Abstract

Background

Digital Image Correlation (DIC) is an image-based measurement technique routinely used in experimental mechanics, which provides displacement and strain maps of an observed surface/volume. The metrological performance of DIC has reached its limit which is directly determined by the texture of the imaged surface/volume.

Objective

This paper proposes a novel DIC strategy, which relies on a virtual image. This image, noiseless and of infinite resolution, is moreover optimized for providing measurements with the best metrological performance.

Methods

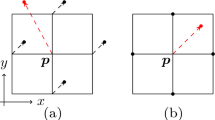

The so-called Virtual DIC retrieves the displacement fields by comparing this virtual image to the experimental images. No interpolation is required and processing optimal textures such as checkerboards is possible.

Results

Virtual DIC is first applied on synthetic images for comparison purposes with a usual DIC approach. Outstanding metrological performance is observed thanks to the possibility of processing checkerboard patterns.

Conclusions

The proposed Virtual DIC is twofold: (i) thanks to the use of a closed-form expression, built-in DIC operators are elaborated without recurring to noisy and poorly defined real images. Interpolation is therefore avoided; (ii) it makes possible it to process checkerboard patterns, which offers the best metrological performance.

Similar content being viewed by others

Data Availability

Data will be provided on demand.

References

Sutton MA, Mingqi C, Peters WH, Chao YJ, McNeill SR (1986) Application of an optimized digital correlation method to planar deformation analysis. Image Vis Comput 4(3):143–150. https://doi.org/10.1016/0262-8856(86)90057-0

Garcia D (2001) Mesure de formes et de champs de déplacements tridimensionnels par stéréo-corrélation d’images. PhD thesis, Institut National Polytechnique de Toulouse

Wang Y, Lava P, Coppieters S, Houtte PV, Debruyne D (2013) Application of a multi-camera stereo DIC set-up to assess strain fields in an Erichsen test: methodology and validation. Strain 49(2):190–198. https://doi.org/10.1111/str.12027

Dufour J-E, Hild F, Roux S (2015) Shape, displacement and mechanical properties from isogeometric multiview stereocorrelation. J Strain Anal Eng Des 50(7):470–487. https://doi.org/10.1177/0309324715592530

Passieux J-C, Bugarin F, David C, Périé J-N, Robert L (2015) Multiscale displacement field measurement using digital image correlation: application to the identification of elastic properties. Exp Mech 55(1):121–137. https://doi.org/10.1007/s11340-014-9872-4

Bay BK, Smith TS, Fyhrie DP, Saad M (1999) Digital volume correlation: three-dimensional strain mapping using x-ray tomography. Exp Mech 39(3):217–226. https://doi.org/10.1007/BF02323555

Jailin C, Buljac A, Bouterf A, Hild F, Roux S (2018) Fast 4D tensile test monitored via X-CT: single projection based digital volume correlation dedicated to slender samples. J Strain Anal Eng Des

Lucas BD, Kanade T (1981) An iterative image registration technique with an application to stereo vision. In: Proceedings of the 7th International Joint Conference on Artificial Intelligence - Volume 2. IJCAI’81. Morgan Kaufmann Publishers Inc., San Francisco, CA, USA, pp 674–679. http://dl.acm.org/citation.cfm?id=1623264.1623280

Baker S, Matthews I (2004) Lucas-Kanade 20 years on: a unifying framework. Int J Comput Vis 56(3):221–255. https://doi.org/10.1023/B:VISI.0000011205.11775.fd

Schreier HW, Sutton MA (2002) Systematic errors in digital image correlation due to undermatched subset shape functions. Exp Mech 42(3):303–310. https://doi.org/10.1007/BF02410987

Wang YQ, Sutton MA, Bruck HA, Schreier HW (2009) Quantitative error assessment in pattern matching: effects of intensity pattern noise, interpolation, strain and image contrast on motion measurements. Strain 45(2):160–178. https://doi.org/10.1111/j.1475-1305.2008.00592.x

Wang YQ, Sutton MA, Ke XD, Schreier HW, Reu PL, Miller TJ (2011) On error assessment in stereo-based deformation measurements. Exp Mech 51(4):405–422

Ke XD, Schreier HW, Sutton MA, Wang YQ (2011) On error assessment in stereo-based deformation measurements. Exp Mech 51(4):423–441

Pan B, Yu L, Wu D, Tang L (2013) Systematic errors in two-dimensional digital image correlation due to lens distortion. Opt Lasers Eng 51(2):140–147. https://doi.org/10.1016/j.optlaseng.2012.08.012

Pan B (2013) Bias error reduction of digital image correlation using Gaussian pre-filtering. Opt Lasers Eng 51(10):1161–1167. https://doi.org/10.1016/j.optlaseng.2013.04.009

