Abstract

This work aims to introduce a simple high-performance sensitive electrochemical sensor of reformed carbon paste (CP) with iron oxide nanoparticles (IONs). It was developed to determine one of the most important drugs called vitamin B6 in a medium of phosphate buffer (PBS) over pH ranging from 5.0 to 8.0. The electrochemical and surface characterization was achieved by different techniques comprising electrochemical impedance spectroscopy (EIS), cyclic voltammetry (CV), differential pulse voltammetry (DPV), and scanning electron microscopy (SEM). The studied effects were, pH, buffer, interference, scan rate, accumulation time, and calibration plot. The sensitive electrode produced a linear calibration curve in a concentration range from 8.88 up to 1000.0 µM, with limits of detection and qualification estimated at 9.06 and 30.2 µM, respectively Also, this method was established in human urine real samples and pharmaceutical drugs which have been shown a good result for vitamin B6 detection.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Every day, our body produces muscles, skin, and bones; also, it sends thousands of nerve signals between body and brain. But to have the opportunity for doing all of this, some useful raw materials are needed by your body, which contains 30 or more vitamins, minerals, and certain nutrients that the body cannot manufacture in enough quantities by itself [1]. Vitamins are nutrients essential for doing a various important bodily function as the generation of energy and red blood cell productions for managing anemia. It needs our body about 13 vitamins; eight of them construct the water soluble of a group B vitamins. One of such things is vitamin B6 (pyridoxine) which acts as antioxidant, aids in the metabolism of protein, helps in neurotransmitters and hemoglobin production [2, 3]; may improve mood by reducing depression symptoms [4,5,6,7]; may be useful in treating symptoms of PMS [8]; handles nausea during pregnancy [9], promotes eye health for preventing eye diseases [10,11,12,13,14]; reduces Alzheimer’s [15,16,17], heart disease [18,19,20,21], and cancer risks [22, 23]; and may treat inflammation associated with rheumatoid arthritis [24,25,26,27]. Vitamin B6-rich foods are chickpeas, turkey, fish (salmon, tuna), starchy vegetables, potatoes, bananas, meats, organ meats, fortified cereals, and whole grains [28]. The RDA (recommended dietary allowance) is 1.7 mg and 1.5 mg for men and women over 50, respectively [2, 29, 30].

Several studies have examined numerous analytical approaches for detecting vitamin B6, including HPLC, spectrophotometric methods, electrophoresis, and fluorimetric methods. All those methods show little flexibility and portability, and also, they are time consuming. Electrocatalytic methods have received great attention in present as they show simple procedure, high sensitivity, fast response, and good accuracy [31,32,33,34,35]. Carbon paste electrodes (CPEs) and chemically modified CPEs are well recognized due to their vast applicable potential window, chemical inertness, low residual background current, ease of fabrication, low cost, excellent stability, low detection limits, and safe disposability after the use with diverse sorts of modulators [31, 36, 37]. Various previous studies for electrochemical techniques used to detect vitamin B6 were mentioned as the determination of vitamin B6 by using vanadium(III) Schiff base complex modified GCE [38], determination of vitamin B6 in preparation of pharmaceutical compounds by cyclic voltammetry with a copper(II) hexacyano-ferrate(III) modified CPE [39], voltammetric sensor for simultaneous determination of vitamin B6 and vitamin C using ZrO2 nanoparticle/ionic liquids CPE in food samples [40]. So, we can say that electrochemical sensors are ideal systems to monitor insert of biological compound using portable devices especially when using the low-cost carbon paste electrode doped with nanoparticle like iron oxide nanoparticles (IONs) in this study [36, 41,42,43,44].

Nanomaterials combining electrochemical sensors for vitamin B6 assurance are an amazing class of materials because of their special multi-functionality. Iron oxides (compounds) are a natural compound that could be synthesized easily in lab as a result of combination of iron and oxygen chemically. There are about 16 identified iron oxides including oxides, hydroxides, and oxide-hydroxides. These minerals are produced as a result of aqueous reactions under various pH and redox conditions. O, Fe, and/or OH are included in the basic composition, but differ in the valence of iron and the overall crystal structure [45,46,47]. IONs consist of maghemite (γ-Fe2O3) and/or magnetite (Fe3O4) particles with a ranging diameter from 1 to 100 nm.

Applications are found in drug delivery, magnetic data storage, biosensing, etc. [48,49,50,51,52]. Because of IONs’ superparamagnetic properties, they had attracted a considerable interest, and hence, their potential for biomedical applications are arising from its nontoxicity and biocompatibility [53, 54]. Recently, IONs have attracted a great attention due to their unique properties like superparamagnetic, easy separation methodology, surface-to-volume ratio, and a greater surface area. Using a suitable surface chemistry, many chemical, biological, and physical methods have been adopted to synthesize magnetic NPs. Also, it exhibits great prospective in the fields of life sciences like agriculture, environment, and biomedicine [52, 54]. The convenience of using the iron oxide nanoparticle–modified carbon paste electrode (IONCPE) in sensing vitamin B6 was checked using different voltammetric techniques. This proposed modification for vitamin B6 detection has confirmed its utility as a sensitive, fast, and easily fabricated electrode with low cost. Both urine and centrum multivitamin samples showed an adequate response toward the newly proposed electrochemical sensor. Till now, no approved article has appeared to be dealing with the detection of vitamin B6 using IONCPE near the biological pH.

