Abstract

Cationic ligand exchange is one of the most predominant mechanisms for the removal of ammonia from wastewater through complex formation. The complexation technique occurs between the metal ions loaded on the surface of Amberlite IR-120 and ammonia which is present in the medium. Cu(II)-loaded Amberlite IR-120 (R-Cu2+) was prepared and described using FT-IR, TGA, SEM, and EDX techniques. The prepared R-Cu2+ was applied for the elimination of ammonia from an aqueous solution. Different cations such as Co2+ and Ni2+ were loaded onto Amberlite IR-120 to study the impact of counter cation on the removal efficiency of ammonia. The ammonia removal percentage followed the order; R-Cu2+ > R-Ni2+ > R-Co2+. The effects of contact time, pH, initial concentration, temperature, and coexisting ions on the removal of ammonia from wastewater by R-Cu2+ were investigated. The equilibrium adsorbed amount of ammonia was found to be 200 mg/g at pH = 8.6 and 303 K within 60 min using 0.1 g R-Cu2+ and an initial concentration of ammonia of 1060 mg/L. The removal of ammonia using R-Cu2+ obeyed the non-linear plot of both Freundlich and Langmuir isotherms. According to the thermodynamic parameters, the adsorption of ammonia onto R-Cu2+ was an endothermic and spontaneous process. The time-adsorption data followed the pseudo-second-order and intraparticle diffusion models. Moreover, the resulting product (R-Cu(II)-amine composite) from the adsorption process exhibited high catalytic activity and could be low-cost material for the elimination of dyes such as aniline blue (AB), methyl green (MG), and methyl violet 2B (MV2B) from wastewater.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water is the most indispensable thing for life on earth. water contamination is one of the most serious issues facing humans and living organisms worldwide due to agricultural activities, industrialization, and rapid-growing global population (Elkady et al. 2020). Ammonia nitrogen (NH3-N) plays an essential role in marine life, it represents a nutrient for plant growth. However, it is the primary pollutant in wastewater, it results from municipal sewage, industrial wastewater, and agricultural sources or from the decomposition of organic nitrogen compounds which discharged into water streams (Zhu et al. 2019). The fertilizers industry and the manufacturing of many industrial products such as fibers, explosives, plastics, rubber, pulp, paper, chemicals, and pharmaceuticals are considered the major source of ammonia-contaminated water (Karri et al. 2018).

Large amounts of contaminated water containing high concentrations of ammonia leak into the surrounding water resources. As a result, serious environmental problems were caused such as the eutrophication of surface water due to algae growth that leads to the reduction of dissolved oxygen in water, and toxicity to fish and aquatic life (Adam et al. 2019, Zhu et al. 2019).

According to the World Health Organization (WHO) and the U.S. environmental protection agency (EPA), a level of ammonia in surface water of more than 10 mg N L−1 is more dangerous to human health and other aquatic organisms’ life (Liu et al. 2018). However, the maximum concentration of ammonia in drinking water and natural water should be 1.5 mg N L−1 and 0.2 mg L−1, respectively.

Nowadays, with the increasing toxic effect of ammonia on human health and aquatic organisms, the removal of ammonia (NH4+) from wastewater is the main task. There are different methods for the removal of NH4+ including chemical precipitation (Han et al. 2021), photocatalytic oxidation (Yu, Yu et al. 2021), air stripping, break-point chlorination (Zhang et al. 2022), biological methods such as nitrification and denitrification (Adam et al. 2019), membrane filtration (Rohani et al. 2021), reverse osmosis (Gui et al. 2020), adsorption (Vocciante et al. 2018), and ion exchange (Qin et al. 2020). Specifically, ion exchange and adsorption techniques are regarded as a better choice for the treatment of NH4+-contaminated wastewater. This is due to high removal efficiency, ease of application, and operation. Moreover, the adsorbents should be effectively low cost, environmentally friendly, practicable alternative properties, and favorable for commercial purposes (Elsherbiny et al. 2017; Huang et al. 2018).

A large number of adsorbents were applied for the removal of ammonia (NH4+) from wastewater, among these adsorbents various types of zeolites (Peng et al. 2017), clays, bentonite (Cheng et al. 2019), fly ash (Tang, Xu et al. 2020), activated carbon (Ghany et al. 2017), and synthetic organic resin (Han et al. 2021). However, these conventional adsorbents have low adsorption capacity and required secondary physical and chemical treatments that increase the adsorption operation costs (Chen et al. 2017a, b, c). The existence of other competing ions such as (Na+, K+, and Ca2+) reduces the selectivity of imitative ion exchange resins, the maximum adsorption capacity (qmax) of zeolite for removal of NH4+ is 1.54 mol kg−1, while in the presence of Na+ removal efficiency decreased from 90 to 36% (Jiang et al. 2018).

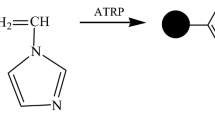

Ligand exchange technology was suggested to enhance the removal efficiency of ammonia (NH4+) by ion exchange resins (Chen et al. 2017a, b, c). Cation exchange resin was loaded with a metal ion, which formed a complex with the polluted substance. The term “ligand exchange” was suggested by Helfferich in 1962, who studied the selectivity of the ion exchanger toward ammonium ion (Chen et al. 2017a, b, c).

The removal of NH4+ from wastewater by ligand exchange reactions can be represented as the following (Chen et al. 2017a, b, c): -

where R denotes the cation exchange resin such as Amberlite IR-120.

Several transition metals such as Cu2+, Ni2+, Co2+, and Zn2+ were loaded onto cation exchange resin and served as ligand exchangers (Chen et al. 2017a, b, c; Chen et al. 2019). There is an electrostatic interaction between the active group of ion exchange resin and metal ions. A complex between the metal ion and NH4+ was formed and NH4+ replaced the aqua molecule in the solvation shell of metal (Clark and Tarpeh 2020).

The removal of NH4+ from wastewater using titanate by cation exchange process was recently studied (Zhang et al. 2021). Chen Yan et al. used Zn(II)-supported on poly ligand exchange resin for the removal of NH4+ from wastewater (Chen et al. 2019). Recent studies showed the removal of NH4+ by high silica zeolite granules regenerated with ozone (Doekhi-Bennani et al. 2021) and manganese oxides (MnOs) (Zhang et al. 2020). Moreover, iron oxide nanoparticles dispersed on zeolite by green synthesis were utilized for the removal of NH4+ from an aqueous solution (Xu et al. 2020).

Strongly cation exchange resins such as Amberlite IR-120 (R-H) are used as adsorbents for the removal of NH4+ from wastewater. R-H is sulfonated polystyrene cross-linked with divinylbenzene (Alguacil 2019). It is characterized by the gel form of an active site strongly cationic sulfonated group, which plays an essential role in the separation of charged species from an aqueous solution. R-H resin is an excellent general-purpose cation exchange resin that can be used for a wide variety of water demineralization applications because of its high surface area, non-toxicity, and microporous spherical structure.