Pan B, Yu L, Wu D (2013) High-accuracy 2d digital image correlation measurements with bilateral Telecentric lenses: error analysis and experimental verification. Exp Mech 53(9):1719–1733. https://doi.org/10.1007/s11340-013-9774-x

Pan B, Xie H, Wang Z (2010) Equivalence of digital image correlation criteria for pattern matching. Appl Opt 49(28):5501–5509. https://doi.org/10.1364/AO.49.005501

Neggers J, Blaysat B, Hoefnagels JPM, Geers MGD (2016) On image gradients in digital image correlation. Int J Numer Meth Eng 105(4):243–260. https://doi.org/10.1002/nme.4971

Wang Y, Lava P, Reu P, Debruyne D (2016) Theoretical analysis on the measurement errors of local 2D DIC: Part I temporal and spatial uncertainty quantification of displacement measurements. Strain 52(2):110–128. https://doi.org/10.1111/str.12173

Su Y, Zhang Q, Xu X, Gao Z (2016) Quality assessment of speckle patterns for DIC by consideration of both systematic errors and random errors. Opt Lasers Eng 86:132–142. https://doi.org/10.1016/j.optlaseng.2016.05.019

Blaysat B, Grédiac M, Sur F (2016) Effect of interpolation on noise propagation from images to DIC displacement maps. Int J Numer Methods Eng 108(3):213–232. https://doi.org/10.1002/nme.5212. https://hal.science/hal-01255944/

Blaysat B, Grédiac M, Sur F (2016) On the propagation of camera sensor noise to displacement maps obtained by DIC - an experimental study. Exp Mech 56(6):919–944. https://doi.org/10.1007/s11340-016-0130-9. https://hal.science/hal-01269655/

Rossi M, Lava P, Pierron F, Debruyne D, Sasso M (2015) Effect of DIC spatial resolution, noise and interpolation error on identification results with the VFM. Strain 51(3):206–222. https://doi.org/10.1111/str.12134

Bomarito, G.F, Ruggles TJ, Hochhalter JD, Cannon AH (2017) Investigation of optimal digital image correlation patterns for deformation measurement. In: Sutton M, Reu PL (eds) International Digital Imaging Correlation Society. Conference Proceedings of the Society for Experimental Mechanics Series. Springer. https://doi.org/10.1007/978-3-319-51439-0_5

Lehoucq RB, Reu PL, Turner DZ (2017) The effect of the ill-posed problem on quantitative error assessment in digital image correlation. Exp Mech. https://doi.org/10.1007/s11340-017-0360-5

Reu PL, Toussaint E, Jones E, Bruck HA, Iadicola M, Balcaen R, Turner DZ, Siebert T, Lava P, Simonsen M (2018) DIC challenge: developing images and guidelines for evaluating accuracy and resolution of 2D analyses. Exp Mech 58(7):1067–1099. https://doi.org/10.1007/s11340-017-0349-0

Blaysat B, Neggers J, Grédiac M, Sur F (2020) Towards criteria characterizing the metrological performance of full-field measurement techniques - Application to the comparison between local and global versions of DIC. Exp Mech 60(3):393–407. https://doi.org/10.1007/s11340-019-00566-4. https://hal.science/hal-02436541

Passieux J-C, Bouclier R (2019) Classic and inverse compositional Gauss-Newton in Global DIC. Int J Numer Meth Eng 119(6):453–468. https://doi.org/10.1002/nme.6057

Sur F, Blaysat B, Grédiac M (2021) On biases in displacement estimation for image registration, with a focus on Photomechanics. J Math Imaging Vision 63:777–806

Fayad SS, Seidl DT, Reu PL (2020) Spatial dic errors due to pattern-induced bias and grey level discretization. Exp Mech 60(2):249–263. https://doi.org/10.1007/s11340-019-00553-9

Fouque R, Bouclier R, Passieux J-C, Périé J-N (2021) Fractal pattern for multiscale digital image correlation. Exp Mech 61(3):483–497. https://doi.org/10.1007/s11340-020-00649-7

Reu PL, Blaysat B, Andó E, Bhattacharya K, Couture C, Couty V, Deb D, Fayad SS, Iadicola MA, Jaminion S, Klein M, Landauer AK, Lava P, Liu M, Luan LK, Olufsen SN, Réthoré J, Roubin E, Seidl DT, Siebert T, Stamati O, Toussaint E, Turner D, Vemulapati CSR, Weikert T, Witz JF, Witzel O, Yang J (2022) DIC Challenge 2.0: developing images and guidelines for evaluating accuracy and resolution of 2D analyses. Exp Mech. https://doi.org/10.1007/s11340-021-00806-6