Experimental

Chemicals and reagents

Vitamin B6 in its pure form (≥ 99.0%) used to prepare its stock solution was purchased from Pharaonia Pharmaceuticals (Egypt). Sodium phosphate dibasic, sodium phosphate monobasic, ammonium hydroxide, sulfuric, hydrochloric, and phosphoric acids used in preparing 0.1 M supporting electrolytes were all purchased from Sigma-Aldrich. Graphite microparticles (< 50 μm) was purchased from Merck, Darmstadt, Germany, and mixed with paraffin oil obtained from Aldrich, USA, to prepare CPE. Ferric chloride (FeCl3) from El-Nasr Pharma and Ferrous sulphate (FeSO4) from Riedl de Haen were used to prepare IONs.

Ascorbic acid from Merck and caffeine powder from Alpha Chemika (Mumbai, India) were used for the interference studies. Glucose, sucrose, starch, urea, and uric acid were obtained from MISR-Scientific Company. L-( +)-Ascorbic acid was brought from Alpha-Chem., India.

Instruments and methodology

The entire electrochemical experiments were done at room temperature in an ordinary 25.0 mL of three-electrode cell by applying the bare electrode or the IONCPE as working electrode (WE), a platinum rod as counter electrode (CE), and a saturated calomel electrode as reference electrode (RE).

This electrochemical cell was in connection with a Bio-logic SAS model SP-150 potentiostat supplied and a computer-controlled EC-Lab® electrochemical software, France, in order to perform all the electrochemical measurements including cyclic voltammetry (CV), differential pulse voltammetry (DPV), and electrochemical impedance spectroscopy (EIS).

EIS measurements were accomplished using 10 mV ac amplitude over a range of frequency of 100 mHz to 100 kHz. The EC-Lab® software was used to analyze and fit the data with a superlative equivalent model circuit. To determine the pH of the solutions, Adwa 1030 digital pH meter (Romania) was linked to a glass electrode and utilized. Analyzing the electrode’s surface morphology and composition were done using a scanning electron microscope (SEM) (Model Quanta 250 Field Emission Gun) attached with energy-dispersive X-ray (EDX) unit (FEI Company, Japan).

To reach a reproducible result, measurements were repeated for at least three times.

ION preparations

A simple method for preparing IONs by preparing 50.0 mL of 0.2 M Fe+3 salt solution (FeCl3) and 50.0 mL of 0.1 M Fe+2 (FeSO4) in a proper cup and stirred for 30 min in water bath followed by heating. After that, NH4OH was added drop wisely until pH 11.0 achieved and stirred further for 20.0 min in the same conditions, finally, let it to cool at room temperature.

IONCPE preparations

IONCPE sensor could be synthesized by hand blending 5.0 g of graphite powder with 3.0 mL of paraffin oil in a clean mortar for about 10 min to obtain a homogeneous paste [55]. After that, 0.05 g of IONs were chemically mixed with the acquired CP; the resulting mixture were then used to fill a hole of 3.0 mm diameter at a Teflon tube end to prepare the IONCPE. Finally, the electrode’s surface was refined and smoothed using a sand paper.

Sensor applications and preparation of real sample

Using two different samples (urine and Centrum multivitamin) and amount of vitamin B6 is being measured using a proper way.

Firstly, for detecting the Vitamin in urine samples we added 0.25 mL of urine to 100.0 mL, 0.1 M of PBS (pH 6.0),(1:400), in order to get rid of any matrix effect. After that we take 22.5 mL from this mixture in the electrochemical cell then make addition till we reach 25.0 mL wisely using vitamin B6 through the standard addition method.

Second, pharmacological samples were prepared by dissolving one tablet into 250.0 mL of distilled water. Then, 2.5 mL from the drug solution were added to 20.0 mL of 0.1 M of PBS (pH 6.0) and gather it with the electrochemical cell and make additions till reaching 25.0 mL wisely using vitamin B6.

Results and discussion

Characterizations of the surface

The surface of the modified electrode morphology was assigned using EDX and SEM analysis as presented in Fig. 1.

CP in Fig. 1A seems like a compact and opaque surface that enhances the good compatibility of graphite powder with the mineral oil and paste formation. The surface of the modified electrode was significantly different, exhibiting additional colony of well mixed iron nanoparticles with the CPE to give the new IONCPE in Fig. 1B. In the same manner, a further magnification for the electrode (Fig. 1C, D) shows the average size of the ION which is nearly 200 nm in size. The existence of iron, oxygen, and carbon peaks was confirmed by EDX data of the IONCPE surface as shown in Fig. 1E, indicating the well electrode preparation.

