Abstract

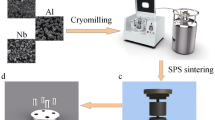

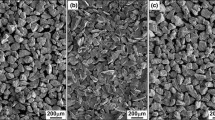

To provide insight into the influence of an electric field on the kinetics of diffusion, fully lamellar γ-TiAl was processed by a rapid, two-stage, solid-state reactive sintering via spark plasma sintering (SPS) of a cryomilled Ti, Al powder blend. Cryomilling was implemented in the current study to attain a nanostructured grain size in the Ti and Al powder blend, and thereby provide insight into the influence of grain size on the underlying diffusion kinetics. Following a two-step process involving SPS at 873 K (600 °C) for 15 minutes and 1523 K (1250 °C) for 30 minutes, a fully lamellar TiAl alloy, with submicron lamellar spacing, was successfully obtained. Microstructural refinement in the Ti and Al powders during cryomilling led to an increase in solid-state diffusion, and the underlying mechanisms are discussed in detail.

Similar content being viewed by others

References

Z.A. Munir, U. Anselmi-Tamburini and M. Ohyanagi: J. Mater. Sci., 2006, vol. 41, pp. 763-77.

J. Zhao, J.E. Garay, U. Anselmi-Tamburini, and Z.A. Munir: J. Appl. Phys., 2007, vol. 102, 114902.

J.E. Garay, U. Anselmi-Tamburini and Z.A. Munir: Acta Mater., 2003, vol. 51, pp. 4487-95.

N. Bertolino, J. Garay, U. Anselmi-Tamburini and Z.A. Munir: Philos. Mag. B, 2002, vol. 82, pp. 969-85.

J.R. Friedman, J.E. Garay, U. Anselmi-Tamburini and Z.A. Munir: Intermetallics, 2004, vol. 12, pp. 589-97.

T. Kondo, M. Yasuhara, T. Kuramoto, Y. Kodera, M. Ohyanagi and Z.A. Munir: J. Mater. Sci., 2008, vol. 43, pp. 6400-05.

U. Anselmi-Tamburini, J.E. Garay and Z.A. Munir: Mater. Mater. Sci. Eng. A, 2005, vol. 407, pp. 24-30.

T. Kondo, T. Kuramoto, Y. Kodera, M. Ohyanagi and Z.A. Munir: J. Ceram. Soc. Jpn., 2008, vol. 116, pp. 1187-92.

H. Clemens and H. Kestler: Adv Eng Mater, 2000, vol. 2, pp. 551-70.

K. Gebauer: Intermetallics, 2006, vol. 14, pp. 355-60.

K. Liu, Y.C. Ma, M. Gao, G.B. Rao, Y. Y. Li, K. Wei, X.H. Wu and M.H. Loretto: Intermetallics, 2005, vol. 13, pp. 925-28.

T. Tetsui: Mater. Mater. Sci. Eng. A, 2002, vol. 329, pp. 582-88.

G.P. Chaudhari and V.L. Acoff: Intermetallics 2010, vol. 18, pp. 472-78.

Y.Y. Chen, H.B. Yu, D.L. Zhang and L.H. Chai: Mater. Mater. Sci. Eng. A, 2009, vol. 525, pp. 166-73.

M.A. Lagos and I. Agote: Intermetallics, 2013, vol. 36, pp. 51-56.

O. Ertorer, T. Topping, Y. Li, W. Moss and E.J. Lavernia: Scripta Mater., 2009, vol. 60, pp. 586-89.

D.B. Witkin and E.J. Lavernia: Prog Mater Sci, 2006, vol. 51, pp. 1-60.

N. Bertolino, M. Monagheddu, A. Tacca, P. Giuliani, C. Zanotti and U.A. Tamburini: Intermetallics, 2003, vol. 11, pp. 41-49.

G.K. Williamson and W.H. Hall: Acta Metall., 1953, vol. 1, pp. 22-31.

