Abstract

Background

Image-based global correlation involves a class of ill-posed inverse problems associated with speckle quality and deformation gradients on specimen surfaces. However, the method used to simultaneously integrate the prior information related to images and deformations and effectively regularize these inverse problems still faces severe challenges, especially when complex heterogeneous deformation gradients exist over sample surfaces with locally degraded speckle patterns.

Objective

We propose a novel self-adaptive meshing-based regularization for global image correlation to determine spatially complex heterogeneous deformations.

Methods

A virtual truss system with a linearly elastic constitutive relationship is employed to self-adaptively implement surface meshing by numerically balancing the exerted virtual forces under the constraints of the local speckle image quality and deformation gradients. The 2-norm-based condition number of the local stiffness matrix is introduced to ensure numerical stability during meshing.

Results

The algorithms can behave as a smart regularization procedure integrating all the prior information during numerical calculations, consequently achieving an accurate, precise and robust characterization of heterogeneous deformations, as demonstrated by virtual simulations and actual experiments.

Conclusions

The regularization strategy coupled to image-based correlation is also promising for automatic quantification of complex heterogeneous deformations, particularly from images with locally degraded speckle patterns.

Similar content being viewed by others

Abbreviations

- \({e}_{ZNSSD}\) :

-

ZNSSD-based error function

- \({\Omega }_{t}\) :

-

A specific finite element

- \(\Omega\) :

-

Region of interest (ROI)

- p :

-

Global nodal displacement vector

- N:

-

Total number of nodes

- f(X,Y) :

-

Pixel gray in the reference image

- g(x,y):

-

Pixel gray in the target image

- f m :

-

Mean pixel gray in a specific element in the reference image

- g m :

-

Mean pixel gray in a specific element in the target image

- M:

-

Number of pixels in a specific element

- \(\Delta f\) :

-

Gray normalized coefficient of reference image

- \(\Delta g\) :

-

Gray normalized coefficient of target image

- \((X,Y)\) :

-

An arbitrary point in the reference image

- \((x,y)\) :

-

An arbitrary point in the target image

- u:

-

X-direction displacement component

- v:

-

Y-direction displacement component

- t:

-

Element number

- Te :

-

Total number of elements

- q :

-

Total number of nodes on the specific element

- (uit,v it):

-

ith node displacement in the tth element

- φi :

-

Shape function of the ith node

- p t :

-

The nodal displacement vector of the tth element

- H t :

-

Total assembly matrix

- \(Q\lbrack f\left(X,Y\right),W\rbrack\) :

-

Weighted gray gradient (WGG) in the vicinity of an arbitrary location (X,Y)

- \(W(X,Y,{D}_{o})\) :

-

Weighted window function

- (X c ,Y c ) :

-

Center of the Gaussian window

- \({D}_{o}\) :

-

Shape control parameter of Gaussian window

- \(\overline{Q }\) :

-

Normalized WGG

- \(\underset{f(X,Y)}{\mathrm{max}}Q\) :

-

Maximum WGG over the ROI

- \({\mathbf{F}}_{b}\) :

-

Force vector acting on a specific bar

- \({k}_{b}\) :

-

Spring constant

- \({L}_{0}\) :

-

Original length in the reference configuration

- L :

-

Length in the current configuration

- b :

-

Unit vector along the bar’s compression direction

- F N(a):

-

Resultant force acting on an arbitrary node

- \(a\) :

-

Node location

- \({h}_{b}\) :

-

Flexibility of bars in the structure

- a m :

-

Node location after the nth iteration

- a o :

-

Initial node location

- JN :

-

Total number of bars on a specified node

- F bj :

-

Force acting on the jth bar on the specified nodes

- L 0j :

-

Length of the jth bar in the reference configuration

- L j :

-

Length of the jth bar in the current configuration

- b j :

-

Unit vector in the jth bar’s compression direction

- \(\Lambda\) :

-

Local strain gradient

- \(\overline{\Lambda }\) :

-

Normalized strain gradient

- \({L}_{min}\) :

-

The lower limit of bar length

- \(\psi(X,Y;\overline Q,\overline\Lambda)\) :

-

Meshing index

- \({\omega }_{Q}\) :

-

Weighted factor of normalized WGG

- \({\omega }_{\Lambda }\) :

