Abstract

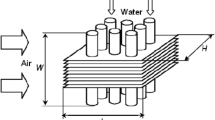

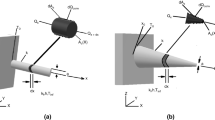

A heat dissipation model of a rectangular porous fin is established based on constructal theory. First, the constructal design of rectangular porous fin is conducted by selecting a complex function minimization, which composed of linear weighting sum of maximum temperature difference and pumping power consumption, as optimization objective. Effects of gap height, air inlet velocity, total porous fin volume and porosity on the optimal constructs are investigated, respectively. The findings show that the complex function can attain its double minimum at a value of 0.802 when the fin length and number are optimized, and the corresponding optimal fin length and number are 8.01 mm and 10, respectively. In comparison to original design, the complex function and maximum temperature difference after twice optimization are decreased by 19.80% and 66.31%, respectively. Second, the comprehensive performance of porous fin is improved by simultaneously optimizing the fin length and number. The artificial neural network is applied to predict the fin performances, which is used to conduct multi-objective optimization based on NSGA-II algorithm. Optimal structure of porous fin for multiple requirements is gained by LINMAP and TOPSIS decision-making strategies. The findings in this study can serve as theoretical guides for fin thermal designs of electronic devices.

Similar content being viewed by others

References

van Erp R, Soleimanzadeh R, Nela L, et al. Co-designing electronics with microfluidics for more sustainable cooling. Nature, 2020, 585: 211–216

Lohrasbi S, Hammer R, Essl W, et al. A comprehensive review on the core thermal management improvement concepts in power electronics. IEEE Access, 2020, 8: 166880–166906

Wang L, Xie Z H, Chen L G, et al. Equivalent thermal resistance minimization for a circular disc heat sink with reverting microchannels based on constructal theory and entransy theory. Sci China Tech Sci, 2021, 64: 111–121

Chen C, You J, Feng H J, et al. A multi-objective study on the constructal design of non-uniform heat generating disc cooled by radial- and dendritic-pattern cooling channels. Sci China Tech Sci, 2021, 64: 729–744

Yao X L, Shi Q L, Liu Q, et al. An investigation on application potentiality of microstructure heat sinks with different flow topological morphology. Sci China Tech Sci, 2022, 65: 2895–2909

Zhou J H, Chen X M, Li Q. Numerical study on two-phase boiling heat transfer performance of interrupted microchannel heat sinks. Sci China Tech Sci, 2022, 65: 679–692

Wang X Y, Xu X H, Liang X G. Enhancement of laminar flow heat transfer with single/double-inclined ribs for unilaterally-heated channel. Sci China Tech Sci, 2023, 66: 2108–2118

Yan K, Wang Y Y, Pan Y, et al. Topology optimization of simplified convective heat transfer problems using the finite volume method. Sci China Tech Sci, 2023, 66: 1352–1364

Cao X, Chen Y P. Design and numerical analysis of serpentine microchannel integrated with inner-wall ridges for enhanced droplet mixing. Sci China Tech Sci, 2023, 66: 560–573

Yang H X, Zhang G H, Dou B L, et al. The regulation mechanism and heat transfer enhancement of composite mixed paraffin and copper foam phase change materials. Sci China Tech Sci, 2023, 66: 2346–2360

Fang X Y, Nong X L, Liao Z R, et al. A novel preheating method for the Li-ion battery using supercooled phase change materials. Sci China Tech Sci, 2023, 66: 193–203

Fathi M, Heyhat M M, Zabetian Targhi M, et al. Porous-fin microchannel heat sinks for future micro-electronics cooling. Int J Heat Mass Transfer, 2023, 202: 123662

Kim S Y, Paek J W, Kang B H. Flow and heat transfer correlations for porous fin in a plate-fin heat exchanger. J Heat Transfer, 2000, 122: 572–578

Badruddin I A, Zainal Z A, Narayana P A A, et al. Heat transfer by radiation and natural convection through a vertical annulus embedded in porous medium. Int Commun Heat Mass Transfer, 2006, 33: 500–507

Naidu S V, Dharma Rao V, Sarma P K, et al. Performance of a circular fin in a cylindrical porous enclosure. Int Commun Heat Mass Transfer, 2004, 31: 1209–1218