In this work, the removal of NH4+ from wastewater by ligand exchange technique was studied. R-H was loaded with Cu(II), Ni(II), and Co(II) ions, (R-Cu2+, R-Ni2+, and R-Co2+), and used for the removal of NH4+ from wastewater. The removal process was carried out through ligand exchange and complexation as a promising method to increase the selectivity of the loaded resin toward the adsorption of NH4+. The effect of contact time, pH, initial ammonia concentration, temperature, and coexisting ions were examined. The use of Cu(II), Ni(II), and Co(II) in this work is attributed to their ability to form a stable and significant colored complex with ammonia which is an indication for the removal of ammonia from the solution. Afterward, the loaded R-H with copper ammonia complex was applied as a catalyst for the oxidative degradation of some organic polluted dyes. Therefore, ligand exchange resin has a dual role in the consecutive removal of NH4+ and dyes from wastewater.

Experimental

Materials

Strongly acidic exchange resin, Amberlite IR-120 (R-H) was purchased from Fluka (Fluka Chemie AG, CH-9470 Buchs, Switzerland). R-H is a spherical bead. It has thermal stability of about 120 °C, its total exchange capacity is 4.4 meq/g (dry) and 1.9 meq/g (wet) (H+-form) (1.9 mol/L). Its particle size is 0.6–0.8 mm and moisture content is 44–48% as obtained from the supplier.

Thymol (5-methyl-2-isopropylphenol) and sodium nitroprusside dihydrate (pentacyano nitrosyl ferrate II) were purchased from LANXESS AG 50,569 cologne, Germany, and used without further purification. Ammonium hydroxide (36%), sodium hypochlorite (4–5%), and acetic acid (99%) were obtained from ADWIC, Egypt. Phosphoric acid (99%) and hydrochloric acid (30%) were purchased from SDFCL, India. Sodium hydroxide, sodium carbonate, sodium hydrogen carbonate, boric acid, cobalt (II) chloride, nickel (II) chloride, and copper sulfate were obtained from Sigma-Aldrich. Hydrogen peroxide (50%, as an oxidant) was obtained from Merck, Germany, and its initial concentration was determined using potassium permanganate (Leonard 1990). Aniline blue (AB), methyl green (MG), and methyl violet 2B (MV2B) were purchased from Sigma-Aldrich. All the chemical reagents of analytical grade.

Instrumental measurements

The UV/Vis measurements were carried out on a high-performance double-beam spectrophotometer with an electronic temperature controller (SPECORD 210 PLUS, Analytic Jena, Germany). The pH of the medium was adjusted using a pH bench meter (AD1030, Adwa, Hungary). A water shaker thermostat (Julabo D-7633 Seelbach, Germany) was used to shake the mixtures during the adsorption process. The concentration of metals was determined by an inductively coupled plasma optical emission spectrometer (ICP-OES) Optima 7000 DV with a double monochromator and a simultaneous CCD array detector (Perkin Elmer, USA). The thermogravimetric analysis (TGA) was recorded on (Shimadzu TG-50 thermal analyzer, Japan) from 30 °C up to 800 °C with a scanning rate of 10 °C min–1 under N2. FT-IR analysis was performed using (JASCO FT-IR-4100, Japan) within the wavenumber range of 4000–400 cm−1. Scanning electron microscope (SEM) measurements were performed with (QUANTA FEG250 microscope). The energy dispersive X-ray spectroscopy (EDX) analysis was investigated using IT100LA operating at an accelerating voltage of 20.00 keV attached to an SEM device.

Preparation of metal ions supported on ligand exchange resin (R-Mn.+)

An appropriate amount of R-H was washed repeatedly with distilled water to remove any fine particles and non-adhesive impurities, then filtrated and air-dried before use. It was regenerated with (0.1 M HCl) to increase the capacity of the exchanger and then was washed with distilled water to remove excess Cl− ions which were detected by AgNO3 test and dried at room temperature overnight (Salem 2001).

25 g of R-H was dispersed and saturated with 500 mL of CuSO4 solution (0.5 M). This mixture was magnetically stirred for 24 h to achieve the equilibrium state and the resin was converted to Cu2+-form. Afterward, it was filtered and washed thoroughly with distilled water several times until no Cu(II) was detected in the filtrate according to ICP-OES measurements. The R-Cu2+ product was dried in an oven at 50 °C for 12 h. The loaded amount of Cu(II) ions onto the resin was determined by measuring the concentration of copper ions before and after the loading process using an ICP-OES spectrometer (Chen et al. 2019). R-Ni2+ and R-Co2+ were similarly prepared using the same circumstances procedure for R-Cu2+.

Batch equilibrium measurements

To investigate the adsorption capacity of cationic ligand exchange resin (R-M2+) for the removal of NH4+ from an aqueous solution. A fixed amount of R-M2+ (0.1 g) was added into a series of Erlenmeyer conical flasks (100 mL) with stoppers that contain a certain volume of distilled water (19 mL). A definite volume (1 mL) of ammonia solution (3395 mg/L) was taken by micropipette and then added to each flask and all of these flasks were immediately shaken at 120 rpm in a shaker water thermostat at a controlled temperature of 30 ± 0.2 °C for a given period. The adsorption capacities of (R-M2+) at different time intervals were specified by determining the concentration of NH4+ that is free in the solution. The concentration of NH4+ was determined using indothymol blue method (ITB) (Zamora-Garcia et al. 2021). This method is based on the Berthelot reaction, and it is the most widely used colorimetric method for the determination of ammonia in wastewater (Lin et al. 2019). It is based on the development of the indothymol blue color formed between ammonia and thymol. The development of indothymol color occurs through two steps; the first step involves the reaction between ammonia and hypochlorite which form monochloroamine at pH 10. The second step implies the development of indothymol blue due to the reaction between thymol and monochloroamine at pH 12. This step is catalyzed by sodium nitroprusside which reduces the reaction time to 3 min (Zhu et al. 2019). The intensity of the blue color is proportional to the concentration of ammonia present in the sample. A certain amount of ammonia solution was transferred into a 25-mL volumetric flask. To this solution, 0.25 mL of sodium nitroprusside dihydrate solution (1% w/v in H2O), 0.25 mL of hypochlorite solution (0.5% w/v in carbonate buffer at pH 10), and 0.5 mL of thymol (6% w/v in sodium hydroxide 2 M) were added. This mixture was diluted to 25 mL with distilled water and left for 3 min. The absorbance of the blue color was recorded at λmax = 693 nm using a UV–Vis spectrometer (SPECORD 200 PLUS) (Loan et al. 2013, Zamora-Garcia et al. 2021).

The removal efficiency percentage, R (%), and the adsorption capacity at time t, qt (mg/g) of NH4+ solution onto R-M2+ at different times were estimated using Eqs. 2 and 3.

where Co represents the initial concentration of NH4+ (mg/L), Ct represents the non-adsorbed concentration of NH4+, V is the volume of solution (L), and m (g) is the mass of adsorbent.

