Abstract

The crystallography of bainitic ferrite nucleated at austenite grain boundaries was studied in an Fe-9Ni-0.15C (mass pct) alloy. The relationship between bainitic ferrite orientations (variants) and grain boundary characters, i.e., misorientation and boundary orientation, was examined by electron backscatter diffraction analysis in scanning electron microscopy and serial sectioning observation. Bainitic ferrite holds nearly the Kurdjumov–Sachs (K-S) orientation relationship with respect to the austenite grain into which it grows. At the beginning of transformation, the variants of bainitic ferrite are severely restricted by the following two rules, both advantageous in terms of interfacial energy: (1) smaller misorientation from the K-S relationship with respect to the opposite austenite grain and (2) elimination of the larger grain boundary area by the nucleation of bainitic ferrite. As the transformation proceeds, variant selection establishing plastic accommodation of transformation strain to a larger extent becomes important. Those kinds of variant selection result in formation of coarse blocks for small undercooling.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

Y. Ohmori, H. Ohtani, T. Kunitake: Trans. ISIJ, 1971, vol. 11, pp. 250–59

T. Furuhara, H. Kawata, S. Morito, T. Maki: Mater. Sci. Eng. A, 2006, vol. 431, pp. 228–36

T.E. Swarr, G. Krauss: Metall. Trans. A, 1976, vol. 7A, pp. 41–48

M.J. Roberts: Metall. Trans., 1970, vol. 1, pp. 3287–94

S. Morito, H. Yoshida, T. Maki, X. Huang: Mater. Sci. Eng. A, 2006, vol. 438, pp. 237–40

S. Matsuda, T. Inoue, M. Ogasawara: Trans. JIM, 1968, vol. 9, pp. 343–48

S. Matsuda, T. Inoue, H. Mimura, Y. Okamura: Trans. ISIJ, 1972, vol. 12, pp. 325–33

A.F. Gourgues, H.M. Flower, T.C. Lindley: Mater. Sci. Technol., 2000, vol. 16, pp. 26–40

S. Morito, H. Tanaka, R. Konishi, T. Furuhara, T. Maki: Acta Mater., 2003, vol. 51, pp. 1789–99

H. Kitahara, R. Ueji, N. Tsuji, Y. Minamino: Acta Mater., 2006, vol. 54, pp. 1279–88

T. Maki, K. Tsuzaki, I. Tamura: Trans. ISIJ, 1980, vol. 20, pp. 207–14

E. Bouyne, H.M. Flower, T.C. Lindley, A. Pineau: Scripta Mater., 1998, vol. 39, pp. 295–300

A. Lambert-Perlade, A.F. Gourgues, A. Pineau: Acta Mater., 2004, vol. 52, pp. 2337–48

H. Kawata, K. Sakamoto, T. Moritani, T. Furuhara, S. Morito, T. Maki: Mater. Sci. Eng. A, 2006, vol. 438, pp. 140–44

T. Furuhara, T. Maki: Mater. Sci. Eng. A, 2001, vol. 312, pp. 145–54

J.K. Lee, H.I. Aaronson: Acta Metall., 1979, vol. 23, pp. 799–808

J.K. Lee, H.I. Aaronson: Acta Metall., 1979, vol. 23, pp. 809–20

K. Ameyama, T. Maki, I. Tamura: J. Jpn. Inst. Met., 1986, vol. 50, pp. 602–11

T. Furuhara, S. Takagi, H. Watanabe, T. Maki: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 1630–41

C.P. Luo, G.C. Weatherly: Acta Metall., 1987, vol. 35, pp. 1963–72

P.M. Kelly: Mater. Trans. JIM, 1992, vol. 33, pp. 235–42

Acknowledgments

Professor Kozo Osamura (Emeritus Professor, Kyoto University) and Dr. Hiroki Adachi (Department of Materials Science and Engineering, Kyoto University) are deeply appreciated for permitting the authors to use the FESEM-OIM system in their laboratory.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation given in the symposium entitled “Solid-State Nucleation and Critical Nuclei during First Order Diffusional Phase Transformations,” which occurred October 15–19, 2006 during the MS&T meeting in Cincinnati, Ohio under the auspices of the TMS/ASMI Phase Transformations Committee.

Appendix

Appendix

1.1 Calculation of transformation strain

Transformation strain without or with plastic accommodation was estimated by the phenomenological theory of martensite crystallography.

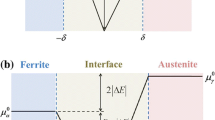

During fcc → bcc martensitic transformations, the Bain lattice correspondence is maintained accommodation. Under this correspondence, the following Bain strain is generated:

Here, three orthogonal axes are set to be [100] γ //[110] α , \( \left[ {010} \right]_\gamma //\left[ {\bar 110} \right]_\alpha \), and [001] γ //[001] α . Assuming the K-S orientation relationship between BF and the γ matrix, (111) γ //(011) α , \( \left[ {\bar 101} \right]_\gamma //\left[ {\bar 1\bar 11} \right]_\alpha \), the transformation strain can be given by the Bain strain and the rigid body rotation;

In the preceding equation, T 1 and T 2 are matrices that accomplish clockwise rotations of 9.74 deg around \( \left[ {1\bar 10} \right]_\gamma \) and of 5.26 deg around [111] γ , respectively. To calculate the maximum misfit strain, the method previously used by Luo and Weatherly[20] was applied. The misfit strain along a given direction p = [x, y, z] is described as follows:

The maximum strain of a magnitude of 0.3878 is obtained along p max = [0.6534, 0.2312, 0.7208] γ by solving the following conditions:

To estimate the strain after accommodation, a double shear LID model proposed by Kelly[21] to analyze the crystallography of LM was applied as in the previous study.[9]

where R is the rigid body rotation, and S 1 and S 2 are the matrices that represent lattice invariant shear for \( \left( {{\rm{hhl}}} \right)\left[ {1\bar 10} \right]_\gamma \) and \( \left( {{\rm{hll}}} \right)\left[ {0\bar 11} \right]_\gamma \) slip modes, respectively. The direction of the maximum strain is f max = [−0.2013, −0.7071, −0.6779] γ . Then, the misorientations of those directions and the grain boundary plane or slip directions in the opposite matrix grain γ 2 were analyzed in each BF.

Rights and permissions

About this article

Cite this article

Furuhara, T., Kawata, H., Morito, S. et al. Variant Selection in Grain Boundary Nucleation of Upper Bainite. Metall Mater Trans A 39, 1003–1013 (2008). https://doi.org/10.1007/s11661-008-9510-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9510-9