Electrochemical functioning of vitamin B6 at IONCP modified sensor

To improve the measurement conditions, different types of buffer solutions such as 0.1 M of Britton–Robinson buffer (B-R), H2SO4, HCl, and 0.1 M of phosphate buffer solution (PBS) were tried out for using as supporting electrolytes. From Fig. 2A, we can see that there is approximately no peak in the case of HCl and H2SO4 solutions. On the other hand, using B-R buffer solution gives wide and broad peak, while PBS exhibited a sharp and clear peak, so making it the proper working solution.

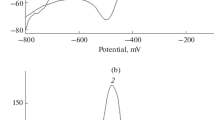

A CVs of 1.0 mM vitamin B6 at scan rate 0.05 Vs−1 using four different supporting electrolytes. B CVs of 1.0 mM vitamin B6 at BCPE and IONCPE in 0.1 M PBS (pH 6.0) and scan rate 0.05 Vs−1. C, D EIS (in the form of Bode and Nyquist plots, respectively) technique at 1.0 mM vitamin B6 and in 0.1 M PBS (pH 6.0). D (inset) The most optimum equivalent circuit

In order to develop any electrochemical sensor, it is necessary to know its performance toward vitamin B6 compared with bare CPE. Checking the sensitivity and validation of using the IONCPE in detecting vitamin B6 was done by CV technique. Figure 2B illustrates the CVs of CPE and IONCPE in 0.1 M of PBS at (pH = 6.0) as supporting electrolyte containing 1.0 mM vitamin B6 with scan rate 0.05 Vs−1. Obviously now the oxidation of vitamin B6 on IONCPE is an irreversible reaction with clear separate oxidation peak appears at peak potential of about 0.78 V and brilliant peak current around 140.0 µA, which is approximately 9.3 times greater than the one of the bare electrode (15.0 µA).

Electrochemical impedance spectroscopy (EIS) studies including both Bode and Nyquist plots shown in Fig. 2C and D, respectively, is an effective tool to confirm the results of the CVs and assure that a higher electrocatalytic activity is attained by IONCPE towards the oxidation of 1.0 mM vitamin B6 than the bare CPE. The Nyquist plot is a semicircle part which indicates that the process is not mainly diffusion but charge transfer dependent. The best fit to the data done using an equivalent circuit shown in Fig. 2D inset with an acceptable error of an average 1%, where R1 represents the resistance of the solution; Q2 is “the constant phase element, CPE,” which related in parallel combination to R2, “the resistance of outer layers”; and C3 is “the double-layer capacitance,” which also combined parallel with R3, “the inner layer resistance” [56,57,58,59,60]. Due to surface roughness, an empirical exponent (α = 0 to 1) is proposed to monitor the deviation from a capacitive ideality behavior. For ideal capacitor, it is always corresponding to α = 1, whereas at α = 0.5, it becomes the CPE in Warburg component [61,62,63,64,65,66]. Table 1 introduces the greatest fitting values obtained from the equivalent circuit for the two electrodes’ impedance data, BCPE and IONCPE. The resistance value of the solution, R1, was almost constant for each electrode within the experimental errors limits. IONCPE demonstrate relatively greater capacitance values or lower impedance values compared to BCPE, indicating a more conducting behavior and to confirm the highest oxidation peak current that was achieved from CV results.

Effect of solution pH

The CV technique revealed the effect of changing the pH of the solution on the electro-oxidation of vitamin B6 at a concentration of 1.0 mM in 0.1 M PBS (pH 5.0–7.0) at IONCPE (Fig. 3A). It is clear that the electro-oxidation of vitamin B6 is pH dependent due to the complex distribution of species resulting from acid base and hydration equilibria. In an acidic environment (pH 5.0), the current peak expands and begins to disappear, which can be attributed to the protonation of the vitamin B6 molecule, which is electroactive only in its unprotonated form. As the pH increases, an optimal peak appears and for this work so that the optimal operating pH has been set to be 6.0.

A CVs of 1.0 mM vitamin B6 at scan rate 0.05 Vs−1 in PBS 0.1 M at different pH values (5.0–7.0). Inset, the relation between the anodic peak current and pH values for IONCPE. B Nyquist plots of 1.0 mM vitamin B6 at different pH values and its corresponding Bode plots in the inset. C The effect of pH on the anodic peak potential of vitamin B6 at IONCPE

The pH influence on the current peak (Fig. 3A, inset) shows that the current increases as the pH rises from 5.0 to 6.0, then drops as the pH rises, confirming the process of vitamin B6 protonation in an acidic media and becoming electro-inactive.