Jovani T, Chanal H, Blaysat B, Grédiac M (2022) Direct residual stress identification during machining. J Manuf Process 82:678–688. https://doi.org/10.1016/j.jmapro.2022.08.015

Rouwane A, Bouclier R, Passieux J-C, Périé J-N (2022) Architecture-driven digital image correlation technique (ADDICT) for the measurement of sub-cellular kinematic fields in speckle-free cellular materials. Int J Solids Struct 234–235:111223. https://doi.org/10.1016/j.ijsolstr.2021.111223

Bouyra Q, Blaysat B, Chanal H, Grédiac M (2022) Using laser marking to engrave optimal patterns for in-plane displacement and strain measurement. Strain 58(2):12404. https://doi.org/10.1111/str.12404

Bossuyt S (2013) Optimized patterns for digital image correlation. In: Proceedings of the 2012 Annual Conference on Experimental and Applied Mechanics, vol 3. pp 239–248. http://dx.doi.org/10.1007/978-1-4614-4235-6_34

Shi Y, Blaysat B, Chanal H, Grédiac M (2022) Designing Patterns for DIC with Poisson Image Editing. Exp Mech. Available online. https://doi.org/10.1007/s11340-022-00862-6

Hao Z, Chen G, Ke H, Deng L, Liu L (2022) Characterization of out-of-plane tensile stress-strain behavior for GFRP composite materials at elevated temperatures. Compos Struct 290:115477. https://doi.org/10.1016/j.compstruct.2022.115477

Grédiac M, Blaysat B, Sur F (2019) On the optimal pattern for displacement field measurement: random speckle and DIC, or checkerboard and LSA? Exp Mech 60:509–534. https://doi.org/10.1007/s11340-019-00579-z. https://hal.science/hal-02462030/

Bomarito GF, Hochhalter JD, Ruggles TJ, Cannon AH (2017) Increasing accuracy and precision of digital image correlation through pattern optimization. Opt Lasers Eng 91:73–85. https://doi.org/10.1016/j.optlaseng.2016.11.005

Grédiac M, Blaysat B, Sur F (2019) Extracting displacement and strain fields from checkerboard images with the localized spectrum analysis. Exp Mech 59(2):207–218. https://doi.org/10.1007/s11340-018-00439-2. https://hal.science/hal-01926054

Bomarito GF, Hochhalter JD, Ruggles TJ (2017) Development of optimal multiscale patterns for digital image correlation via local grayscale variation. Exp Mech. https://doi.org/10.1007/s11340-017-0348-1

Wang Z, Wu H, Kang K, Wang S, Li Y, Hou W, Riaz H, Li L, Li C (2019) DIC/Moiré hybrid method based on regular patterns for deformation measurement. Opt Express 27(13):18435–18444. https://doi.org/10.1364/OE.27.018435

Semin B, Auradou H, François MLM (2011) Accurate measurement of curvilinear shapes by virtual image correlation. Eur Phys J Appl Phys 56(1):10701. https://doi.org/10.1051/epjap/2011110275

Tong W (2013) Formulation of Lucas-Kanade digital image correlation algorithms for non-contact deformation measurements: a review. Strain 49(4):313–334. https://doi.org/10.1111/str.12039

Pan B, Wang B (2016) Digital image correlation with enhanced accuracy and efficiency: a comparison of two subpixel registration algorithms. Exp Mech 56(8):1395–1409. https://doi.org/10.1007/s11340-016-0180-z

Sur F, Blaysat B, Grédiac M (2016) Determining displacement and strain maps immune from aliasing effect with the grid method. Opt Lasers Eng 86:317–328. https://doi.org/10.1016/j.optlaseng.2016.06.010. https://hal.science/hal-01352868

Reu P (2014) All about speckles: aliasing. Exp Tech 38(5):1–3. https://doi.org/10.1111/ext.12111

Herráez MA, Burton DR, Lalor MJ, Gdeisat MA (2002) Fast two-dimensional phase-unwrapping algorithm based on sorting by reliability following a noncontinuous path. Appl Opt 41(35):7437–7444. https://doi.org/10.1364/ao.41.007437

Mullen M. 2D and 3D phase unwrapping using SRNCP. https://github.com/mfmullen/PhaseUnwrapping. Accessed 10 Feb 2023

Sur F, Blaysat B, Grédiac M (2018) Rendering deformed speckle images with a Boolean model. J Math Imaging Vision 60(5):634–65. https://doi.org/10.1007/s10851-017-0779-4. https://hal.science/hal-01664997

Grédiac M, Blaysat B, Sur F (2017) A critical comparison of some metrological parameters characterizing Local Digital Image Correlation and Grid Method. Exp Mech 57(6):871–903. https://doi.org/10.1007/s11340-017-0279-x. https://hal.inria.fr/hal-01509611/

