Abstract

Purpose

Biodegradable mulch film is considered an environmentally friendly alternative to non-biodegradable-based mulch film for agricultural use. The purpose of this study is to compare the environmental impact of non-biodegradable mulch film to biodegradable mulch films for use in Nordic conditions, including assessing their plastic pollution potential.

Methods

A life cycle assessment was conducted to calculate the potential environmental impacts of the films, while the plastic pollution potential was assessed with a dynamic material flow analysis, considering degradation over time and fate to various environmental compartments. The plastic pollution potential was based on empirical degradation data in Nordic conditions.

Results and discussion

The results of the LCA and MFA analyses show that the use of non-biodegradable material in Nordic conditions leads to the lowest environmental impacts and pollution if it is fully collected after use. In fact, biodegradable mulch film leads to higher environmental impacts over its life cycle in most environmental impact categories. However, comparing environmental burdens from non-biodegradable and biodegradable mulch film is difficult due to the lack of data on biodegradable films. The results further highlight that biodegradable films will reach a dynamic equilibrium (a plateau phase) in soils in Nordic conditions between the degradation of old film and the application of new film, if not enough time is given for the films to entirely degrade. Farmers would need to apply biodegradable films with several years of interval, if the films should be entirely degraded.

Conclusions

This study supports the recommendations that biodegradable plastic has potential when used as mulch film, but these recommendations should be situation-specific, depending on farmers’ ability to handle the mulch film properly. The authors highlight that the LCA results are uncertain due to limited data availability and encourage the biodegradable plastic industry to be more transparent by making their LCIA data available.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

Plastic mulching materials are used in agriculture as they provide numerous advantages for crop production, e.g. to regulate soil moisture content, temperature, and limit the growth of weeds, thus helping to sustain or increase crop (often fruit and vegetables) yield (Steinmetz et al. 2016; Briassoulis and Giannoulis 2018). However, this once revolutionary material has, in some places, turned into a major problem of plastic pollution also known as “white pollution” (Liu 2014) as mulches made from conventional plastics present challenges once they have reached their end-of-life as they need to be collected and disposed of after use. The collection after use is often costly and time-consuming for the farmers and recycling is often difficult as the films are contaminated with soil and plant residues (Briassoulis and Giannoulis 2018). Some recycling facilities do not accept contaminated plastic films; thus, as a result, large amounts of plastic go to landfills, leading to negative environmental impact (Le Moine 2014). Moreover, conventional films left on the field or lost in nature can accumulate in the environment, compromising gas exchange and water infiltration (Sander 2019). These lost plastic mulches will fragment into microplastics over time, which can lead to adverse effects such as reducing soil functioning (Qi et al. 2018; Steinmetz et al. 2016; Zhang et al. 2018).

In search of alleviating the end-of-life and environmental problems associated with conventional plastics, biodegradable plastics have been suggested as a solution (SAPEA 2020; Hann et al. 2021). Biodegradable polymers, usually made from renewable raw materials such as lignin, cellulose, starch and bioethanol, provide crop production benefits comparable to non-biodegradable mulch film, usually made from fossil-based material. Biodegradable films are designed to be tilled into the soil after use, thereby avoiding the cost and challenges of end-of-life collection, reducing some environmental impact, and lessening problems with agricultural plastic pollution (Razza and Cerutti 2017).

Common to the polymers constituting biodegradable mulch films is the presence of ester bonds or polysaccharides, which are amenable to microbial hydrolysis and should, in theory, lead to the complete conversion to microbial biomass, CO2 and water (Brodhagen et al. 2015; Touchaleaume et al. 2018). The biodegradation test of the OECD, applied to evaluate chemicals within REACH in Europe, is a test conducted in the laboratory-activated sludge from wastewater treatment plants. Its aim is to demonstrate that mesophilic microorganisms can carry out an ultimate degradation of the substance under examination.

For mulch films, biodegradability is assessed using the international standard EN 17033 (2018) on biodegradable mulch films in agriculture, which specifies test methods and evaluation criteria regarding the biodegradation, ecotoxicity, film properties, and constituents of the biodegradable mulch films. The certification “OK Biodegradable soil” is used as the basis, which requires 90% CO2 conversion within 24 months in an aerobic incubation at constant temperature (20–28 °C). Nonetheless, biodegradability in-laboratory does not guarantee that in-field degradation will follow the same timeframe, as the biodegradation rate will depend on environmental conditions such as temperature and moisture content (OWS 2017; Griffin-LaHue et al. 2022). For Nordic climate conditions, it is feared that the mulch films will only degrade over a longer period due to low temperatures in soils (NIVA 2022). The degradation rate, rather than the ability to degrade, is of importance in terms of environmental impacts and risk assessment, as it is unclear how plastic particles impact soil health, crop yields, and field characteristics (Ferreira-Filipe et al. 2022; Sintim et al. 2019), but the impacts will likely be larger, the longer time it takes to degrade.

Life cycle assessment (LCA) is the most widely used method for quantifying environmental impacts. Several LCAs have been performed for different types of biodegradable starch blends and applications, e.g. shopping bags (Gironi and Piemonte 2011) compost bags (Bastioli 2001), packaging film (Choi et al. 2018) and food packaging (Piemonte 2011), all showing that starch blends have lower GWP than fossil-based plastics. Early reviews have however established the difficulty in concluding on the most environmentally sound material when comparing biobased/fossil-based biodegradable plastics and conventional fossil-based material, as studies vary highly in their results. In addition, the focus had been on non-renewable energy use and greenhouse gas (GHG) emissions only (Weiss 2012). Later studies showed that bio-based biodegradable materials may have higher environmental impacts than conventional equivalents in the categories of eutrophication, acidification, and stratospheric ozone depletion, because of the agricultural practice for producing biomass (Yates and Barlow 2013).

Few LCA studies have focused on the environmental impact of biodegradable plastics used in agriculture, but the existing research shows converging results regarding the environmental benefit of biodegradable mulch film. Fossil-based biodegradable mulch film made of polybutylene adipate terephthalate (PBAT) was compared to low-density polyethylene (LDPE) film and performed worse for the analysed impact categories of non-renewable energy use and GHG emissions, mainly due to the energy credits that LDPE got from incineration with energy recovery (Schrijvers et al. 2014). Two different mulch films, conventional PE and biodegradable (starch polymer), were tested for their environmental performance in an Italian context (Razza et al. 2010). The overall reduction of the potential impacts when biodegradable mulch film was used as an alternative to non-biodegradable plastic ranged from 25 to 80% for evaluated impact categories including GHG emissions, acidification, eutrophication, and non-renewable energy resources. Strawberry production in Italy where biodegradable agricultural mulch film was used (Mater-Bi®) instead of conventional PE reduced GHG and non-renewable energy emissions by 10–15% (Girgenti et al. 2014).