Also, the peak current was decreasing with increased solution pH and almost highest in the pH 6.0 as it is expected that the vitamin is in an anionic form only in very strong basic solution (pH > 9.0) due to the deprotonating of the (− OH) group bonded to the pyridinic ring. This may also cause to a decrease in the peak current. On the other hand, decreases of anodic peak current in the high basic pH may also be attributed to the changes in electrostatic interaction between vitamin B6 and IONs and the changes in electrode reaction rates. Also, the influence of changing pH of PBS was studied using Nyquist and Bode plots (Fig. 3B). It gives the same tendency as CVs. It shows that the lowest value of impedance is obtained with lowest semicircle diameter for pH = 6.0 and the highest value of conductivity.

The change of the anodic peak potential Ep for the oxidation of vitamin B6 as a function of pH is demonstrated in Fig. 3C. The anodic Ep shifted negatively with enlarging pH value according to a linear relation between pH and the potential peak corresponding to the following equation:

With a proton-transfer step in the electro-oxidation of vitamin B6, the anodic peak potential dependence on pH is demonstrated. The slope (0.022 V/pH) differs from the ideal Nernstian slope (0.059 V/pH) at 25 °C, indicating that the number of transferred electrons and protons are not equal, which could be due to the oxidation mechanism’s complexity.

Effect of scan rate

The scan rate effect on the anodic peak current of 1.0 mM vitamin B6 in 0.1 M PBS was demonstrated using the CV technique (Fig. 4A). We can see that increasing the scanning rate in a very wide range from 0.01 to 2.0 Vs−1 increases the peak current and also shifts the peak potential to more positive values, ensuring irreversible electrochemical oxidation [67].

A CVs of 1.0 mM vitamin B6 at 0.1 M PBS (pH 6.0) using varying scan rates (0.01–2.0 Vs−1). B The anodic peak current versus the square root of scan rate at BCPE and IONCPE, respectively. C Relation between logarithm the anodic peak current vs. logarithm the scan rate at IONCPE. D The anodic peak potentials against logarithm the scan rate at IONCPE

A linear relationship between the anodic peak current and the square root of the scan rate (Fig. 4B) asserts the presence of a diffusion-controlled mechanism and represented as:

Also, a linear relationship between log (I) versus log (ν) with slope of 0.37 (Fig. 4C) indicates an adsorption-controlled mechanism which reflects that CPEs are excellent for adsorbing particles on its active surface through the electrode reaction, due to their surface passivation. So overall, it is a mixed diffusion–adsorption mechanism.

The kinetic parameters from Fig. 4D are determined using the Laviron model (Eq. 4), which represents a linear relationship between the peak potential and the logarithm of scan rate and is represented as follows [68]:

where α is the electron-transfer coefficient, which for irreversible processes is around 0.4–0.6 [69] and n is the number of electrons exchanged in the electro-oxidation reaction, which for vitamin B6 was calculated from Eq. 4 to be approximately two electrons [70].

The active surface area of IONCPE was assigned using the CV technique in 1.0 mM K4Fe(CN)6 and 0.1 M KCl as an electrolyte. By applying the Randles–Sevcik equation (Eq. 5) [58, 71]:

where Ipa is the anodic peak current (A), n is the number of transferred electrons through the redox reaction and is equal to 1, A is the electro-active area of the electrode (cm2), C is the concentration of K4Fe(CN)6 (mol cm−3), D is the diffusion coefficient = 7.6 × 10−6 (cm2 s−1), and ν is the scan rate (Vs−1). For the BCPE, the area is calculated to be 0.069 cm2. For the IONCPE, the average electro-active area is 0.439 cm2.

The electro-oxidation mechanism of pyridoxine may proceed with the formation of the aldehyde (pyridoxal) and the subsequent oxidation to pyridoxic acid, according to the scheme reported in Scheme 1. In some cases, only an overall process was observed because pyridoxal is present as hemiacetal form but the free aldehyde (the electroactive one) is negligible, and then a previous chemical transformation at the electrode is necessary on the time scale of the voltammetric experiment [70].

The slope in Fig. 4B equals (2.69 × 105) n3/2ACD1/2 according to the Randles–Sevcik equation and by substituting with the electrode area; the diffusion coefficients of both CPE and IONCPE were estimated to be 8.0 × 10−3 and 25.1 × 10−2 cm2 s−1, respectively. It is obvious that using ION as a modifier has facilitated the diffusion of vitamin B6 molecules through the electrolyte as well as increasing the active surface area by a factor of 6.9.

Effect of accumulation time

In order to examine the response of IONCPE, CVs for 1.0 mM vitamin B6 in 0.1 M of PBS solution (pH 7.4) were recorded over different time intervals (Fig. 5). A rapid increase in the anodic peak currents with the immersion time of sensor occurs, till reach maximum at 5.0 min, then decrease again till a stable plateau at high times above 25.0 min.

