Abstract

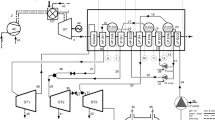

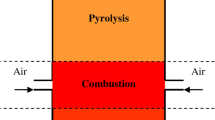

A membrane reactor for steam methane reforming heated by molten salt (MS-SMRMR) is studied based on finite time thermodynamics for decreasing carbon emissions and improving hydrogen production rate (HPR). Effects of flow directions of sweep gas and molten salt on MS-SMRMR are researched. Profiles of temperatures, HPR, and local entropy generation rates (EGRs) of MS-SMRMR are analyzed. Hybrid particle swarm optimization algorithm is utilized to obtain the minimum of specific EGR (SEGR), ratio of EGR to HPR. Multi-objective optimization about HPR maximization and EGR minimization is performed by utilizing NSGA-II. The EGR caused by the mass transfer process is the largest among all irreversible processes in the MS-SMRMR. The membrane length should be slightly shorter than the reactor length when the flow direction of sweep gas is different from that of reaction mixture. When flow directions of molten salt and sweep gas are opposite to that of reaction mixture, SEGR is the smallest. Compared with SEGR calculated by utilizing initial parameters, SEGRs after primary, twice and triple optimizations reduce by 1.2%, 5.5% and 5.7%, respectively. SEGR can be further decreased by adjusting other operating parameters. Pareto front provides many optimization results, and it contains SEGR minimization. In Pareto front, an optimum decision point is obtained based on decision-making of TOPSIS, and its EGR and HPR, respectively, increase by 7.12% and 13.24%, compared with those obtained by using initial parameters. The results have certain theoretical guiding significance for optimization designs of MS-SMRMR.

Similar content being viewed by others

References

Gao L, Li S, Jin H G, et al. Possible energy network with poly-generation system and CCS for China. Sci China Tech Sci, 2010, 53: 33–39

Guo L J, Jin H, Ge Z W, et al. Industrialization prospects for hydrogen production by coal gasification in supercritical water and novel thermodynamic cycle power generation system with no pollution emission. Sci China Tech Sci, 2015, 58: 1989–2002

Trenchev G, Nikiforov A, Wang W, et al. Atmospheric pressure glow discharge for CO2 conversion: Model-based exploration of the optimum reactor configuration. Chem Eng J, 2019, 362: 830–841

Olah G A, Goeppert A, Prakash G K S. Beyond Oil and Gas: The Methanol Economy. 2nd ed. Weinheim: Wiley-VCH, 2006

Shih C F, Zhang T, Li J H, et al. Powering the future with liquid sunshine. Joule, 2018, 2: 1925–1949

Saeidi S, Fazlollahi F, Najari S, et al. Hydrogen production: Perspectives, separation with special emphasis on kinetics of WGS reaction: A state-of-the-art review. J Ind Eng Chem, 2017, 49: 1–25

Saebea D, Authayanun S, Patcharavorachot Y. Performance analysis of direct steam reforming of methane in SOFC with SDC-based electrolyte. Energy Rep, 2020, 6: 391–396

Forutan H R, Karimi E, Hafizi A, et al. Expert representation chemical looping reforming: A comparative study of Fe, Mn, Co and Cu as oxygen carriers supported on Al2O3. J Ind Eng Chem, 2015, 21: 900–911

Nasr M, Tawfik A, Ookawara S, et al. Continuous biohydrogen production from starch wastewater via sequential dark-photo fermentation with emphasize on maghemite nanoparticles. J Ind Eng Chem, 2015, 21: 500–506

Lee S, Lim H. The effect of changing the number of membranes in methane carbon dioxide reforming: A CFD study. J Ind Eng Chem, 2020, 87: 110–119

Barnoon P, Toghraie D, Mehmandoust B, et al. Comprehensive study on hydrogen production via propane steam reforming inside a reactor. Energy Rep, 2021, 7: 929–941