L. Balogh, T. Ungar, Y. Zhao, Y.T. Zhu, Z. Horita, C. Xu and T.G. Langdon: Acta Mater., 2008, vol. 56, pp. 809-20.

J. Schuster and M. Palm: J. Phase Equilib. Diffus., 2006, vol. 27, pp. 255-77.

L. Xu, Y.Y. Cui, Y.L. Hao and R. Yang: Mater. Mater. Sci. Eng. A, 2006, vol. 435, pp. 638-47.

W. Yao, A. P. Wu, G.S. Zou and H.L. Ren: Mater. Mater. Sci. Eng. A, 2008, vol. 480, pp. 456-63.

K. Kulkarni, Y. Sun, A.K. Sachdev and E.J. Lavernia: Scripta Mater., 2013, vol. 68, pp. 841-44.

H.M. Wen, T.D. Topping, D. Isheim, D.N. Seidman and E.J. Lavernia: Acta Mater., 2013, vol. 61, pp. 2769-82.

E.J. Lavernia, B.Q. Han and J.M. Schoenung: Mater. Mater. Sci. Eng. A, 2008, vol. 493, pp. 207-14.

J. Benjamin and T. Volin: Metall. Trans. B, 1974, vol. 5B, pp. 1929-34.

F.S. Sun, P. Rojas, A. Zuniga and E.J. Lavernia: Mater. Mater. Sci. Eng. A, 2006, vol. 430, pp. 90-97.

C. Suryanarayana: Prog Mater Sci, 2001, vol. 46, pp. 1-184.

F. Zhou, D. Witkin, S.R. Nutt and E.J. Lavernia: Mater. Mater. Sci. Eng. A, 2004, vol. 375, pp. 917-21.

O. Ertorer, A. Zuniga, T. Topping, W. Moss and E.J. Lavernia: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 91-103.

C.C. Koch: Nanostruct Mater, 1993, vol. 2, pp. 109-29.

Y.J. Lin, B. Yao, Z.H. Zhang, Y. Li, Y. Sohn, J.M. Schoenung and E.J. Lavernia: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 4247-57.

D.R. Lide: Handbook of Chemistry and Physics, 84th ed., CRC Press, Boca Raton, 2003.

G. Welsch, R. Boyer, and E.W. Collings: Materials Properties Handbook: Titanium Alloys, ASM International, Materials Park, 1994.

C.C. Koch: Nanostruct. Mater., 1997, vol. 9, pp. 13-22.

T. Voisin, L. Durand, N. Karnatak, S. Le Gallet, M. Thomas, Y. Le Berre, J.F. Castagne and A. Couret: J. Mater. Process. Technol., 2013, vol. 213, pp. 269-78.

Y. Sun, K. Kulkarni, A.K. Sachdev, and E.J. Lavernia: Metall. Mater. Trans. A, DOI:10.1007/s11661-014-2216-2.

J. Safarian and T.A. Engh: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 747-53.

J.G. Luo and V.L. Acoff: Mater. Mater. Sci. Eng. A, 2004, vol. 379, pp. 164-72.

R. Orru, G. Cao and Z.A. Munir: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1101-08.

Y. Mishin and C. Herzig: Mater. Mater. Sci. Eng. A, 1999, vol. 260, pp. 55-71.

L. C. Luther: J. Chem. Phys., 1965, vol. 43, pp. 2213-18.

E.W. Elcock and C.W. McCombie: Phys. Rev., 1958, vol. 109, pp. 605-06.

Acknowledgments

The experimental support and advice provided by Ertorer Osman, Haiming Wen, Yizhang Zhou, and Baolong Zheng is greatly appreciated. The authors would like to thank the management of General Motors for supporting this research. EJL would also like to thank the support from National Science Foundation with a grant number NSF DMR-1210437.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 6, 2013.

Rights and permissions

About this article

Cite this article

Sun, Y., Kulkarni, K., Sachdev, A.K. et al. Synthesis of γ-TiAl by Reactive Spark Plasma Sintering of Cryomilled Ti and Al Powder Blend, Part I: Influence of Processing and Microstructural Evolution. Metall Mater Trans A 45, 2750–2758 (2014). https://doi.org/10.1007/s11661-014-2215-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2215-3