The LCA methodology does currently not account for plastic pollution. In fact, the leakage of plastic fractions to the biosphere in their inventory modelling has largely been ignored. A few recently published articles (Croxatto Vega et al. 2021; Maga et al. 2021; Stefanini et al. 2020; Chitaka and von Blottnitz 2021; Zanghelini et al. 2020) have included the leakage propensity of plastics. The guidelines published by Quantis and UN Environment regarding plastic releases to the aquatic environment (Peano et al. 2020) provide a promising initial benchmark for life-cycle studies to improve plastic leakage accountability. Data and developments made within the PlasticLeak project are the first steps in plastic leakage assessment, but from a life cycle impact assessment (LCIA) perspective, fate and effect models of plastic pollution are still scarce (Boulay et al. 2021). The work relating plastic emissions to LCIA is nonetheless under development, with the aim of developing characterisation factors (CFs). Civancik-Uslu et al. (2019), Stefanini et al. (2020) and Galafton et al. (2023) have proposed simplified fate factors for microplastic emissions by combining parameters representing environmental release (price of the plastic items or the incentive to return them after use), dispersion (weight of the plastic item), and persistence (material degradation rate). In addition, Maga et al. (2022) have proposed CFs for calculating the impacts of plastic pollution based on a plastic’s residence time in the environment, so the CF is solely based on the fate factor. The exposure and damage factors are hence lacking for having a full CF. Woods et al. (2019) outline a preliminary approach for an endpoint effect factor for entanglement in macroplastics, while Saling et al. (2020) focus on the fate of microplastics and a preliminary quantification of eco-toxic effects on marine biota at a midpoint level. Høiberg et al. (2022) proposed an indicator for potentially affected fraction of species on a global and regional scale for potential entanglement impacts at current levels of marine plastic pollution, which can further be applied in LCIA, and Corella-Puertas et al. (2023) have proposed CFs for microplastic physical effects in marine environments for eleven polymer types. The inclusion of microplastics as an impact category in LCA is an area of study currently under methodological development, mainly through MarILCA project (Boulay et al. 2021), and has so far mainly focused on the marine compartment.

With the lack of knowledge of the environmental impact of biodegradable compared to non-biodegradable-based mulch film and the effect of plastic pollution on the soil in Nordic conditions, it is not currently possible to advise farmers on what type of film to use. This study aims to evaluate the environmental performance of biodegradable and non-biodegradable mulch film using LCA in a Nordic context, for giving recommendations to farmers and policymakers on the choice of mulch film material. In Norway, a total of 8800 t agricultural film (both degradable and non-degradable) was put on the market in 2018 (Hann et al. 2021). Specifically for vegetable and berry production, it is estimated that 100 − 150 t degradable films are used (Sundt et al. 2020). The majority of lettuce producers use biodegradable mulch film which is applied yearly (NLR 2023). However, the use of bio-based and biodegradable plastics increases by an estimated 2 − 3% annually, which is equivalent to non-biodegradable plastic (100% petroleum-based) (Hann et al. 2018). In addition, this study presents an attempt to quantify the impacts of plastic pollution by calculating its potential accumulation in nature over time, using a dynamic material flow analysis (MFA) model, to give indications on the plastic pollution from the two mulch films. Even if the newer LCIA literature presents methods for including aspects of plastic pollution in LCA, the methods were deemed immature for the purpose of this study. For instance, the CFs proposed by Corella-Puertas et al. (2023) do not include the polymer types assessed in this study. The authors wanted to use the empirical data for Norwegian conditions, to reflect a Nordic situation—as most of the tests on biodegradable mulch films have been performed in warmer climates. Therefore, a dynamic MFA approach is presented in this article for assessing the fate of plastic pollution.

2 Methodology

2.1 LCA

2.1.1 Goal and scope

Vegetable and berry production are the main systems using plastic mulching film in Norway. Lettuce production was used in this case study to assess plastic mulch film characteristics and used amounts. The functional unit (FU) was set to “1 ha of mulched agricultural land for cultivating lettuce” as it was assumed to be no differences in functionality of non-biodegradable and biodegradable plastic mulch film, e.g. no effect on yield levels (Razza and Cerutti 2017). In this study, an attributional LCA methodology was applied with a cradle-to-grave approach. The system boundaries of the study are shown in Fig. 1.

With the lack of knowledge of the environmental impact of biodegradable compared to non-biodegradable-based mulch film and the effect of plastic pollution on the soil in Nordic conditions, it is not currently possible to advise farmers on what type of film to use. This study aims to evaluate the environmental performance of biodegradable and non-biodegradable mulch film using LCA in a Nordic context, for giving recommendations to farmers and policymakers on the choice of mulch film material and their related environmental impacts. In addition, this study presents an attempt to quantify the impacts of plastic pollution by calculating its potential accumulation in nature over time, using a dynamic material flow analysis (MFA) model, to give an indication on the plastic accumulation from the two films.

2.1.2 Life cycle inventory

The non-biodegradable mulch film used in this study was low-density polyethylene (LDPE) which is the most used material for conventional mulch film (Hann et al. 2021). The biodegradable mulch film was a blend of polybutylene adipate terephthalate (PBAT) and corn starch, which is also commonly found on the market for biodegradable mulch film (Akhir and Mustapha 2022). The PBAT in the biodegradable mulch film was modelled from literature data (Brookes 2007). Because several PBAT/starch ratios were found in the literature and are used on the market (Borchani et al. 2015) a PBAT/starch ratio of both 70/30 and 30/70 was assessed to evaluate the starch content’s significance for the environmental performance of the films.

Starch and LDPE granulate were modelled, in addition to the extrusion into films with ecoinvent 3.8 data. All upstream processes such as energy use and transport were modelled with ecoinvent 3.8 data. All mulch films were black in colour. For 1 FU approximately 4980 m2 plastic was needed; see Table 1 for information on film characteristics and Supplementary Information describing how the area of mulched film was calculated.

The non-biodegradable mulch film was assumed to be produced in central Europe and transported to Norway by lorry (1600 km). The biodegradable plastic granulate was produced in Southern Europe, with maize starch produced in Germany and maize sourced from a global market. The mulch film was then transported from central Europe to Norway by ship and lorry (2500 km and 500 km, respectively). Transport distances were based on expert opinions.

At the farm, the biodegradable mulch film is applied on the field by a tractor and tilled into the soil after use with the use of a tractor. The biodegradable mulch film is assumed to degrade in the soil after use, but its degradation potential and rate in Nordic conditions have been investigated (Joner and Coutris 2022). Potential emissions of GHG from the degradation of the biodegradable mulch film were nonetheless included according to Hermann et al. (2011).