Hajjaji N, Pons M N, Houas A, et al. Exergy analysis: An efficient tool for understanding and improving hydrogen production via the steam methane reforming process. Energy Policy, 2012, 42: 392–399

Likkasit C, Maroufmashat A, Elkamel A, et al. Solar-aided hydrogen production methods for the integration of renewable energies into oil & gas industries. Energy Convers Manage, 2018, 168: 395–406

Giaconia A, de Falco M, Caputo G, et al. Solar steam reforming of natural gas for hydrogen production using molten salt heat carriers. AIChE J, 2008, 54: 1932–1944

De Falco M, Caputo G, Frattari S, et al. Solar steam reforming for enriched methane production: Reactor configurations modeling and comparison. Int J Hydrogen Energy, 2014, 39: 13979–13990

Li P L, Chen L G, Xia S J, et al. Entropy generation rate and hydrogen production rate analyses for steam methane reforming reactor heated by molten salt (in Chinese). Power Gener Technol, 2020, 41: 415–428

Li P, Chen L, Xia S, et al. Entropy generation rate minimization for steam methane reforming reactor heated by molten salt. Energy Rep, 2020, 6: 685–697

Uemiya S, Sato N, Ando H, et al. Steam reforming of methane in a hydrogen-permeable membrane reactor. Appl Catal, 1991, 67: 223–230

Gallucci F, Paturzo L, Famà A, et al. Experimental study of the methane steam reforming reaction in a dense Pd/Ag membrane reactor. Ind Eng Chem Res, 2004, 43: 928–933

De Falco M, Di Paola L, Marrelli L. Heat transfer and hydrogen permeability in modelling industrial membrane reactors for methane steam reforming. Int J Hydrogen Energy, 2007, 32: 2902–2913

Chen Y M, Zhao Y C, Zhang J Y, et al. Hydrogen production through CO2 sorption-enhanced methane steam reforming: Comparison between different adsorbents. Sci China Tech Sci, 2011, 54: 2999–3008

Anzelmo B, Liguori S, Mardilovich I, et al. Fabrication & performance study of a palladium on alumina supported membrane reactor: Natural gas steam reforming, a case study. Int J Hydrogen Energy, 2018, 43: 7713–7721

Lutz A, Bradshaw R, Keller J, et al. Thermodynamic analysis of hydrogen production by steam reforming. Int J Hydrogen Energy, 2003, 28: 159–167

Özkara-Aydınoğlu Ş. Thermodynamic equilibrium analysis of combined carbon dioxide reforming with steam reforming of methane to synthesis gas. Int J Hydrogen Energy, 2010, 35: 12821–12828

Pashchenko D. First law energy analysis of thermochemical waste-heat recuperation by steam methane reforming. Energy, 2018, 143: 478–487

Andresen B, Berry R S, Nitzan A, et al. Thermodynamics in finite time. I. The step-Carnot cycle. Phys Rev A, 1977, 15: 2086–2093

Salamon P, Andresen B, Berry R S. Thermodynamics in finite time. II. Potentials for finite-time processes. Phys Rev A, 1977, 15: 2094–2102

Andresen B, Berry R S, Ondrechen M J, et al. Thermodynamics for processes in finite time. Acc Chem Res, 1984, 17: 266–271

Chen L G, Wu C, Sun F R. Finite time thermodynamic optimization or entropy generation minimization of energy systems. J Non-Equil Thermody, 1999, 24: 327–359

Chen L G, Sun F R. Advances in Finite Time Thermodynamics: Analysis and Optimization. New York: Nova Science Publishers, 2004

Shu L W, Chen L G, Sun F R, et al. Thermodynamic optimization of distillation, separation, drying and reaction processes and devices: The state of the arts. Int J Energy Environ Econ, 2006, 12: 203–214

