Abstract

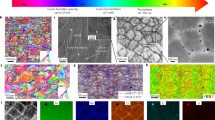

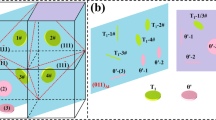

The periodic structural characteristics of the grains in the overlapping region of the WAAM deposited additive bead translate into spatially dependent local anisotropic mechanical properties. At the fusion boundary, the epitaxial growth causes the formation of columnar grains due to the high temperature gradient (G)/growth rate (R) ratio. As the solidification progresses to the centre of the overlapping region, the cooling rate decreases/or has a low value of G/R ratio. The grain structure changes to irregular lath-type morphology. After friction stir processing (FSP), the solidification microstructures are refined and have equiaxed grain morphology. The presence of \(\mathrm{E}, \, \overline{\mathrm{E} } , \, \mathrm{ J}, \, \overline{\mathrm{J} }, \, \mathrm{ and \, F}\) shear components have been observed along with the cube and \(\upgamma\)—fiber texture components. The presence of the two major components {111} < 112 > and {111} < 110 > of the \(\upgamma\)—fiber confirms the improvement in the percent elongation/formability of the overlapping region. The geometric necessary dislocations (GNDs) appearing around ferrite/cementite interface and near to the grain boundaries (GBs), the dislocation pinning by the sub-micron/nanoscale cementite particles via Orowan looping, and dynamic recovery associated networks/or subgrain boundaries formation are the main reasons for the three stages of work hardening rate \(\left(\theta =\frac{{\text{d}}\sigma }{{\text{d}}\varepsilon } \right)\).

Similar content being viewed by others

References

Z. Pan, D. Ding, B. Wu, D. Cuiuri, H. Li, and J. Norrish: Transactions on intelligent welding manufacturing, Springer, Singapore, 2018, pp. 3–24.

M. Chaturvedi, E. Scutelnicu, C.C. Rusu, L.R. Mistodie, D. Mihailescu, and S.A. Vendan: Metals (Basel), 2021, https://doi.org/10.3390/met11060939.

S. Singh, S.K. Sharma, and D.W. Rathod: Mater. Today Proc., 2020, vol. 47, pp. 6564–575.

N. Chernovol, B. Lauwers, and P. van Rymenant: Procedia CIRP, 2020, vol. 95, pp. 60–5.

Y. Wang, X. Xu, Z. Zhao, W. Deng, J. Han, L. Bai, X. Liang, and J. Yao: J. Manuf. Process., 2021, vol. 71, pp. 306–16.

B. Wu, Z. Pan, D. Ding, D. Cuiuri, H. Li, J. Xu, and J. Norrish: J. Manuf. Process., 2018, vol. 35, pp. 127–39.

R. Stegemann, S. Cabeza, V. Lyamkin, G. Bruno, A. Pittner, R. Wimpory, M. Boin, and M. Kreutzbruck: J. Magn. Magn. Mater., 2017, vol. 426, pp. 580–87.

D. Jafari, T.H.J. Vaneker, and I. Gibson: Mater. Des., 2021, vol. 202, p. 109471.

C. Shen, M. Reid, K.D. Liss, Z. Pan, Y. Ma, D. Cuiuri, S. van Duin, and H. Li: Addit. Manuf., 2019, vol. 29, p. 100774.

Z. Lin, K. Song, and X. Yu: J. Manuf. Process., 2021, vol. 70, pp. 24–45.

Y. Zeng, X. Wang, X. Qin, L. Hua, and M. Xu: Ultrasonics, 2021, vol. 110, p. 106273.

X. He, T. Wang, K. Wu, and H. Liu: Meas. J. Int. Meas. Confed., 2021, vol. 173, p. 108633.

M.A. Somashekara, M. Naveenkumar, A. Kumar, C. Viswanath, and S. Simhambhatla: Int. J. Adv. Manuf. Technol., 2017, vol. 90, pp. 2009–25.