For R-Cu2+ as an adsorbent, the influence of temperature on NH4+ uptake was performed at 20, 30, and 40 °C ± 0.2 °C, respectively using fixed initial NH4+ concentration and amount of R-Cu2+ (0.1 g). Universal buffer (consisting of a certain volume of 0.2 M NaOH solution which was poured in 100 mL of a mixture of 0.04 M acetic, 0.04 M phosphoric, and 0.04 M boric) of pH range from 2 to 12 were utilized to know the impact of pH in the removal efficiency of NH4+.

Synthetic wastewater

Synthetic wastewater was prepared by dissolving 5 g of industrial urea fertilizer in 100 mL of distilled water. A certain amount of sodium chloride, potassium chloride, calcium chloride, and ammonium chloride (0.01 g of each one) was added to this solution. Then, 20 mL from this synthetic wastewater was added to 0.1 g of R-Cu2+ and the system was shaken in a shaker water thermostat at 120 rpm and 30 ± 0.2 °C for 60 min. The adsorbed amount of NH4+ was determined as described in “Batch equilibrium measurements.”

Catalytic oxidation of dyes

The recovery and reusability of R-Cu(II)-amine composite after washing with distilled water several times and drying in an oven at 50 °C for 12 h were studied. It was used for the catalytic degradation of three dyes by the oxidation process. Stock solutions (1 × 10−3 mol L−1) of AB, (5 × 10−4 mol L−1) of MG, and (2.4 × 10−3 mol L−1) of MV2B dyes were prepared. The optimum reaction mixture was set up in a 100 mL Erlenmeyer flask. In these flasks, 0.05 g of R-Cu (II) amine composite was added to a certain volume of the dye’s solution and the appropriate concentration of H2O2 solution. The flasks were put in a water shaker thermostat at 30 °C ± 1 °C and agitated at 120 rpm for a given period. The change in the absorbance of each dye solution was determined with time.

The degradation efficiency was determined using Eq. 4.

where Ao is the initial absorbance of dye and At is the absorbance at time t (min).

Results and discussion

Loading of metal ions on R-H

R-H was loaded with different amounts of copper (II), nickel (II), and cobalt (II) as measured by ICP-OES spectroscopy. It was found that 1 g of R-H has been loaded with 122.8 mg/g, (3.864 meq/g, 87.8%), 3.960 mg/g, (0.134 meq/g, 3.05%), and 0.750 mg/g (0.026 meq/g, 0.59%) of copper (II), nickel (II), and cobalt (II), respectively.

This can be attributed to the selectivity of the sulfonate (-SO3H) functional group of R-H towards loaded metal ions. It was written that this selectivity increases with increasing the atomic size of metal ions (Chandrasekara and Pashley 2015). The ionic radius of three metals decreases according to the order Cu(II) > Ni(II) > Co(II). As a result, the highest loaded amount on R-H was found for Cu(II).

Characterization

FT-IR

The FT-IR spectra of R-H and R-Cu2+ are shown in Fig. 1a. For parent R-H, there is a stretching vibration of O–H groups which originated from H2O molecule due to moisture are shown around 3434 cm−1. The peaks at 2920 cm−1 have corresponded to the symmetric and asymmetric C–H stretching vibration of C–H and –CH2 groups. The observed peak at 2370 cm−1 is due to O–H stretching mode that is originated from the polymer (Singare et al. 2011). The band at 1637 cm−1 indicates C = C stretching vibration of aromatic rings. Stretching vibration of O–S–O group of sulfonic acid was recorded at 1388 cm−1 and the peaks observed at 1170 cm−1 and 999 cm−1 are represented to symmetric stretching of –SO3− group (Prekob et al. 2019). The band at 835 cm−1 represented bending C–H out-of-plane deformation of the aromatic ring and at 679 cm−1 attributed to –SO3H groups (Ghosh et al. 2015). After loading Cu2+ on the resin’s surface (R-Cu2+), the stretching –OH peak at 3434 cm−1 was shifted to 3460 cm−1 suggesting the formation of Cu(OH)2 (Idrees et al. 2018). The peaks at 1170 cm−1 and 999 cm−1 were shifted to 1188 cm−1 and 1036 cm−1, respectively, suggesting the formation of the coordinated covalent bond between Cu(II) and sulfonate groups (Jha et al. 2009). However, the peak at 679 cm−1 kept on its position as in R-H (679 cm−1) indicating some of –SO3H groups were still free on the resin surface.

TGA

The thermal stability of R-Cu(II)-amine composite was investigated via TGA technique as displayed in Fig. 1(b). The thermogram of R-Cu(II)-amine composite demonstrated that a total loss of weight of about 93.08% in three separate steps. The first step showed that about 19.42% loss of weight was at the temperature range of 28–100 °C. This is attributed to the evaporation of adsorbed water molecules from the surface. The second step represented the complete decomposition of amino ligands in the complex of Cu (II)–amine with a weight loss of 9.677% in the range of 100–295 °C (Inba et al 2013). The last weight loss step was noted above 295 °C with 63.96% degradation. This corresponds to the degradation of the organic polymer of R-H leaving thermally stable metal oxide as a residue (Singare et al. 2011).

SEM

The surface morphology of R-H, R-Cu2+, and R-Cu(II)-amine complex was investigated by SEM (Fig. 2a, b, c). The surface of pure R-H is a plane spherical structure. But in the case of R-Cu2+, it was observed that some grains have been generated on its surface which indicates the impregnation of R-H with Cu2+ (Singare et al. 2011). Also, the grain species turned out to be a coarse coating at the surface of R-Cu(II)-amine composite which indicated the complex formation between ammonia and the Cu2+ ions at the surface of R-Cu2+.

EDX

The adsorption of ammonium ions on the surface of R-Cu2+ was confirmed by EDX measurement. Figure 2d presents the EDX spectra of R-Cu(II)-amine composite. EDX composition analysis for R-Cu(II)-amine complex indicates the presence of C, N, O, S, and Cu elements (Table 1).

Kinetics of NH4 +removal by metal ions supported on ligand exchange resin (R-Mn+)

A comparison study between the removal efficiency of NH4+ using R-Cu2+, R-Ni2+, and R-Co2+, at the same initial concentration of NH4+ was carried out. It was found that the uptake amount of NH4+ by R-Cu2+ (qe = 200 mg/g) was more than that by R-Ni2+ (qe = 158.55 mg/g) and by R-Co2+ (qe = 143.18 mg/g), as shown in Fig. 3a. The highest removal efficiency in the case of R-Cu2+ can be attributed to the highest loaded concentration of Cu2+ ion on the surface of R-H than Ni2 and Co2+ (Demirbas et al. 2005). In this work, the adsorption process was governed by two processes. One was the ion exchange between (H+) which is the non-loaded parts of R-H with NH4+. The other one was the metal-nitrogen bonding between the loaded Cu2+ and NH4+ at the surface (Clark and Tarpeh 2020) (see Fig. 8). So, R-Cu2+ was established as the best adsorbent which can be applied for the removal of NH4+ from wastewater. So, detailed experiments concentrated on the removal efficiency of NH4+ using R-Cu2+ were achieved under different conditions.