Berry R S, Salamon P, Andresen B. How it all began. Entropy, 2020, 22: 908

Chen L G, Li J. Thermodynamic Optimization Theory for Two-Heat-Reservoir Cycles (in Chinese). Beijing: Science Press, 2020

Chen L G, Ma K, Feng H J, et al. Optimal configuration of a gas expansion process in a piston-type cylinder with generalized convective heat transfer law. Energies, 2020, 13: 3229

Chen L G, Ma K, Ge Y L, et al. Re-optimization of expansion work of a heated working fluid with generalized radiative heat transfer law. Entropy, 2020, 22: 720

Chen L G, Meng F K, Ge Y L, et al. Performance optimization of a class of combined thermoelectric heating devices. Sci China Tech Sci, 2020, 63: 2640–2648

Chen L G, Wang C, Zhang L, et al. Progress in thermodynamic analyses and optimizations for key component units in sea-based fuel synthesis systems (in Chinese). Sci Sin Tech, 2021, 51: 137–175

Chen L G, Wang C, Zhang L, et al. Thermodynamic Optimization Theory for Key Component Units in Sea-Based Fuel Synthesis System (in Chinese). Beijing: Science Press, 2022

Qiu S S, Ding Z M, Chen L G, et al. Performance optimization of thermionic refrigerators based on van der Waals heterostructures. Sci China Tech Sci, 2021, 64: 1007–1016

Qiu S S, Ding Z M, Chen L G, et al. Performance optimization of three-terminal energy selective electron generators. Sci China Tech Sci, 2021, 64: 1641–1652

Bejan A. Entropy Generation Through Heat and Fluid Flow. New York: Wiley, 1982

Bejan A. Entropy Generation Minimization. Boca Raton: CRC Press, 1996

Bejan A. Entropy generation minimization, exergy analysis, and the constructal law. Arab J Sci Eng, 2013, 38: 329–340

Sciacovelli A, Verda V, Sciubba E. Entropy generation analysis as a design tool—A review. Renew Sustain Energy Rev, 2015, 43: 1167–1181

Avellaneda J M, Bataille F, Toutant A, et al. Entropy generation minimization in a channel flow: Application to different advection-diffusion processes and boundary conditions. Chem Eng Sci, 2020, 220: 115601

Kingston D, Wilhelmsen Ø, Kjelstrup S. Minimum entropy production in a distillation column for air separation described by a continuous non-equilibrium model. Chem Eng Sci, 2020, 218: 115539

Månsson B, Andresen B. Optimal temperature profile for an ammonia reactor. Ind Eng Chem Proc Des Dev, 1986, 25: 59–65

Pantoleontos G, Kikkinides E S, Georgiadis M C. A heterogeneous dynamic model for the simulation and optimisation of the steam methane reforming reactor. Int J Hydrogen Energy, 2012, 37: 16346–16358

Li P L, Chen L G, Xia S J, et al. Maximum hydrogen production rate optimization for tubular steam methane reforming reactor. Int J Chem Reactor Eng, 2019, 17: 20180191

Jahanmiri A, Eslamloueyan R. Optimal temperature profile in methanol synthesis reactor. Chem Eng Commun, 2002, 189: 713–741

Wang C, Chen L G, Xia S J, et al. Maximum production rate optimization for sulphuric acid decomposition process in tubular plug-flow reactor. Energy, 2016, 99: 152–158

Nummedal L, Kjelstrup S, Costea M. Minimizing the entropy production rate of an exothermic reactor with a constant heat-transfer coefficient: The ammonia reaction. Ind Eng Chem Res, 2003, 42: 1044–1056

Li P L, Chen L G, Xia S J, et al. Entropy generation rate minimization for methanol synthesis via a CO2 hydrogenation reactor. Entropy, 2019, 21: 174

Li P L, Chen L G, Xia S J, et al. Total entropy generation rate minimization configuration of a membrane reactor of methanol synthesis via carbon dioxide hydrogenation. Sci China Tech Sci, 2022, 65: 657–678

