Abstract

Sewage sludge is regarded by wastewater treatment plants as problematic, from a financial and managerial point of view. Thus, a variety of disposal routes are used, but the most popular is methane fermentation. The proportion of macromolecular compounds in sewage sludges varies, and substrates treated in methane fermentation provide different amounts of biogas with various quality and quantity. Depending on the equipment and financial capabilities for methane fermentation, different methods of sewage sludge pretreatment are available. This review presents the challenges associated with the recalcitrant structure of sewage sludge and the presence of process inhibitors. We also examined the diverse methods of sewage sludge pretreatment that increase methane yield. Moreover, in the field of biological sewage sludge treatment, three future study propositions are proposed: improved pretreatment of sewage sludge using biological methods, assess the changes in microbial consortia caused with pretreatment methods, and verification of microbial impact on biomass degradation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Continuously expanded exploitation of fossil fuels is leading to their depletion; hence, exploration into novel sources and methods for the provision of infinite electrical energy and heat inflow, while maintaining comparative usage to conventional sources, is of vital importance. Moreover, the exploitation is not only leading to depletion but also impacts the environment during the sourcing and use. Non-renewable fossil fuels affect climate changes by releasing large amounts of carbon dioxide into the air when are burned. That also forces us to minimize its usage and search for alternative solutions.

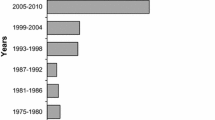

In general, human activity creates a vast amount of wastes, which gives rise to potential opportunities in the circular economy. The wastewaters are produced daily in domestic households, industries, and entertainment sectors, to name a few, which are treated in a wastewater treatment plant. However, a common side product of such treatment is the generation of sewage sludge that has the potential to be useful in biogas production. In recent years, biogas production by anaerobic digestion and its further usage is ever expanding and delving deeper in to unique and interesting areas of science. Figure 1 shows the number of papers published using the following keywords: sewage sludges, pretreatment, and anaerobic digestion.

Methane formation is an anaerobic microbial process that decreases the amount of dry and organic matter of substrates, causing stabilization of the properties of the sewage sludge. During this process, biogas is released which contains mainly methane and carbon dioxide at levels of 50–70% and 30–50% (v/v), respectively; however, residuals of hydrogen, hydrogen sulfide, and volatile organics also reside (Shrestha et al. 2020; Czatzkowska et al. 2020). The amount and quality of biogas are determined by the substrate characteristics and the ability of the fermenting microorganisms to conduct the following four phases: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. According to reports, methane production during anaerobic digestion is mostly dependent on the composition of the sewage sludge used in the fermentation process and methods used to treat the biomass (Li et al. 2019; Park et al. 2021; Liu et al. 2021b; Akbay et al. 2021). A high amount of organic matter influences the efficacy and rate of the anaerobic digestion, thus sludge treatment. Moreover, usually, the sludges produced by the wastewater treatment plants contain considerable quantities of heavy metals, pathogens, and bacteria (Liew et al. 2022). Generally, recalcitrant and low degradable biomass limits the hydrolysis stage, which impacts anaerobic digestion. During this stage, cell walls are destroyed and extracellular polymeric substances (EPSs) are released and degraded by acidogenic microorganisms, which employ EPSs as organic material. This is an important mechanism due to compounds in sewage sludge being considered relatively unfavorable substrates for microbial degradation. This stems from their structure, which protects the cell from osmotic lysis (Appels et al. 2010). EPSs are known as the dewaterability disruptor of sludge that bind with bacterial cell walls or remain in suspension. They prevent desiccation of the bacterial cell and promote water binding, making sludges difficult to dewater. In the case of thermal methods, bonded and intracellular water is more easily released compared to other methods, i.e., chemical method (Pilli et al. 2014). Additionally, depending on the sewage sludge composition and limitations of microorganism consortia, it is difficult to convert all raw materials during hydrolysis and avoid organic matter in post-fermented sludges. Research has shown that hydrolysis is a slow and limiting phase of anaerobic digestion (Li et al. 2019; Junior et al. 2021); therefore, it is important to study over improvement of pretreatment methods or hydrolysis before anaerobic digestion. The utilization of biological, chemical, thermal, or mechanical methods for the disintegration of sludge flocs and the release of simpler compounds increase biogas production (Lindmark et al. 2012; Tsapekos et al. 2015; Shrestha et al. 2017; Liang et al. 2021). Nevertheless, anaerobic digestion is a popular treatment process due to proven efficiency, reduction of pollutants, stabilization of sludges, and reduction of sludges demanding utilization (Pilli et al. 2014; Patinvoh et al. 2016). Thus, it is important to develop biomass pretreatment that will allow more effective usage of biomass and increase biogas production using an eco-friendly method and low financial outlay. The first phase of fermentation determines the effectiveness of the whole process, where the decomposition of macromolecular compounds into monomers and smaller molecules used by microorganisms in the following stages (Ziemiński and Frąc, 2021; Neumann et al. 2016). In 1978, Haug et al. conducted the first pretreatment of biomass via thermal methodology for sludge dewaterability and biodegradability under anaerobic conditions. Since this development, numerous publications on this subject have been published, which propose a plethora of combined methods and the utilization of biomass sources. However, even though pretreatment research focusing on hydrolysis improvement has been conducted for the last 40 years, comprehensive verification and testing has yet to be achieved. Nowadays, the majority of studies examine various biomass and comparison of methods in order to enhance methane production, as well as degradation or transformation of hard to decompose compounds. Moreover, pretreatment methods must consider ecological and economic aspects, including the removal of heavy metals and pharmaceuticals. In addition, there are increasing opportunities to recover various useful substances such as volatile fatty acids (VFAs), nutrients (nitrogen, phosphorus, potassium) and enzymes (Ye et al. 2020; Sichler et al. 2021). This review examines sewage sludge pretreatment methods for methane fermentation with view on substances that present limitations on the process, i.e., cellulose, hemicellulose, proteins, and lipids. Furthermore, the advantages and disadvantages of sludge pretreatment are reviewed and their influence on the methane production yield.

Methane fermentation of sewage sludge

The instantly increasing human population has caused an increase in wastewater and sewage sludge volumes generated post treatment (Duan et al. 2011). In 2010, the world’s population was 6.956.823.603, and in 2020, it increased to 7.794.798.739. On November 2022, the population reached 8 billion. According to Population Division of the Department of Economic and Social Affairs United Nations, the number of people will increase over the next few years, which will influence heavily the production of wastes and sewage sludge. According to World Population Prospects (2022), the growth to 8.5 billion in 2030 and 9.7 billion is expected by 2050.

In the last decade, the volumes of sewage sludge production generated in wastewater treatment plants (WWTPs) were increasing continuously, which is caused by the increasing population. Table 1 shows sludge production in chosen European countries between 2010 and 2019 (Eurostat, the statistical office of the European Union). That is why biogas production through anaerobic digestion becomes more interesting.

Factors impacting on the sewage sludge management

In biogas production, various sources of substrates are used depending on availability, geography, optional price and demand, type of active industry in the area, and possibilities for usage. These factors impact methane yield in relation to microorganisms’ potential such as the ability to grow in extreme conditions, incubation temperature, and environmental preferences (Passos et al. 2015). In methane fermentation, easily fermented substrates include livestock manure, food-processing wastes, and sewage sludge (Patinvoh et al. 2016; Córdoba et al. 2018).

Sewage sludges are composed of organic macromolecule compounds, varying in concentration and proportion. Wastewater flowing into WWTP is not only from private households but also from breweries, dairy factories, and paper industries, to name a few (Aski et al. 2020), which dictate the high concentration of lipids, proteins, cellulose and hemicellulose, and other polysaccharides in wastewater and then in sewage sludge. All sewage sludges are produced during wastewater treatment; hence, the composition of the sewage sludge is directly related to the composition of the wastewater that goes directly into the wastewater treatment plant. Thus, it can contain a qualitative and quantitative variety of lipids, pathogens, pharmaceuticals and their derivatives, or heavy metals. Methane fermentation of sewage sludge, other than its positive aspect for sludge stabilization and biogas production, creates wastes. These wastes depend on the degree of fermentation, calorific value, and element content such as phosphorus, potassium, calcium, and heavy metals, which can be managed, burned, or used as fertilizer. Moreover, wastewater treatment plants must contend with the presence of challenging compounds, such as insoluble proteins (about 30%, w/w TS in municipal primary sludge) (e.g., keratin) and polysaccharides (about 26%, w/w TS in municipal primary sludge) (e.g., cellulose) (Glińska et al. 2020). Recalcitrant form and difficulties in degradation of these compounds hinder the large amounts of dry matter and organic matter present in the post-fermented sewage sludge. As with almost every resource, sewage sludges must be pretreated to become efficient and safe biomass during and after the process of fermentation. These treatments must be cost-efficient and effective for various types of sewage sludge. Three groups of methods of sludge pretreatment are used, i.e., chemical, physical (including thermal and mechanical), and biological methods. Each provides different advantages and disadvantages in sewage sludge treatment, presented in Table 2. The applied impact is related to the amount of biogas produced and the level of stability of the sewage sludge. According to the literature, the most effective are thermal methods, which provide improvement in methane yield production up to 1000% (Appels et al. 2008; Nguyen et al. 2021), although the costs of energy needed to heat the sludges need to be considered. Mechanical methods provide usually not less than 100% improvement in methane production, and their use in the industry is most common (Yue et al. 2021). Usage of the chemical methods provides around 50% of the better methane production, but they are regarded to be harmful for the environment and sewage sludge itself (Zhang et al. 2023). Biological methods are not as effective as other methods mentioned above; however, they are regarded to be the safest and can be improved with other methods at a relatively low cost from other methods (Wandera et al. 2019; Liang et al. 2021). As mentioned previously, wastewater treatment plants choose pretreatment methods depending on their financial and technological possibilities, but also according to the sludge composition, mainly the presence of hard-to-decompose substances. The main purpose of the anaerobic digestion is to decrease the amount of organic substances present, i.e., in the sewage sludges, so their products could be used further in the future. Without the proper treatment, the large amount of organic matter residues remains, and eventual deposition in the environment may be dangerous for the soil and water. Sewage sludges that are not treated properly can cause odors, environmental pollution due to the recalcitrant leakage, and finally potentially hazardous influence on the human and animal health (Nguyen et al. 2021). Proper pretreatment provides not only the possibility for decreasing sludges volume directed from WWTPs but also their further usage due to stabilization of the sewage sludge properties during the anaerobic digestion, and the production of the biogas is its beneficial feature. The usage of the sewage sludges as a source for the methane production and providing its better composition contributes in a circular economy strategy.