The non-biodegradable mulch film is applied on the field with a tractor. After use, it is removed by tractor and transported to the closest waste management facility for either recycling or incineration. It is assumed that 90% of the films are collected to proper waste handling, while 10% are lost to the environment (Bauchmüller et al. 2021). Green Dot Norway (Grønt Punkt Norge) is responsible for the collection and recycling of agricultural mulching film in Norway. Approximately two-thirds are recycled at the facility of Folldal Gjenvinning (350 km), while the remaining amounts are exported to recycling plants in Europe, here assumed Germany (1600 km). The collected films are contaminated with soil, moisture and stones, which makes them 48.2% heavier than their initial weight (Grønt Punkt Norge 2023). Based on figures from Green Dot Norway for 2022, the rate of recycled plastics over the collected amounts results in a recycling rate of 51.8%, which is similar to levels reported elsewhere (Hann et al. 2021). However, when correcting for contamination, the rate of recycled plastics over the amounts put on the market results into recycling rate of 77.1% (Grønt Punkt Norge 2023). The remaining 22.9% are assumed incinerated. Because we are assessing the plastic flows in this study, the latter Figs. (77.1% and 22.9%) are used for modelling the waste treatment (shares of recycling and incineration) of non-degradable mulch film after its collection.

Primary LCI data for the recycling process of LDPE was not collected in this study. It can be assumed that recycling mulch film has higher impacts than recycling household plastic waste as the films are more contaminated, hence needing more washing (Dong et al. 2022; Tan et al. 2023). It is important to note that the ecoinvent 3.8 recycling dataset used in this study does not take into account the operations for additional cleaning the LDPE mulch film as well as residues disposal and is likely to underestimate the burdens from recycling.

Credits from energy generation from district heating have previously been assessed as an important factor for determining the GWP of mulch films (Schrijvers et al. 2014). It was therefore deemed appropriate to account for this function as well, by expanding the system boundaries to include credits from incineration, and from recycling for the sake of consistency. In a system expansion approach, the burdens from the recycling activities are allocated to the product generating recycled material. Hence, the system is expanded by including avoided burdens from the substitution of virgin material (de Sadeleer and Lyng 2022). Incineration was assumed to avoid district heating, while recycling avoids the production of virgin material. The recycled non-biodegradable mulch film was assumed to replace virgin LDPE at a rate of 75% (Zampori and Pant 2019). A detailed LCI is provided in Supplementary Information.

2.1.3 Impact assessment

SimaPro 9.0 (PRé, 2022) and the ecoinvent 3.8 (Wernet et al. 2016) cut-off database were used to perform the LCA with the Environmental Footprint 3 method (EF 3.1), the impact assessment method adopted in Environmental Footprint transition phase of the European Commission (Fazio et al. 2018). Environmental impact categories assessed were global warming potential (GWP), ionising radiation potential (IRP), particulate matter (PM), photochemical ozone formation (POF), acidification (AP), freshwater eutrophication (FEP), marine eutrophication (MEP), terrestrial eutrophication (TEP), freshwater ecotoxicity (FE), land use (LU), water use (WU), fossil resource use (FRU), mineral and metal resource use (RUM), ozone depletion (OD), human toxicity, cancer (HT, C) and human toxicity non-cancer (HT, non-C).

2.2 MFA

2.2.1 Model description

Material flow analysis (MFA) is a method for tracking the flows of a substance in a system. In this case, MFA is used to calculate the flow of plastics stemming from 1 ha of mulched agricultural land for cultivating lettuce over 10 years (see Table 1 for weights). The static MFA model presented by Pauna et al. (2023) (Pauna et al. Manuscript in preparation) is used as a basis for this study and is further developed into a dynamic model, with the aim to include degradation of the biodegradable mulch film and not only its spread in nature, hereby adding a time dimension to the model. A period of 10 years is chosen as reference to give an indication of the amounts of plastics accumulating over a short period of time, that a farmer for instance could relate to, but long enough to highlight how the degradation relates to the inflow of new mulch film.

The system boundaries of the systems and the covered flows are illustrated in Fig. 1. The flows included are pellets loss from polymer production and product manufacturing, tyre wear from transport, and release to nature in the use phase. The model is input-driven before the use phase and output-driven after the use phase. According to Peano et al. (2020), 0.03% of the polymer produced is lost, and 0.03% from product manufacturing. The division between emissions to land and water for these life cycle stages is based on factors from Kawecki and Nowack (2019). From the use phase, 100% of the film is plough into the soil, while 10% is assumed lost for non-biodegradable films (Bauchmüller et al. 2021). Emissions from tyre wear are also based on factors from Peano et al. (2020) and represent the amount of rubber released by the wearing of tyres under transport processes of non-biodegradable and degradable plastics, including all transport stages between the various life cycle stages. The division of emissions to land and water is also based on (Peano et al. 2020). See Pauna et al. (2023) for all transfer coefficients of the model, and their repartition between environmental compartments, which are based on factors from (Peano et al. 2020) and (Corella-Puertas et al. 2022). The density of the biodegradable films might be higher than the non-biodegradable films, which would influence the transfer to the different environmental compartments (non-degradable plastics might end up in river sediments rather than the ocean for instance). However, the values reported in the literature for the transfer between compartments are highly uncertain, as they depend on multiple factors. This part of the model is therefore not investigated in detail due to the large variations, as this is a simplified model of the emissions over time and follows the recommendations of selected literature. Further research is however called upon to specify these factors.

The static MFA model distinguishes between emissions of macro- and microplastics, which this analysis does not do. It is in fact unclear at which point in time the films have degraded from macro- to microplastics, as the empirical data shows a fragmentation of the film on the edges rather than a full degradation, which releases more and more microplastics while the initial macroplastic decreases in size. Therefore, the emissions in this study are not distinguished on size, which would be needed if CFs should have been applied to include the plastic emissions as part of an LCA. The absolute values presented in Table 2 represent the stock of plastics diverted to soil and water from each life cycle stage. The sum of the use phase equals the initial amount of mulch film left on the field. For the non-biodegradable film, the 90% collection scenario was applied.

The potential accumulation of plastics in soil, freshwater and ocean is modelled for 10 years, developing the MFA model from a static to a dynamic model. Empirical data on the degradation of biodegradable mulch film over 2 years in Norwegian conditions (Joner and Coutris 2022) was used as a basis for calculating the degradation rates of the use phase over time. The experiments, which aimed at investigating the in situ degradation of the two types of biodegradable mulch films most used in Norway, under various climatic conditions, soil types, soil depths and agricultural practices, were run by NIBIO, the Norwegian Institute of Bioeconomy Research as part of the DGrade project (NIBIO 2023). The experiments were performed by digging mulch film into the fields and analysing the biodegradation rates over two years. Data was collected for various locations in Southern and Western Norway and are assumed representative of the southern part of the country (excluding hence the Arctic areas). As far as the authors know, this work is the only current data point available on the degradation of mulch film in Nordic conditions. Work has been conducted on the matter in other climatic conditions, and the results also show slower degradation rates than obtained under laboratory conditions (Griffin-LaHue et al. 2022; Sintim et al. 2020; Liao and Chen 2021). The data points from Joner and Coutris (2022) therefore seem to be a reasonable estimation of the degradation conditions in Nordic conditions, even if it can be argued that the data can be considered as conservative. In fact, when used on field under operating conditions, the mulch films would have been exposed to UV light before being tilled into the soil, which might lead to faster degradation than what was measured in the experiments.

