Abstract

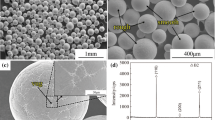

The difficulty of achieving full densification of TiAl powder by pressureless sintering makes spark plasma sintering (SPS) an attractive alternative. In this study, Ti-48Al-2Cr-Nb alloy was fabricated by SPS from gas-atomized TiAl powder. Near-full densification was achieved after 4 min at 1100°C under applied pressure of 80 MPa, accompanied by the formation of an unexpected bright-contrast phase when observed under backscattered scanning electron microscopy. Detailed characterization revealed that the bright-contrast phase was composed of oxygen- and carbon-enriched α-Ti and chromium-enriched β-Ti. A two-particle model was used to simulate the current passing through the particles during SPS. The model predicts that when a high density of current passes through the narrow particle–particle contact area, it can produce a high-temperature zone (~ 1-μm-thick surface layer), in which the temperature is high enough to allow the decomposition of the surface oxide layer and melting of the TiAl alloy underneath. These complex changes lead to the formation of the unexpected phase.

Similar content being viewed by others

References

D.E. Alman, Intermetallics 13, 572 (2005).

R. Gerling, H. Clemens, and F.P. Schimansky, Adv. Eng. Mater. 6, 23 (2004).

U. Habel and B.J. McTiernan, Intermetallics 12, 63 (2004).

L. Zhao, J. Beddoes, P. Au, and W. Wallace, Adv. Perform. Mater. 4, 421 (1997).

R. Gerling and F.P. Schimansky, Mater. Sci. Eng. A 329, 45 (2002).

H.M. Zhang, X.B. He, X.H. Qu, and L.M. Zhao, Mater. Sci. Eng. A 526, 31 (2009).

W. Limberg, T. Ebel, F.P. Schimansky, R. Hoppe, M. Oehring, and F. Pyczak, Euro PM2009, (2009).

Y.H. Wang, J.P. Lin, Y.H. He, Y.L. Wang, and G.L. Chen, Intermetallics 16, 215 (2008).

X. Lu, X.B. He, B. Zhang, L. Zhang, X.H. Qu, and Z.X. Guo, Intermetallics 17, 840 (2009).

H. Jabbar, J.P. Monchoux, F. Houdellier, M. Dollé, F.P. Schimansky, F. Pyczak, M. Thomas, and A. Couret, Intermetallics 18, 2312 (2010).

M. Schloffer, F. Iqbal, H. Gabrisch, E. Schwaighofer, F.P. Schimansky, S. Mayer, A. Stark, T. Lippmann, M. Göken, F. Pyczak, and H. Clemens, Intermetallics 22, 231 (2012).

A. Huang, D. Hu, M.H. Loretto, J. Mei, and X. Wu, Scripta Mater. 56, 253 (2007).

M. Omori, Mater. Sci. Eng. A 287, 183 (2000).

S.I. Cha, S.H. Hong, and B.K. Kim, Mater. Sci. Eng. A 351, 31 (2003).

Z. Shen, M. Johnsson, Z. Zhao, and M. Nygren, J. Am. Ceram. Soc. 85, 1921 (2002).

C. Shearwood, Y.Q. Fu, L. Yu, and K.A. Khor, Scripta Mater. 52, 455 (2005).

T. Takeuchi, E. Bétourné, M. Tabuchi, H. Kageyama, Y. Kobayashi, A. Coats, F. Morrison, D.C. Sinclair, and A.R. West, J. Mater. Sci. 34, 917 (1999).

A. Couret, G. Molenat, J. Galy, and M. Thomas, Intermetallics 16, 1134 (2008).

Y.H. Wang, J.P. Lin, Y.H. He, Y.L. Wang, and G.L. Chen, Mater. Sci. Eng. A 489, 55 (2008).

M. Tokita, E. Bldg, and K. Sc, Mechanism of Spark Plasma Sintering, Proceeding of the International Symposium on Microwave. 1997.

Z.H. Zhang, Z.F. Liu, J.F. Lu, X.B. Shen, F.C. Wang, and Y.D. Wang, Scripta Mater. 81, 56 (2014).