Calibration curve study

In order to validate the sensitivity of IONCPE for vitamin B6 electrochemical determination, a linear relation between the anodic current peak and a different concentrations of vitamin B6 (Fig. 6) can be represented by the linear equation:

Figure 6 inset shows the corresponding differential pulse curves for increasing vitamin B6 concentrations (from 8.88 up to 1000.0 µM) in 0.1 M of PBS (pH 6.0) and scan rate 0.01 Vs−1 using IONCPE. Limit of quantification (LOQ) and limit of detection (LOD) were calculated by the following equations [72]:

They were found to be 30.2 and 9.06 µM, respectively, which enhanced the electrode sensitivity. The reproducibility of the suggested electrode was controlled five times under the same terms by repeated measurements resulting in a relative standard deviation (RSD) of 3.7%.

Comparison with several electrochemical sensors already described for vitamin B6 detection is given in Table 2. However, those methods are using expensive or toxic chemicals besides the difficulty in fabrication compared to the proposed modified electrode in this work. So, this method has confirmed its reliability and sensitivity for vitamin B6 detection with a relatively low detection limit and a good selectivity.

Commercial samples analysis

Vitamin B6 was detected in actual samples such as urine and pharmaceuticals to identify the application of the new sensor through DPV, by spiking the samples with standard concentrations of vitamin B6 using the standard addition method.

Figure 7 shows the calibration curve for using the IONCP sensor with baby urine samples, which gave a straight line in a concentration range of 8–1000 µM. From the equation of the calibration curve (Ipa (µA) = 0.057C (M) + 10.135), the concentration of vitamin B6 in urine samples was calculated. The correlation coefficient was r2 = 0.966, the LOD was 52.63 µM, and the LOQ was 175.44 µM. To guarantee that the suggested approach is validated in urine samples, Table 3 shows the suggested technique of detection of vitamin B6 for four distinct concentrations on the curve exhibits accuracy and precision; each of these was done five times.

Results are shown in Table 3, confirming that the modified electrode can be used for estimating vitamin B6 in pharmaceutical samples with satisfactory recoveries for every sample between 98.03 and 102.0% with RSDs of 1.1–3.7%. Every measurement of the oxidation current peak was accomplished with average of five replicate measurements determining the amount in the actual samples of vitamin B6.

Interfering materials, sensor selectivity, reproducibility, and long-term stability

To assess the impact of different interfering substances on the detection of vitamin B6 by IONCPE, a constant concentration of vitamin B6 (500 µM) was spiked with the same and doubled concentrations of different compounds, including sucrose, glucose, starch, urea, uric acid, and vitamins such as ascorbic acid (vitamin C), thiamine hydrochloride (B1), riboflavin (B2), nicotinic acid (B3), pantothenic acid (B5), biotin (B8), folic acid (B9), and cyanocobalamin (B12). Vitamin B6 has been studied on the voltammetric response as presented in Table 4. B1, B2, B3, B5, and B8 resulted not to be electroactive in the reported system (within the explored potential range and in the chosen supporting electrolyte). Also, other vitamins such as ascorbic acid (vitamin C) were examined for selection of the suggested technique for vitamin B6. By using the same experimental conditions, CV measurements were performed and the sensor could detect both of them at separate peak potentials of 1.13 V for vitamin B6 and 0.42 V for vitamin C (Fig. 8), without altering the vitamin B6 sensor response, ensuring high selectiveness of sensors.

For reproducibility of IONCPE validation in terms of RSD, 5 sequential voltammetric determinations for 50 μM of vitamin B6 have been carried out without evident vitamin B6 peak current alteration with RSD value of 2.4%. This guarantees the accuracy of the investigated electrode.

The long-term stability of the proposed procedure was assessed by keeping IONCPE in a fridge (4 °C) for a week. Then, a voltammetric measurement for vitamin B6 was carried out, revealing a current response at 98% of the value obtained after new preparation immediately reflects high electrode storage stability.

Conclusion

A new selective and sensitive electrochemical sensor with excellent performance for vitamin B6 was constructed on the basis of the modification of CPE with IONs. Several electrochemical methods were used to optimize the circumstances of measurement to achieve the best sensitive determination of vitamin B6. The newly prepared sensor showed its efficiency in detection with a wide linear dynamic range of 8.88–1000 µM of vitamin B6 and LOD of 9.06 µM. The proposed method was simple, easy, affordable, and sufficiently sensitive for detecting vitamin B6 in pharmacological and baby urine real samples under physiological conditions precisely.