Y. Li, Q. Han, G. Zhang, and I. Horváth: Int. J. Adv. Manuf. Technol., 2018, vol. 96, pp. 3331–344.

L. Palmeira Belotti, J.A.W. van Dommelen, M.G.D. Geers, C. Goulas, W. Ya, and J.P.M. Hoefnagels: J. Mater. Process. Technol., 2022, https://doi.org/10.1016/j.jmatprotec.2021.117373.

C. Wang, T.G. Liu, P. Zhu, Y.H. Lu, and T. Shoji: Mater. Sci. Eng. A, 2020, https://doi.org/10.1016/j.msea.2020.140006.

C.E. Seow, H.E. Coules, G. Wu, R.H.U. Khan, X. Xu, and S. Williams: Mater. Des., 2019, vol. 183, p. 108157.

T.A. Rodrigues, V. Duarte, R.M. Miranda, T.G. Santos, and J.P. Oliveira: Materials (Basel), 2019, https://doi.org/10.3390/ma12071121.

B. Zhang, W.J. Meng, S. Shao, N. Phan, and N. Shamsaei: Mater. Des. Process. Commun., 2019, https://doi.org/10.1002/mdp2.29.

S. Paddea, J.A. Francis, A.M. Paradowska, P.J. Bouchard, and I.A. Shibli: Mater. Sci. Eng. A, 2012, vol. 534, pp. 663–72.

S. Ghorbani, R. Ghasemi, R. Ebrahimi-Kahrizsangi, and A. Hojjati-Najafabadi: Mater. Sci. Eng. A, 2017, vol. 688, pp. 470–79.

X. Li, J. Chen, P. Hua, K. Chen, W. Kong, H. Chu, Y. Wu, and W. Zhou: Fusion Eng. Des., 2018, vol. 128, pp. 175–81.

A. Güral, B. Bostan, and A.T. Özdemir: Mater. Des., 2007, vol. 28, pp. 897–903.

A.J.M. Gomes, J.C.F. Jorge, L.F.G. de Souza, and I. de Souza Bott: Mater. Sci. Forum, 2013, vol. 758, pp. 21–32.

J.C.F. Jorge, J.L.D. Monteiro, A.J.D.C. Gomes, I.D.S. Bott, L.F.G. De Souza, M.C. Mendes, and L.S. Araújo: J. Mater. Res. Technol., 2019, vol. 8, pp. 561–71.

A.G. Olabi and M.S.J. Hashmi: J. Mater. Process. Technol., 1995, vol. 55, pp. 117–22.

S. Sirohi, A. Gupta, C. Pandey, R.S. Vidyarthy, K. Guguloth, and H. Natu: Opt. Laser Technol., 2022, https://doi.org/10.1016/j.optlastec.2021.107610.

A.N. Vasileiou, M.C. Smith, J.A. Francis, D.W. Rathod, J. Balakrishnan, and N.M. Irvine: Int. J. Press. Vessel. Pip., 2019, vol. 172, pp. 379–90.

S. Kožuh, M. Gojic, and L. Kosec: Kov. Mater., 2009, vol. 47, pp. 253–62.

A. Riemer, S. Leuders, M. Thöne, H.A. Richard, T. Tröster, and T. Niendorf: Eng. Fract. Mech., 2014, vol. 120, pp. 15–25.

N. Ullah Khan, S.K. Rajput, V. Gupta, V. Verma, and T. Soota: Science direct to study mechanical properties and microstructures of MIG welded high strength low alloy steel. Mater. Today, 2019, vol. 18, pp. 2550–555.

A.A. Anshari and M. Imam: Innovation in materials science and engineering, Springer, Singapore, 2019.