-

Weighted factor of normalized strain gradient

- \({L}_{max}\) :

-

Upper limit of bar length

- β :

-

Ratio of Lmax to Lmin

- E :

-

Green strain tensor

- F :

-

Deformation gradient tensor

- I :

-

Identity tensor in two-dimensional space

- C A :

-

Coefficient matrix

- W S :

-

Strain window size

- R :

-

Residual matrix

- k a :

-

Iterative number of the adaptive algorithm

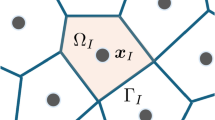

- \({\Omega }_{s}\) :

-

Local regions with different speckle densities

- \(\Gamma\) :

-

Number of Ωs

- \({S}_{\Omega }\) :

-

Total number of speckle granules in the Ωsth local region

- \({I}_{0}\) :

-

Peak value of gray intensity of a single speckle granule

- \({R}_{\mathrm{s}}\) :

-

Average radius of speckle granule

- \(({X}_{S},{Y}_{S})\) :

-

Central coordinates of the sth speckle granule

- \([{U}_{s}{V}_{s}{]}^{T}\) :

-

Displacement vector of the sth speckle granule

- \({\xi }_{g}(X,Y)\) :

-

Potential white Gaussian noises superimposed on the reference image

- \({\eta }_{g}(x,y)\) :

-

Potential white Gaussian noises superimposed on the target image

- \({\alpha }_{X}\) :

-

Amplitude of simulated sinusoidal displacement field in X direction

- \({p}_{X}\) :

-

Period of simulated sinusoidal displacement field in X direction

- \(\Delta\) :

-

Mean error of the measured displacement

- \(\sigma\) :

-

Standard deviation of the measured displacement

- \({(U}_{Sn},{V}_{Sn})\) :

-

nth node displacement prescribed on the synthetic speckle images

- \({(U}_{n},{V}_{n})\) :

-

Measured displacement vector on the nth node

- \(\delta n\) :

-

Measurement error on the nth node

- \(\alpha\) :

-

Amplitude of the bi-sinusoidal displacement field

- \(p\) :

-

Period of the bi-sinusoidal displacement field

References

van Dijk N, Wu D, Persson C, Isaksson P (2019) A global digital volume correlation algorithm based on higher-order finite elements: Implementation and evaluation. Int J Solids Struct 168:211–227

Chawla K (2019) Composite Materials: Science and Engineering (4th ed). Springer International Publishing

Orteu J (2009) Image Correlation for Shape, Motion and Deformation Measurements. Springer US

Temenoff J, Mikos A (2009) Biomaterials: The Intersection of Biology and Materials Science. Pearson Prentice Hall

Sanchez J, Benaroya H (2014) Review of force reconstruction techniques. J Soun Vib 333:2999–3018

Bai R, Ma Y, Lei Z, Feng Y, Zou J, Liu D (2020) Shear deformation and energy absorption analysis of flexible fabric in yarn pullout test. Compos A Appl Sci Manuf 128:105678

Engqvist J, Wallin M, Ristinmaa M, Hall S (2016) Modelling and experiments of glassy polymers using biaxial loading and digital image correlation. Int J Solids Struct 102–103:100–111

Ye J, Andre S, Farge L (2015) Kinematic study of necking in a semi-crystalline polymer through 3D digital image correlation. Int J Solids Struct 59:58–72

Pan B, Yu L, Wu D (2013) High-Accuracy 2D Digital Image Correlation Measurements with Bilateral Telecentric Lenses: Error Analysis and Experimental Verification. Exp Mech 53(9):1719–1733

Reagan D, Sabato A, Niezrecki C (2018) Feasibility of using digital image correlation for unmanned aerial vehicle structural health monitoring of bridges. Struct Health Monit 17(5):1056–1072

Huang J, Qin L, Peng X, Zhu T, Xiong C, Zhang Y, Fang J (2009) Cellular traction force recovery: An optimal filtering approach in two-dimensional Fourier space. J Theor Biol 259(4):811–819

Huang J, Wang L, Xiong C, Yuan F (2016) Elastic hydrogel as a sensor for detection of mechanical stress generated by single cells grown in three-dimensional environment. Biomaterials 98:103–112