The adsorbed amount of NH4+ onto R-Cu2+ changes within time. It increased sharply in the first 20 min and attained the equilibrium state within 50 min (Fig. 3a).

The initial rapid adsorption of NH4+ onto R-Cu2+ can be assigned to a large number of the exchangeable active sites which increases both exchange and complexation’s rates. After that, the adsorption process became slower and slower till reached equilibrium due to no vacant active site on the surface. The maximum adsorption capacities (qmax) of NH4+ on different loaded resins, nanocomposites, and metal oxides surfaces reported in the literature were shown in Table 2. R-Cu2+ has the highest adsorption capacity of NH4+ in an alkaline medium (pH = 8.6) using a small amount of R-Cu2+ (0.1 g) in a short contact time, only 60 min. The other loaded resins had smaller qmax than R-Cu2+ despite using a big amount of each resin and long contact time (reached sometimes to 24 h) as seen in Table 2. Nickel, strontium, and zirconia oxides decorated graphene oxide (NiSr–ZrO2/GO) had a comparable value of qmax, but still, R-Cu2+ showed the highest one. This reflects that R-Cu2+ is a good candidate for the removal of NH4+ from an aqueous solution.

Three kinetic models namely, pseudo-first-order, pseudo-second-order, and intraparticle diffusion models (Eqs. 5, 6, and 7, respectively) were applied to find out the relation between NH4.+ concentration and adsorption rate and fitting the experimental data of adsorption (Lagergren 1898) (Weber Jr and Morris 1963, Sparks 1989; Cheng et al. 2019)

where qe and qt (mg/g) are the adsorbed amount of NH4+ at equilibrium and at contact time t, respectively. k1 (min−1), k2 (g/mg min), and kp (mg.g−1.min1/2) are the rate constant of pseudo-first-order, pseudo-second-order, and intraparticle diffusion, respectively. C (mg.g-1) is a constant term that represents the thickness of the boundary layer.

The values of kinetic parameters, the correlation coefficient, R2, and the calculated adsorption capacity (qe,cal) were presented in Table 3. According to this Table, the adsorption of NH4+ onto R-Cu2+ did not fit the pseudo-first-order model due to the low value of the correlation coefficient (R2 ≈ 0.81). In addition, the values of (qe,cal) and the experimental one (qe,exp) were not compatible. However, the calculated (qe,cal) from the pseudo-second-order equation was matched very well with the experimental one (qe,exp). Additionally, the value of (R2) was close to unity, indicating that the pseudo-second-order model is the best one to describe the adsorption of NH4+ from an aqueous solution onto the surface of R-Cu2+. The validity of the pseudo-second-order model to process indicates the adsorption mechanism was carried out by the chemical adsorption process (Zhang, Wang et al. 2020; Idrees et al. 2021; Özer and İmamoğlu 2022).

The fitting data of the intraparticle diffusion model showed two straight lines as presented in Fig. 4, indicating that the adsorption mechanism involved two steps. The first step was mainly due to the film diffusion and the fitting line away from the origin implying that the adsorption of NH4+ occurred over the external surface. Therefore, intraparticle diffusion was not the rate-controlling step. The second step was assigned to intraparticle diffusion (Elsherbiny et al. 2020). The values of kp1 and kp2 were listed in Table 3, where the value of kp1 was greater than that of kp2.

Impact of pH

The pH of the medium is one of the most critical factors for the removal of NH4+ by R-Cu2+. Since it possesses a significant role in the ratio of two forms of ammonia and the adsorbent surface, the impact of pH in the removal of NH4+ was examined in the pH range from 2 to 12 using a universal buffer, while the initial concentration of NH4+, amount of R-Cu2+, and temperature were kept constant (Fig. 5). NH4+ in an aqueous solution is available in two forms, ammonium ion (NH4+) and unionized ammonia (NH3), and the proportion of both forms depends on pH and temperature. At a pH lower than 4, the amount of NH4+ uptake is slightly increased, this is due to the predominant form of ammonia in this range being NH4+. On the other hand, when the pH increases from 4 to 8, the removal efficiency increased significantly from 10.6 to 65.2%. This increase is attributed to ammonium ion being gradually converted to NH3 which reacts with Cu2+ to form Cu (II)-amine complex as shown in Eq. (1). However, above pH 8, the NH4+ removal efficiency decreased, because of the considerably increased concentration of hydroxide ions developed in an alkaline medium. This increase of OH− can form a precipitate of copper (II) hydroxide Cu(OH)2. It was written that the formation of Cu(OH)2 at higher pH values leads to a decrease in the amount of copper loaded on the resin (Chen et al. 2019) and subsequently, decreases the adsorbed amount of ammonia.

Impact of initial NH4 + concentration

The impact of the initial NH4+ concentration [NH4+]o was studied by changing its concentration between 398.6 to 1686 mg. L−1 (Fig. 6). The removal efficiency of NH4+ using R-Cu2+ at given time increases from 89.22 to 93.98% as the initial concentration of NH4+ raises from 398.6 to 1686 mg. L−1. This is due to an enhancement of the concentration gradient of NH4+ in the solution that leads to a large mass transfer driving force (Wang et al. 2020). Additionally, the available adsorption active site of adsorbent (R-Cu2+) becomes fewer due to continuous blocking of this site with NH4+ to form (R-Cu(II)-amine composite). On the other hand, some ammonia molecules do not get absorbed and remain free in the solution (Ding and Sartaj 2016). Moreover, the distribution coefficient, Kd (partition coefficient, PC) was calculated at different initial concentrations of NH4+ and its values were listed in Table 4. The partition coefficient, PC, and/or Kd reflect the adsorption performance of an adsorbent (Batool et al. 2020). In the case of adsorption, the partition coefficient, Kd, is the ratio of the amount of adsorbate adsorbed per mass of adsorbent solid to the amount of the adsorbate remaining in solution per solution volume, (Kd = qe/Ce). As seen in Table 4, the value of Kd is increased with increasing the initial concentration of NH4+ until 1191 mg L−1and after that it declined at high concentrations.

