Abstract

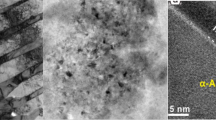

The mechanical alloying process is a new method for producing composite metal powders with controlled microstructures. It is unique in that it is an entirely solid state process, permitting dispersion of insoluble phases such as refractory oxides and addition of reactive alloying elements such as aluminum and titanium. Interdispersion of the ingredients occurs by repeated cold welding and fracture of free powder particles. Refinement of structure is approximately a logarithmic function of time, and depends on the mechanical energy input to the process and work hardening of the materials being processed. A condition of steady state processing is eventually achieved marked by saturation (constant) hardness and constant particle size distribution, although structural refinement continues. Evidence of this is presented, and the nature of the cold welding and characteristics of the processed powder are described.

Similar content being viewed by others

References

J. S. Benjamin:Met. Trans., 1970, Vol. 1, pp. 2943–51.

F. C. Kelly:Weld. J., 1951, Vol. 30, p. 728.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Benjamin, J.S., Volin, T.E. The mechanism of mechanical alloying. Metall Trans 5, 1929–1934 (1974). https://doi.org/10.1007/BF02644161

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02644161