Lignocellulose complex

Cellulose is a troublesome compound, which is a part of a lignocellulose complex that also contains hemicellulose and lignin. The combinative effect of these compounds negatively influences the effectiveness of lignocellulose decomposition. Lignin is regarded as the most recalcitrant compound to undergo biochemical decomposition (Wagland et al. 2011; Li et al. 2021). Lignocellulose contains ca. 40–60% cellulose and 20–40% hemicellulose; hence, it is a potential carbon source for biogas production (Kang et al. 2014). According to Zhen et al. (2017), the utilization of lignocellulose as a substrate promotes the production of biogas containing approx. 50–70% CH4 and 25–50% CO2. Lignocellulose degradation process is mainly associated with bacteria and fungi performance, and isolation of enzymes produced by microorganisms (Zhang et al. 2018). Although lignocellulose is a limiting compound, thus for proper usage, it is necessary to convert it into simpler and more soluble compounds, which requires lignin removal methodology (Shah et al. 2018). Wagland et al. (2011) showed that high temperature is the most efficient way for the decomposition of such biomass. In the case of other approaches, including chemical methods, pretreatment with high energy may assist the degradation process. An alternative for high-temperature pretreatment or assisted temperature pretreatment is the chemical method, where incorporation of acids and bases removes or degrades various compounds. For lignin removal or pretreatment from sewage sludges, the alkaline pretreatment approach is preferred, which mainly utilizes KOH, Ca(OH)2, and NaOH (Dai et al. 2018). Ethanol, benzene, and ethylene glycol have also been investigated for lignin removal (Taherzadeh and Karimi, 2008). The possibility of biomass fermentation increases in the presence of bases due to lignin degradation (Patinvoh et al. 2016). However, alkaline treatment decreases the degree of polymerization of lignocellulosic biomass compounds, promoting lignin removal, and increases organic matter solubility in sludge and easier cellulose degradation by enzymatic and microbial impact (Liu et al. 2021a). Thus, alkaline treatment method is a promising and efficient way to lignocellulosic biomass decomposition. In the reference to the chemical treatment, the utilization of acids in pretreatment and assisted pretreatment methodology increases the fragility of the biomass in fermentation and promotes intramolecular bond cleavage between lignin, hemicellulose, and cellulose in the cell wall (Taherzadeh and Jeihanipour 2012). The disturbance over chemical construction enables the more efficient operation of cellulolytic enzymes. It is known that the presence of acids contributes to the hydrolysis of celluloses and hemicelluloses but does not dissolve lignin, only contributing to its partial destruction (Solarte-Toro et al. 2019). Fernandes et al. (2012) reported that biomass adapted to 4.9 g NH4+-N*/L and a lack of inhibition of the hydrolysis of cellulose after the addition of ammonia concentration 2.4–7.8 g NH4+-N*/L. Free ammonia addition is known as an effective method to improve anaerobic methane production. Using it as a pretreatment method can enhance the fermentation process but also adapt biomass to handle any ammonia concentration (Wei et al. 2017a).

Proteins and lipids

Usually, the main part of the sewage sludge organic matter consists of carbohydrates; hence, numerous studies focus on the hydrolysis and decomposition of such compounds. However, in the case of proteinaceous sewage sludge, the amount of protein content exceeds that of carbohydrates. Proteinaceous sewage sludge originates from the dairy industry, and it is characterized as a valuable source for methane production, due to its high VFA content. In some industries, protein content in dairy wastewater is over 40% of total oxygen demand, but the addition of carbohydrate matter can increase protein conversion in the sewage sludge. Moreover, pH influences methane production through the composition of VFA (Liu et al. 2021a). The use of sludges rich in protein sources, such as keratin wastes (e.g., feathers), contains over 90% of crude protein instead, or mixed with sewage sludge may provide higher biogas production. Due to the insolubility of the crude protein, it is necessary to provide access for microorganisms, which allow effective decomposition and conversion into soluble oligomers (Patinvoh et al. 2016). According to Ma et al. (2019), alkaline fermentation leads to efficient VFA enhancement production providing a carbon source for biological nutrient removal and increased degradation of difficult to biodegrade organic matter. Reports have shown that increased VFA concentration contributes to intensification of biogas production (Worwag and Kwarciak-Kozłowska 2019).

The prevalence of proteins in sewage sludge can also inhibit the process. Inhibition of bacterial activity can occur when substrates and products are in significant concentrations. Thus, the properly chosen pretreatment method may be beneficial for the process, from the point of troubleshooting and economy of the treatment. Under such conditions, more VFA is produced, which may lead to inhibition of the process (Shah et al. 2018). When VFA concentration is too high (>3.6 g*/L (Zhang et al. 2001)), inhibition of methanogenesis and hydrolysis/acidogenesis occurs due to organic overloading (Fotidis et al. 2012). Methanogens are not able to remove hydrogen and volatile organic acids faster than they are produced, resulting in this compound accumulation that causes changes in pH and disturbance of the hydrolysis and acidogenesis stages (Ponsá et al. 2008). High concentrations of ammonia can also inhibit methanogenesis, which is commonly present in complex wastes, mainly in animal manures, black water, or waste oil from gastronomy (Belmonte et al. 2011). Shi et al. (2017) observed that the presence of free ammonia (0.045 g*/L) caused an inhibitory effect of methanogenesis and accumulation of VFAs. Belmonte et al. (2011) showed that the concentration of free ammonia above 0.04 g NH3-N*/L caused IC50 (concentration at which a substance exerts half of its maximal inhibitory effect) of 56–84% for methanogenic bacteria present in raw swine wastewater and 84–94% for treated swine wastewater.

Methods of sewage sludge treatment

The pretreatment methods of sewage sludges are used to support the process of methane fermentation (Patinvoh et al. 2016; Wluka et al. 2021; Nguyen et al. 2021; Machnicka and Grübel 2023). Methods used for the pretreatment of biomass for biogas production on a large scale are chemical, or physical, including thermal and mechanical. Recently, more attention gains also biological methods, based on microorganisms possessing particular features and enzymes produced by them (Kumar and Gopal 2015; Junior et al. 2021; Nguyen et al. 2021). For now, biological methods find their appliance only in the lab scale. The effectiveness of these methods can be compared only with the impact on the precise substrate (Lee et al. 2010). The potential advantages and disadvantages of the proposed methods are compared in Table 2.

All described methods demand high investment or operating costs, but in the long-term appliance, advantages may be overall the negative aspects. There is no universal pretreatment method for all biomass types; thus, the methods described in Table 2 and the potential of their usage are usually different depending on the composition of biomass sources. Nevertheless, each of the presented provides an increase in methane production and improved sewage sludge stabilizations, which decrease WWTP overall costs.

Chemical methods

Pretreatment using chemical methods commonly employs acids and bases, which decrease recalcitration, and improves decomposition or degradation of biomass. Depending on the composition and origin of the biomass, various solutions of different concentrations are used to increase decomposed solid compounds and methane yield. Unoptimized and unbalanced pretreatment methods can lead to the production of inhibitors, such as furfurals during high thermal acidic pretreatment of the lignocellulosic substrate in order to degrade cellulose and hemicellulose (Chen et al. 2007), or VFA during alkali pretreatment of proteinaceous sludge. From a financial point of view, chemical methods are highly desirable. They are easily modified and result in high methane yield. In most reported cases, chemical pretreatment avoids subjection to thermal conditions. The most commonly used chemicals are HCl, H2SO4, H3PO4, HNO3, and HNO2 for acid pretreatment and NaOH, KOH, Ca(OH)2, Mg(OH)2, CaO, and ammonia for alkali pretreatment. Lü et al. (2007) examined alkali pretreatment and determined that using ammonia in protein hydrolysis caused its biodegradation. In the case of lipids, different concentrations of ammonia displayed varying degrees of influence on easy and hard biodegradable lipids. Wei et al. (2017a) verified the influence of free ammonia on methane production, where the addition of 250 mg NH3-N/L of the free ammonia was effective in enhancing methane fermentation. The greatest improvement of biochemical methane potential and hydrolysis rate was determined for 420–680 mg NH3-N/L.