Iwakiri I G I, Miguel C V, Madeira L M. Modeling and simulation of a steam-selective membrane reactor for power-to-methanol. Comput Chem Eng, 2022, 156: 107555

Johannessen E, Kjelstrup S. Minimum entropy production rate in plug flow reactors: An optimal control problem solved for SO2 oxidation. Energy, 2004, 29: 2403–2423

Nummedal L, Røsjorde A, Johannessen E, et al. Second law optimization of a tubular steam reformer. Chem Eng Processing-Process Intensification, 2005, 44: 429–440

Wilhelmsen Ø, Johannessen E, Kjelstrup S. Energy efficient reactor design simplified by second law analysis. Int J Hydrogen Energy, 2010, 35: 13219–13231

Ao C Y, Xia S J, Song H J, et al. Entropy generation minimization of steam methane reforming reactor with linear phenomenological heat transfer law (in Chinese). Sci Sin Tech, 2018, 48: 25–38

Li P L, Chen L G, Xia S J, et al. Thermodynamic optimization for membrane reactor of steam methane reforming heated by molten salt (in Chinese). J Eng Thermophys, 2021, 42: 1363–1369

Li P L, Chen L G, Xia S J, et al. Multi-objective optimal configurations of a membrane reactor for steam methane reforming. Energy Rep, 2022, 8: 527–538

Kingston D, Razzitte A C. Entropy generation minimization in dimethyl ether synthesis: A case study. J Non-Equil Thermody, 2018, 43: 111–120

Zhang L, Chen L G, Xia S J, et al. Entropy generation minimization for reverse water gas shift (RWGS) reactors. Entropy, 2018, 20: 415

Zhang L, Xia S J, Chen L G, et al. Entropy generation rate minimization for hydrocarbon synthesis reactor from carbon dioxide and hydrogen. Int J Heat Mass Transfer, 2019, 137: 1112–1123

Sun M, Xia S J, Chen L G, et al. Minimum entropy generation rate and maximum yield optimization of sulfuric acid decomposition process using NSGA-II. Entropy, 2020, 22: 1065

Kong R, Chen L G, Xia S J, et al. Entropy generation rate minimization for sulfur trioxide decomposition membrane reactor. Energy Rep, 2022, 8: 1483–1496

Kong R, Chen L G, Xia S J, et al. Minimization of entropy generation rate during hydrogen iodide decomposition reaction process (in Chinese). Sci Sin Tech, 2021, 51: 565–579

Kong R, Chen L G, Xia S J, et al. Performance analysis of hydrogen iodide decomposition membrane reactor under different sweep modes. Energy Convers Manage, 2021, 244: 114436

Kong R, Chen L G, Xia S J, et al. Minimization of entropy generation rate in hydrogen iodide decomposition reactor heated by high-temperature helium. Entropy, 2021, 23: 82

Kong R, Chen L G, Xia S J, et al. Optimal configuration of hydrogen iodide decomposition membrane reactor based on minimum entropy generation rate (in Chinese). J Eng Thermophys, 2021, 42: 1637–1644

Khademi M H, Alipour-Dehkordi A, Tabesh M. Optimal design of methane tri-reforming reactor to produce proper syngas for Fischer-Tropsch and methanol synthesis processes: A comparative analysis between different side-feeding strategies. Int J Hydrogen Energy, 2021, 46: 14441–14454

van der Ham L V, Gross J, Kjelstrup S. Two performance indicators for the characterization of the entropy production in a process unit. Energy, 2011, 36: 3727–3732

Chen L G, Zhang L, Xia S J, et al. Entropy generation minimization for CO2 hydrogenation to light olefins. Energy, 2018, 147: 187–196

Cao X P, Jia S K, Luo Y Q, et al. Multi-objective optimization method for enhancing chemical reaction process. Chem Eng Sci, 2019, 195: 494–506