M. Imam, R. Ueji, and H. Fujii: J. Mater. Process. Technol., 2016, vol. 230, pp. 62–71.

P. Xue, Z.Y. Ma, Y. Komizo, and H. Fujii: Mater. Lett., 2016, vol. 162, pp. 161–64.

K. Ito, T. Okuda, R. Ueji, H. Fujii, and C. Shiga: Mater. Des., 2014, vol. 61, pp. 275–80.

H. Yamamoto, Y. Danno, K. Ito, Y. Mikami, and H. Fujii: Mater. Des., 2018, vol. 160, pp. 1019–28.

S.Q. Moinuddin and A. Sharma: Mater. Des., 2015, vol. 67, pp. 293–302.

M. Imam, S.N.S.H. Chittajallu, H. Gururani, H. Yamamoto, K. Ito, P.K. Parchuri, R. Mishra, A. Sharma, A. Richhariya, and V. Chinthapenta: Mater. Today Proc., 2022, vol. 56, pp. 690–705.

M.A. Ali Anshari, M. Imam, M.Z. Khan Yusufzai, V. Chinthapenta, and R. Mishra: Mater. Sci. Eng. A, 2021, vol. 805, p. 140582.

X. Yuan, H. Qiu, F. Zeng, W. Luo, H. Li, X. Wang, N. Guan, and F. Cui: J. Manuf. Process., 2022, vol. 77, pp. 63–74.

C. Vundru, R. Singh, W. Yan, and S. Karagadde: J. Manuf. Sci. Eng. Trans. ASME, 2020, vol. 142, pp. 1–3.

F. Montevecchi, G. Venturini, A. Scippa, and G. Campatelli: Procedia CIRP, 2016, vol. 55, pp. 109–14.

C. Cambon, S. Rouquette, I. Bendaoud, C. Bordreuil, R. Wimpory, and F. Soulie: Weld. World, 2020, vol. 64, pp. 1427–435.

F. Montevecchi, G. Venturini, N. Grossi, A. Scippa, and G. Campatelli: Addit. Manuf., 2018, vol. 21, pp. 479–86.

M.O. Couto, A.G. Rodrigues, F. Coutinho, R.R. Costa, A.C. Leite, F. Lizarralde, and J.C.P. Filho: J. Control. Autom. Electr. Syst., 2022, https://doi.org/10.1007/s40313-021-00880-0.

J. Ding, P. Colegrove, J. Mehnen, S. Ganguly, P.M.S. Almeida, F. Wang, and S. Williams: Comput. Mater. Sci., 2011, vol. 50, pp. 3315–322.

E.A. Bonifaz: Lect. Notes Comput. Sci. (including Subser. Lect. Notes Artif. Intell. Lect. Notes Bioinformatics), vol. 11539, LNCS, 2019, pp. 647–59.

K.P. Prajadhiama, Y.H. Manurung, Z. Minggu, F.H. Pengadau, M. Graf, A. Haelsig, T.-E. Adams, and H.L. Choo: MATEC Web Conf., 2019, vol. 269, p. 05003.

V. Javaheri, N. Khodaie, A. Kaijalainen, and D. Porter: Mater. Charact., 2018, vol. 142, pp. 295–308.

Z. Ling, J. Fang, Y. Zhou, and Z. Yuan: Energy Procedia, 2012, vol. 16, pp. 444–50.

C. Wang, X. Wang, J. Kang, G. Yuan, and G. Wang: Materials (Basel), 2019, https://doi.org/10.3390/ma12071070.

G. Liang, Q. Tan, Y. Liu, T. Wu, X. Yang, Z. Tian, A. Atrens, and M.X. Zhang: J. Mater. Sci., 2021, vol. 56, pp. 3995–4005.