References

Clifford J, Curely J, Water-soluble vitamins: B-complex and vitamin C. Colorado State University. Libraries

Skarupski KA et al (2010) Longitudinal association of vitamin B-6, folate, and vitamin B-12 with depressive symptoms among older adults over time. Am J Clin Nutr 92(2):330–335

Farag AS et al (2019) Simultaneous determination of caffeine and pyridoxine in energy drinks using differential pulse voltammetry at glassy carbon electrode modified with nafion®. Electroanalysis 31(8):1494–1499

Clayton PT (2006) B 6-responsive disorders: a model of vitamin dependency. J Inherit Metab Dis 29(2):317–326

Lenze EJ et al (2007) Onset of depression in elderly persons after hip fracture: Implications for prevention and early intervention of late-life depression. J Am Geriatr Soc 55(1):81–86

Hvas A-M et al (2004) Vitamin B6 level is associated with symptoms of depression. Psychother Psychosom 73(6):340–343

Merete C, Falcon LM, Tucker KL (2008) Vitamin B6 is associated with depressive symptomatology in Massachusetts elders. J Am Coll Nutr 27(3):421–427

Doll H et al (1989) Pyridoxine (vitamin B6) and the premenstrual syndrome: a randomized crossover trial. J R Coll Gen Pract 39(326):364–368

Vutyavanich T, Wongtra-ngan S, Ruangsri R-A (1995) Pyridoxine for nausea and vomiting of pregnancy: a randomized, double-blind, placebo-controlled trial. Am J Obstet Gynecol 173(3):881–884

Christen WG et al (2009) Folic acid, vitamin B6, and vitamin B12 in combination and age-related macular degeneration in a randomized trial of women. Arch Intern Med 169(4):335

Sofi F et al (2008) Low vitamin B6 and folic acid levels are associated with retinal vein occlusion independently of homocysteine levels. Atherosclerosis 198(1):223–227

Axer-Siegel R et al (2004) Association of neovascular age-related macular degeneration and hyperhomocysteinemia. Am J Ophthalmol 137(1):84–89

Seddon JM et al (2006) Evaluation of plasma homocysteine and risk of age-related macular degeneration. Am J Ophthalmol 141(1):201–203

Seddon JM et al (2006) C-reactive protein and homocysteine are associated with dietary and behavioral risk factors for age-related macular degeneration. Nutrition 22(4):441–443

Malouf R, Evans JG (2003) Vitamin B6 for cognition. Cochrane Database of Syst Rev (4).

Seshadri S et al (2002) Plasma homocysteine as a risk factor for dementia and Alzheimer’s disease. N Engl J Med 346(7):476–483

Oulhaj A et al (2010) Homocysteine as a predictor of cognitive decline in Alzheimer’s disease. Int J Geriatr Psychiatry 25(1):82–90

Lin P-T et al (2006) Low pyridoxal 5′-phosphate is associated with increased risk of coronary artery disease. Nutrition 22(11–12):1146–1151

Vermeulen E et al (2004) Effect of homocysteine-lowering treatment with folic acid plus vitamin B6 on cerebrovascular atherosclerosis and white matter abnormalities as determined by MRA and MRI: a placebo-controlled, randomized trial. Eur J Clin Invest 34(4):256–261

Vermeulen EG et al (2000) Effect of homocysteine-lowering treatment with folic acid plus vitamin B6 on progression of subclinical atherosclerosis: a randomised, placebo-controlled trial. The Lancet 355(9203):517–522

Endo N et al (2006) Antioxidant activity of vitamin B6 delays homocysteine-induced atherosclerosis in rats. Br J Nutr 95(6):1088–1093

Bird RP (2018) The emerging role of vitamin B6 in inflammation and carcinogenesis. Adv Food Nutr Res 83:151–194

Ueland PM et al (2017) Inflammation, vitamin B6 and related pathways. Mol Aspects Med 53:10–27

Chiang E-PI et al (2003) Abnormal vitamin B6 status is associated with severity of symptoms in patients with rheumatoid arthritis. Am J Med 114(4):283–287

Chiang E-PI et al (2005) Pyridoxine supplementation corrects vitamin B6 deficiency but does not improve inflammation in patients with rheumatoid arthritis. Arthritis Res Ther 7(6):1–8

Woolf K, Manore MM (2008) Elevated plasma homocysteine and low vitamin B-6 status in nonsupplementing older women with rheumatoid arthritis. J Am Diet Assoc 108(3):443–453

Huang S et al (2010) Vitamin B 6 supplementation improves pro-inflammatory responses in patients with rheumatoid arthritis. Eur J Clin Nutr 64(9):1007–1013

Tabanlıgil Calam T (2021) A novel, efficient and sensitive method for the simultaneous determination of riboflavin (vitamin B2) and pyridoxine hydrochloride (vitamin B6) in food and pharmacological samples using an electrochemical sensor based on 4, 4'-diamino benzophenone

Katan M (2005) How much vitamin B6 is toxic? Ned Tijdschr Geneeskd 149(46):2545–2546

Spinneker A et al (2007) Vitamin B6 status, deficiency and its consequences-an overview. Nutr Hosp 22(1):7–24

Reddy YVM et al (2022) Strategies, advances, and challenges associated with the use of graphene-based nanocomposites for electrochemical biosensors. Advances in Colloid and Interface Science p. 102664.