Varol Y, Oztop H F, Varol A. Effects of thin fin on natural convection in porous triangular enclosures. Int J Thermal Sci, 2007, 46: 1033–1045

Makinde O D, Aziz A. MHD mixed convection from a vertical plate embedded in a porous medium with a convective boundary condition. Int J Thermal Sci, 2010, 49: 1813–1820

Taklifi A, Aghanajafi C, Akrami H. The effect of MHD on a porous fin attached to a vertical isothermal surface. Transp Porous Media, 2010, 85: 215–231

Gorla R S R, Bakier A Y. Thermal analysis of natural convection and radiation in porous fins. Int Commun Heat Mass Transfer, 2011, 38: 638–645

Kundu B, Bhanja D. An analytical prediction for performance and optimum design analysis of porous fins. Int J Refrig, 2011, 34: 337–352

Kundu B, Lee K S. A proper analytical analysis of annular step porous fins for determining maximum heat transfer. Energy Convers Manage, 2016, 110: 469–480

Sowmya G, Gireesha B J, Berrehal H. An unsteady thermal investigation of a wetted longitudinal porous fin of different profiles. J Therm Anal Calorim, 2021, 143: 2463–2474

Hosseinzadeh S, Hosseinzadeh K, Hasibi A, et al. Thermal analysis of moving porous fin wetted by hybrid nanofluid with trapezoidal, concave parabolic and convex cross sections. Case Stud Therm Eng, 2022, 30: 101757

Jain A, Abbas M M, Torabi M. Steady state thermal analysis of a porous fin with radially outwards fluid flow. Int J Heat Mass Transfer, 2023, 209: 124109

Hashemi A S, Heydari M, Loghmani G B. Iterative compact finite difference method for the numerical study of fully wet porous fins with different profile shapes. Appl Numer Math, 2023, 186: 358–377

Bejan A. Street network theory of organization in nature. J Adv Transport, 1996, 30: 85–107

Bejan A. Constructal-theory network of conducting paths for cooling a heat generating volume. Int J Heat Mass Transfer, 1997, 40: 799–816

Bejan A. Shape and structure, from engineering to nature. Entropy, 2001, 3: 293–294

Lorenzini G, Moretti S, Conti A. Fin Shape Thermal Optimization Using Bejan’s Constructal Theory. San Francisco: Morgan & Claypool Publishers, 2011

Chen L G. Progress in study on constructal theory and its applications. Sci China Tech Sci, 2012, 55: 802–820

Chen L, Feng H, Xie Z, et al. Progress of constructal theory in China over the past decade. Int J Heat Mass Transfer, 2019, 130: 393–419

Chen L G, Yang A B, Feng H J, et al. Constructal design progress for eight types of heat sinks. Sci China Tech Sci, 2020, 63: 879–911

Chen L G, Wu W J, Feng H J. Constructal Design for Heat Conduction. London: Book Publisher International, 2021

Bejan A. Heat Transfer: Evolution, Design and Performance. New York: John Wiley & Sons, 2022

Feng H, Chen L, Ge Y. Constructal optimization of a rectangular non-uniform heat generation area with irregular high thermal conductivity material. Case Studies Thermal Eng, 2023, 49: 103403

Bejan A. Constructal design evolution versus topology optimization. Int Commun Heat Mass Transfer, 2023, 141: 106567

Almogbel M, Bejan A. Cylindrical trees of pin fins. Int J Heat Mass Transfer, 2000, 43: 4285–4297

Lorenzini G, Rocha L A O. Constructal design of T-Y assembly of fins for an optimized heat removal. Int J Heat Mass Transfer, 2009, 52: 1458–1463

Bello-Ochende T, Meyer J P, Bejan A. Constructal multi-scale pin-fins. Int J Heat Mass Transfer, 2010, 53: 2773–2779

Lorenzini G, Corrêa R L, Domingues dos Santos E, et al. Constructal design of complex assembly of fins. J Heat Transfer, 2011, 133: 081902

Hajmohammadi M R, Poozesh S, Nourazar S S. Constructal design of multiple heat sources in a square-shaped fin. J Process Mech Eng, 2012, 226: 324–336