Zhang Y Z, He N E, Masuku C M, et al. A multi-objective reactive distillation optimization model for Fischer-Tropsch synthesis. Comput Chem Eng, 2020, 135: 106754

Deb K, Pratap A, Agarwal S, et al. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Computat, 2002, 6: 182–197

Wang J F, Yan Z Q, Wang M, et al. Multi-objective optimization of an organic Rankine cycle (ORC) for low grade waste heat recovery using evolutionary algorithm. Energy Convers Manage, 2013, 71: 146–158

Shahhosseini H R, Farsi M, Eini S. Multi-objective optimization of industrial membrane SMR to produce syngas for Fischer-Tropsch production using NSGA-II and decision makings. J Nat Gas Sci Eng, 2016, 32: 222–238

Zhang L, Chen L G, Xia S J, et al. Multi-objective optimization for helium-heated reverse water gas shift reactor by using NSGA-II. Int J Heat Mass Transfer, 2020, 148: 119025

Shi S S, Ge Y L, Chen L G, et al. Four-objective optimization of irreversible Atkinson cycle based on NSGA-II. Entropy, 2020, 22: 1150

Zhang Z M, Feng H J, Chen L G, et al. Multi-objective constructal design for compound heat dissipation channels in a three-dimensional trapezoidal heat generation body. Int Commun Heat Mass Transfer, 2021, 127: 105584

Feng H J, Tang W, Chen L G, et al. Multi-objective constructal optimization for marine condensers. Energies, 2021, 14: 5545

Bayat M, Garmroodi Asil A. Robust multi-objective optimization of methanol steam reforming for boosting hydrogen production. Int J Hydrogen Energy, 2021, 46: 29795–29811

Tang C Q, Chen L G, Feng H J, et al. Four-objective optimizations for an improved irreversible closed modified simple Brayton cycle. Entropy, 2021, 23: 282

Chen C, You J, Feng H J, et al. A multi-objective study on the constructal design of non-uniform heat generating disc cooled by radial- and dendritic-pattern cooling channels. Sci China Tech Sci, 2021, 64: 729–744

Shi S S, Chen L G, Ge Y L, et al. Performance optimizations with single-, bi-, tri-, and quadru-objective for irreversible diesel cycle. Entropy, 2021, 23: 826

Shi S S, Ge Y L, Chen L G, et al. Performance optimizations with single-, bi-, tri-, and quadru-objective for irreversible Atkinson cycle with nonlinear variation of working fluid’s specific heat. Energies, 2021, 14: 4175

Gong Q R, Ge Y L, Chen L G, et al. Performance analysis and four-objective optimization of an irreversible rectangular cycle. Entropy, 2021, 23: 1203

Xie T C, Xia S J, Wang C. Multi-objective optimization of Brauntype exothermic reactor for ammonia synthesis. Entropy, 2022, 24: 52

Park S, Na J, Kim M, et al. Multi-objective Bayesian optimization of chemical reactor design using computational fluid dynamics. Comput Chem Eng, 2018, 119: 25–37

Cai L, He T Z, Xiang Y L, et al. Study on the reaction pathways of steam methane reforming for H2 production. Energy, 2020, 207: 118296

Xu J G, Froment G F. Methane steam reforming, methanation and water-gas shift: I. Intrinsic kinetics. AIChE J, 1989, 35: 88–96

Xu J G, Froment G F. Methane steam reforming: II. Diffusional limitations and reactor simulation. AIChE J, 1989, 35: 97–103

Yaws C L. Chemical Properties Handbook. New York: McGraw-Hill, 1999

Pushnov A S. Calculation of average bed porosity. Chem Pet Eng, 2006, 42: 14–17

Hicks R E. Pressure drop in packed beds of spheres. Ind Eng Chem Fund, 1970, 9: 500–502