Shah et al. (2018) studied alkali reagents of various concentrations in conjunction with different heating processes, including water bath, autoclaving and short time microwaving. The results showed that the highest delignification, compared to the other methods, was obtained using 2% NaOH and short time microwave heating process, providing biogas yield of 560 mL/g VS.

Wei et al. (2017b) showed that during acid pretreatment, addition of N/L free nitrous acid increased methane production by 16±1% and 16–17% reduction of dewatered sludge for final disposal. According to Zahedi et al. (2016), addition of free nitrous acid (2.49 mg N-HNO2/L) and incubation for 5 h increased the solubility of organic matter and methane production up to 25%.

Liu et al. (2021b) reported that pH regulation and chemical pretreatment were achieved using NaCl and NaOH. They determined that at pH = 11.0 the concentration of soluble proteins and VFA was higher than that at the pH = 3.0. Hence, pH modification impacted not only on VFA production but also the percentage of individual VFA. All acids and bases described above are used for sewage sludge treatment in research and industry. Dai et al. (2018) researched chemical and biological pretreatment of rice straw. Pretreatment using cellulase with NaOH, HCl, and CO(NH2) increased biogas production under anaerobic conditions. HCl dissolved hemicellulose by approx. 12.5–7.1%. After cellulase pretreatment, cellulose degradation was 38.3–10.9%. Pretreatment using 6% NaOH resulted in TS and VS removal of 53.8% and 36.8%, respectively. Song et al. (2014) compared seven chemicals alkali and acid pretreatment methods of various concentrations: H2SO4, HCl, H2O2, and CH3COOH at concentrations of 1%, 2%, 3%, and 4% (w/w) for acid pretreatment and NaOH, Ca(OH)2, and NH3*H2O at concentrations of 4%, 6%, 8%, and 10% (w/w) for alkaline pretreatment. The results showed that H2O2 and Ca(OH)2 were the most efficient, giving 216.7 and 206.6 mL of CH4/g VS.

Physical methods

The complex structure of sewage sludge compounds prevents effective processing, forcing mechanical, ultrasound, microwave, or explosion treatment before anaerobic digestion. The main goal for pretreatment of sewage sludge is to increase the accessibility of the surface area and pore size, and cell walls break down, allowing microorganisms access to nutrients, thus improving biomass decomposition (Zhen et al. 2017). Physical pretreatment methods are preferable to treat difficult biomass, such as hard food wastes; agricultural residues from straw, crops, and wood; and forest residues (Rodriguez et al. 2017). Mechanical methods of disintegration reduce particle size due to external stress and pressure, converting compact masses of biomass into more soluble material (Shrestha et al. 2020). The size of particles impacts biogas production, where larger particles result in lower chemical oxygen demand (Nguyen et al. 2021). Ultrasound is considered an effective mechanical method. During ultrasonication, microbubbles that form collapse after reaching the critical size and cavitation occur. This process increased with increasing temperature and pressure, initiating hydro-mechanical shear forces and the presence of reactive radicals (H∙ and ∙OH). The decomposition of sludge flocs and release of intercellular material by physical methods have the hydro-mechanical shear forces and oxidizing influence of radicals, but the greatest impact has hydro-thermal shear forces (Pilli et al. 2011).

Another commonly used method of pretreatment involves microwaves, where the generated heat causes disintegration of compounds via hydrogen bond cleavage due to changes in dipole orientation at the polarized side chains in the cell membranes of macromolecules (Park et al. 2004, Serrano et al. 2016). Microwave is considered a promising pretreatment method and is normally used in crop straw pretreatment (Liu et al. 2021a). It is a rapid heating source, promoting thermal and nonthermal effects, resulting in enhanced biogas production, and it is regarded a supporting method for chemical treatment (Xu, 2015; Zaidi et al. 2019). Elalami et al. (2020) determined that using a single microwave or ultrasound pretreatment was less effective than the combined methods with alkali pretreatment. Moreover, mild microwave or ultrasonic pretreatment did not affect lignin degradation; however, the utilization of NaOH showed a substantial effect. Furthermore, alkali pretreatment reduces lipid content by saponification.

For mechanical pretreatment, various beaters or mills can be employed. Rodriguez et al. (2018) used the Hollander beater for anaerobic digestion of algae Pelvetia canaliculata. This resulted in maximum methane production of 283 mL/g VS and increased methane yield up to 43% in reference to non-pretreated algae. The Hollander beater was used also by Tedesco et al. (2014), where after pretreatment at 50°C for 10 min, biogas production increases by 52% and methane yield by 53% compared to the control sample. Rice straw biogas production using biological pretreatment supported by milling was performed by Mustafa et al. (2017). First biomass was treated with fungal strains and then prior into a mill. This combination increased methane production by 165%. It is known that particle size matters. Izumi et al. (2010) verified its effect on anaerobic digestion of food wastes. Bead milling was used and enhanced methane production by 28%, compared to the non-pretreated sample. Depending on the used biomass, physical method may give different results, so also comparison inside the group of methods is studied. Suresh et al. (2013) showed higher methane production using green algae Ettlia sp. as a substrate with the pretreatment under autoclave conditions compared to using sonicated residue and 250 W microwave. Montingelli et al. (2015) verified the influence of microwaves, ball milling, and beating on micro-algae biomass and determined that beating increased methane yield up to 37%, but ball milling and microwave method gave lower methane yield compared to biomass without pretreatment.

Among all pretreatment methods, thermal hydrolytic pretreatment reduces the VS and enhances biogas production (Chen et al. 2018). Thermal hydrolysis is a commonly used pretreatment method in industry for effective sludge treatment (Liang et al. 2021). Such pretreatment methodologies improve dewaterability, solubilization, and liquefaction of organic matter (Pilli et al. 2014). Additionally, thermal hydrolysis decreases particle size and viscosity, which increases access of the microbes and enzymes to the substrate (Chen et al. 2019). Reports have shown that thermal hydrolysis used on a full scale at WWTP increases the net electrical production of biogas by 20% (Tyagi and Lo 2013; Liang et al. 2021). The temperature range of thermal pretreatment is between 60 and 270°C, which categorizes pretreatment into low- (below 100°C) and high-temperature thermal pretreatment (above 100°C). High-temperature thermal pretreatment destroys sewage sludge particles and releases intracellular water, which is also achieved by particle collisions that causes gel structure destruction (Chu et al. 1999). Furthermore, an increase in temperature increases the chemical oxygen demand (Perez-Elvira et al. 2010). An increase in carbohydrate concentration was observed up to 130 °C and then decreases above 165°C. The results were obtained using spectrophotometric techniques by quantifying carbonyl groups (Pilli et al. 2014). The best results in sludge biodegradability, dewaterability, and biogas production (an increase of 40–80%) were obtained using pretreatment in 160 for 30 min and 180°C for 60 min. Low- and high-temperature pretreatment differs in the treatment time which is needed to obtain the same biogas generation. In the case of low-temperature pretreatment, the time period use can be hours or even days, with an increase of 20–50% in biogas production in comparison to samples never treated. The anaerobic pretreatment may be conducted in mesophilic and thermophilic conditions, or of their combination as two-stage anaerobic digestion. Under these conditions, hyperthermophilic chamber is used, followed by a mesophilic digester, causing an increase of solid-state hydrolysis, acidogenesis in thermophilic conditions, and then methanogenesis in a mesophilic environment (Handous et al. 2019). Ruffino et al. (2020) compared temperature-phased anaerobic digestion (TPAD) regarding conventional anaerobic digestion and showed higher efficiency in volatile solid (VS) reduction and methane generation. Amodeo et al. (2021) studied two different organic fractions of municipal solid wastes in co-digestion with digested sludge and determined an increase of methane production for both substrates at 55°C of solid retention time. Xiao et al. (2018) compared TPAD and food wastes with single-stage digestion in mesophilic and thermophilic anaerobic digestion and determined that lower methane yields were obtained when temperature-phased pretreatment was used. All thermal pretreatment methods influence methane production, enhance VFA generation, solubilization, and soluble chemical oxygen demand (sCOD) (Pilli et al. 2014; Junior et al. 2021). Low-temperature pretreatment increases sCOD, proteins, and sludge solubilization, but at a very low level, compared to high-temperature treatment (Chen et al. 2018). Thermal pretreatment consists of heat energy provided by heat exchangers or steam explosion, generating high pressure and heat. Such pretreatment methods enhance solubilization. The highest methane yield was observed after pretreatment for 15 min at 10 bar and 10 min at 15 bar. Similarly, studies conducted by Lizasoain et al. (2016) confirmed a positive influence of steam explosion regarding reed biomass, in which increased methane yield up to 89% was obtained after 15 min pretreatment at 200°C. A comparative study of steam explosion at 170°C and regular thermal sludge treatment in the autoclave (70, 100, and 125°C) was conducted by Liu et al. (2019). It was found that steam explosion had the potential to pretreat granular aerobic biomass with low methane yield caused by high mineral content. According to reports, the method that considers mineral content may be useful for resource recovery.