Chai H, Xie Z, Xiao X, Xie H, Huang J, Luo S (2020) Microstructural characterization and constitutive modeling of deformation of closed-cell foams based on in situ x-ray tomography. Int J Plasticity 131:102730

Narayanan A, Dubey K, Davies C, Dear J (2017) The creep of alloy 617 at 700 °C: Material properties, measurement of strain and comparison between finite element analysis and digital image correlation. Int J Solids Struct 129:195–203

Gerbig D, Bower A, Savic V, Herctor L (2016) Coupling digital image correlation and finite element analysis to determine constitutive parameters in necking tensile specimens. Int J Solids Struct 97–98:496–509

Wittevrongel L, Lava P, Lomov S, Debruyne D (2015) A Self Adaptive Global Digital Image Correlation Algorithm. Exp Mech 55(2):361–378

Pan B (2018) Digital image correlation for surface deformation measurement: historical developments, recent advances and future goals. Meas Sci Technol 29(8):082001

Elguedj T, Rethore J, Buteri A (2011) Isogeometric analysis for strain field measurements. Comput Methods Appl Mech Engrg 200(1–4):40–56

Besnard G, Hild F, Roux S (2006) “Finite-Element” Displacement Fields Analysis from Digital Images: Application to Portevin–Le Chatelier Bands. Exp Mech 46(6):789–803

Kleinendorst S, Hoefnagels J, Verhoosel C, Ruybalid A (2015) On the use of adaptive refinement in isogeometric digitalimage correlation. Int J Numer Meth Eng 104(10):944–962

Lava P, Cooreman S, Debruyne D (2010) Study of systematic errors in strain fields obtained via DIC using heterogeneous deformation generated by plastic FEA. Opt Lasers Eng 48(4):457–468

Huang J, Zhu T, Pan X, Qin L, Peng X, Xiong C, Fang J (2010) A high-efficiency digital image correlation method based on a fast recursive scheme. Meas Sci Technol 21(3):035101

Yuan Y, Zhan Q, Xiong C, Huang J (2017) Digital image correlation based on a fast convolution strategy. Opt Lasers Eng 97:52–61

Pan B, Bo W, Lubineau G, Moussawi A (2016) Comparison of Subset-Based Local and Finite Element-Based Global Digital Image Correlation. Exp Mech 55(5):887–901

Huang J, Pan X, Peng X, Yuan Y, Xiong C, Fang J, Yuan F (2013) Digital image correlation with self-adaptive Gaussian windows. Exp Mech 53(3):505–512

Yuan Y, Huang J, Peng X, Xiong C, Jing F, Fan Y (2014) Accurate displacement measurement via a self-adaptive digital image correlation method based on a weighted ZNSSD criterion. Opt Lasers Eng 52:75–85

Hild F, Roux S (2012) Comparison of Local and Global Approaches to Digital Image Correlation. Exp Mech 52(9):1503–1519

Persson P, Strang G (2004) A Simple Mesh Generator in Matlab. SIAM Rev 46(2):329–345

Remacle J, Lambrechts J, Seny B, Marchandise E, Johnen A, Geuzainet C (2012) Blossom-Quad: A non-uniform quadrilateral mesh generator using a minimum-cost perfect-matching algorithm. Int J Numer Meth Eng 89(9):1102–1119

Mendoza A, Neggers J, Hild F, Roux S (2019) Complete mechanical regularization applied to digital image and volume correlation. Comput Methods Appl Mech Engrg 355:27–43

Zhan Q, Yuan Y, Fan X, Huang J, Xiong C, Yuan F (2016) Digital image correlation involves an inverse problem: A regularization scheme based on subset size constraint. Opt Lasers Eng 81:54–62

Yang R (2014) A regularized finite-element digital image correlation for irregular displacement field. Opt Lasers Eng 56:67–73

Press W, Teukolsky S, Vetterling W, Flannery B (2007) Numerical Recipes: The Art of Scientific Computing (3rd ed). Cambridge University Press

Thomas T, Roux S, Morgeneyer T, Hild F (2014) Localized strain field measurement on laminography data with mechanical regularization. Nucl Instrum Meth B 324:70–79

Cofaru C, Philips W, Paepegem W (2010) Improved Newton-Raphson digital image correlation method for full-field displacement and strain calculation. Appl Optics 49(33):6472–6484