Adsorption isotherms models

To obtain information about the distribution of adsorbate molecules between the liquid phase and solid phase at the equilibrium state, adsorption isotherm was studied. Ammonia adsorption isotherm has been investigated at several initial concentrations and three different temperatures. Figure 7 presents the experimental isotherm data and the equilibrium adsorbed amount, qe was increased as the equilibrium concentration of NH4+ raised to about 100 mg L−1. Afterward, no further increment was observed, and the plateau was attained. The equilibrium adsorption process was checked using linear and non-linear forms of Freundlich (Eqs. 8 and 9, respectively) and Langmuir models (Eqs. 10 and 11, respectively). Additionally, the experimental data were introduced in Temkin and Dubinin-Radushkevich (D-R) isotherms (Eqs. 12 and 13, respectively).

where Ce (mg L−1) is the concentration of NH4+ at equilibrium, qmax (mg g−1) is the maximum adsorption capacity of NH4+, and KL (L mg−1) is Langmuir adsorption constant that is related to the adsorption energy (Doekhi-Bennani et al. 2021). KF (mg g−1) and 1/n are Freundlich constants related to the adsorption capacity and adsorption intensity, respectively. KT (L mg−1) is Temkin equilibrium constant connected to the maximum binding energy, and B1 (J mol−1) is a constant representing the heat of adsorption which is calculated from the following expression B = RT/b; R is the gas constant, T is the absolute temperature (K), and b is the adsorption potential (Chen et al. 2017a, b, c). qm is the monolayer capacity (mg g−1), and ε is the Polanyi’s potential. The value of ε can be written as follows: ε = RT ln[1 + 1/Ce]. The value of B gained from the slope of D-R’s plot is utilized to calculate the mean adsorption energy (E, kJ mol−1) which was obtained from the following equation:

The linear and non-linear plots of Freundlich and Langmuir isotherms were presented in Fig. S1, S2. S3 and S4, respectively. All parameters obtained from the isotherm models along with their correlation coefficient (R2) were listed in Table 5. Visually (Figs. S1- S4) and comparing the values of (R2), the experimental data were fitted with both non-linear Freundlich and Langmuir models, especially at higher temperatures. However, the linear Langmuir model failed to represent the equilibrium adsorption data of NH4+ on R-Cu2+, whereas it can be described by linear Freundlich, Temkin, and D-R models. According to the data in Table 5, the values of (1/n) were larger than unity and decreased with increasing temperature, indicating the adsorption process becomes favorable at higher temperatures. However, the KF values increase with increasing temperature. This suggests that the adsorption process is of an endothermic nature and favorable at higher temperatures (Fu et al. 2021).

From Temkin model, it was found that the value of B1 decreased with increasing temperature. In addition, the better-fitting results of Temkin model indicated that the adsorption of NH4+ is dominated by chemisorption, which is in agreement with the results of the pseudo-second-order model. The value of E, which was calculated form D-R model gives information about the mechanism of adsorption. Its value was higher than 20 kJ/mol (except at 293 K), indicating the adsorption of NH4+ onto R-Cu2+ is governed by chemical adsorption (Elsherbiny et al. 2020) coinciding with Temkin model. This value confirms that the removal of ammonia from an aqueous solution using R-Cu2+ was through complexation and R-Cu(II)-amine composite was formed. Additionally, this value was increased with increasing the temperature.

Thermodynamic parameters

Deep insight into the changes in the energetic parameters related to the adsorption process was provided from thermodynamic studies. The parameters of adsorption thermodynamics can be calculated by introducing the experimental data at three different temperatures into the following equations (Elsherbiny 2013).

where Kd is the distribution coefficient (Kd = qe/Ce), ΔGads is the change in Gibbs-free energy of the adsorption process, \(\Delta {H}_{\mathrm{ads}}\) (kJmol−1) is the enthalpy change, and \(\Delta {S}_{\mathrm{ads}}\) (Jmol−1 K−1) is the entropy change. The distribution coefficient (Kd) and the thermodynamic parameters were presented in Table 6. As shown in Table 6, the value of Kd enhanced as temperature increased from 293 to 313 K. The values of \(\Delta {S}_{\mathrm{ads}}\) and \(\Delta {H}_{\mathrm{ads}}\) were determined by plotting Van’t Hoff’s equation (Eq. 15). The positive value of ΔHads indicates the endothermic nature of the adsorption process. While, the positive value of ΔSads revealed that the degree of the disorder increased at the solid–liquid interface during the adsorption of NH4+ onto R-Cu2+ (Pan et al. 2019). The negative values of ΔGads demonstrated that the adsorption of NH4+ is a feasible and spontaneous process. Furthermore, the value of ΔGads becomes more negative with increasing temperature, suggesting the adsorption of NH4+ onto R-Cu2+ was more favorable and spontaneous at higher temperatures.

Effect of competing ions

To evaluate the interference of species in industrial wastes on the adsorption process, 100 mg/L of various ions such as K+, Na+, Ca2+, NO3−, SO42−, and Cl− were used. The experiment was done in batches with 0.1 g of R-Cu2+, 1060 mg/L of ammonia, and a 60 min adsorption time. The remaining NH4+ concentration was measured after adsorption. The results revealed that the removal efficiency of NH4+ declined from 93.91 to 72.50%, 71.69%, and 48.65% in presence of Na+, K+, and Ca2+, respectively. This was mainly because of the competitive adsorption between cations and NH4+ in simulated wastewater on R-Cu2+ through the ion exchange process (Ren et al. 2021). So, the cations had a slight influence on the removal efficiency of ammonia except for Ca2+. The greatest impact of Ca2+ on the adsorption process is because of its high valence form (Ren et al. 2021). It was written that the selectivity of ion exchange materials is dictated by differences in ion valence, hydration radius, and hydration energy (Clark and Tarpeh 2020). Large hydration radii and high energies cause poor affinity to ion exchange functional groups: high valence causes high affinity and typically overshadows hydration effects (Epsztein et al. 2018, 2019). In terms of anions, the removal efficiency of NH4+ fell to 75.74%, 71.54%, and 69.48% in the existence of NO3−, Cl−, and SO42−, respectively. As appeared from these results, both cations and anions have limited impact on the removal efficiency of NH4+ using R-Cu2+ because the most removal amount of NH4+ is due to complex formation with Cu2+ at the surface (Feng and Sun 2015).

Synthetic wastewater

To study the effectiveness of R-Cu2+ for the removal of NH4+ from wastewater, an adsorption experiment was done on synthetic wastewater. The removal efficiency of NH4+ was 84.54% compared to 93.92% in absence of co-ions in water. The reason for this dropped off was the competition with the other ions in the synthetic wastewater to adsorb on R-Cu2+ through an ion exchange mechanism. By comparing with other studies in the literature (Soetardji et al. 2015; Mochizuki et al. 2016; Chen et al. 2017a, b, c), R-Cu2+ was less sensitive to the existing of competing ions towards the removal efficiency of NH4+.

Adsorption mechanism

The adsorption of ammonia on R-Cu(II) probably occurs through a combination of complexation and ion exchange process (see Fig. 8). FT-IR spectroscopy was used to confirm the interaction between R-Cu(II) and ammonia. FT-IR spectra of R-Cu(II) before and after the adsorption of NH4+ were shown in Fig. 1. After the adsorption of NH4+ on R-Cu(II), the peak of SO2 group was shifted from 1388 to 1401 cm−1. Moreover, a new band appeared at 517 cm−1 attributed to the stretching vibration of N–Cu which confirms the complex formation between Cu (II) ion and NH4+ (Chen et al. 2019). SEM images display the surface structure of R-Cu(II) after adsorption of NH4+ (Fig. 2c). It can be seen that the grain species on R-Cu(II) surface turned to be a coarse coating at the surface of R-Cu(II)-amine composite which indicated the complex formation between NH4+ and the Cu2+ ions at the surface of R-Cu2+. Moreover, it was written that the removal of ammonia using an ion exchanger involves the exchange of ions from the solution with ions from an exchanger (Chen et al. 2017a, b, c). So, it can be concluded that both complexation and ion exchange processes participate in the adsorption of NH4+ on R-Cu(II). However, complexation has the strongest role in the removal process of ammonia in this study as confirmed by the isotherm studies (“Adsorption isotherms models”).