Biological methods

Over the past few years, biological method using microorganisms and enzymes under aerobic and anaerobic conditions is a promising biomass pretreatment method. During the process, extensive degradation of lignin conducted by white-rot fungi and their enzymes responsible for the decay was observed (Adney et al. 2009). Fungi are considered to be the most effective microorganisms in biodegradation of lignocellulosic biomass, but other microorganisms have also their part. The influence of microorganisms is highly effective and improves both the pretreatment and fermentation process. Under optimal conditions, microorganisms stop the activity of inhibitors if they are biodegradable, or accumulated it while the concentration of non-biodegradable inhibitors is low. A high concentration of inhibitors leads to microbe death (Chen et al. 2007). Microorganisms can originate from various environments such as soil, manure, compost, food wastes, and sewage sludges (Kumar and Gopal 2015; Pessuto et al. 2016; Rodriguez et al. 2017; Baba et al. 2017; Zhang et al. 2018). Since microorganisms are already present in the environment, their addition cannot lead to microbial pollution, but the improper number, causing disturbance in the community, may decrease process efficiency. Similarly, as with chemical and physical pretreatment, biological methods may provide positive or negative biogas production effects. Microbial consortia during biogas production undergo various processes, which depend on the accessibility of nutrients and proper process conditions. Any disturbance in the microbial balance or presence of inhibitors may stop the biogas production process, or change its composition. As mentioned, microorganisms can take part in substrate treatment under aerobic or anaerobic conditions. Aerobic pretreatment consists of oxygenation, through the injection of oxygen into the pre-fermentation reactor, which improves the hydrolysis of macromolecular organic compounds by increasing the autochthonous microorganisms. Oxygenation, also called micro-aeration pretreatment, not only impacts microbial activity and diversity, causing hydrolysis increase, but also methane production (Nguyen and Khanal 2018). Micro-aeration stabilizes the liberation of exoenzymes, which biodegrade compounds that remain recalcitrant under anaerobic conditions (Ahn et al. 2014). Supporting impact on organic compound treatment in the aerobic pretreatment has a high temperature, which stimulates microbial consortia to produce enzymes (i.e., proteases) responsible for improving biomass solubility and organic compound degradation (Neumann et al. 2016). Nguyen et al. (2019) suggested that such pretreatment method could be used as an effective control strategy when the organic loading rate was high, thus, confirming rapid VFA conversion, followed by methane production, conducted by facultative anaerobic microorganisms and hydrogenotrophic methanogens. Using limited micro-aeration in to corn straw anaerobic digestion produces the following maximum results: 216.8 mL/g VS of methane yield and 54.3% removal of VS (Fu et al. 2016). Fu et al. (2016) showed changes in the microbial community structure and improvement of specific methanogenic activity after micro-aeration. Under micro-aerobic conditions, increased numbers of phylum Firmicutes, class Clostridia, and order Clostridiales were observed (Mustapha et al. 2018). As mentioned, micro-aeration at high temperature generates positive results and high potential, but research (Table 3; Ding et al. 2017; Liang et al. 2021) confirms high methane yield when using only high temperature and microorganisms. Biological pretreatment can proceed by the aforementioned methods described, using inoculation of the biomass with microorganisms, their activity products (isolated enzymes), or commercially available enzymes. According to reports, the basic assumption is that microorganisms present in the substrate use available compounds as food, allowing the use of the biodegradable products by other microorganisms, which undergo the following stages. The addition of extra microorganisms can disturb the balance in the microbial community of sewage sludge but also improve the process. The influence of microorganism inoculation is noticeable when using autochthonous microorganisms according to Pessuto et al. (2016) for anaerobic digestion of swine manure, where an increase in biogas and methane production was determined.

Supporting the pretreatment with enzymes has gained lot of interest. The addition of hydrolytic enzymes provides enhanced hydrolysis and increases biogas production, sludge solubilization, and degradation of the extracellular polymeric substances (EPSs) (Yin et al. 2016). Enzymes may be an alternative for thermochemical methods of hydrolysis, diminishing overall costs, as the enzymes may be produced by a wide range of bacteria and fungi (Miao et al. 2013; Mahdy et al. 2014).

There are 4 ways of enzyme addition methods according to Brémond et al. (2018), which rely on (1) addition to a dedicated pretreatment vessel, (2) direct addition to the hydrolysis and acidification vessel over a two-stage process, (3) direct addition to the digester in a single-stage process, and (4) addition to the recirculated anaerobic digestion leachate. Depending on the substrate, the composition and parameters of enzymes used should be optimized, such as isoelectric point, specificity, activity, and temperature (Divya et al. 2015). The research conducted by Zhao et al. (2018) compared chemical and biological pretreatment using enzymes, fungi, and alkali (NaOH) and combined NaOH with both fungi and enzymes. The combination of the two enzymes gave methane yield of approx. 276.16 and 273.75 mL/g TS, respectively. The presence of NaOH gave the same result as the first obtained during enzyme pretreatment, confirming that chemical pretreatment could be replaced by a safer method. NaOH combined with one enzyme pretreatment method increased methane production to over 20.24% compared to the control, but fungal treatment decreased biogas production and inhibited the process. Enzymes were used also by Moon and Song (2011), where hydrolysis reaction was conducted for 10 h. A mixture of enzymes (carbohydrase, protease, and lipase in ratio 1:2:1) was examined, generating 0.35 L CH4/gCOD. Biological methods have already been studied, but compared to chemical or physical pretreatment, they seem to be equally popular.

Biological methods using enzymes are a promising approach, but their price is high, and the time of producing enzymes by microorganisms is long. Hence, the production and subsequent recovery of enzymes are reasonable from the economical point of view (Marín et al. 2018). Cellulases were extracted from the substrate, which was further tested for methane production. The authors obtained 552±66, 543±47, and 663±40 mL biogas/g VS for apple pomace, orange peel, and rice fiber after 25 days, respectively, confirming the positive influence of enzymes. The authors tested recovered enzymes, which determined their potential reusability. Table 3 shows examples of pretreatment methods, the concentration of VFAs, sCOD, and methane yield, depending on the used biomass and total and volatile solids.

Pretreatment methods are useful not only for increasing biomass fragility but also for heavy metals or pharmaceutical removal from the sludges to the liquid phase; such methods include steam explosion pretreatment. This approach employs high pressure and heat causing break down of sludge structures and contained compounds. The steam explosion eliminates the need for chemical usage; hence, it can be considered as an eco-friendly pretreatment method (Aski et al. 2020). Aski et al. (2020) confirmed that this method allowed for pharmaceutical and heavy metal removal, such as ibuprofen (in 65 and 69%), acetaminophen (in 66 and 70%), amoxicillin (in 66 and 70%), lead (in 78 and 70%), and cadmium (in 79%) removal from primary sludge and waste-activated sludge by facilitating the leaching them out into the liquid phase. Physical pretreatment methods can be applied to sewage sludge pretreatment, as well as reduction of dangerous impact of pharmaceuticals, antibiotics, and heavy metals. Zhang et al. (2019) described that an influencing factor that reduces antibiotic resistance genes (ARGs) was present in chicken manure, when supported with activated carbon. The authors noted that ARG removal rate was obtained 87–95% in a digester with microwave pretreatment supported with activated carbon and 34–58% in the digester with substrate only microwaved. In other studies, Bao et al. (2020) showed an increase of VFA and sCOD concentration after ultrasound-alkali pretreatment of waste-activated sludge and methane yield of approx. 97±1.85% in reference to the control reactor. The research was conducted using a combined process of microbial electrolysis cell and anaerobic digestion. The obtained results suggest that such pretreatment not only supports the degradation of organic compounds and increases biogas production but also supports VFA recovery that becomes precursors for the production of higher-value biofuel and biochemical generation.

Currently, the methane produced in anaerobic digestion is used by wastewater treatment plants for its purposes, to provide heat and energy for WWTPs’ infrastructure, or it is simply burned. Future perspective of using biogas as green energy source for larger group of consumers should be considered. Improved production of biogas may fulfil the energy demand with environmentally friendly replacement for fossil fuels.

Conclusion

Sludges for fermentation may contain inhibitors, indigestible, and hard to degrade compounds, but their presence should not determine the low effectiveness of the process. An efficient process may be possible with proper supporting methods, providing effective treatment of substrates, with high energy benefits. One of the critical aspects is high methane potential of the substrate, which is determined only after all possible pretreatment methods are tested, because certain methods may not impact, increase, or decrease biogas and methane production. All described methods improve hydrolysis and methane yield, but the best effects are obtained using mechanical methods. Such methods are expensive and require high energy contribution, which, in the circular economy, can be returned in biogas production. Chemical methods may be less effective when used separately, can cause the production of inhibitors, and destroy equipment and large investment and exploitation costs. Biological methods produce comparative methane yields to other pretreatment methods but may not be yet considered as an alternative method for chemical or physical pretreatment on a large scale. Moreover, they are costly and cannot be easily transformed from a lab scale into the industry. All methods provide higher efficiency when they are used in combination with the other techniques, from a different category. As methane fermentation is a biological process, any change may cause microbial consortia balance disturbance; thus, it should be obligatory to verify the condition of the biomass activity before and after pretreatment, revealing the pretreatment effect. Both, the influence of pretreatment on microorganisms consortium present in the sewage sludges, and the influence of the microorganisms on the biodegradability of sludge and composition changes. Additionally, the analysis for determining hydrolysis effectiveness should be systematized, which will allow for proper comparison of possible methods. The greatest challenge for sustainable and efficient anaerobic digestion is possessing energy and economic balance, when considering ecological aspects. Moreover, very often efficient pretreatment methods are expensive when tested and used already in lab scale; therefore, they may not be attractive for industries. Potential influence on the pretreated substrate environment should be considered and the possibility of recovery compounds, substrates, or as circular economy attitude. For future studies, more attention should be given to the improvement of biological pretreatment methods without using chemical supported methods, as well as conducting additional recovery of used materials for a more eco-friendly approach.

