Abstract

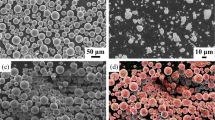

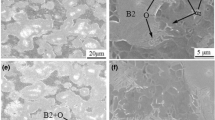

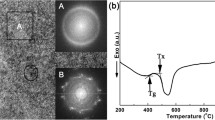

Fabrication of ternary Nb–17Si–23Ti alloys was attempted by in situ reaction laser melting deposition (LMD) with dual powder feeding method from Nb-28 at.% Ti powder mixture and pure Si powder. The microstructures of the as-deposited alloys were examined with scanning electronic microscope, and the phase constituents were analyzed by X-ray energy-dispersive spectrometer and X-ray diffraction. Furthermore, the effect of laser power on microstructure characteristics, microhardness and indentation fracture toughness was also investigated. The in situ reaction LMD process resulted in remarkable refinement of the microstructure. The as-deposited samples mainly consisted of NbSS, metastable (NbTi)3Si and Ti-rich NbSS. With the increase in the laser power from 1000 to 2000 W, the NbSS morphology changed from discontinuous dendritic to near equiaxed, but the Ti-rich NbSS phase tended to vanish. Furthermore, with the increase in the laser power, the microhardness of as-deposited samples increased from 822 to 951 HV, while the indentation fracture toughness was improved from 12.3 to 14.1 MPa m1/2. The corresponding mechanism is also discussed.

Similar content being viewed by others

References

B.P. Bewlay, M.R. Jackson, P.R. Subramanian, J.C. Zhao, Metall. Mater. Trans. A 34, 2043 (2003)

M.R. Jackson, B.P. Bewlay, R.G. Rowe, D.W. Skelly, H.A. Lipsitt, JOM 48, 39 (1996)

C.M. Liu, H.M. Wang, S.Q. Zhang, H.B. Tang, A.L. Zhang, J. Alloys Compd. 583, 162 (2014)

J.C. Zhao, J.H. Westbrook, MRS Bull. 28, 622 (2003)

W.Y. Kim, H. Tanaka, A. Kasama, S. Hanada, Intermetallics 9, 827 (2001)

N. Sekido, Y. Kimura, S. Miura, F. Wei, Y. Mishima, J. Alloys Compd. 425, 223 (2006)

T. Fei, Y. Yu, C. Zhou, J. Sha, Mater. Des. 116, 92 (2017)

K.S. Chan, Mater. Sci. Eng., A 329, 513 (2002)

J. Sha, C. Yang, J. Liu, Scr. Mater. 62, 859 (2010)

T. Murakami, S. Sasaki, K. Ichikawa, A. Kitahara, Intermetallics 9, 621 (2001)

Y. Wang, X. Guo, Y. Qiao, Mater. Des. 116, 461 (2017)

K. Zelenitsas, P. Tsakiropoulos, Mater. Sci. Eng. A 416, 269 (2006)

J. Geng, P. Tsakiropoulos, G. Shao, Mater. Sci. Eng. A 441, 26 (2006)

B.P. Bewlay, M.R. Jackson, R.R. Bishop, J. Phase Equilib. 19, 577 (1998)

J. Sha, H. Hirai, H. Ueno, T. Tabaru, A. Kitahara, S. Hanada, Metall. Mater. Trans. A 34, 85 (2003)

X. Li, H. Chen, J. Sha, H. Zhang, Mater. Sci. Eng., A 527, 6140 (2010)

B.P. Bewlay, M.R. Jackson, J.C. Zhao, P.R. Subramanian, M.G. Mendiratta, J.J. Lewandowski, MRS Bull. 28, 646 (2003)

B. Guo, X. Guo, Mater. Sci. Eng. A 617, 39 (2014)

W. Liu, J. Sha, Mater. Des. 111, 301 (2016)

E.M. Lawrence, J. Mater. Sci. Technol. 32, 987 (2016)

G.P. Dinda, A.K. Dasgupta, J. Mazumder, Mater. Sci. Eng. A 509, 98 (2009)

R. Dicks, F. Wang, X. Wu, J. Mater. Process. Technol. 209, 1752 (2009)

R.R. Dehoff, P.M. Sarosi, P.C. Collins, L.F. Hamish, J.M. Michael, MRS Online Proc. Libr. 753, 2 (2011)

Y. Guo, L. Jia, S. Sun, B. Kong, J. Liu, H. Zhang, Mater. Des. 109, 37 (2016)

A.G. Evans, E.A. Charles, J. Am. Ceram. Soc. 59, 371 (1976)

J.L. Yu, K.F. Zhang, Scr. Mater. 59, 714 (2008)

M.G. Mendiratta, J.J. Lewandowski, D.M. Dimiduk, Metall. Trans. A 22, 1573 (1991)

K. Zelenitsas, P. Tsakiropoulos, Intermetallics 13, 1079 (2005)

L. Su, L. Jia, Y. Feng, H. Zhang, S. Yuan, H. Zhang, Mater. Sci. Eng. A 560, 672 (2013)

K.A. Jackson, J.D. Hunt, A.I.M.E. Met, Soc. Trans. 236, 1129 (1966)

C.T. Lynch, J.P. Kershaw, (CRC Press, Boca Raton 1972), p. 121

Y. Li, S. Miura, K. Ohsasa, C. Ma, H. Zhang, Intermetallics 19, 460 (2011)

N. Hansen, Scr. Mater. 51, 801 (2004)

L. Wang, N. Wang, W.J. Yao, Y.P. Zheng, Acta Mater. 88, 283 (2015)

M.C. Flemings, Metall. Trans. A 5, 2121 (1974)

H. Attar, K.G. Prashanth, L.C. Zhang, M. Calin, I.V. Okulov, S. Scudino, C. Yang, J. Eckert, J. Mater. Sci. Technol. 31, 1001 (2015)

Y. Li, D. GU, Mater. Des. 63, 856 (2014)

H. Liao, W. Huang, Q. Wang, F. Jia, J. Mater. Sci. Technol. 30, 146 (2014)

Y.J. Liang, X. Cheng, H.M. Wang, Acta Mater. 118, 17 (2016)

K. Arafune, A. Hirata, J. Cryst. Growth 197, 811 (1999)

E. Guo, S.S. Singh, C. Mayer, X. Meng, Y. Xu, L. Luo, M. Wang, N. Chawla, J. Alloys Compd. 704, 89 (2017)

Acknowledgement

The authors are grateful to the support by the National Natural Science Foundation of China (Grant No. 51605456).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Liu, W., Xiong, HP., Li, N. et al. Microstructure Characteristics and Mechanical Properties of Nb-17Si-23Ti Ternary Alloys Fabricated by In Situ Reaction Laser Melting Deposition. Acta Metall. Sin. (Engl. Lett.) 31, 362–370 (2018). https://doi.org/10.1007/s40195-017-0619-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0619-y