M. Mahmoudiniya, A.H. Kokabi, M. Goodarzi, and L.A.I. Kestens: Mater. Sci. Eng. A, 2020, vol. 769, p. 138490.

X. Wu, H. Lin, W. Luo, and H. Jiang: J. Mater. Res. Technol., 2021, vol. 15, pp. 6067–078.

S. Kumar, S.K. Nath, and V. Kumar: Mater. Des., 2016, vol. 90, pp. 177–84.

Y. Qi, J. Li, C. Shi, and Q. Zhu: High Temp. Mater. Process., 2019, vol. 38, pp. 183–91.

B. Shassere, A. Nycz, M.W. Noakes, C. Masuo, and N. Sridharan: Appl. Sci., 2019, https://doi.org/10.3390/app9040787.

M. Singh, R. Kumar, D.K. Shukla, and K.S. Arora: Mater. Res. Express, 2018, https://doi.org/10.1088/2053-1591/aaf156.

J. Xie, C. Cai, Y. Liang, Z. Liu, and Y. Ma: Opt. Laser Technol., 2022, vol. 148, p. 107729.

H.R.K. Zarchi, A. Khajesarvi, S.S.G. Banadkouki, and M.C. Somani: Rev. Adv. Mater. Sci., 2019, vol. 58, pp. 206–17.

G.J. Davies and J.G. Garland: Int. Metall. Rev., 1975, vol. 20, pp. 83–108.

T.W. Nelson, J.C. Lippold, and M.J. Mills: Weld. J. (Miami, Fla), 1999, vol. 78, p. 329.

R. Song, D. Ponge, and D. Raabe: Scr. Mater., 2005, vol. 52, pp. 1075–080.

N. Afrin, D.L. Chen, X. Cao, and M. Jahazi: Scr. Mater., 2007, vol. 57, pp. 1004–007.

D. Embury and O. Bouaziz: Steel-based composites: driving forces and classifications. Annu. Rev. Mater. Res., 2010, vol. 40, pp. 213–41.

S.H. He, B.B. He, K.Y. Zhu, and M.X. Huang: Acta Mater., 2017, vol. 135, pp. 382–89.

J.M. Choung and S.R. Cho: J. Mech. Sci. Technol., 2008, vol. 22, pp. 1039–051.

H. Beladi, I.B. Timokhina, X.Y. Xiong, and P.D. Hodgson: Acta Mater., 2013, vol. 61, pp. 7240–250.

S. Ragu Nathan, V. Balasubramanian, S. Malarvizhi, and A.G. Rao: Def. Technol., 2015, vol. 11, pp. 308–17.

X. Yang, X. Di, X. Liu, D. Wang, and C. Li: Mater. Charact., 2019, vol. 155, p. 109818.

A. Heidarzadeh, S. Mironov, R. Kaibyshev, G. Çam, A. Simar, A. Gerlich, F. Khodabakhshi, A. Mostafaei, D.P. Field, J.D. Robson, A. Deschamps, and P.J. Withers: Prog. Mater. Sci., 2020, vol. 117, p. 100752.

K. Kadau, T.C. Germann, P.S. Lomdahl, B.L. Holian, D. Kadau, P. Entel, M. Kreth, F. Westerhoff, and D.E. Wolf: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2004, vol. 35, pp. 2719–723.

B.S. Murty, M.K. Datta, and S.K. Pabi: Sadhana - Acad. Proc Eng. Sci., 2003, vol. 28, pp. 23–45.

L.M. Clarebrough, M.E. Hargreaves, and M.H. Loretto: Acta Metall., 1958, vol. 6, pp. 725–35.

X. Li and X. Jiang: Eng. Fract. Mech., 2019, vol. 212, pp. 258–68.

S. Kou: Welding metallurgy, Wiley, Hoboken, 2003.

M.C. Flemings: Metall. Trans., 1974, vol. 5, pp. 2121–134.

H. Ebrahimzadeh and S.A.A.A. Mousavi: Mater. Des., 2012, vol. 38, pp. 115–23.

N.A. Berjeza, S.P. Velikevitch, V.I. Mazhukin, I. Smurov, and G. Flamant: Appl. Surf. Sci., 1995, vol. 86, pp. 303–09.

Y. He, M. Zhong, N. Jones, J. Beuth, and B. Webler: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2021, vol. 52, pp. 4206–221.

