141927.

K. Wei, L.R. Xiao, B. Gao, L. Li, Y. Liu, Z.G. Ding, W. Liu, H. Zhou, and Y.H. Zhao: J. Magnes Alloy, 2020, vol. 8, pp. 1221–27.

C. Zhao, Z. Li, J. Shi, X. Chen, T. Tu, Z. Luo, R. Cheng, A. Atrens, and F. Pan: J. Magnes. Alloy, 2019, vol. 7, pp. 672–80.

L. Gao, R.S. Chen, and E.H. Han: J. Alloy Compd., 2009, vol. 481, pp. 379–84.

R. Ahmad, Z.X. Wu, and W.A. Curtin: Acta Mater., 2020, vol. 183, pp. 228–41.

Z.X. Wu, R. Ahmad, B.L. Yin, S. Sandlöbes, and W.A. Curtin: Science, 2018, vol. 359, pp. 447–52.

R. Ni, Z.W. Jiang, D.D. Yin, W. Yang, H. Zhou, J. Zheng, and Q.D. Wang: Metall. Mater. Trans. A, 2022, vol. 53A, pp. 535–55.

S.R. Kalidindi, A. Abusafieh, and E. El-Danaf: Exp. Mech., 1997, vol. 37, pp. 210–15.

S.R. Agnew and Ö. Duygulu: Int. J. Plast., 2005, vol. 21, pp. 1161–93.

R. Hielscher, C.B. Silbermann, E. Schmidl, and J. Ihlemann: J. Appl. Crystallogr., 2019, vol. 52, pp. 984–96.

F. Bachmann, R. Hielscher, and H. Schaeben: Solid State Phenom., 2010, vol. 160, pp. 63–68.

B.S. El-Dasher, B.L. Adams, and A.D. Rollett: Scr. Mater., 2003, vol. 48, pp. 141–45.

R. Ni, S.J. Ma, L.J. Long, J. Zheng, H. Zhou, Q.D. Wang, and D.D. Yin: Mater. Sci. Eng. A, 2021, vol. 804, p. 140738.

W.X. Wu, L. Jin, J. Dong, and W.J. Ding: Mater. Sci. Eng. A, 2014, vol. 593, pp. 48–54.

L. Wang, Z. Huang, H. Wang, A. Maldar, S. Yi, J. Park, P. Kenesei, E. Lilleodden, and X. Zeng: Acta Mater., 2018, vol. 155, pp. 138–52.

A. Githens, S. Ganesan, Z. Chen, J. Allison, V. Sundararaghavan, and S. Daly: Acta Mater., 2020, vol. 186, pp. 77–94.

M. Kamaya: Mater. Charact., 2012, vol. 66, pp. 56–67.

G. Martin, C.W. Sinclair, and J. Schmitt: Scr. Mater., 2013, vol. 68, pp. 695–98.

A. Harte, M. Atkinson, M. Preuss, and J. Quinta Da Fonseca: Acta Mater., 2020, vol. 195, pp. 555–70.

Y. Zeng, X. Xiong, X. Qian, D. Xia, X. Shang, B. Jiang, and D. Yin: Met. Mater. Int., 2023, vol. 29, pp. 1885–95.

X. Hou, Z. Cao, L. Wang, S. Xu, S. Kamado, and L. Wang: Mater. Sci. Eng. A, 2011, vol. 528, pp. 7805–10.

S. Lyu, R. Zheng, W. Xiao, Y. Huang, S. Gavras, N. Hort, G. Li, and C. Ma: Mater. Sci. Eng. A, 2019, vol. 760, pp. 426–30.

M. Lentz, M. Klaus, I.J. Beyerlein, M. Zecevic, W. Reimers, and M. Knezevic: Acta Mater., 2015, vol. 86, pp. 254–68.

H. Li, D.E. Mason, T.R. Bieler, C.J. Boehlert, and M.A. Crimp: Acta Mater., 2013, vol. 61, pp. 7555–67.

D.D. Yin, Q.D. Wang, C.J. Boehlert, Z. Chen, H.M. Li, R.K. Mishra, and A. Chakkedath: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 6438–52.

C. Albrecht, A. Kumar, S. Xu, A. Hunter, and I.J. Beyerlein: Phys. Rev. Mater., 2021, vol. 5, p. 43602.

Z. Wu and W.A. Curtin: Proc. Natl. Acad. Sci. U.S.A., 2016, vol. 113, pp. 11137–42.

I.P. Jones and W.B. Hutchinson: Acta Metall., 1981, vol. 29, pp. 951–68.

T. Nogaret, W.A. Curtin, J.A. Yasi, L.G. Hector, and D.R. Trinkle: Acta Mater., 2010, vol. 58, pp. 4332–43.

H. Tonda and S. Ando: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 831–36.

C. Dai, P. Saidi, L.K. Béland, Z. Yao, and M.R. Daymond: Comp. Mater. Sci., 2019, vol. 170, p. 109183.

P. Hidalgo-Manrique, V. Herrera-Solaz, J. Segurado, J. Llorca, F. Gálvez, O.A. Ruano, S.B. Yi, and M.T. Pérez-Prado: Acta Mater., 2015, vol. 92, pp. 265–77.

S.S. Jiang, Y. Jia, X.K. Wang, and J.F. Jiang: Mater Charact, 2020, vol. 165, 110384.

F. Di Gioacchino and J. Quinta Da Fonseca: Int. J. Plast., 2015, vol. 74, pp. 92–109.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Nos. 52171125 and 52071178). We would like to thank the Analytical and Testing Center of Southwest Jiaotong University for assistance with SEM and EBSD characterization. We would like to thank Ms. Lin Ma for improving the English writing.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y.B., Ni, R., Zheng, X.H. et al. Understanding the Reversed Tension–Compression Asymmetry of an Extruded Mg-10Y Sheet from the Perspective of Slip Activity and Plastic Heterogeneity. Metall Mater Trans A 55, 1673–1689 (2024). https://doi.org/10.1007/s11661-024-07360-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-024-07360-5