Figures and tables of this word can be found in online version of the paper

References

Adney WS, van der Lelie D, Berry AM, Himmel ME (2009) In: Himmel ME (ed) Understanding the biomass decay community, biomass recalcitrance. Blackwell Publishing Ltd, pp 454–479. https://doi.org/10.1002/9781444305418.ch15

Agabo-Garciá C, Pérez M, Rodríguez-Morgado B, Parrado J, Solera R (2019) Biomethane production improvement by enzymatic pre-treatments and enhancers of sewage sludge anaerobic digestion. Fuel 255:115713. https://doi.org/10.1016/j.fuel.2019.115713

Ahn YM, Wi J, Park JK, Higuchi S, Lee NH (2014) Effects of pre-aeration on the anaerobic digestion of sewage sludge. Environ Eng Res 19(1):59–66. https://doi.org/10.4491/eer.2014.19.1.059

Akbay HEG, Dizge N, Kumbur H (2021) Enhancing biogas production of anaerobic co-digestion of industrial waste and municipal sewage sludge with mechanical, chemical, thermal, and hybrid pretreatment. Bioresour Technol 340:125688. https://doi.org/10.1016/j.biortech.2021.125688

Amodeo C, Hattou S, Buffiere P, Benbelkacem H (2021) Temperature phased anaerobic digestion (TPAD) of organic fraction of municipal solid waste (OFMSW) and digested sludge (DS): effect of different hydrolysis conditions. Waste Manage 126:21–29. https://doi.org/10.1016/j.wasman.2021.02.049

Appels L, Baeyens J, Degrève J, Dewil R (2008) Principles and potential of the anaerobic digestion of waste-activated sludge. Prog Energ Combust 34(6):755–781. https://doi.org/10.1016/j.pecs.2008.06.002

Appels L, Degrève J, Van der Bruggen B, Van Impe J, Dewil R (2010) Influence of low temperature thermal pre-treatment on sludge solubilization, heavy metal release and anaerobic digestion. Bioresour Technol 101(15):5743–5748. https://doi.org/10.1016/j.biortech.2010.02.068

Aski AL, Borghei A, Zenouzi A, Ashrafi N, Taherzadeh MJ (2020) Steam explosion pretreatment of sludge for pharmaceutical removal and heavy metal release to improve biodegradability and biogas production. fermentation 6(34):1–15. https://doi.org/10.3390/fermentation6010034

Baba Y, Matsuki Y, Mori Y, Suyama Y, Tada C, Fukuda Y, Saito M, Nakai Y (2017) Pretreatment of lignocellulosic biomass by cattle rumen fluid for methane production: Bacterial flora and enzyme activity analysis. J Biosci Bioeng 123(4):489–496. https://doi.org/10.1016/j.jbiosc.2016.11.008

Bao H, Yang H, Zhang H, Liu Y, Su H, Shen M (2020) Improving methane productivity of waste activated sludge by ultrasound and alkali pretreatment in microbial electrolysis cell and anaerobic digestion coupled system. Environ Res 180:108863. https://doi.org/10.1016/j.envres.2019.108863

Belmonte M, Hsieh CF, Figueroa C, Campos JL (2011) Effect of free ammonia nitrogen on the methanogenic activity of swine wastewater. Electron J Biotechn 14(3):2–2. https://doi.org/10.2225/vol14-issue3-fulltext-11

Brémond U, de Buyer R, Steyer J-P, Bernet N, Carrere H (2018) Biological pretreatments of biomass for improving biogas production: an overview from lab scale to full-scale. Renew Sust Energ Rev 90:583–604. https://doi.org/10.1016/j.rser.2018.03.103

Chen H, Chang S (2017) Impact of temperatures on microbial community structures of sewage sludge biological hydrolysis. Bioresour Technol 245(Part A):502–510. https://doi.org/10.1016/j.biortech.2017.08.143

Chen Y, Cheng JJ, Creamer KS (2007) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99(10):4044–4064. https://doi.org/10.1016/j.biortech.2007.01.057

Chen S, Li N, Dong B, Zhao W, Dai L, Dai X (2018) New insights into the enhanced performance of high solid anaerobic digestion with dewatered sludge by thermal hydrolysis: organic matter degradation and methanogenic pathways. J Hazard Mater 342:1–9. https://doi.org/10.1016/j.jhazmat.2017.08.012

Chen S, Dong B, Dai X, Wang H, Li N, Yang D (2019) Effect of thermal hydrolysis on the metabolism of amino acids in sewage sludge in anaerobic digestion. Waste Manage 88:309–318. https://doi.org/10.1016/j.wasman.2019.03.060

Chu CP, Feng WH, Chang BW, Chou CH, Lee DJ (1999) Reduction in microbial density level through freezing and thawing. Water Res 33(16):3532–3535. https://doi.org/10.1016/S0043-1354(99)00067-6

Córdoba V, Fernández M, Santalla E (2018) The effect of substrate/inoculum ration on the kinetics of methane production in swine wastewater anaerobic digestion. Environ Sci Pollut R 25:21308–21317. https://doi.org/10.1007/s11356-017-0039-6

Czatzkowska M, Harnisz M, Korzeniewska E, Koniuszewska I (2020) Inhibitors of the methane fermentation process with particular emphasis on the microbiological aspects: a review. Energy Sci Eng 8(5):1880–1897. https://doi.org/10.1002/ese3.609

Dai BL, Guo XJ, Yuan DH, Xu JM (2018) Comparison of different pretreatments of rice straw substrate to improve biogas production. Waste Biomass Valorization 9:1503–1512

Ding HH, Chang S, Liu Y (2017) Biological hydrolysis pretreatment on secondary sludge: enhancement of anaerobic digestion and mechanism study. Bioresour Technol 244(1):989–995. https://doi.org/10.1016/j.biortech.2017.08.064

Divya D, Gopinath LR, Christy PM (2015) A review on current aspects and diverse prospects for enhancing biogas production in sustainable means. Renewable Sustainable Energy Rev 42:690–699. https://doi.org/10.1016/j.rser.2014.10.055

dos Santos FJ, de Oliveira D, Maldonado RR, Kamimura ES, Furigo S Jr (2020) Enzymatic pretreatment and anaerobic co-digestion as a new technology to high-methane production. Appl Microbiol Biotechnol 104:4235–4246. https://doi.org/10.1007/s00253-020-10526-x

Duan N, Dong B, Wu B, Dai X (2011) High-solid anaerobic digestion of sewage sludge under mesophilic conditions: feasibility study. Bioresour Technol 104:150–156. https://doi.org/10.1016/j.biortech.2011.10.090

Elalami S, Carrere H, Abdelouahdi K, Garcia-Bernet D, Peydecastaing J, Vaca-Medina G, Ouukarroum A, Zeroual Y, Barakat A (2020) Mild microwaves, ultrasonic and alkaline pretreatments for improving methane production: impact on biochemical and structural properties of olive pomace. Bioresour Technol 229:122591. https://doi.org/10.1016/j.biortech.2019.122591

Eurostat, the Statistical Office of the European Union, water statistics on national level, Sewage sludge production and disposal, last update: 10.08.2022. 2022https://ec.europa.eu/eurostat/cache/metadata/en/env_nwat_esms.htm. Accessed 14 March 2023

Fernandes TV, Keesman KJ, Zeeman G, van Lier JB (2012) Effect of ammonia on the anaerobic hydrolysis of cellulose and tributyrin. Biomass Bioenerg 47:316–323. https://doi.org/10.1016/j.biombioe.2012.09.029

Fotidis IA, Karakashev D, Kotsopoulos TA, Martzopoulous GG, Angelidaki I (2012) Effect of ammonium and acetate on methanogenic pathway and methanogenic community composition. FEMS 83:38–48. https://doi.org/10.1111/j.1574-6941.2012.01456.x

Fu SF, Wang F, Shi XS, Guo RB (2016) Impacts of microaeration on the anaerobic digestion of corn straw and the microbial community structure. Chem Eng J 287:523–528. https://doi.org/10.1016/j.cej.2015.11.070

Gahlot P, Balasundaram G, Tyagi VK, Atabani AE, Suthar S, Kazmi AA, Štěpanec L, Juchelková D, Kumar A (2022) Principles and potential of thermal hydrolysis of sewage sludge to enhance anaerobic digestion. Environ Res 214:113856. https://doi.org/10.1016/j.envres.2022.113856

Glińska K, Lerigoleur C, Giralt J, Torrens E, Bengoa C (2020) Valorization of cellulose recovered from WWTP sludge to added value levulinic acid with a Brønsted acidic ionic liquid. Catalysts 10:1004. https://doi.org/10.3390/catal10091004

Grönroos A, Kyllönen H, Korpijärvi K, Pirkonen P, Paavola T, Jokela J, Rintala J (2005) Ultrasound assisted method to increase soluble chemical oxygen demand (SCOD) of sewage sludge for digestion. Ultrason Sonochem 12:115–120. https://doi.org/10.1016/j.ultsonch.2004.05.012

Handous N, Gannoun H, Hamdi M, Bouallagui H (2019) Two-stage anaerobic digestion of meat processing solid wastes: methane potential improvement with wastewater addition and solid substrate fermentation. Waste Biomass Valori 10:131–142. https://doi.org/10.1007/s12649-017-0055-2

Haug RT, Stuckey DC, Gossett JM, McCarty PL (1978) Effect of thermal pretreatment on digestibility and dewaterability of organic sludges. J Water Pollut Control Fed 50(1):73–85