Catalytic activity application of R-Cu(II)-amine composite for decolorization of dyes

Wastewater discharge during dyes manufacturing and textile dyeing cause serious problems for both the environment and human life. This type of pollutant is produced by manufacturing poisonous and potentially carcinogenic materials, which contain highly colored organic compounds that have a low degradation ability (Salem et al. 2014). The valorization of the resulting product R-Cu(II)-amine composite was carried out. This product was applied as a catalyst to degrade three different organic dyes namely, aniline blue (AB), methyl green (MG), and methyl violet (MV2B) from an aqueous solution. The degradation of these dyes was done in the presence of H2O2 as an eco-friendly oxidant. Figure 9a presents the time decay of the absorbance of the three dyes. The degradation efficiency of each dye was calculated using Eq. (4). Figure 9b shows the degradation efficiency of the three dyes in presence of R-Cu(II)-amine composite and H2O2. At a glance at Fig. 9b, MG dye was completely degraded within 40. However, about 92.64% and 90.26% of AB and MV2B dyes were degraded after 50 min. and 90 min, respectively.

(a) Absorbance-time plots for the catalytic degradation of [MV] = 1.86 × 10−4 mol L−1, [AB] = 7.5 × 10−5 mol L−1, and [MG] = 2.5 × 10−5 mol L−1 using 0.05 g of R-Cu(II)-amine composite and [H2O2] = 0.01 mol L−1 at 30 °C. (b) Removal efficiency of the AB, MG, and MV2B by R-Cu2+ (0.05 g) and R-Cu(II)-amine composite (0.05 g) in the presence of [H2O2] = 0.01 mol L−1 at 30 °C

A blank experiment was done by the addition of H2O2 solution to the solution of three dyes without R-Cu(II), and R-Cu(II)-amine compost to examine the applicability of H2O2 to degrade the dyes without catalyst. No change in their colors was noticed within 4 h. On the other hand, the loaded resin R-Cu2+ was tested for the degradation of the same three dyes in presence of H2O2 and the results were shown in Fig. 9b. As shown in Fig. 9b, AB was not completely affected by R-Cu2+ as a catalyst. However, about 49.64% and 76.71% of the initial concentration of MG and MV2B were degraded, within 40 and 90 min., respectively. Comparing these results confirmed the ability of R-Cu(II)-amine composite as an efficient catalyst for the degradation of both anionic and cationic dyes from wastewater.

Mechanism of dyes degradation

Many researchers have gone that the active species, such as hydroxyl (•OH) and/or perhydroxyl (HO•2), are responsible primarily for the degradation of the dye when using H2O2 as an oxidant (Salem et al. 1994; Gemeay 1996, Elsherbiny and El‐Ghamry 2015). They suggested an initial step of fast adsorption of both H2O2 and dye molecules on the surface of the catalyst (R-Cu(II)-amine). Followed by the reduction of Cu2+ with H2O2 to generate the less oxidative HO2• radicals (Eq. 18). After that, Cu2+ will be regenerated with the formation of the hydroxyl radicals •OH and OH− (Etaiw et al. 2011) (Eq. 19). The generated radical species •OH will attack rapidly dye molecules (Eq. 20) to form the final oxidation products as follows:

Recycling of R-Cu(II)-amine composite as a catalyst

The reusability of the catalyst is fundamental to sustainable and economical operation. Here, the degradation of the three dyes (AB, MG, and MV2B) with H2O2 in the presence of R-Cu(II)-amine composite as a catalyst was carried out for four reusability cycles. At the end of each cycle, the catalyst was washed thoroughly with water and H2O2 solution, dried, and then re-entered into the next catalytic reaction cycle. This process was carried out under the same reaction conditions. Figure 10 shows that the efficiency of degradation of the three dyes with R-Cu(II)-amine composite decreased slightly through the four cycles. This confirms that this catalyst could be recycled successfully at various times with only a slight decay in its activity.

Conclusion

In conclusion, Amberlite IR-120 (R-H) was successfully loaded with Cu2+, Ni2+, and Co2+ through a cation exchange mechanism to form R-Mn+. The highest loaded amount was found in the case of Cu2+ with a value of 122.8 mgg−1 for 1 g of R-H. The loaded resin R-Mn+ was applied to get rid of ammonia from the aqueous solution and the highest removal efficiency was found in the case of R-Cu2+. The presence of co-ions in the wastewater had a little negative effect on the removal efficiency of NH4+. The adsorption of NH4+ from an aqueous solution onto the surface of R-Cu2+ obeyed the pseudo-second-order kinetic model. The non-linear plot of Freundlich and Langmuir isotherms represented the adsorption process. The removal mechanism was governed by chemical adsorption and formation of R-Cu(II)-amine composite. The formed R-Cu(II)-amine composite was used as an efficient catalyst for the degradation of aniline blue, methyl green, and methyl violet dyes from an aqueous solution in presence of H2O2.

Data availability

All the data and materials are available in the manuscript.

References

Adam MR, Othman MHD, Abu Samah R, Puteh MH, Ismail AF, Mustafa A, Rahman MA, Jaafar J (2019) Current trends and future prospects of ammonia removal in wastewater: a comprehensive review on adsorptive membrane development. Sep Purif Technol 213:114–132

Alguacil FJ (2019) The removal of toxic metals from liquid effluents by ion exchange resins. Part IX: Lead(II)/H+/Amberlite IR-120. Revista de Metalurgia 55(1)

Batool S, Idrees M, Ahmad M, Ahmad M, Hussain Q, Iqbal A, Kong J (2020) Design and characterization of a biomass template/SnO2 nanocomposite for enhanced adsorption of 2,4-dichlorophenol. Environ Res 181:108955

Chandrasekara NPGN, Pashley RM (2015) Study of a new process for the efficient regeneration of ion exchange resins. Desalination 357:131–139

Chen Q, Zhou K, Chen Y, Wang A, Liu F (2017a) A novel poly ligand exchanger–Cu (II)-loaded chelating resin for the removal of ammonia-nitrogen in aqueous solutions. Environ Technol 38(22):2824–2834

Chen Q, Zhou K, Chen Y, Wang A, Liu F (2017b) Removal of ammonia from aqueous solutions by ligand exchange onto a Cu(ii)-loaded chelating resin: kinetics, equilibrium and thermodynamics. RSC Adv 7(21):12812–12823

Chen Q, Zhou K, Hu Y, Liu F, Wang A (2017c) Effect of competing ions and causticization on the ammonia adsorption by a novel poly ligand exchanger (PLE) ammonia adsorption reagent. Water Sci Technol 75(5–6):1294–1308

Chen Y, Chen W, Chen Q, Peng C, He D, Zhou K (2019) Removal of ammonia-nitrogen in wastewater using a novel poly ligand exchanger-Zn(II)-loaded chelating resin. Water Sci Technol 79(1):126–136