Hareesha N, Manjunatha J (2020) Elevated and rapid voltammetric sensing of riboflavin at poly (helianthin dye) blended carbon paste electrode with heterogeneous rate constant elucidation. J Iran Chem Soc 17(6):1507–1519

Manjunatha J et al (2013) Simultaneous determination of ascorbic acid, dopamine and uric acid at poly (aniline blue) modified carbon paste electrode: a cyclic voltammetric study. Int J Pharm Pharm Sci 5(2):355–362

Tigari G, Manjunatha J (2019) Electrochemical preparation of poly (arginine)-modified carbon nanotube paste electrode and its application for the determination of pyridoxine in the presence of riboflavin: an electroanalytical approach. J Anal Test 3(4):331–340

Raril C, Manjunatha JG (2020) Fabrication of novel polymer-modified graphene-based electrochemical sensor for the determination of mercury and lead ions in water and biological samples. J Anal Sci Technol 11(1):1–10

Shetti NP et al (2020) Skin-patchable electrodes for biosensor applications: a review. ACS Biomater Sci Eng 6(4):1823–1835

Killedar L et al (2022) Fast and facile electrochemical detection and determination of fungicide carbendazim at titanium dioxide designed carbon-based sensor. Mater Chem Phys 285:126131

Prasad PS et al (2018) Determination of Vitamin-B6 by Vanadium (III) Schiff base complex modified GCE. Mater Today: Proceedings 5(2):9026–9032

Mekonnen A et al (2014) Square wave voltammetric determination of pyridoxine in pharmaceutical preparations using cobalthexacyanoferrate modified carbon paste electrode. J Chem Pharm Res 6(1):544–551

Baghizadeh A et al (2015) A voltammetric sensor for simultaneous determination of vitamin C and vitamin B 6 in food samples using ZrO 2 nanoparticle/ionic liquids carbon paste electrode. Food Anal Methods 8(3):549–557

Estelrich J et al (2015) Iron oxide nanoparticles for magnetically-guided and magnetically-responsive drug delivery. Int J Mol Sci 16(4):8070–8101

Lemire JA, Harrison JJ, Turner RJ (2013) Antimicrobial activity of metals: mechanisms, molecular targets and applications. Nat Rev Microbiol 11(6):371–384

Hareesha N, Manjunatha J (2020) Fast and enhanced electrochemical sensing of dopamine at cost-effective poly (DL-phenylalanine) based graphite electrode. J Electroanal Chem 878:114533

Manjunatha J (2020) A surfactant enhanced graphene paste electrode as an effective electrochemical sensor for the sensitive and simultaneous determination of catechol and resorcinol. Chem Data Collect 25:100331

Schwertmann U, Cornell RM (2008) Iron oxides in the laboratory: preparation and characterization. John Wiley & Sons.

Cornell RM and Schwertmann U (2003) The iron oxides: structure, properties, reactions, occurrences and uses. John Wiley & Sons.

Fernández-Remolar DC (2015) Iron oxides, hydroxides and oxy-hydroxides. Encyclopedia of astrobiology, p. 1268–1270

Cordova G et al (2017) Magnetic force microscopy characterization of superparamagnetic iron oxide nanoparticles (SPIONs). arXiv preprint arXiv:1704.08316

Hasany FS et al (2013) Magnetic iron oxide nanoparticles: chemical synthesis and applications review. Curr Nanosci 9(5):561–575

Xie J, Jon S (2012) Magnetic nanoparticle-based theranostics. Theranostics 2(1):122

Laurent S et al (2008) Magnetic iron oxide nanoparticles: synthesis, stabilization, vectorization, physicochemical characterizations, and biological applications. Chem Rev 108(6):2064–2110

Shetti NP et al (2018) Electrochemical behavior of thiosalicylic acid at γ-Fe2O3 nanoparticles and clay composite carbon electrode. Electrochim Acta 269:204–211

Pankhurst QA et al (2003) Applications of magnetic nanoparticles in biomedicine. J Phys D Appl Phys 36(13):R167

Shetti NP et al (2020) Hetero-nanostructured iron oxide and bentonite clay composite assembly for the determination of an antiviral drug acyclovir. Microchem J 155:104727

Atta NF, Galal A, Azab SM (2011) Electrochemical morphine sensing using gold nanoparticles modified carbon paste electrode. Int J Electrochem Sci 6:5066–5081

Fekry A (2010) Impedance and hydrogen evolution studies on magnesium alloy in oxalic acid solution containing different anions. Int J Hydrog Energy 35(23):12945–12951

Fekry A, Ameer M (2011) Electrochemical investigation on the corrosion and hydrogen evolution rate of mild steel in sulphuric acid solution. Int J Hydrog Energy 36(17):11207–11215

Fekry A et al (2015) A novel electrochemical nicotine sensor based on cerium nanoparticles with anionic surfactant. RSC Adv 5(64):51662–51671

Fekry AM (2017) A new simple electrochemical Moxifloxacin Hydrochloride sensor built on carbon paste modified with silver nanoparticles. Biosens Bioelectron 87:1065–1070

Fekry AM (2016) Electrochemical behavior of a novel nano-composite coat on Ti alloy in phosphate buffer solution for biomedical applications. RSC Adv 6(24):20276–20285