Chen L, Yang A, Xie Z, et al. Constructal entropy generation rate minimization for cylindrical pin-fin heat sinks. Int J Thermal Sci, 2017, 111: 168–174

Cong R, Ozaki Y, Machado B, et al. Constructal design of a rectangular fin in a mixed convective confined environment. Inventions, 2018, 3: 27

Barik A K, Swain P K. Constructal invasion of fins for melting time prediction of a phase change material in a triplex-tube heat exchanger. J Energy Storage, 2022, 54: 105281

Ahmed H H, Bhanja D, Nath S. Computational study to predict the thermal performance and optimal design parameters of a T-shaped fin subjected to natural convection. J Process Mech Eng, 2023, 237: 1235–1248

Hajabdollahi H, Shafiey Dehaj M, Masoumpour B, et al. Optimal design analysis of a tubular heat exchanger network with extended surfaces using multi-objective constructal optimization. Front Energy, 2023, 16: 862–875

Bhanja D, Kundu B. Heat transfer and fin performance comparison between constructal T-shaped porous and solid fin. AIP Conf Proc, 2010, 1298: 122–128

Bhanja D, Kundu B. Thermal analysis of a constructal T-shaped porous fin with radiation effects. Int J Refrig, 2011, 34: 1483–1496

Hazarika S A, Deshamukhya T, Bhanja D, et al. Thermal analysis of a constructal T-shaped porous fin with simultaneous heat and mass transfer. Chin J Chem Eng, 2017, 25: 1121–1136

Li F, Zhu W, He H. Numerical optimization on microchannel flow and heat transfer performance based on field synergy principle. Int J Heat Mass Transfer, 2019, 130: 375–385

Li F, Ma Q, Xin G, et al. Heat transfer and flow characteristics of microchannels with solid and porous ribs. Appl Thermal Eng, 2020, 178: 115639

Gulotta T, Guarino F, Cellura M, et al. Constructal law optimization of a boiler. Int J Heat Tech, 2017, 35: 297–305

Feng H, Chen L, Xie Z, et al. Multi-objective constructal design for a marine boiler considering entropy generation rate and power consumption. Energy Rep, 2022, 8: 1519–1527

Feng H, Zhang Z, Chen L, et al. Constructal design for tree-shaped compound heat transfer channel in a disc heat generation body. Int Commun Heat Mass Transfer, 2022, 132: 105929

Feng H, Sun K, Chen L, et al. Constructal design of a nanofluid cooling channel with sidewall ribs and cavities in a rectangular heat generation body. Case Stud Thermal Eng, 2023, 41: 102640

Wang J, Sun Z, Dai Y, et al. Parametric optimization design for supercritical CO2 power cycle using genetic algorithm and artificial neural network. Appl Energy, 2010, 87: 1317–1324

Rashidi M M, Galanis N, Nazari F, et al. Parametric analysis and optimization of regenerative Clausius and organic Rankine cycles with two feedwater heaters using artificial bees colony and artificial neural network. Energy, 2011, 36: 5728–5740

Lee H, Kang M, Jung K W, et al. An artificial neural network model for predicting frictional pressure drop in micro-pin fin heat sink. Appl Thermal Eng, 2021, 194: 117012

Polat M E, Cadirci S. Artificial neural network model and multi-objective optimization of microchannel heat sinks with diamond-shaped pin fins. Int J Heat Mass Transfer, 2022, 194: 123015

Shi S, Ge Y, Chen L, et al. Performance optimizations with single-, bi-, tri-, and quadru-objective for irreversible atkinson cycle with nonlinear variation of working fluid’s specific heat. Energies, 2021, 14: 4175

Yu C, Zhu X, Li Z, et al. Optimization of elliptical pin-fin microchannel heat sink based on artificial neural network. Int J Heat Mass Transfer, 2023, 205: 123928

Deb K, Pratap A, Agarwal S, et al. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Computat, 2002, 6: 182–197

Zhang L, Chen L, Xia S, et al. Multi-objective optimization for helium-heated reverse water gas shift reactor by using NSGA-II. Int J Heat Mass Transfer, 2020, 148: 119025