As project and research partners, the authors were granted access to the raw data for further use in the MFA development. No degradation rates are applied for the amounts stemming from the other life cycle stages (material production, processing and transport). In fact, pellets from the material production and processing stages are not assumed to end up in the soil in the same manner as the mulch film which is applied on farmland. As the conditions will differ, the degradation data will not apply to the material production and processing steps. For the transport stage, rubber will not degrade over a 10-year period as it is a non-degradable material.

Because it is unknown how the degradation will develop after the 2 years studied by Joner and Coutris (2022), various potential degradation rates are calculated from year 3 to 10, fitted to the empirical data: a negative quadratic function, an exponential function and a linear function. Degradation in water is likely to be slower than in soil due to lower temperatures and less microbial activity (Joner and Coutris 2022), a degradation being two times slower than the degradation rates in soil is therefore assumed. It is not distinguished between degradation rates in freshwater and oceans.

Table 3 presents the degradation rates for the biodegradable film in soil and water, for the three functions. Year 0 is the first year that mulch film is applied on the field and plough into the soil after use for the biodegradable variant. The degradation rates were applied to the initial masses plough in the soil (Table 2). It should be noted that the authors were not able to get information on specific PBAT/starch ratios from the film suppliers as this is confidential information. The ratio 70/30 PBAT/starch is the most common according to the literature, and it is therefore assumed that this was used in the experiments. However, as it is uncertain which ratio was used in the field experiments, the degradation rates used as a basis for the MFA do not distinguish between the ratio for the films. However, as stated in Sect. 2.1.2 two ratios was assessed in the LCA, in order to evaluate the starch content’s significance for the environmental performance of the films.

2.2.2 Scenario description

Scenarios are performed for the parameters considered especially uncertain for assessing their sensitivity to the results. The following parameters were scrutinised: the application rates of mulch films, the degradation rates in both soil and water, and the collection rate of non-biodegradable mulch films.

It is unclear how often the farmers will apply mulch film on the field, as this will depend on the type of production process and fruits/vegetables produced. The reuse of mulch films for a second or third growing season would not apply for lettuce production in Nordic countries, but would for other berries or vegetables needing thicker films, such as strawberry production for instance. Scenarios without crop rotation practices (application of new mulch film every year) and with crop rotation practices (application of new mulch film every 2 and 3 years) are presented for the biodegradable film, for the three degradation types (negative quadratic, exponential and linear). While it is clear that the degradation of degradable films in water will be slower than in soil due to lower temperatures and less microbial activity (Joner and Coutris 2022), it is unclear how much slower. Therefore, a scenario with a degradation rate being 10 times slower in water than in soil is analysed and presented for the application of mulch film every second year. The application of new film for non-biodegradable plastics is also presented. Finally, the effect of different collection rates (75, 90 and 99%) after using non-biodegradable mulch films is assessed. The scenarios are summarised in Table 4.

3 Results

3.1 Life cycle impact assessment

Life cycle assessment results show that non-biodegradable mulch film made of LDPE has a better environmental profile compared to both biodegradable mulch film made of 70/30 and 30/70 PBAT-starch blend for all chosen impact categories, except for FRU (−12%) for the 30/70 blend; see Fig. 2. Energy use in the production of the film material was the main contributor to FRU for both LDPE and biodegradable film and in total less energy was consumed for the production of PBAT-starch 30/70 blend compared to the LDPE film.

Environmental impact of non-degradable mulch film (LDPE) and biodegradable mulch film (PBAT-starch 70/30 blend and PBAT-starch 30/70 blend). Note that the impacts of ozone depletion are taken out because the impacts are over 1000% and over 2000% larger for the PBAT 30/70 and PBAT 70/30 compared to non-degradable film, which makes the figure difficult to read

Several impact categories were much higher for the PBAT starch-blends compared to the LDPE mulch film. OD leads to impacts with over 593% and 1243% increase for the 30/70 and 70/30 blends, respectively, a significant increase in impacts compared to the non-degradable films, which is explained by the use of acid in the production of the degradable films. WU increases with over 400% for the two blends, respectively. Irrigation of corn during the farm stage and water use in PBAT production were the main sources contributing to this impact category. FE increases with over 200% and 150% for the two blends, respectively. The use of agrochemicals when producing corn was the main contributor to the FE for the biodegradable mulch film.

A majority of the impact categories followed a similar pattern, with the LDPE film having the lowest impact followed by the PBAT-starch blend of 30/70 and then the PBAT-starch blend of 70/30; see Supplementary Information. Exceptions of this pattern were for MEP, LU and FE where the lower concentration starch blend of 30% for the biodegradable film resulted in a 6% increase for the MEP, 30% for LU and 74% for the FE compared to the PBAT-starch blend of 70/30 due to increased fertiliser, land use and use of agrochemicals at the farm stage when corn is cultivated.

The contribution to GWP was the lowest for the non-degradable LDPE film, when the replacement of virgin LDPE was included; see Fig. 3. However, if it was assumed that the recycled LDPE film did not replace any virgin LDPE or heat on the market, the GWP potential would be 2.5% lower for the biodegradable mulch film with a PBAT-starch blend of 30/70; see Supplementary Information. The PBAT-starch blend of 30/70 would outperform LDPE film for 3 out of 16 impact categories with the assumption that the recycled LDPE film did not replace any virgin LDPE or heat on the market (see Supplementary Information).

Production of the mulch film is the major contributor to the GWP impact category (between 56 and 69%) for all types of mulch films in this study. The production of PBAT has a higher contribution to GWP than the production of starch; hence, the more starch blended into the biodegradable mulch film, the lower the carbon footprint. The production of PBAT-starch blend of 30/70 has a higher GWP contribution than the conventional LDPE film and the resource use needed to remove the conventional mulch film from the field and to have it recycled does not exceed the total emissions from the biodegradable 30/70 PBAT-starch blend. The PBAT-starch 70/30 blend will result in a higher carbon footprint than conventional mulch film as the PBAT production generates more emissions than conventional LDPE. Field operations were the second largest contributor to GWP for conventional mulch film (29%) followed by incineration and (10%) recycling (10%). For both biodegradable films, the field operation processes were the second largest contributor to GWP (24% and 18%, respectively) followed by mineralisation (7 and 11%, respectively). The transports were of minor importance for the GWP.

3.2 MFA

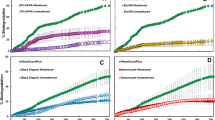

The results of the dynamic MFA, representing the plastic pollution potential by calculating the mass of plastics accumulated in nature after 10 years from the use of mulch film, are presented in Fig. 4 for all assessed scenarios.