Cheng H, Zhu Q, Xing Z (2019) Adsorption of ammonia nitrogen in low temperature domestic wastewater by modification bentonite. J Clean Prod 233:720–730

Clark B, Tarpeh WA (2020) Selective recovery of ammonia nitrogen from wastewaters with transition metal-loaded polymeric cation exchange adsorbents. Chem – A Eur J 26(44):10099–10112

Demirbas A, Pehlivan E, Gode F, Altun T, Arslan G (2005) Adsorption of Cu(II), Zn(II), Ni(II), Pb(II), and Cd(II) from aqueous solution on Amberlite IR-120 synthetic resin. J Colloid Interface Sci 282(1):20–25

Ding Y, Sartaj M (2016) Optimization of ammonia removal by ion-exchange resin using response surface methodology. Int J Environ Sci Technol 13(4):985–994

Doekhi-Bennani Y, Leilabady NM, Fu M, Rietveld LC, van der Hoek JP, Heijman SGJ (2021) Simultaneous removal of ammonium ions and sulfamethoxazole by ozone regenerated high silica zeolites. Water Res 188:116472

Elkady M, Salama E, Amer WA, Ebeid EM, Ayad MM, Shokry H (2020) Novel eco-friendly electrospun nanomagnetic zinc oxide hybridized PVA/alginate/chitosan nanofibers for enhanced phenol decontamination. Environ Sci Pollut Res Int 27(34):43077–43092

Elsherbiny AS (2013) Adsorption kinetics and mechanism of acid dye onto montmorillonite from aqueous solutions: stopped-flow measurements. Appl Clay Sci 83–84:56–62

Elsherbiny AS, El-Ghamry HA (2015) Synthesis, characterization, and catalytic activity of new Cu (II) complexes of Schiff base: effective catalysts for decolorization of Acid Red 37 dye solution. Int J Chem Kinet 47(3):162–173

Elsherbiny AS, El-Hefnawy ME, Gemeay AH (2017) Adsorption efficiency of polyaspartate-montmorillonite composite towards the removal of Pb(II) and Cd(II) from aqueous solution. J Polym Environ 26(2):411–422

Elsherbiny AS, Gemeay AH, Salem MA (2020) Adsorption efficiency of graphene oxide towards cyanine dyes with different alkyl chain lengths. Sep Sci Technol 56(2):266–274

Epsztein R, Shaulsky E, Dizge N, Warsinger DM, Elimelech M (2018) Role of ionic charge density in donnan exclusion of monovalent anions by nanofiltration. Environ Sci Technol 52(7):4108–4116

Epsztein R, Shaulsky E, Qin M, Elimelech M (2019) Activation behavior for ion permeation in ion-exchange membranes: role of ion dehydration in selective transport. J Membr Sci 580:316–326

Etaiw SEDH, Elsherbiny AS, Badr El-din AS (2011) Characterization and catalytic activity of new metal-organic frameworks resulted from self-assembly of Ph3SnCl, K [Cu (CN) 2] and nitrogen donor ligands. Chinese J Chem 29(7):1401–1410

Feng Z, Sun T (2015) A novel selective hybrid cation exchanger for low-concentration ammonia nitrogen removal from natural water and secondary wastewater. Chem Eng J 281:295–302

Fu G, Zhao Y, Zhou S, Chen C, Zhong Y, Xu Y (2021). Efficient removal of nitrogen and phosphorus in aqueous solutions using modified water treatment residuals-sodium alginate beads. Environ Sci Pollut Res Int

Gemeay AH (1996) Catalytic activity of silica gel surface modified by transition metal-aminosilane complexes in the decomposition of hydrogen peroxide. Colloids Surf, A 116(3):277–284

Ghany HA, Ahmed M, Ashour E (2017) Adsorption of ammonia onto activatedcarbon prepared from rice straw. Int J Adv Res 5(2):1180–1196

Ghosh S, Dhole K, Tripathy MK, Kumar R, Sharma RS (2015) FTIR spectroscopy in the characterization of the mixture of nuclear grade cation and anion exchange resins. J Radioanal Nucl Chem 304(2):917–923

Gui S, Mai Z, Fu J, Wei Y, Wan J (2020). Transport models of ammonium nitrogen in wastewater from rare earth smelteries by reverse osmosis membranes. Sustainability 12(15)

Han B, Butterly C, Zhang W, He JZ, Chen D (2021). Adsorbent materials for ammonium and ammonia removal: a review. Journal of Cleaner Production 283

Huang J, Kankanamge NR, Chow C, Welsh DT, Li T, Teasdale PR (2018) Removing ammonium from water and wastewater using cost-effective adsorbents: a review. J Environ Sci (china) 63:174–197

Idrees M, Batool S, Kalsoom T, Yasmeen S, Kalsoom A, Raina S, Zhuang Q, Kong J (2018) Animal manure-derived biochars produced via fast pyrolysis for the removal of divalent copper from aqueous media. J Environ Manage 213:109–118

Idrees M, Batool S, Javed MS, Ahmad M, Khan QU, Imran M, Rasaki SA, Mwizerwa JP, Chen Z (2021) Adsorption and electrochemical facet of polymer precursor to yield mesoporous carbon ceramic. Sep Purif Technol 275:119199

JeslinKanagaInba P, Annaraj B, Thalamuthu S, Neelakantan MA (2013) Cu(II), Ni(II), and Zn(II) complexes of salan-type ligand containing ester groups: synthesis, characterization, electrochemical properties, and in vitro biological activities. Bioinorg Chem Appl 2013:439848

Jha MK, Van Nguyen N, Lee J-C, Jeong J, Yoo J-M (2009) Adsorption of copper from the sulphate solution of low copper contents using the cationic resin Amberlite IR 120. J Hazard Mater 164(2–3):948–953

Jiang Y, Minami K, Sakurai K, Takahashi A, Parajuli D, Lei Z, Zhang Z, Kawamoto T (2018) High-capacity and selective ammonium removal from water using sodium cobalt hexacyanoferrate. RSC Adv 8(60):34573–34581

Karri RR, Sahu JN, Chimmiri V (2018) Critical review of abatement of ammonia from wastewater. J Mol Liq 261:21–31

Lagergren SK (1898) About the theory of so-called adsorption of soluble substances. Sven Vetenskapsakad Handingarl 24:1–39

Leonard M. A. (1990). Vogel's textbook of quantitative chemical analysis. 5th edn: Revised by G. H. Jeffery, J. Bassett, J. Mendham and R. C. Denney. Pp. 877. Longman, Harlow. 1989. £3400. Endeavour 14(2): 100

Lin K, Zhu Y, Zhang Y, Lin H (2019). "Determination of ammonia nitrogen in natural waters: Recent advances and applications." Trends in Environmental Analytical Chemistry 24.