Tang C, Chen L, Feng H, et al. Four-objective optimizations for an improved irreversible closed modified simple brayton cycle. Entropy, 2021, 23: 282

Chen L G, Li P L, Xia S J, et al. Multi-objective optimization for membrane reactor for steam methane reforming heated by molten salt. Sci China Tech Sci, 2022, 65: 1396–1414

Zang P, Ge Y, Chen L, et al. Power density characteristic analysis and multi-objective optimization of an irreversible porous medium engine cycle. Case Studies Thermal Eng, 2022, 35: 102154

Li P, Chen L, Xia S, et al. Multi-objective optimal configurations of a membrane reactor for steam methane reforming. Energy Rep, 2022, 8: 527–538

Ge Y, Shi S, Chen L, et al. Power density analysis and multi-objective optimization for an irreversible dual cycle. J Non-Equilibr Thermodyn, 2022, 47: 289–309

Xu H, Chen L, Ge Y, et al. Multi-objective optimization of Stirling heat engine with various heat and mechanical losses. Energy, 2022, 256: 124699

Zhu H, Chen L, Ge Y, et al. Multi-objective constructal design for quadrilateral heat generation body with vein-shaped high thermal conductivity channel. Entropy, 2022, 24: 1403

Zhu H, Chen L, Ge Y, et al. Multi-objective constructal design for square heat-generation body with “arrow-shaped” high-thermal-conductivity channel. Energies, 2022, 15: 5235

Jin Q, Xia S J, Li P L, et al. Multi-objective performance optimization of regenerative S−CO2 Brayton cycle based on neural network prediction. Energy Convers Manage, 2022, 14: 100203

Yang W, Feng H, Chen L, et al. Power and efficiency optimizations of a simple irreversible supercritical organic Rankine cycle. Energy, 2023, 278: 127755

Chen X, Li X, Pan M, et al. Superstructure-free synthesis and multi-objective optimization of supercritical CO2 cycles. Energy Convers Manage, 2023, 284: 116966

Jaiswal A K, Afzal A. Design optimization of prismatic rib turbulators in a rectangular channel based on multi-objective criterion. Int J Thermal Sci, 2023, 185: 108091

Wang D, Zhang H, Wang G, et al. Experimental and numerical study on the heat transfer and flow characteristics of convex plate heat exchanger based on multi-objective optimization. Int J Heat Mass Transfer, 2023, 202: 123755

Wang W D, Wang W Q, Yang C, et al. A multi-objective power flow optimization control strategy for a power split plug-in hybrid electric vehicle using game theory. Sci China Tech Sci, 2021, 64: 2718–2728

Han H G, Zhang L L, Hou Y, et al. Adaptive candidate estimation-assisted multi-objective particle swarm optimization. Sci China Tech Sci, 2022, 65: 1685–1699

Mohtaram S, Wu W D, Aryanfar Y, et al. Multi-objective evolutionary optimization and thermodynamics performance assessment of a novel time-dependent solar Li-Br absorption refrigeration cycle. Sci China Tech Sci, 2022, 65: 2703–2722

Liu T X, Zheng Z M, Qin Y L, et al. New operation strategy and multi-objective optimization of hybrid solar-fuel CCHP system with fuel thermochemical conversion and source-loads matching. Sci China Tech Sci, 2023, 66: 528–547

Tang W, Feng H, Chen L, et al. Constructal design for a boiler economizer. Energy, 2021, 223: 120013

Chen L, Shi S, Ge Y, et al. Ecological function performance analysis and multi-objective optimization for an endoreversible four-reservoir chemical pump. Energy, 2023, 282: 128717

Chen L, Shi S, Ge Y, et al. Power density performances and multi-objective optimizations for an irreversible Otto cycle with five specific heat models of working fluid. Energy, 2023, 282: 128817

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant No. 52171317) and Graduate Innovative Fund of Wuhan Institute of Technology (Grant No. CX2022070).

Rights and permissions

About this article

Cite this article

Liu, X., Feng, H., Chen, L. et al. Constructal design of a rectangular porous fin considering minimization of maximum temperature difference and pumping power consumption. Sci. China Technol. Sci. 67, 919–929 (2024). https://doi.org/10.1007/s11431-023-2495-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-023-2495-y