Abdelrahman E, Essa K (2015) Three least-squares minimization approaches to interpret gravity data due to dipping faults. Pure Appl Geophys 172(2):427–438

Abdelrahman E-SM, Abo-Ezz ER, Essa KS (2012) Parametric inversion of residual magnetic anomalies due to simple geometric bodies. Explor Geophys 43(3):178–189

Abo-Ezz E, Essa K (2016) A least-squares minimization approach for model parameters estimate by using a new magnetic anomaly formula. Pure Appl Geophys 173(4):1265–1278

Essa K, Mehanee S, Smith PD (2008) A new inversion algorithm for estimating the best fitting parameters of some geometrically simple body to measured self-potential anomalies. Explor Geophys 39(3):155–163

Essa KS, Elhussein M (2019) Magnetic interpretation utilizing a new inverse algorithm for assessing the parameters of buried inclined dike-like geological structure. Acta Geophysica, p. 1–12

Essa KS, Elhussein M (2017) A new approach for the interpretation of magnetic data by a 2-D dipping dike. J Appl Geophys 136:431–443

Bard AJ, Faulkner LR (2001) Fundamentals and applications. Electrochemical. Methods 2:482

Azab SM, Fekry AM (2017) Electrochemical design of a new nanosensor based on cobalt nanoparticles, chitosan and MWCNT for the determination of daclatasvir: a hepatitis C antiviral drug. RSC Adv 7(2):1118–1126

Pelossof G et al (2013) Controlling interfacial electron transfer and electrocatalysis by pH-or ion-switchable DNA monolayer-modified electrodes. Chem Sci 4(3):1137–1144

Brunetti B, Desimoni E (2014) Voltammetric determination of vitamin B6 in food samples and dietary supplements. J Food Compos Anal 33(2):155–160

Luan F et al (2018) CoS2-decorated ionic liquid-functionalized graphene as a novel hydrazine electrochemical sensor. Talanta 182:529–535

Shehata M, Fekry AM, Walcarius A (2020) Moxifloxacin hydrochloride electrochemical detection at gold nanoparticles modified screen-printed electrode. Sensors 20(10):2797

Hu Q et al (2001) Separation and determination of three water-soluble vitamins in pharmaceutical preparations and food by micellar electrokinetic chromatography with amperometric electrochemical detection. Anal Chim Acta 437(1):123–129

Gu H-Y, Yu A-M, Chen H-Y (2001) Electrochemical behavior and simultaneous determination of vitamin B2, B6, and C at electrochemically pretreated glassy carbon electrode. Anal Lett 34(13):2361–2374

Teixeira MF et al (2004) Voltammetric determination of pyridoxine (Vitamin B6) at a carbon paste electrode modified with vanadyl (IV)–Salen complex. Anal Chim Acta 508(1):79–85

David IG et al (2015) Voltammetric determination of B 1 and B 6 vitamins using a pencil graphite electrode. Chem Pap 69(7):901–910

Nie T et al (2013) Electroactive species-doped poly (3, 4-ethylenedioxythiophene) films: Enhanced sensitivity for electrochemical simultaneous determination of vitamins B2, B6 and C. Biosens Bioelectron 50:244–250

Markopoulou C, Kagkadis K, Koundourellis J (2002) An optimized method for the simultaneous determination of vitamins B1, B6, B12, in multivitamin tablets by high performance liquid chromatography. J Pharm Biomed Anal 30(4):1403–1410

Sonkar PK et al (2017) Highly dispersed multiwalled carbon nanotubes coupled manganese salen nanostructure for simultaneous electrochemical sensing of vitamin B2 and B6. J Electroanal Chem 807:235–243

Marszałł ML et al (2005) High-performance liquid chromatography method for the simultaneous determination of thiamine hydrochloride, pyridoxine hydrochloride and cyanocobalamin in pharmaceutical formulations using coulometric electrochemical and ultraviolet detection. J Chromatogr A 1094(1–2):91–98

Habibi B, Jahanbakhshi M, Abazari M (2014) A modified single-walled carbon nanotubes/carbon-ceramic electrode for simultaneous voltammetric determination of paracetamol and caffeine. J Iran Chem Soc 11(2):511–521

Cottica SM et al (2009) Voltammetric determination of pyridoxine (vitamin B6) in drugs using a glassy carbon electrode modified with chromium (III) hexacyanoferrate (II). J Braz Chem Soc 20:496–501

Wu Y-H, Song F-J (2008) Voltammetric Investigation of Vitamin B_6 at a Glassy Carbon Electrode and Its Application in Determination. Bull Korean Chem Soc 29(1):38–42

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Moustafa, A., El-Kamel, R.S., Abdelgawad, S. et al. Electrochemical determination of vitamin B6 (pyridoxine) by reformed carbon paste electrode with iron oxide nanoparticles. Ionics 28, 4471–4484 (2022). https://doi.org/10.1007/s11581-022-04673-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-022-04673-6