X. Lingda, Z. Guoli, M. Gaoyang, W. Chunming, and J. Ping: J. Alloys Compd., 2021, vol. 858, p. 157669.

R.E. Smallman and A.H.W. Ngan: Mod. Phys. Metall., 2014, https://doi.org/10.1016/B978-0-08-098204-5.00012-2.

C. Du, J.P.M. Hoefnagels, S. Kölling, M.G.D. Geers, J. Sietsma, R. Petrov, V. Bliznuk, P.M. Koenraad, D. Schryvers, and B. Amin-Ahmadi: Mater. Charact., 2018, vol. 139, pp. 411–20.

Z. Du, X. Sun, F.L. Ng, Y. Chew, C. Tan, and G. Bi: Mater. Des., 2021, vol. 210, p. 110029.

C. Cayron, F. Barcelo, and Y. de Carlan: Acta Mater., 2010, vol. 58, pp. 1395–402.

M. Strangwood: Phase Transform. Steels, 2012, vol. 1, pp. 187–224.

K. Koumatos, and A. Muehlemann: Acta Crystallogr. A, 2017, Vol. 73, pp. 1–12.

T. Furuhara, H. Kawata, S. Morito, G. Miyamoto, and T. Maki: Meta. Mater. Trans. A., 2008, vol. 39A, pp. 1003–013.

S.M. Chowdhury, D.L. Chen, S.D. Bhole, E. Powidajko, D.C. Weckman, and Y. Zhou: Metal. Mater. Trans. A., 2011, vol. 42, pp. 1974–989.

T.R. McNelley, S. Swaminathan, and J.Q. Su: Scr. Mater., 2008, vol. 58, pp. 349–54.

R.W. Fonda and K.E. Knipling: Sci. Technol. Weld. Join., 2011, vol. 16, pp. 288–94.

S. Emami, T. Saeid, and R. Azari Khosroshahi: J. Ultrafine Grained Nanostruct. Mater., 2018, vol. 51, pp. 20–5.

A.I. Gordienko, L.S. Derevyagina, A.G. Malikov, A.M. Orishich, N.S. Surikova, and M.N. Volochaev: Mater. Sci. Eng. A, 2020, vol. 797, p. 140075.

T. Nguyen, D.J. Luscher, and J.W. Wilkerson: J. Mech. Phys. Solids, 2017, vol. 108, pp. 1–29.

H.K.D.H. Bhadeshia and S.R. Honeycombe: Steels, Edward Arnold, London, 2006, pp. 129–54.

Y.T. Zhou, X.H. Shao, S.J. Zheng, and X.L. Ma: J. Mater. Sci. Technol., 2022, vol. 101, pp. 28–36.

C. Gracia-mateo: Metals, 2018, Vol. 8, p. 166.

H. Guo, Q. Li, Y. Fan, and X. Feng: J. Mater. Res. Technol., 2020, vol. 9, pp. 9206–218.

G.K. Bansal, S. Tripathy, A.K. Chandan, V. Rajinikanth, C. Ghosh, V.C. Srivastava, and S. Ghosh Chowdhury: Mater. Sci. Eng. A, 2021, vol. 826, p. 141937.

A. Heidarzadeh, K. Kazemi-Choobi, H. Hanifian, and P. Asadi: Microstructural evolution, Woodhead Publishing, Cambridge, 2014.

T. Song and B. Charles De Cooman: Metal. Mater. Trans. A., 2013, vol. 44A, pp. 1686–705.

Acknowledgments

The authors sincerely acknowledge the funding support under the Early Career Research (ECR) Grant by the Department of Science and Technology (DST), Government of India, for carrying out the research reported in this manuscript.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Anshari, M.A.A., Mishra, R., Imam, M. et al. Comparison of the Microstructures and Mechanical Properties in the Overlapping Region of Low Carbon Steel Additive Bead Fabricated by WAAM and FSP. Metall Mater Trans A 54, 869–895 (2023). https://doi.org/10.1007/s11661-022-06934-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06934-5