Iglesias-Iglesias R, Campanaro S, Treu L, Kennes C, Veiga MC (2019) Valorization of sewage sludge for volatile fatty acids production and role of microbiome on acidogenic fermentation. Bioresour Technol 291:121817. https://doi.org/10.1016/j.biortech.2019.121817

Izumi K, Okishop Y, Nahao N, Niwa C, Yamamoto S, Toda T (2010) Effects of particle size on anaerobic digestion of food waste. Int Biodeter Biodegr 64(7):601–608. https://doi.org/10.1016/j.ibiod.2010.06.013

Jankowska E, Chwiałkowska J, Stodolny M, Oleśkowicz-Popiel P (2015) Effect of pH and retention time on volatile fatty acids production during mixed culture fermentation. Bioresour Technol 190:274–280. https://doi.org/10.1016/j.biortech.2015.04.096

Jiang X, Lyu Q, Bi L, Liu Y, Xie Y, Ji G, Huan C, Xu L, Yan Z (2022) Improvement of sewage sludge anaerobic digestion through synergistic effect combined trace elements enhancer with enzyme pretreatment and microbial community response. Chemosphere 286:131356. https://doi.org/10.1016/j.chemosphere.2021.131356

Junior IV, de Almaida R, Cammarota MC (2021) A review of sludge pretreatment methods and co-digestion to boost biogas production and energy self-sufficiency in wastewater treatment plants. J. Water Process. Eng. 40:101857. https://doi.org/10.1016/j.jwpe.2020.101857

Kakar FL, Liss SN, Elbeshbishy R (2022) Differential impact of acidic and alkaline conditions on hydrothermal pretreatment, fermentation and anaerobic digestion of sludge. Water Sci Technol 86(12):3077–3092. https://doi.org/10.2166/wst.2022.368

Kang Q, Appels L, Tan T, Dewil R (2014) Bioethanol from lignocellulosic biomass: current findings determine research priorities. Sci World J 2014:298153. https://doi.org/10.1155/2014/298153

Kazimierowicz J, Zieliński M, Bartkowska I, Dębowski M (2022) Effect of acid whey pretreatment using ultrasonic disintegration on the removal of organic compounds and anaerobic digestion efficiency. Int J Env Res Pub He 19:11362. https://doi.org/10.3390/ijerph191811362

Klassen V, Blifernez-Klassen O, Wibberg D, Winkler A, Kalinowski J, Posten C, Kruse O (2017) Highly efficient methane generation from untreated microalgae biomass. Biotechnol Biofuels 10:186. https://doi.org/10.1186/s13068-017-0871-4

Kumar BL, Gopal DVRS (2015) Effective role of indigenous microorganisms for sustainable environment. 3 Biotech 5:867–876. https://doi.org/10.1007/s13205-015-0293-6

Lee JY, Yoo C, Jun SY, Ahn CY, Oh HM (2010) Comparison of several methods for effective lipid extraction from microalgae. Bioresour Technol 101(1):S75–S77. https://doi.org/10.1016/j.biortech.2009.03.058

Li Y, Chen Y, Wu J (2019) Enhancement of methane production in anaerobic digestion process a review. Appl Energ 240:120–137. https://doi.org/10.1016/j.apenergy.2019.01.243

Li P, He C, Cheng C, Jiao Y, Shen D, Yu R (2021) Prediction of methane production from co-digestion of lignocellulosic biomass with sludge based on the major composition of lignocellulosic biomass. Environ Sci Pollut Res 28:25808–25818. https://doi.org/10.1007/s11356-020-12262-1

Liang JJ, Li B, Wen L, Li R, Li X (2021) Thermal hydrolysis of wastewater sludge followed by fungal fermentation for organic recovery and hyphae fiber production. Engineering 7(2):203–2011. https://doi.org/10.1016/j.eng.2020.09.002

Liew CS, Yunus NM, Chidi BS, Lam MK, Goh PS, Mohamad M, Sin JC, Lam SM, Lim JW, Lam SS (2022) A review on recent disposal of hazardous sewage sludge via anaerobic digestion and novel composting. J Hazard Mater 423:126995. https://doi.org/10.1016/j.jhazmat.2021.126995

Lindmark J, Leksell N, Schnürer A, Thorin E (2012) Effects of mechanical pre-treatment on the biogas yield from ley crop silage. Appl Energ 97:498–502. https://doi.org/10.1016/j.apenergy.2011.12.066

Liu H, Wang J, Liu X, Fu B, Chen J, Yu HQ (2012) Acidogenic fermentation of proteinaceous sewage sludge Effect of pH. Water Res 46:799–807. https://doi.org/10.1016/j.watres.2011.11.047

Liu Y, Nilsen PJ, Maulidiany ND (2019) Thermal pretreatment to enhance biogas production of waste aerobic granular sludge with and without calcium phosphate precipitates. Chemosphere 234:725–732. https://doi.org/10.1016/j.chemosphere.2019.06.104

Liu J, Zhao M, Lv C, Yue P (2020) The effect of microwave pretreatment on anaerobic co-digestion of sludge and food waste: performance, kinetics and energy recovery. Environ Res 189:109856. https://doi.org/10.1016/j.envres.2020.109856

Liu Q, Pan S, Zhou L, Feng L, Li Z, Du L, Wei Y (2021a) Improving the biogas potential of rice straw through microwave-assisted ammoniation pretreatment during anaerobic digestion. BioEnerg Res 15:1240–1250. https://doi.org/10.1007/s12155-021-10299-9

Liu X, Du M, Lu Q, He D, Song K, Yang Q, Duan A, Wang D (2021b) How does chitosan affect methane production in anaerobic digestion? Environ Sci Technol 55(23):15843–15852. https://doi.org/10.1021/acs.est.1c04693

Lizasoain J, Rincón M, Theuretzbacher F, Enguídanos R, Nielsen RJ, Potthast A, Zweckmair T, Gronauer A, Bauer A (2016) Biogas production from reed biomass: effect of pretreatment using different steam explosion conditions. Biomass Bioenerg 95:84–91. https://doi.org/10.1016/j.biombioe.2016.09.021

Lü F, He PJ, Shao LM, Lee DJ (2007) Effects of ammonia on hydrolysis of proteins and lipids from fish residues. Appl Microbiol Biotechnol 75:1201–1208. https://doi.org/10.1007/s00253-007-0935-7

Ma S, Hu H, Wang J, Liao K, Ma H, Pen H (2019) The characterization of dissolved organic matter in alkaline fermentation of sewage sludge with different pH for volatile fatty acids production. Water Res 164:114924. https://doi.org/10.1016/j.watres.2019.114924

Machnicka A, Grübel K (2023) The effect of pre-treatment and anaerobic digestion for pathogens reduction in agricultural utilization of sewage sludge. Environ Sci Pollut Res 30:13801–13710. https://doi.org/10.1007/s11356-022-23164-9

Mahdy A, Mendez L, Ballesteros M, González-Fernández C (2014) Enhanced methane production of Chlorella vulgaris and Chlamydomonas reinhardtii by hydrolytic enzymes addition. Energ Convers Manage 85:551–557. https://doi.org/10.1016/j.enconman.2014.04.097

Mahdy A, Wandera SM, Aka B, Qiao W, Dong R (2019) Biostimulation of sewage sludge solubilization and methanization by hyper-thermophilic pre-hydrolysis stage and the shifts of microbial structure profiles. Sci Total Environ 699:134373. https://doi.org/10.1016/j.scitotenv.2019.134373

Marín M, Sánchez A, Artola A (2018) Production and recovery of cellulases through solid-state fermentation of selected lignocellulosic wastes. J Clean Prod 209:937–946. https://doi.org/10.1016/j.jclepro.2018.10.264

Miao H, Lu M, Zhao M, Huang Z, Ren H, Yan Q, Ruan W (2013) Enhancement of Taihu blue algae anaerobic digestion efficiency by natural storage. Bioresour Technol 149:359–366. https://doi.org/10.1016/j.biortech.2013.09.071

Montingelli ME, Benyounis KY, Stokes J, Olabi AG (2015) Pretreatment of macroalgal biomass for biogas production. Energ Convers Manage 108:202–209. https://doi.org/10.1016/j.enconman.2015.11.008

Moon HC, Song IS (2011) Enzymatic hydrolysis of food waste and methane production using UASB bioreactor. Int J Green Energy 8:361–371. https://doi.org/10.1080/15435075.2011.557845

Mustafa AM, Poulsen TG, Xia Y, Sheng K (2017) Combinations of fungal and milling pretreatments for enhancing rice straw biogas production during solid-state anaerobic digestion. Bioresour Technol 224:174–182. https://doi.org/10.1016/j.biortech.2016.11.028

Mustapha NA, Hu A, Yu CP, Sharuddin SS, Ramli N, Shirai Y, Maeda T (2018) Seeking key microorganisms for enhancing methane production in anaerobic digestion of waste sewage sludge. Appl Microbiol Biot 102:5323–5334. https://doi.org/10.1007/s00253-018-9003-8

Myszograj S, Płuciennik-Koropczuk E (2023) Thermal disintegration of sewage sludge as a method of improving the biogas potential. Energies 16(1):559. https://doi.org/10.3390/en16010559

Nah IW, Kang YW, Hwang KY, Song WK (2000) Mechanical pretreatment of waste activated sludge for anaerobic digestion process. Water Res 34(8):2362–2368. https://doi.org/10.1016/S0043-1354(99)00361-9