Grédiac M, Sur F, Badulescu C, Mathias J-D (2013) Using deconvolution to improve the metrological performance of the grid method. Opt Lasers Eng 51(6):716–734. https://doi.org/10.1016/j.optlaseng.2013.01.009

Piro JL, Grédiac M (2004) Producing and transferring low-spatial-frequency grids for measuring displacement fields with moiré and grid methods. Exp Tech 28(4):23–26

JCGM Member Organizations (2012) International vocabulary of metrology – basic and general concepts and associated terms (VIM), vol 200. BIPM

Chrysochoos A, Surrel Y (2012) Chapter 1. Basics of metrology and introduction to techniques. In: Grédiac M, Hild F (eds) Full-field Measurements and Identification in Solid Mechanics. Wiley, pp 1–29

Wittevrongel L, Lava P, Lomov SV, Debruyne D (2015) A self adaptive global digital image correlation algorithm. Exp Mech 55(2):361–378. https://doi.org/10.1007/s11340-014-9946-3

Bornert M, Brémand F, Doumalin P, Dupré JC, Fazzini M, Grédiac M, Hild F, Mistou S, Molimard J, Orteu JJ, Robert L, Surrel Y, Vacher P, Wattrisse B (2009) Assessment of digital image correlation measurement errors: methodology and results. Exp Mech 49:353–370. https://doi.org/10.1007/s11340-008-9204-7

iDICs - DIC Challenge. https://idics.org/challenge/. Accessed 10 Feb 2023

Blaber J, Adair B, Antoniou A (2015) NCORR: open-source 2D digital image correlation MATLAB software. Exp Mech 55(6):1105–1122. https://doi.org/10.1007/s11340-015-0009-1

Acknowledgements

The authors acknowledge support from the ANR Grant ANR-18-CE08-0028-01. This work was also sponsored by the French government research program “Investissements d’Avenir” through the IDEX-ISITE initiative 16-IDEX-0001 (CAP 20-25), and from the AURA regional council.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Vocabulary and Definitions

Appendix: Vocabulary and Definitions

Three metrological parameters are discussed in this paper, namely the measurement resolution, the bias and the spatial resolution. Their definition, already given in [39, 52], are recalled below for the sake of complitness:

-

Measurement resolution: in Ref. [55], the measurement resolution is defined by the smallest change in a quantity being measured that causes a perceptible change in the corresponding indication. More precisely, it is proposed in [56] to define it as the change in quantity being measured that causes a change in the corresponding indication greater than one standard deviation of the measurement noise, which enables us to quantify the measurement resolution. This definition is quite arbitrary, any other (reasonable) multiple of the standard deviation being also potentially acceptable, but the idea is that the resolution quantifies the smallest change not likely to be caused by measurement noise [56].

-

Spatial resolution: the spatial resolution denoted by \(\ell _{\lambda }\) is defined here by the lowest period of a sinusoidal deformation that the technique is able to reproduce before losing a certain percentage \(\lambda\) of amplitude, this quantity being chosen a priori [57]. The advantage of this definition is that it is not based on an arbitrary value for the subset size in Local DIC or for the elements size in Global DIC. This makes it possible to compare the spatial resolution between these two techniques.

-

Bias:a systematic error generally occurs when a given technique returns actual details in displacement and strain maps. It is due to the fact that the amplitude of such apparent details is generally lower than the amplitude of the actual detail. This apparent “damping” is a bias, which can be quantified by considering a sinusoidal reference displacement field, and measuring the relative loss of amplitude exhibited by the displacement field returned by the technique under study, as suggested in Refs. [57,58,59,60]. Of course, the loss of amplitude depends on the frequency f of the sine function. This loss of amplitude is denoted here by l(f). In this context, the spatial resolution defined above is defined for a given bias \(\lambda\), the relation between \(\ell _{\lambda }\) and \(\lambda\) being that \(\ell _{\lambda }\) is the smallest value such that \(l(1/\ell _{\lambda })=\lambda\). We call here \(\lambda\) the bias of the method. This is a slight abuse of language since fixing \(\lambda\) does not mean that the damping of any displacement or strain field is actually equal to this \(\lambda\) value. Note finally that for DIC, the effect quantified here by \(\lambda\) is often referred to as the “matching bias”, because it occurs when there is a mismatch between the subset shape function used to describe the displacement within subsets on the one hand, and the degree of the actual displacement if the latter is described by a polynomial on the other hand.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shi, Y., Blaysat, B., Chanal, H. et al. Introducing Virtual DIC to Remove Interpolation Bias and Process Optimal Patterns. Exp Mech 63, 637–653 (2023). https://doi.org/10.1007/s11340-023-00941-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-00941-2