Abstract

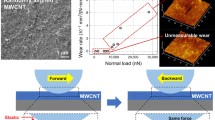

We describe a direct atomic layer deposition method to grow lubricant tungsten disulfide (WS2) films. The WS2 films were deposited on a Si (100) substrate and a zinc sulfide (ZnS) film coated the Si (100) substrate using tungsten hexacarbonyl and hydrogen sulfide as precursors. The ZnS film served as an intermediate layer to facilitate the nucleation and growth of the WS2 films. The thickness of the WS2 films was measured via scanning electron microscope, the microstructure was probed with an X-ray diffractometer and a transmission electron microscope. The friction coefficient was measured with a ball-on-disk tester under dry nitrogen. The results reveal that the WS2 films deposited on both substrates are ~175 nm and have (002) and (101) crystal orientations. The WS2 film deposited on the ZnS coated Si substrate exhibits a stronger (002) orientation and a denser crystal structure than that deposited on the Si substrate. The WS2 films on both substrates have low friction coefficients. However, due to the stronger (002) orientation and denser crystal structure, the friction coefficient of the WS2 film deposited on ZnS coated Si substrate is smaller with longer wear life.

Similar content being viewed by others

References

Sarkar D, Xie X, Liu W, et al. A subthermionic tunnel field-effect transistor with an atomically thin channel. Nature, 2015, 526: 91–95

Zhang K, Hu S, Zhang Y, et al. Self-induced uniaxial strain in WS2 monolayers with local van der Waals-stacked interlayer interactions. ACS Nano, 2015, 9: 2704–2710

Hwang H, Kim H, Cho J. WS2 nanoplates consisting of disordered graphene-like layers for high rate lithium battery anode materials. Nano Lett, 2011, 11: 4826–4830

Nandi D K, Sen U K, Dhara A, et al. Intercalation based tungsten disulfide (WS2) Li-ion battery anode grown by atomic layer deposition. Rsc Adv, 2016, 6: 38024–38032

Steinmann M, Muller A, Meerkamm H. A new type of tribological coating for machine elements based on carbon, molybdenum disulphide and titanium diboride. Tribol Int, 2004, 37: 879–885

Ho W K, Yu J C, Lin J, et al. Preparation and photocatalytic behavior of WS2 and WS2 nanocluster sensitized TiO2. Langmuir, 2004, 20: 5865–5869

Xu Y, Hu E, Hu K, et al. Formation of an adsorption film of WS2 nanoparticles and dioctyl sebacate on a steel surface for alleviating friction and wear. Tribol Int, 2015, 92: 172–183

Huang H D, Tu J P, Gan L P, et al. An investigation on tribological properties of graphite nanosheets as oil additive. Wear, 2006, 261: 140–144

Singer I L, Bolster R N, Wegand J, et al. Hertzian stress contribution to low friction behavior of thin WS2 coatings. Appl Phys Lett, 1990, 57: 995–997

Prasad S, Zabinski J. Lubricants: Super slippery solids. Nature, 1997, 387: 761–763

Erdemir A. A crystal-chemical approach to lubrication by solid oxides. Tribol Lett, 2000, 8: 97–102

Donnet C, Martin J M, Le Mogne T, et al. Super-low friction of WS2 coatings in various environments. Tribol Int, 1996, 29: 123–128

Scharf T W, Prasad S V. Solid lubricants: A review. J Mater Sci, 2013, 48: 511–531

Ye Y, Chen J, Zhou H. An investigation of friction and wear performances of bonded molybdenum disulfide solid film lubricants in fretting conditions. Wear, 2009, 266: 859–864

Hu J, Wheeler R, Zabinski J, et al. Transmission electron microscopy analysis of Mo–W–S–Se film sliding contact obtained by using focused ion beam microscope and in situ microtribometer. Tribol Lett, 2008, 32: 49–57

Scharf T W, Kotula P G, Prasad S V. Friction and wear mechanisms in WS2/Sb2O3/Au nanocomposite coatings. Acta Mater, 2010, 58: 4100–4109

Wu H, Yang R, Song B, et al. Biocompatible inorganic fullerene-like molybdenum disulfide nanoparticles produced by pulsed laser ablation in water. ACS Nano, 2011, 5: 1276–1281

Bergmann E, Melet G, Muller C, et al. Friction properties of sputtered dichalcogenide layers. Tribol Int, 1981, 14: 329–332

Nyberg H, Sundberg J, Sarhammar E, et al. Extreme friction reductions during initial running-in of W-S-C-Ti low-friction coatings. Wear, 2013, 302: 987–997

Chen R S, Tang C C, Shen W C, et al. Ohmic contact fabrication using a focused-ion beam technique and electrical characterization for layer semiconductor nanostructures. J Visualized Exp, 2015

Park J, Lee W, Choi T, et al. Layer-modulated synthesis of uniform tungsten disulfide nanosheet using gas-phase precursors. Nanoscale, 2015, 7: 1308–1313

George S M, Ott A W, Klaus J W. Surface chemistry for atomic layer growth. J Phys Chem, 1996, 100: 13121–13131

Leskel A M, Ritala M. Atomic layer deposition chemistry: Recent developments and future challenges. Angew Chem Int Ed, 2003, 42: 5548–5554

George S M. Atomic layer deposition: An overview. Chem Rev, 2009, 110: 111–131

Blanquart T, Niinisto J, Gavagnin M, et al. Atomic layer deposition and characterization of vanadium oxide thin films. Rsc Adv, 2013, 3: 1179–1185

Chai Z, Liu Y, Lu X, et al. Influence of crystal structure on friction coefficient of ZnO films prepared by atomic layer deposition. Sci China Tech Sci, 2016, 59: 506–512

Browning R, Padigi P, Solanki R, et al. Atomic layer deposition of WS2 thin films. Mater Res Express, 2015, 2: 035006

Jang Y, Yeo S, Kim H, et al. Wafer-scale, conformal and direct growth of WS2 thin films by atomic layer deposition. Appl Surf Sci, 2016, 365: 160–165

Song J G, Park J, Lee W, et al. Layer-controlled, wafer-scale, and conformal synthesis of tungsten disulfide nanosheets using atomic layer deposition. ACS Nano, 2013, 7: 11333–11340

Scharf T W, Prasad S V, Dugger M T, et al. Growth, structure, and tribological behavior of atomic layer-deposited tungsten disulphide solid lubricant coatings with applications to MEMS. Acta Mater, 2006, 54: 4731–4743

Lee W Y, More K L. Crystal orientation and near-interface structure of chemically vapor deposited WS2 films. J Mater Res, 1995, 10: 49–53

Chung J W, Dai Z R, Ohuchi F S. WS2 thin films by metal organic chemical vapor deposition. J Cryst Growth, 1998, 186: 137–150

Zhang X, Lauwerens W, He J, et al. Reorientation of randomly oriented MoS x coatings during fretting wear tests. Tribol Lett, 2004, 17: 607–612

Bowden F P, Tabor D. The Friction and Lubrication of Solids. Oxford: Oxford University Press, 2001

Prasad S, Mc Devitt N, Zabinski J. Tribology of tungsten disulfide films in humid environments: The role of a tailored metal-matrix composite substrate. Wear, 1999, 230: 24–34

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Y., Chai, Z., Lu, X. et al. A direct atomic layer deposition method for growth of ultra-thin lubricant tungsten disulfide films. Sci. China Technol. Sci. 60, 51–57 (2017). https://doi.org/10.1007/s11431-016-0538-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-016-0538-x