Neumann P, Pesante S, Venegas M, Vidal G (2016) Development in pre-treatment methods to improve anaerobic digestion of sewage sludge. Rev Environ Sci Bio 15:173–211. https://doi.org/10.1007/s11157-016-9396-8

Nguyen D, Khana SK (2018) A little breath of fresh air into an anaerobic system: how microaeration facilitates anaerobic digestion process. Biotechnol Adv 36(7):1971–1983. https://doi.org/10.1016/j.biotechadv.2018.08.007

Nguyen D, Wu Z, Shrestha S, Lee PH, Raskin L, Khanal SK (2019) Intermittent micro-aeration: new strategy to control volatile fatty acid accumulation in high organic loading anaerobic digestion. Water Res 166:115080. https://doi.org/10.1016/j.watres.2019.115080

Nguyen VK, Chaudhary DK, Dahal RH, Tring NH, Kim J, Chang SW, Hong Y, La DD, Nguyen XC, Ngo HH, Chung WJ, Nguyen DD (2021) Review on pretreatment techniques to improve anaerobic digestion of sewage sludge. Fuel 285:119105. https://doi.org/10.1016/j.fuel.2020.119105

Özön E, Erdinçler A (2019) Effects of microwave, H2O2/MW and H2O2/heat pre-treatments on the methane production from wastewater sludges: experimental and modeling approach. Environ Sci Pollut Res 26:35411–35421. https://doi.org/10.1007/s11356-019-05190-2

Park B, Ahn JH, Kim J, Hwang S (2004) Use of microwave pre-treatment for enhanced anaerobiosis of secondary sludge. Water Sci Technol 50(9):17–23

Park M, Kim N, Jung S, Jeong T-Y, Park D (2021) Optimization and comparison of methane production and residual characteristics in mesophilic anaerobic digestion of sewage sludge by hydrothermal treatment. Chemosphere 264(Part 2):128516. https://doi.org/10.1016/j.chemosphere.2020.128516

Passos F, Hom-Diaz A, Blanquez P, Vincent T, Ferrer I (2015) Improving biogas production from microalgae by enzymatic pretreatment. Bioresour Technol 199:347–351. https://doi.org/10.1016/j.biortech.2015.08.084

Patinvoh RJ, Osadolor OA, Chandolias K, Sárvári H, Taharzadeh MJ (2016) Innovative pretreatment strategies for biogas production. Bioresour Technol 224:13–24. https://doi.org/10.1016/j.biortech.2016.11.083

Perez-Elvira SI, Fdz-Polanco M, Fdz-Polanco F (2010) Increasing the performance of anaerobic digestion: pilot scale experimental study for thermal hydrolysis of mixed sludge. Front Environ Sci En 4(2):135–141. https://doi.org/10.1007/s11783-010-0024-5

Pessuto J, Scopel BS, Perondi D, Godingo M, Dettmer A (2016) Enhancement of biogas and methane production by anaerobic digestion of swine manure with addition of microorganisms isolated from sewage sludge. Process Saf Environ 104(Part A):233–239. https://doi.org/10.1016/j.psep.2016.08.020

Pilli S, Bhunia P, Yan S, LeBlanc RJ, Tyagi RD, Surampalli RY (2011) Ultrasonic pretreatment of sludge: a review. Ultrason Sonochem 18(1):1–18. https://doi.org/10.1016/j.ultsonch.2010.02.014

Pilli S, Yan S, Tyagi RD, Surampalli RY (2014) Thermal pretreatment of sewage sludge to enhance anaerobic digestion: a review. Crit Rev Env Sci Tec 45(6):669–702. https://doi.org/10.1080/10643389.2013.876527

Ponsá S, Ferrer I, Vázquez F, Font X (2008) Optimization of the hydrolytic-acidogenic anaerobic digestion stage (55°C) of sewage sludge: influence of pH and solid content. Water Res 42:3972–3980. https://doi.org/10.1016/j.watres.2008.07.002

Presti D, Cosenza A, Capri FC, Gallo G, Alduina R, Mannina G (2021) Influence of volatile solids and pH for the production of volatile fatty acids: batch fermentation tests using sewage sludge. Bioresour. Technol 342:125853. https://doi.org/10.1016/j.biortech.2021.125853

Qiao W, Yan X, Ye J, Sun Y, Wang W, Zhang Z (2011) Evaluation of biogas production from different biomass wastes with/without hydrothermal pretreatment. Renew Energ 36(12):3313–3318. https://doi.org/10.1016/j.renene.2011.05.002

Rodriguez C, Alaswad A, Benyounis KY, Olabi AG (2017) Pretreatment techniques used in biogas production from grass. Renewable Sustainable Energy Rev 68(2):1193–1204. https://doi.org/10.1016/j.rser.2016.02.022

Rodriguez C, Alaswad A, El-Hassan Z, Olabi AG (2018) Improvement of methane production from P. canaliculata through mechanical pretreatment. Renew Energ 119:73–78. https://doi.org/10.1016/j.renene.2017.12.025

Ruffino B, Campo G, Cerutti A, Scibilia G, Lorenzi E, Zanetti M (2020) Comparative analysis between a conventional and a temperature-phased anaerobic digestion system: monitoring of the process, resources transformation and energy balance. Energ Convers Manage 223:113463. https://doi.org/10.1016/j.enconman.2020.113463

Serrano A, Siles JA, Martin MA, Chica AF, Estévez-Pastor FS, Toro-Baprista E (2016) Improvement of anaerobic digestion of sewage sludge through microwave pre-treatment. J Environ Manage 177:231–239. https://doi.org/10.1016/j.jenvman.2016.03.048

Shah TA, Ali S, Afzal A, Tabassum R (2018) Effect of alkali pretreatment on lignocellulosic waste biomass for biogas production. Int J Renew Energy Res 8(3):1. https://doi.org/10.20508/ijrer.v8i3.7725.g7431

Shi X, Lin J, Zuo J, Li P, Li X, Guo X (2017) Effects of free ammonia on volatile fatty acid accumulation and process performance in the anaerobic digestion of two typical bio-wastes. J Environ Sci (China) 55:49–57. https://doi.org/10.1016/j.jes.2016.07.006

Shrestha S, Fonoll X, Khanal SK, Raskin L (2017) Biological strategies for enhanced hydrolysis of lignocellulosic biomass during anaerobic digestion: current status and future perspectives. Bioresour Technol 245(Part A):1245–1257. https://doi.org/10.1016/j.biortech.2017.08.089

Shrestha B, Hernandez R, Fortela DLB, Sharp W, Chistoserdov A, Gang D, Revellame E, Holmes W, Zappi ME (2020) A review of pretreatment methods to enhance solids reduction during anaerobic digestion of municipal wastewater sludges and the resulting digester performance: implications to future urban biorefineries. Appl Sci 10(24):9141. https://doi.org/10.3390/app10249141

Sichler TC, Adam C, Montag D, Barjenbruch M (2021) Future nutrient recovery from sewage sludge regarding three different scenarios- German case study. J Clean Prod 333:130130. https://doi.org/10.1016/j.jclepro.2021.130130

Solarte-Toro JC, Romero-Garcia JM, Martínez-Patiño JC, Ruiz-Ramos R, Castro-Galiano E, Cardona-Alzate CA (2019) Acid pretreatment of lignocellulosic biomass for energy vectors production: a review focused on operational conditions and techno-economic assessment for bioethanol production. Renew Sust Energ Rev 107:587–601. https://doi.org/10.1016/j.rser.2019.02.024

Song Z, Yang G, Liu X, Yan Z, Yuan Y, Liao Y (2014) Comparison of seven chemical pretreatments of corn straw for improving methane yield by anaerobic digestion. PLoS ONE 9(4):e93801. https://doi.org/10.1371/journal.pone.0093801

Suresh A, Seo C, Chang HN, Kim YC (2013) Improved volatile fatty acid and biomethane production from lipid removed microalgal residue (LRμAR) through pretreatment. Bioresour Technol 149:590–594. https://doi.org/10.1016/j.biortech.2013.09.123

Taboada-Santos A, Braz GHR, Fernandez-Gonzalez N, Carballa M, Lema JM (2019) Thermal hydrolysis of sewage sludge partially removes organic micropollutants but does not enhance their anaerobic biotransformation. Sci Total Environ 690:534–542. https://doi.org/10.1016/j.scitotenv.2019.06.492

Taherzadeh MJ, Jeihanipour A (2012) In: Mudhoo A (ed) Recalcitrance of lignocellulosic biomass to anaerobic digestion. Biogas Production, pp 27–54. https://doi.org/10.1002/9781118404089.ch2

Taherzadeh MJ, Karimi K (2008) Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. Int J Mol Sci 9(9):1621–1651. https://doi.org/10.3390/ijms9091621

Tedesco S, Barroso TM, Olabi AG (2014) Optimization of mechanical pre-treatment of Laminariaceae spp. biomass-derived biogas. Renew Energ 62:527–534. https://doi.org/10.1016/j.renene.2013.08.023

Tsapekos P, Kouhias PG, Angelidaki I (2015) Biogas production from ensiled meadow grass; effect of mechanical pretreatments and rapid determination of substrate biodegradability via physicochemical methods. Bioresour Technol 182:329–335. https://doi.org/10.1016/j.biortech.2015.02.025