For biodegradable plastics, the levels of plastic present in soil over time vary largely and are sensitive to both the degradation rates and crop rotation practices. An exponential decay leads to the highest pollution levels, as the films degrade slower over time than for the other scenarios, while a negative quadratic function degrades the fastest. Independent of degradation functions, a yearly application of mulch film leads to the highest plastic pollution levels, while applying it every 3 years leads to the lowest pollution levels. Hence, if the degradation rates are low and films are applied yearly, more plastic will be present in nature over time.

The plastic pollution levels from non-biodegradable plastics depend largely on the collection rates after use. If applied every third year, all collection rates will lead to lower emissions compared to the other scenarios assessed. Applied every year however, the collection rate is significant for the pollution levels: a high collection rate (99%) leads to relatively low plastic pollution levels, while a low collection rate (75%) leads to among the highest pollution levels across the assessed scenarios, also compared to biodegradable plastics. Independently of how often films are applied, collecting nearly all non-biodegradable mulch film after use leads to the lowest pollution levels across all scenarios.

The results also show that the longer the degradation rate of the mulch film, the more microplastics will be transferred to the water and ocean compartments. Similarly, the slower the degradation rate is in water, the more will accumulate in the water and ocean compartment.

It can be assumed that it is most likely that biodegradable mulch film will be applied every second year in Nordic conditions for lettuce cultivation and that its degradation will follow a negative quadratic curve (Joner and Coutris 2022). For the non-biodegradable plastics, it is likely that 90% of the films are collected after use (Bauchmüller et al. 2021). For those scenarios, Fig. 5 presents detailed results on the accumulation of plastics in the different environmental compartments for biodegradable and non-degradable plastics, respectively.

For both degradable and non-degradable films, plastic pollution largely stems from the use phase. When applied every second year, the biodegradable mulch film has time to partly disintegrate before a new film is applied. The results show that the soil will keep a constant level of plastic stock if longer crop rotation periods are not maintained. Hence, the biodegradable films will reach a dynamic equilibrium (a plateau phase), balancing the degradation of old film and the inflow of new film. The results hence show that it is important to let time for the biodegradable plastics to disintegrate if the presence of biodegradable plastics in soil over time is seen to have adverse effects. This is in line with the findings of OWS (2017). Note that the levels of non-biodegradable plastics emitted to nature will accumulate over time, in contrast to biodegradable plastics, which will eventually disappear if a farmer stops applying biodegradable film on a field.

4 Discussion

4.1 Interpretation of LCA results

Comparing LCA results of fossil and biobased plastics is difficult due to the spread of data existing in LCA literature (Walker and Rothman 2020). There is a current scientific agreement that fossil-based plastic does better in acidification and eutrophication but worse in climate change and energy use categories, but recent reviews have not been able to support this (Spierling et al. 2018; Walker and Rothman 2020). LCAs comparing biodegradable with conventional mulch film have found biodegradable mulch film to outperform conventional film (Razza et al. 2010) but the opposite has also been reported (Schrijvers et al. 2014). Our results imply that the biodegradable mulch film modelled in this case is not a better alternative to conventional mulch film from an environmental perspective. Regarding the production of the mulch film, the biodegradable material has a worse environmental profile in a cradle-to-grave perspective compared to non-biodegradable LDPE film, but the more starch material included, the better the environmental profile becomes for the PBAT-starch blend, (except for MEP, LU and FE). Starch needs to be blended with another material when used as mulch film, for the material not to become too brittle and degrade too fast (Hann et al. 2021). In this study corn starch produced from corn on a global market was used, hence LU impact will increase, as well as the competition with other agricultural production, the more starch that is blended into the plastic film. Ideally, bio-based plastic should be produced from excess biomass waste that has no other uses (generation 2 bioplastic) (Patel et al. 2018).

It is important to choose the right feedstock blend for the biodegradable material to produce an environmentally sustainable mulch film. The data used in this study to model PBAT originates from 2007 (Brookes 2007) as we have not found any updated data for PBAT production. The lack of data for this study and in general for the production of biodegradable plastic film poses a problem when wanting to evaluate environmental sustainability per se, and in comparison, to conventional plastic film. The uncertainty in the results due to a lack of data makes it difficult to advise farmers on what plastic film to use from an environmental perspective. It has been highlighted that performing LCAs of biobased plastics is a difficult task due to many uncertainties about the life cycle of these relatively new materials for example uncertainties about production processes (Hermansson et al. 2019). There is also a lack of LCA assessments that have evaluated biobased plastics over the complete life cycle, likely because of the difficulties of finding data for all the life cycle stages (Molina-Besch 2022) which is also applicable to biodegradable plastics. There is a clear need for bioplastic producers to become more transparent and to openly share LCI data on the production of biodegradable and biobased plastic so that the right decisions can be made on how and when to use it from a sustainability perspective.

The LCA analysis has assumed that conventional film is sent to recycling, as is common practice in Nordic countries. However, there is evidence that the film can be incinerated on-site (Eldby 2013), which would largely influence the impacts of end-of-life, especially the impacts on climate change. This case has however not been assessed in this study. The importance of proper waste handling should be clearly communicated to farmers applying mulch film in their activities. In addition, the influence of the recycling rates of conventional film would influence its environmental performance, affecting the share sent to incineration and the credits from heat production. The effect of altered recycling rates was, however, not assessed as it was deemed outside of the goal and scope of the study. In fact, farmers do not have influence over the efficiency of the waste handling system, but only on the share of collected film from the fields. Other uncertainties of the LCA results stem from the dataset on PE recycling, which is likely to underestimate the burdens related to contaminated mulch film recycling.

The effect on yield is however not necessarily the same for all crop types, which is a limitation of this study as the results might not be transferable to another crop type.

4.2 Interpretation of MFA results

As it has been pointed out, for instance by Askham et al. (2023), mapping the plastic flows is not enough for assessing the impacts of microplastics on the environment. However, CFs are needed to carry out a full impact assessment and are currently only developed for micro- and macroplastic in the marine compartment. In this study, land-based plastics are the primary plastic leakages to the environment. Therefore, without a CF for plastics on land, the impact assessment would be misleading, demonstrating only a small fraction of the plastic leakage impact caused by the use of mulch films. In addition, the recently published CFs for physical effects on biota from plastic emission (Corella-Puertas et al. 2023) that could have been applied for LDPE do not include PBAT, which is studied in this article. This would again have led to an unfair comparison of plastic pollution impacts between the mulch film types. There is a consensus that microplastics have the potential to be harmful to human health (Corella-Puertas et al. 2022) despite the lack of quantified damage. Therefore, it is possible without any quantitative damage assessment on specific species to conclude that the impacts of microplastics and macroplastics are of great concern and that a reduction in emissions of these plastic leakages is beneficial. Hence, using the potential accumulation of plastic pollution in environmental compartments is currently the best indicator for assessing plastic pollution. This study demonstrates that MFA is a valid method for this purpose.