Silva J D, de Abreu C A M. Modelling and simulation in conventional fixed-bed and fixed-bed membrane reactors for the steam reforming of methane. Int J Hydrogen Energy, 2016, 41: 11660–11674

Cruz B M, da Silva J D. A two-dimensional mathematical model for the catalytic steam reforming of methane in both conventional fixed-bed and fixed-bed membrane reactors for the production of hydrogen. Int J Hydrogen Energy, 2017, 42: 23670–23690

de Medeiros J P F, da Fonseca Dias V, da Silva J M, et al. Ther-mochemical performance analysis of the steam reforming of methane in a fixed bed membrane reformer: A modelling and simulation study. Membranes, 2021, 11: 6

Zavoico B A. Solar power tower design basis document, revision 0. Technical Report. San Francisco: Sandia National Laboratories, 2001

Shu J, Grandjean B P A, Kaliaguine S. Methane steam reforming in asymmetric Pd- and Pd-Ag/porous SS membrane reactors. Appl Catal A-General, 1994, 119: 305–325

Gallucci F, Comite A, Capannelli G, et al. Steam reforming of methane in a membrane reactor: An industrial case study. Ind Eng Chem Res, 2006, 45: 2994–3000

Prabhu A K, Liu A, Lovell L G, et al. Modeling of the methane reforming reaction in hydrogen selective membrane reactors. J Membrane Sci, 2000, 177: 83–95

Gnielinski V. Heat transfer coefficients for turbulent flow in concentric annular ducts. Heat Transfer Eng, 2009, 30: 431–436

Summers W A, Shah Y T, Klinzing G E. Heat-transfer parameters for an annular packed bed. Ind Eng Chem Res, 1989, 28: 611–618

Dixon A G. An improved equation for the overall heat transfer coefficient in packed beds. Chem Eng Process, 1996, 35: 323–331

de Wasch A P, Froment G F. Heat transfer in packed beds. Chem Eng Sci, 1972, 27: 567–576

Kunii D, Smith J M. Heat transfer characteristics of porous rocks. AIChE J, 1960, 6: 71–78

Yagi S, Kunii D. Studies on effective thermal conductivities in packed beds. AIChE J, 1957, 3: 373–381

Jess A, Wasserscheid P. Chemical Technology: An Integral Textbook. Weinheim: Wiley-VCH, 2013

De Falco M, Di Paola L, Marrelli L, et al. Simulation of large-scale membrane reformers by a two-dimensional model. Chem Eng J, 2007, 128: 115–125

Magnanelli E, Wilhelmsen Ø, Johannessen E, et al. Energy efficient design of membrane processes by use of entropy production minimization. Comput Chem Eng, 2018, 117: 105–116

Baek S M, Kang J H, Lee K J, et al. A numerical study of the effectiveness factors of nickel catalyst pellets used in steam methane reforming for residential fuel cell applications. Int J Hydrogen Energy, 2014, 39: 9180–9192

Murmura M A, Cerbelli S, Annesini M C. Transport-reaction-permeation regimes in catalytic membrane reactors for hydrogen production. The steam reforming of methane as a case study. Chem Eng Sci, 2017, 162: 88–103

Murmura M A, Cerbelli S, Annesini M C. Modeling fixed bed membrane reactors for hydrogen production through steam reforming reactions: A critical analysis. Membranes, 2018, 8: 34

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51976235 and 51606218), the Hubei Province Natural Science Foundation of China (Grant No. 2018CFB708), and the Self-Topic Project of Naval University of Engineering (Grant No. 20161504). The authors wish to thank the reviewers for their careful, unbiased and constructive suggestions, which led to this revised manuscript.

Rights and permissions

About this article

Cite this article

Chen, L., Li, P., Xia, S. et al. Multi-objective optimization for membrane reactor for steam methane reforming heated by molten salt. Sci. China Technol. Sci. 65, 1396–1414 (2022). https://doi.org/10.1007/s11431-021-2003-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-021-2003-0