J. Diatta, G. Antou, N. Pradeilles, and A. Maître, J. Eur. Ceram. Soc. 37, 4849 (2017).

Z. Trzaska, A. Couret, and J.P. Monchoux, Acta Mater. 118, 100 (2016).

G. Liu, R. Li, T. Yuan, Z. Mei, and F. Zeng, Int. J. Refract. Met. H. 66, 68 (2017).

R. Chaim and M. Margulis, Mater. Sci. Eng. A 407, 180 (2005).

R. Chaim, Mater. Sci. Eng. A 443, 25 (2007).

D. Demirskyi, H. Borodianska, D. Agrawal, A. Ragulya, Y. Sakka, and O. Vasylkiv, J. Alloys Compd. 523, 1 (2012).

J.M. Frei, U. Anselmi-Tamburini, and Z.A. Munir, J. Appl. Phys. 101, 1 (2007).

X. Song, X. Liu, and J. Zhang, J. Am. Ceram. Soc. 89, 494 (2006).

D.M. Hulbert, A. Anders, D.V. Dudina, J. Andersson, D. Jiang, C. Unuvar, U. Anselmi-Tamburini, E.J. Lavernia, and A.K. Mukherjee, J. Appl. Phys. 104, 33305 (2008).

M. Hulbert, A. Anders, J. Anderson, E.J. Lavernia, and A.K. Mukherjee, Scripta Mater. 60, 835 (2009).

T.B. Holland, U. Anselmi-Tamburini, D.V. Quach, T.B. Tran, and A.K. Mukherjee, J. Eur. Ceram. Soc. 32, 3667 (2012).

G. Ji, T. Grosdidier, N. Bozzolo, and S. Launois, Intermetallics 15, 108 (2007).

M. Kyoung II, K. Seung Chul, and L. Kyung Sub, Intermetallics. 10, 185 (2002).

Y. Xia, S.D. Luo, X. Wu, G.B. Schaffer, and M. Qian, Mater. Sci. Eng. A 559, 293 (2013).

C. Collard, Z. Trzaska, L. Durand, J.M. Chaix, and J.P. Monchoux, Powder Tech. 321, 458 (2017).

T. Saunders, S. Grasso, and M.J. Reece, J. Eur. Ceram. Soc. 35, 871 (2015).

N. Chawake, L.D. Pinto, A.K. Srivastav, K. Akkiraju, B.S. Murty, and R.S. Kottada, Scripta Mater. 93, 52 (2014).

D. Veeraraghavan, U. Pilchowski, B. Natarajan, and V.K. Vasudevan, Acta Mater. 46, 405 (1998).

R. Przeliorz, M. Goral, G. Moskal, and L. Swadzba, J. Achiev. Mater. Manuf. Eng. 21, 48 (2007).

I. Egry, R. Brooks, D. Holland-Moritz, R. Novakovic, T. Matsushita, E. Ricci, S. Seetharaman, R. Wunderlich, and D. Jarvis, Int. J. Thermophys. 28, 1026 (2007).

J.M. Montes, F.G. Cuevas, and J. Cintas, Appl. Phys. A 92, 375 (2008).

G.B. Naumov, B.N. Ryzhenko, and I.L. Khodakovsky, Handbook of thermodynamic data (Menlo Park, CA: U.S. Geological Survey, Water Resources Division, 1974).

A. Nérac-Partaix, A. Huguet, and A. Menand, Gamma Titanium Aluminides, 124th TMS Annual Meeting (Las Vegas: Warrendale, 1995), pp. 197–202.

C. Scheu, E. Stergar, M. Schober, L. Cha, H. Clemens, A. Bartels, F.P. Schimansky, and A. Cerezo, Acta Mater. 57, 1504 (2009).

Acknowledgements

Y. Xia would like to thank Dr. Don Rodrigo of Monash University for assistance in the use of the spark plasma sintering system, Dr. Barry Wood of The University of Queensland for x-ray photoelectron spectroscopy (XPS) analysis, and Central South University for start-up funding.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xia, Y., Zhao, J.L. & Qian, M. Spark Plasma Sintering of Ti-48Al-2Cr-2Nb Alloy Powder and Characterization of an Unexpected Phase. JOM 71, 2556–2563 (2019). https://doi.org/10.1007/s11837-019-03590-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03590-w