The results show that over 10 years, a considerable amount of plastics will be present in the environment from the use of biodegradable mulch film (in the range of 85–500 kg). Most of the pollution stems from the use phase, for both non-biodegradable and biodegradable alternatives. Biodegradable films will reach a dynamic equilibrium (a plateau phase) in soils under Nordic conditions, where the degradation of old film balances out the application of new film (Fig. 5). Farmers would hence need to leave the soil without applying biodegradable films, to let the used film entirely degrade, if the presence of biodegradable plastics in soil over time is to be avoided.

The amount of non-degradable plastics present in the environment can also be quite high, depending on the collection rate after EoL and how often the film is applied (in the range of 5–275 kg). In fact, the non-biodegradable films lead to the least pollution over time, if it is fully collected after use (99%), and when the films are applied every third year. The collection rates will however vary with the type of film used, especially its thickness and brittlely (Fig. 6). The thinner and more brittle the film, the more will be likely to fragment when it is applied on the field and end up as plastic pollution in the environment. The results are in line with the conclusions of Hann et al. (2021), who concluded that the choice, from an environmental perspective, between the use of conventional and biodegradable plastics in agriculture depends mainly upon the local collection situation as well as the grower’s requirements.

While the effect of biodegradable films is reversible, as they will degrade over time if no additional film is added to the field, this is not the case for non-biodegradable films, which are persistent and will accumulate and remain in nature for years, as is clearly shown in the results of OWS (2017), highlighting an accumulation of PE mulch film in soil over time. In this sense, emissions of plastics from biodegradable materials do not contribute to the microplastic concern in the same manner as non-degradable plastics do. Nonetheless, large amounts of residual plastic film can have detrimental effects on soil structure, water and nutrient transport and crop growth, thereby disrupting the agricultural environment and reducing crop production, which can be a result of the use of both biodegradable and non-biodegradable films. It is however not determined whether a steady-state level of plastics in soil can cause damage to the soil and the environment, nor the concentration levels at which a damage could occur. These topics would need to be better elucidated in future research.

The development of methods for assessing the effects and risks of plastic emissions in soil comparing biodegradable polymers with non-biodegradable polymers is hence called for. In the meantime, it can be seen as valuable to strive for low plastic pollution levels from both sources for environmental purposes, following a precautionary principle.

It should be noted that the degradation rates have been extrapolated from empirical data over 2 years, leading to uncertainties concerning the degradation rates over time. Nonetheless, as plastic pollution levels were assessed with different degradation rates which led to the same conclusions, it can be concluded that the results are robust. The degradation rates can, however, be different with other climatic conditions, so the findings from this study might not apply to warmer countries such as Spain, Italy or France, which are heavy users of mulch film.

4.3 Future work

Future work on LCA of biodegradable plastics should try to engage producers of biodegradable plastics to enhance data quality and sharing. Further, future research should investigate how agricultural mulch film degrades over longer periods of time in Nordic conditions. The work performed by Joner and Coutris (2022) is a clear starting point, but more data is needed on the degradation rates to correctly assess the time needed for a mulch film to properly degrade in Nordic conditions and, deriving from this, the potential accumulation of degradable plastics in nature over time. In addition, degradation of the films in water has not been investigated empirically in Nordic conditions. It has in this study been assumed that the degradation rates will be slower in water than in soil due to lower temperatures and microbial activities. However, as it has not yet been determined when a product can be accepted as ‘soil biodegradable’, ‘freshwater biodegradable’ or ‘marine biodegradable’ (SAPEA 2020); these assumptions should be further scrutinised. The accumulation of bioplastics was calculated based on a film of 15 μm, typically used for lettuce cultivation. However, the thickness of the film will depend on the type of vegetable or berry cultivated, which will again determine the plastic pollution potential (in mass, as calculated in this study). Research could further assess degradation rates for films of different thicknesses, as this might differ. In addition, research on the environmental impacts of alternatives to plastic mulch film such as wood or straw, which could be applied to certain cultures, is lacking for Nordic conditions and should be further scrutinised. Finally, the effect on yield is however not necessarily the same for all crop types, as was assumed in this study. Further research should assess the methodology presented for other crop types, for further robustness of the results. Lastly, more research is needed for the development of CFs for more polymer types, such as PBAT, which would allow the integration of plastic pollution emissions in an LCA.

5 Conclusion

The results of the two analyses, LCA and MFA, point towards the same conclusion: the use of non-biodegradable material in Nordic conditions leads to the lowest environmental impacts and pollution if it is fully collected after use. There is however a potential for biodegradable plastic mulch film to be a good choice both from an environmental and “plastic pollution” perspective when certain situations occur, such as when non-biodegradable film is not collected properly. In this case, the biodegradable film is a better choice from a plastic pollution perspective if applied every third year, as the biodegradable film needs time to fully degrade. Note that if biodegradable plastic is applied more often than every third year, microplastics will accumulate in the soil. Hence, this study can support the recommendations that biodegradable plastic has potential when used as mulch film but these recommendations should be situation-specific, depending on farmers’ ability to handle the mulch film properly. The authors highlight that the LCA results are uncertain due to limited data availability and encourage the biodegradable plastic industry to be more transparent by making their LCIA data available. In addition, the LCA results must be interpreted in the context of the modelling assumptions and choices made. Finally, our results are a contribution to the scientific community, showing that a dynamic MFA approach can be combined with LCA results for assessing plastic pollution, as long as CFs do not exist for assessing its environmental impacts on soil.

Data availability

Most of the data generated or analysed during this study are included in this published article and its supplementary information file. For more details, datasets are available from the corresponding author upon request.

References

Akhir MAM, Mustapha M (2022) Formulation of biodegradable plastic mulch film for agriculture crop protection: a review. Polym Rev 62:890–918

Askham C, Pauna VH, Boulay A-M, Fantke P, Jolliet O, Lavoie J, Booth AM, Coutris C, Verones F, Weber M, Vijver MG, Lusher A, Hajjar C (2023) Generating environmental sampling and testing data for micro- and nanoplastics for use in life cycle impact assessment. Sci Total Environ 859:160038

Bastioli C (2001) Global status of the production of biobased packaging materials. Starch - Stärke 53

Bauchmüller V, Carus M, Chinthapalli R, Dammer L, Hark N, Partanen A, Ruiz P, Lajewski S (2021) BioSinn: products for which biodegradation makes sense. Hürth: nova-Institut für politische und ökologische Innovation GmbH

Borchani EK, Carrot C, Jaziri M (2015) Biocomposites of Alfa fibers dispersed in the Mater-Bi® type bioplastic: morphology, mechanical and thermal properties. Compos A Appl Sci Manuf 78:371–379

Boulay A-M, Verones F, Vázquez-Rowe I (2021) Marine plastics in LCA: current status and MarILCA’s contributions. Int J LCA 26:2105–2108

Briassoulis D, Giannoulis A (2018) Evaluation of the functionality of bio-based plastic mulching films. Polym Testing 67:99–109

Brodhagen M, Peyron M, Miles C, Inglis DA (2015) Biodegradable plastic agricultural mulches and key features of microbial degradation. Appl Microbiol Biotechnol 99:1039–1056