Tulun Ş, Bilgin M (2019) Enhancement of anaerobic digestion of waste activated sludge by chemical pretreatment. Fuel 254:115671. https://doi.org/10.1016/j.fuel.2019.115671

Tyagi VK, Lo SL (2013) Sludge: A waste or renewable source for energy and resources recovery? Renew Sust Energ Rev 25:708–723. https://doi.org/10.1016/j.rser.2013.05.029

United Nations Department of Economic and Social Affairs, Population Division (2022) World Population Prospects 2022: summary of results. UN DESA/POP/2022/TR/NO. 3, United Nations, New York

Vu HT, Min B (2019) Enhanced methane fermentation of municipal sewage sludge by microbial electrochemical systems integrated with anaerobic digestion. Int J Hydrogen Energ 44(57):30357–30366. https://doi.org/10.1016/j.ijhydene.2019.09.163

Wagland ST, Godley AR, Tyrrel SF (2011) Investigation of the application of an enzyme-based biodegradability test method to a municipal solid waste biodrying process. Waste Manage 31:1467–1471. https://doi.org/10.1016/j.wasman.2011.02.025

Wandera SM, Qiao W, Jiang M, Mahdy A, Yin D, Dong R (2019) Enhanced methanization of sewage sludge using an anaerobic membrane bioreactor integrated with hyperthermophilic biological hydrolysis. Energ Convers Manage 196:846–855. https://doi.org/10.1016/j.enconman.2019.06.054

Wei W, Wang Q, Zhang L, Laloo A, Duan H, Batstone DJ, Yuan Z (2017a) Free nitrous acid pre-treatment of waste activated sludge enhances volatile solids destruction and improves sludge dewaterability in continuous anaerobic digestion. Water Res 130(1):13–19. https://doi.org/10.1016/j.watres.2017.11.050

Wei W, Zhou X, Wang D, Sun J, Wang Q (2017b) Free ammonia pre-treatment of secondary sludge significantly increases anaerobic methane production. Water Res 118(1):12–19. https://doi.org/10.1016/j.watres.2017.04.015

Wluka A, Huang Y, Coenen L, Dsikowitzky L, Schwarzbauer J (2021) Structural diversity of organic contaminants in sewage sludge: a comparison of sewage fingerprints from Germany and China. Discov Water 1:4. https://doi.org/10.1007/s43832-021-00004-4

Worwag M, Kwarciak-Kozłowska A (2019) 29- Volatile fatty acid (VFA) yield from sludge anaerobic fermentation through a biotechnological approach. Industrial and Municipal Sludge. In: MNV P, de Campos Favas PJ, Vithanage M, Mohan SV (eds) Emerging concerns and scope for resource recovery. Butterworth-Heinemann, pp 681–703. https://doi.org/10.1016/B978-0-12-815907-1.00029-5

Xiao B, Qin Y, Zhang W, Wu J, Qiang H, Liu J, Li YY (2018) Temperature-phased anaerobic digestion of food waste: a comparison with single-stage digestions based on performance and energy balance. Bioresour Technol 249:826–834. https://doi.org/10.1016/j.biortech.2017.10.084

Xiong H, Chen J, Wang H, Shi H (2012) Influences of volatile solid concentration, temperature and solid retention time for the hydrolysis of waste activated sludge to recover volatile fatty acids. Bioresour Technol 119:285–292. https://doi.org/10.1016/j.biortech.2012.05.126

Xu J (2015) Chapter 9- Microwave pretreatment. In: Pandey A, Negi S, Binod P, Larroche C (eds) Pretreatment of Biomass, Processes and Technologies. Elsevier, pp 157–172. https://doi.org/10.1016/B978-0-12-800080-9.00009-8

Yan Y, Feng L, Zhang C, Wisniewski C, Zhou Q (2010) Ultrasonic enhancement of waste activated sludge hydrolysis and volatile fatty acids accumulation at pH 10.0. Water Res 44(11):3329–3336. https://doi.org/10.1016/j.watres.2010.03.015

Yang X, Du M, Lee DJ, Wan C, Zheng L, Lli G (2012) Chang JS (2011) Enhanced production of volatile fatty acids (VFAs) from sewage sludge by β-cyclodextrin. Bioresour Technol 110:688–692. https://doi.org/10.1016/j.biortech.2011.08.122

Yang G, Xu Q, Wang D, Tang L, Xia J, Wang Q, Zeng G, Yang Q, Li X (2018) Free ammonia-based sludge treatment reduces sludge production in the wastewater treatment process. Chemosphere 205:484–492. https://doi.org/10.1016/j.chemosphere.2018.04.140

Ye Y, Nho HH, Guo W, Chang SW, Nguyen DD, Zhang X, Zhang J, Liang S (2020) Nutrient recovery from wastewater: from technology to economy. Bioresour Technol Rep 11:100425. https://doi.org/10.1016/j.biteb.2020.100425

Yin Y, Liu YJ, Meng SJ, Kiran EU, Liu Y (2016) Enzymatic pretreatment of activated sludge, food waste and their mixture for enhanced bioenergy recovery and waste volume reduction via anaerobic digestion. Appl Energ 179:1131–1137. https://doi.org/10.1016/j.apenergy.2016.07.083

Yue L, Chen J, Tang S, An X, Hua J, Dong H, Zhou J (2021) Ultrasound and microwave pretreatments promote methane production potential and energy conversion during anaerobic digestion of lipid and food wastes. Energy 228:120525. https://doi.org/10.1016/j.energy.2021.120525

Zahedi S, Icaran P, Yuan Z, Pijuan M (2016) Assessment of free nitrous acid pre-treatment on a mixture of primary sludge and waste activated sludge: effect of exposure time and concentration. Bioresour Technol 216:870–875. https://doi.org/10.1016/j.biortech.2016.06.038

Zaidi AA, Feng R, Malik A, Zhan SZ, Shi Y, Bhutta AJ, Shah AH (2019) Combining microwave pretreatment with iron oxide nanoparticles enhanced biogas and hydrogen yield from green algae. Processes 7:24. https://doi.org/10.3390/pr7010024

Zawieja I, Włodarczyk R, Kowalczyk M (2019) Biogas generation form sonicated excess sludge. Water 11(10):2127. https://doi.org/10.3390/w11102127

Zhang Z, Chen H, Wei B, Zhang Y, Sugiura N, Maekawa T (2001) A kinetic study on inhibition behavior of acetic acid and propionic acid concentration on methane fermentation. Japanese J Water Biol 37(4):135–140. https://doi.org/10.2521/jswtb.37.135

Zhang HY, Krafft T, Gao D, Zheng GD, Cai L (2018) Lignocellulose biodegradation in the biodrying process of sewage sludge and sawdust. Dry Technol 36(3):316–324. https://doi.org/10.1080/07373937.2017.1326502

Zhang L, Loh KC, Zhang J (2019) Jointly reducing antibiotic resistance genes and improving methane yield in anaerobic digestion of chicken manure by feedstock microwave pretreatment and activated carbon supplementation. Chem Eng J 372:815–824. https://doi.org/10.1016/j.cej.2019.04.207

Zhang J, Wang D, Li X, Liu X, Yang Q, Xu Q, Yang G, Duan A, Fang Y (2023) Enhanced short chain fatty acids production from anaerobic fermentation of primary sludge using free ammonia pretreatment. J Clean Prod 389:135862. https://doi.org/10.1016/j.jclepro.2023.135862

Zhao X, Luo K, Zhang Y, Zheng Z, Cai Y, Wen B, Cui Z, Wang X (2018) Improving the methane yield of maize straw: focus on the effects of pretreatment with fungi and their secreted enzymes combined with sodium hydroxide. Bioresour Technol 250:204–213. https://doi.org/10.1016/j.biortech.2017.09.160

Zhen G, Lu X, Kato H, Zhao Y, Li YY (2017) Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: current advances, full-scale application and future perspectives. Renew Sust Energ Rev 69:559–577. https://doi.org/10.1016/j.rser.2016.11.187

Zheng T, Zhang K, Chen X, Ma Y, Xiao B, Liu J (2021) Effects of low- and high-temperature thermal-alkaline pretreatments on anaerobic digestion of waste activated sludge. Bioresour Technol 337:125400. https://doi.org/10.1016/j.biortech.2021.125400

Ziemiński K, Frąc M (2021) Methane fermentation process an anaerobic digestion of biomass: transformations, stages and microorganisms. Afr J Biotechnol 11(18):4127–4139. https://doi.org/10.5897/AJBX11.054

Zou X, Yang R, Zhou X, Cao G, Zhu R, Ouyang F (2020) Effects of mixed alkali-thermal pretreatment on anaerobic digestion performance of waste activated sludge. J Clean Prod 259:120940. https://doi.org/10.1016/j.jclepro.2020.120940

Availability of data and materials

Not applicable

Funding

This work was supported and funded by the Faculty of Energy and Environmental Engineering SUT BKM 08/070/BKM21/0007 (BKM-670/RIE7/2021) for young scientists. A. Ziembińska-Buczyńska is financed by the Faculty of Power and Environmental Engineering of the Silesian University of Technology with the grant no. 08/070/BK_23/0024 (BK-253/RIE7/2023).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were prepared by Magdalena Ćwiertniewicz-Wojciechowska. Formal analysis, supervision, validation, and editing were provided by Grzegorz Cema and Aleksandra Ziembińska-Buczyńska. The first draft of the manuscript was written by Magdalena Ćwiertniewicz-Wojciechowska, and all authors commented on previous version of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher’s note