Liu H, Chen Z, Guan Y, Xu S (2018) Role and application of iron in water treatment for nitrogen removal: a review. Chemosphere 204:51–62

Loan DK, Con TH, Hong TT, Ly LTM (2013) Quick determination of ammonia ions in water environment based on thymol color creating reaction. Environ Sci 1:83–92

Mochizuki T, Kubota M, Matsuda H, Camacho LFE (2016) Adsorption behaviors of ammonia and hydrogen sulfide on activated carbon prepared from petroleum coke by KOH chemical activation. Fuel Process Technol 144:164–169

Özer Ç, İmamoğlu M (2022). Isolation of nickel(II) and lead(II) from aqueous solution by sulfuric acid prepared pumpkin peel biochar. Analytical Letters: 1–13

Pan M, Zhang M, Zou X, Zhao X, Deng T, Chen T, Huang X (2019). The investigation into the adsorption removal of ammonium by natural and modified zeolites: kinetics, isotherms, and thermodynamics. Water SA 45(4 October)

Peng C, Chai L-Y, Tang C-J, Min X-B, Ali M, Song Y-X, Qi W-M (2017) Feasibility and enhancement of copper and ammonia removal from wastewater using struvite formation: a comparative research. J Chem Technol Biotechnol 92(2):325–333

Prekob Á, Hajdu V, Muránszky G, Kocserha I, Fiser B, Viskolcz B, Vanyorek L (2019) Application of carbonized ion exchange resin beads as catalyst support for gas phase hydrogenation processes. React Kinet Mech Catal 129(1):85–94

Qin Y, Zhu X, Su Q, Anumah A, Gao B, Lyu W, Zhou X, Xing Y, Wang B (2020) Enhanced removal of ammonium from water by ball-milled biochar. Environ Geochem Health 42(6):1579–1587

Ren Z, Jia B, Zhang G, Fu X, Wang Z, Wang P, Lv L (2021) Study on adsorption of ammonia nitrogen by iron-loaded activated carbon from low temperature wastewater. Chemosphere 262:127895

Rohani R, Yusoff II, Khairul Zaman N, Mahmood Ali A, Rusli NAB, Tajau R, Basiron SA (2021). Ammonia removal from raw water by using adsorptive membrane filtration process. Separation and Purification Technology 270

Salem IA (2001) Activation of H2O2 by Amberlyst-15 resin supported with copper(II)-complexes towards oxidation of crystal violet. Chemosphere 44(5):1109–1119

Salem MA, Salem IA, Gemeay AH (1994) Kinetics and mechanism of H2O2 decomposition by Cu (II)-, Co (II)-, and Fe (III)-amine complexes on the surface of silica-alumina (25% Al2O3). Int J Chem Kinet 26(11):1055–1061

Salem IA, El-Ghamry HA, El-Ghobashy MA (2014) Catalytic decolorization of Acid blue 29 dye by H2O2 and a heterogeneous catalyst. Beni-Suef University Journal of Basic and Applied Sciences 3(3):186–192

Singare PU, Lokhande RS, Madyal RS (2011) Thermal degradation studies of some strongly acidic cation exchange resins. Open Journal of Physical Chemistry 01(02):45–54

Soetardji JP, Claudia JC, Ju Y-H, Hriljac JA, Chen T-Y, Soetaredjo FE, Santoso SP, Kurniawan A, Ismadji S (2015) Ammonia removal from water using sodium hydroxide modified zeolite mordenite. RSC Adv 5(102):83689–83699

Sparks D (1989). Kinetics of soil chemical processes. Academic Press, San Diego. Kinetics of soil chemical processes. Academic Press, San Diego.: -

Tang H, Xu X, Wang B, Lv C, Shi D (2020). Removal of ammonium from swine wastewater using synthesized zeolite from fly ash. Sustainability 12(8)

Vocciante M, De Folly D’Auris A, Finocchi A, Tagliabue M, Bellettato M, Ferrucci A, Reverberi AP, Ferro S (2018) Adsorption of ammonium on clinoptilolite in presence of competing cations: investigation on groundwater remediation. J Clean Prod 198:480–487

Wang G, Xu Y, Wang C, Gao Y, Li L (2020). Synthesis of two kinds of mesoporous diatomite by microwave assisted sol-gel method and its adsorption of ammonia nitrogen in wastewater. IOP Conference Series: Materials Science and Engineering 782

Weber WJ Jr, Morris JC (1963) Closure to “kinetics of adsorption on carbon from solution.” J Sanit Eng Div 89(6):53–55

Xu Q, Li W, Ma L, Cao D, Owens G, Chen Z (2020) Simultaneous removal of ammonia and phosphate using green synthesized iron oxide nanoparticles dispersed onto zeolite. Sci Total Environ 703:135002

Yu R, Yu X, Fu J, Zhang Y, Liu Y, Zhang Y, Wu S (2021). Removal of ammonia nitrogen in aquaculture wastewater by composite photocatalyst TiO2/carbon fibre. Water and Environment Journal

Zamora-Garcia I, Correa-Tome FE, Hernandez-Belmonte UH, Ayala-Ramirez V, Ramirez-Paredes JP (2021). Mobile digital colorimetry for the determination of ammonia in aquaculture applications. Computers and Electronics in Agriculture 181

Zhang W, Wang Z, Liu Y, Feng J, Han J, Yan W (2021) Effective removal of ammonium nitrogen using titanate adsorbent: Capacity evaluation focusing on cation exchange. Sci Total Environ 771:144800

Zhang L, Wang J, Qiao H, Liu F, Fu Z (2020). Synthesis of manganese oxides for adsorptive removal of ammonia nitrogen from aqueous solutions. Journal of Cleaner Production 272

Zhang Y, Yin S, Li H, Liu J, Li S, Zhang L (2022). Treatment of ammonia‑nitrogen wastewater by the ultrasonic strengthened break point chlorination method. Journal of Water Process Engineering 45

Zhu Y, Chen J, Yuan D, Yang Z, Shi X, Li H, Jin H, Ran L (2019). Development of analytical methods for ammonium determination in seawater over the last two decades. TrAC Trends in Analytical Chemistry 119

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

Marwa A. El-Ghobashy, Mohamed M. Khamis, Abeer S. Elsherbiny, Ibrahim A. Salem: validation; Marwa A. El-Ghobashy, Mohamed M. Khamis, Abeer S. Elsherbiny: formal analysis; Mohamed M. Khamis: investigation and data curation; Abeer S. Elsherbiny, Marwa A. El-Ghobashy, Mohamed M. Khamis: writing-original draft preparation; Marwa A. El-Ghobashy, Abeer S. Elsherbiny: review and editing; Ibrahim A. Salem; put the idea of the work and final revision.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

All the authors agreed to participate in this work.

Consent to publish

All the authors agreed to publish this work in Environmental Science and Pollution Research.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Tito Roberto Cadaval Jr

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El-Ghobashy, M.A., Khamis, M.M., Elsherbiny, A.S. et al. Selective removal of ammonia from wastewater using Cu(II)-loaded Amberlite IR-120 resin and its catalytic application for removal of dyes. Environ Sci Pollut Res 30, 106822–106837 (2023). https://doi.org/10.1007/s11356-023-25677-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-25677-3