Brookes CK (2007) Advancement of biobased products through design, synthesis and engineering of biopolyesters. PhD dissertation, Michigan State University

Chitaka TY, von Blottnitz H (2021) Development of a method for estimating product-specific leakage propensity and its inclusion into the life cycle management of plastic products. Int J LCA 26:1431–1438

Choi B, Yoo S, Park S-I (2018) Carbon footprint of packaging films made from LDPE, PLA, and PLA/PBAT blends in South Korea. Sustainability 10:2369

Civancik-Uslu D, Puig R, Ferrer L, Fullana-I-palmer P (2019) Influence of end-of-life allocation, credits and other methodological issues in LCA of compounds: an in-company circular economy case study on packaging. J Clean Prod 212:925–940

Corella-Puertas E, Guieu P, Aufoujal A, Bulle C, Boulay A-M (2022) Development of simplified characterization factors for the assessment of expanded polystyrene and tire wear microplastic emissions applied in a food container life cycle assessment. J Ind Ecol 26:1882–1894

Corella-Puertas E, Hajjar C, Lavoie J, Boulay A-M (2023) MarILCA characterization factors for microplastic impacts in life cycle assessment: physical effects on biota from emissions to aquatic environments. J Clean Prod 418:138197

Croxatto Vega G, Gross A, Birkved M (2021) The impacts of plastic products on air pollution - a simulation study for advanced life cycle inventories of plastics covering secondary microplastic production. Sustain Prod Consum 28:848–865

de Sadeleer I, Lyng K-A (2022) A life cycle assessment on single-use and reuse beer cups at festivals. Circ Econ Sust 2:1517–1539

Dong H, Yang G, Zhang Y, Yang Y, Wang D, Zhou C (2022) Recycling, disposal, or biodegradable-alternative of polyethylene plastic film for agricultural mulching? A life cycle analysis of their environmental impacts. J Clean Prod 380:134950

Eldby H (2013) Retur av plast i landbruket. In: Agrianalyse (ed) Notat 3

Fazio S, Castellani V, Sala S, Schau EM, Secci M, Zampori L, Diaconu E (2018) Supporting information to the characterisation factors of recommended EF life cycle impact assessment method. New models and differences with ILCD. Available at: http://publications.jrc.ec.europa.eu/repository/handle/JRC109369. Ispra: Euro Com JRC

Ferreira-Filipe DA, Paço A, Natal-Da-luz T, Sousa JP, Saraiva JA, Duarte AC, Rocha-Santos T, Patrício Silva AL (2022) Are mulch biofilms used in agriculture an environmentally friendly solution? - An insight into their biodegradability and ecotoxicity using key organisms in soil ecosystems. Sci Total Environ 828:154269

Galafton C, Maga D, Sonnemann G, Thonemann N (2023) Life cycle assessment of different strawberry production methods in Germany with a particular focus on plastic emissions. Int J LCA 28:611–625

Girgenti V, Peano C, Baudino C, Tecco N (2014) From “farm to fork” strawberry system: current realities and potential innovative scenarios from life cycle assessment of non-renewable energy use and green house gas emissions. Sci Total Environ 473–474:48–53

Gironi F, Piemonte V (2011) Bioplastics and petroleum-based plastics: strengths and weaknesses. Energy Sources, Part a: Recovery, Utilization, and Environmental Effects 33:1949–1959

Griffin-Lahue D, Ghimire S, Yu Y, Scheenstra EJ, Miles CA, Flury M (2022) In-field degradation of soil-biodegradable plastic mulch films in a Mediterranean climate. Sci Total Environ 806:150238

Grønt PN (2023) Tall og fakta for landbruksplast [Online]. Available: https://www.grontpunkt.no/resirkulering/fakta-og-tall#2021. Accessed 2023

Hann S, Scholes R, Briedis R, Kirkevaag K (2018) Bio-based and biodegradable plastics. an assessment of the value chain for biobased and biodegradable plastics in Norway. In: The Norwegian Environment Agency (ed)

Hann S, Fletcher E, Molteno S, Sherrington C, Elliott L, Kong M-A, Sastre S, Martinez V (2021) Relevance of conventional and biodegradable plastics in agriculture. For the European Commission DG Environment. Project conducted under Framework Contract No ENV.B1/FRA/2018/0002 Lot 1

Hermann BG, Debeer L, de Wilde B, Blok K, Patel MK (2011) To compost or not to compost: carbon and energy footprints of biodegradable materials’ waste treatment. Polym Degrad Stab 96:1159–1171

Hermansson F, Janssen M, Svanström M (2019) Prospective study of lignin-based and recycled carbon fibers in composites through meta-analysis of life cycle assessments. J Clean Prod 223:946–956

Høiberg MA, Woods JS, Verones F (2022) Global distribution of potential impact hotspots for marine plastic debris entanglement. Ecol Indic 135:108509

Joner E, Coutris C (2022) Bionedbrytbar plast i matjord. https://vannforeningen.no/wp-content/uploads/2022/12/08-Coutris_Claire.pdf: Vannforeningen

Kawecki D, Nowack B (2019) Polymer-specific modeling of the environmental emissions of seven commodity plastics as macro- and microplastics. Environ Sci Technol 53:9664–9676

Liao J, Chen Q (2021) Biodegradable plastics in the air and soil environment: low degradation rate and high microplastics formation. J Hazard Mater 418:126329

Liu E, He WQ, Yan CR (2014) White revolution’ to ‘white pollution’— agricultural plastic film mulch in China. Environ Res Lett 9

Maga D, Thonemann N, Strothmann P, Sonnemann G (2021) How to account for plastic emissions in life cycle inventory analysis? Resour Conserv Recycl 168:105331

Maga D, Galafton C, Blömer J, Thonemann N, Özdamar A, Bertling J (2022) Methodology to address potential impacts of plastic emissions in life cycle assessment. Int J LCA 27:469–491

Le Moine B (2014) Agri-plastics waste management: a voluntary commitment from the industry. Presented at: Agricultural Film 2014 – International Conference on silage, mulch, greenhouse and tunnel films used in agriculture, Barcelona, Spain (2014) 15–17

Molina-Besch K (2022) Use phase and end-of-life modeling of biobased biodegradable plastics in life cycle assessment: a review. Clean Technol Environ Policy 24:3253–3272

NIBIO (2023) DGRADE - Constraints to degradation of biodegradable plastics in terrestrial systems [Online]. https://www.nibio.no/en/projects/dgrade-constraints-to-degradation-of-biodegradable-plastics-in-terrestrial-systems: Norwegian Institute of Bioeconomy Research. Accessed 2023

NIVA N (2022) Addressing microplastics in a global agreement on plastic pollution. Nordic Council of Ministers

NLR NL (2023) RE: Personal communication with Kari Aarekol

OWS (2017) Expert statement on biodegradable mulch films. https://docs.europeanbioplastics.org/publications/OWS_Expert_statement_mulching_films.pdf

Patel MK, Bechu A, Villegas JD, Bergez-Lacoste M, Yeung K, Murphy R, Woods J, Mwabonje ON, Ni Y, Patel AD, Gallagher J, Bryant D (2018) Second-generation bio-based plastics are becoming a reality - non-renewable energy and greenhouse gas (GHG) balance of succinic acid-based plastic end products made from lignocellulosic biomass. Biofpr 12:426–441

Pauna VH, Saxegård SA, Askham C, Silva M (Manuscript in preparation) Linking material flow analysis with plastic related impacts: how to make progress with what we know. Intended J Ind Ecol

Pauna VH, Saxegård SA, Askham C (2023) PHA from wastewater: a promising strategy for reducing microplastic and macroplastic emissions. NORSUS OR.03.23

Peano L, Kounina A, Magaud V, Chalumeau S, Zgola M, Boucher J (2020) Plastic leakage project, methodological guidelines. EA and Quantis

Piemonte V (2011) Bioplastic wastes: the best final disposition for energy saving. J Polym Environ 19:988–994

PRé (2022) SimaPro. 9.4 ed. Amersfoort, Netherlands: PRé Sustainability BV

Qi Y, Yang X, Pelaez AM, HUERTA LWANGA, E., BERIOT, N., GERTSEN, H., GARBEVA, P. & GEISSEN, V. (2018) Macro- and micro- plastics in soil-plant system: effects of plastic mulch film residues on wheat (Triticum aestivum) growth. Sci Total Environ 645:1048–1056

Razza F, Cerutti AK (2017) Life cycle and environmental cycle assessment of biodegradable plastics for agriculture. In: Malinconico M (ed.) Soil Degradable Bioplastics for a Sustainable Modern Agriculture. Berlin, Heidelberg: Springer Berlin Heidelberg

Razza FF, Tosin F, Degli M, Innocenti F, Guerrini S (2010) Assessing the environmental performance and eco-toxicity effects of biodegradable mulch films. Proceeding sof the VIIth international conference on life cycle assessment in the agri-food sector. Bari 22–24

Saling P, Gyuzeleva L, Wittstock K, Wessolowski V, Griesshammer R (2020) Life cycle impact assessment of microplastics as one component of marine plastic debris. Int J LCA 25:2008–2026

Sander M (2019) Biodegradation of polymeric mulch films in agricultural soils: concepts, knowledge gaps, and future research directions. Environ Sci Technol 53:2304–2315

SAPEA (2020) Biodegradability of plastics in the open environment. Science Advice for Policy by European Academies, Berlin

Schrijvers DL, Leroux F, Verney V, Patel MK (2014) Ex-ante life cycle assessment of polymer nanocomposites using organo-modified layered double hydroxides for potential application in agricultural films. Green Chem 16:4969–4984

Sintim HY, Bandopadhyay S, English ME, Bary AI, Debruyn JM, Schaeffer SM, Miles CA, Reganold JP, Flury M (2019) Impacts of biodegradable plastic mulches on soil health. Agric Ecosyst Environ 273:36–49

Sintim HY, Bary AI, Hayes DG, Wadsworth LC, Anunciado MB, English ME, Bandopadhyay S, Schaeffer SM, Debruyn JM, Miles CA, Reganold JP, Flury M (2020) In situ degradation of biodegradable plastic mulch films in compost and agricultural soils. Sci Total Environ 727:138668

Spierling S, Knüpffer E, Behnsen H, Mudersbach M, Krieg H, Springer S, Albrecht S, Herrmann C, Endres H-J (2018) Bio-based plastics - a review of environmental, social and economic impact assessments. J Clean Prod 185:476–491

Stefanini R, Borghesi G, Ronzano A, Vignali G (2020) Plastic or glass: a new environmental assessment with a marine litter indicator for the comparison of pasteurized milk bottles. Int J LCA 26:767–784

Steinmetz Z, Wollmann C, Schaefer M, Buchmann C, David J, Troger J, Munoz K, Fror O, Schaumann GE (2016) Plastic mulching in agriculture. Trading short-term agronomic benefits for long-term soil degradation? Sci Total Environ 550:690–705

Sundt P, Rønnekleiv HS, Rem T, Schulze P-E (2020) Norske landbaserte kilder til mikroplast - Kartlegging av landbaserte mikroplastkilder i Norge og oppdatering av utslippsestimater. The Norwegian Envionment Agency

Tan Q, Yang L, Wei F, Chen Y, Li J (2023) Comparative life cycle assessment of polyethylene agricultural mulching film and alternative options including different end-of-life routes. Renew Sust Energ Rev 178:113239

Touchaleaume F, Angellier-Coussy H, César G, Raffard G, Gontard N, Gastaldi E (2018) How performance and fate of biodegradable mulch films are impacted by field ageing. J Polym Environ 26:2588–2600

Walker S, Rothman R (2020) Life cycle assessment of bio-based and fossil-based plastic: a review. J Clean Prod 261:121158

Weiss M, Haufe J, Carus M, Brandão M, Bringezu S, Hermann B, Patel MK (2012) A review of the environmental impacts of biobased materials. J Ind Ecol 16:169–181

Wernet G, Bauer C, Steubing B, Reinhard J, Moreno-Ruiz E, Weidema B (2016) The ecoinvent database version 3 (part I): overview and methodology. Int J LCA 21:1218–1230

Woods JS, Rødder G, Verones F (2019) An effect factor approach for quantifying the entanglement impact on marine species of macroplastic debris within life cycle impact assessment. Ecol Indic 99:61–66

Yates MR, Barlow CY (2013) Life cycle assessments of biodegradable, commercial biopolymers—a critical review. Resour Conserv Recycl 78:54–66

Zampori L, Pant R (2019) Suggestions for updating the Product Environmental Footprint (PEF) method. Luxembourg

Zanghelini GM, Cherubini E, Dias R, Kabe YHO, Delgado JJS (2020) Comparative life cycle assessment of drinking straws in Brazil. J Clean Prod 276:123070

Zhang L, Sintim HY, Bary AI, Hayes DG, Wadsworth LC, Anunciado MB, Flury M (2018) Interaction of Lumbricus terrestris with macroscopic polyethylene and biodegradable plastic mulch. Sci Total Environ 635:1600–1608

Acknowledgements

We acknowledge Claire Coutris and Erik Joner from NIBIO for collaborating on the project and Simon Saxegård for his valuable comments.

Funding

This work has been funded by The Research Council of Norway and The Norwegian Retailers’ Environmental Fund (Grant number 303560) through the project DGRADE-Constraints to degradation of biodegradable plastics in terrestrial systems.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Communicated by Brad G. Ridoutt.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

de Sadeleer, I., Woodhouse, A. Environmental impact of biodegradable and non-biodegradable agricultural mulch film: A case study for Nordic conditions. Int J Life Cycle Assess 29, 275–290 (2024). https://doi.org/10.1007/s11367-023-02253-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-023-02253-y