Kleinendorst S, Hoefnagels J, Geers M (2019) Mechanical Shape Correlation: A novel integrated digital image correlation approach. Comput Methods Appl Mech Engrg 345:983–1006

Baldi A, Bertolino F (2016) Assessment of h-refinement procedure for global digital image correlation. Meccanica 51(4):979–991

Blaysat B, Neggers J, Grédiac M, Sur F (2020) Towards Criteria Characterizing the Metrological Performance of Full-field Measurement Techniques: Application to the Comparison Between Local and Global Versions of DIC. Exp Mech 60(3):393–407

Fedele R, Galantucci L, Ciani A (2013) Global 2D digital image correlation for motion estimation in a finite element framework: a variational formulation and a regularized pyramidal, multi-grid implementation. Int J Numer Meth Eng 96:739–762

Yuan Y, Zhan Q, Huang J, Fang J, Xiong C (2016) Digital image correlation with gray gradient constraints: Application to spatially variant speckle images. Opt Lasers Eng 77:85–91

Su Y, Gao Z, Fang Z, Liu Y, Wu S (2019) Theoretical analysis on performance of digital speckle pattern: uniqueness, accuracy, precision, and spatial resolution. Opt Express 27(16):22439–22474

Shao X, Dai X, He X (2015) Noise robustness and parallel computation of the inverse compositional Gauss-Newton algorithm in digital image correlation. Opt Lasers Eng 71:9–19

Sun Y, Pang J, Wong C, Fei S (2005) Finite element formulation for a digital image correlation method. Appl Optics 44(34):7357–7363

Ma S, Zhao Z, Xian W (2012) Mesh-based digital image correlation method using higher order isoparametric elements. J Strain Anal Eng 47(3):163–175

Tong W (2013) Formulation of Lucas-Kanade digital image correlation algorithms for non-contact deformation measurements: A review. Strain 49(4):313–334

Su Y, Zhang Q, Xu X, Gao Z (2016) Quality assessment of speckle patterns for DIC by consideration of both systematic errors and random errors. Opt Lasers Eng 86:132–142

Hai Y, Guo R, Xia H, Feng Y, Zhang Y, He T (2014) Application of the mean intensity of the second derivative in evaluating the speckle patterns in digital image correlation. Opt Lasers Eng 60:32–37

Pan B (2013) Bias error reduction of digital image correlation using Gaussian pre-filtering. Opt Lasers Eng 51:1161–1167

Mazzoleni F, Zappa E, Sutton M, Cigada A (2014) Gaussian pre-filtering for uncertainty minimization in digital image correlation using numerically-designed speckle patterns. Opt Lasers Eng 66:19–33

Hansen P (2007) Regularization Tools version 4.0 for Matlab 7.3. Numer Algorithms 46(2):189–194

Hansen P, Jensen T, Rodriguez G (2007) An adaptive pruning algorithm for the discrete L-curve criterion. J Comput Appl Math 198(2):483–492

Zhang L, Wang T, Jiang Z, Kemao Q, Liu Y, Liu Z, Tang L, Dong S (2015) High accuracy digital image correlation powered by GPU-based parallel computing. Opt Lasers Eng 69:7–12

Wang T, Kemao Q, Seah H, Lin F (2018) A flexible heterogeneous real-time digital image correlation system. Opt Lasers Eng 110:7–17

Liu X, Zhu K, Duan X, Wang P, Han Y, Peng W, Huang J (2021) Extracellular matrix stiffness modulates host-bacteria interactions and antibiotic therapy of bacterial internalization. Biomaterials 277:121098

Huang J, Lin F, Xiong C (2019) Mechanical characterization of single cells based on microfluidic techniques. Trends Analyt Chem 117:47–57

Xue X, Sun Y, Resto-Irizarry A, Yuan Y, Aw Yong K, Zheng Y, Weng S, Shao Y, Chai Y, Studer L, Fu J (2018) Mechanics-guided embryonic patterning of neuroectoderm tissue from human pluripotent stem cells. Nat Mater 17(7):633–641

Petridou N, Spiro Z, Heisenberg C (2017) Multiscale force sensing in development. Nat Cell Biol 19(6):581–588

Ma S, Meng Z, Chen R, Guan K (2019) The Hippo Pathway: Biology and Pathophysiology. Annu Rev Biochem 88(1):577–604

Kim J, Han S, Lei A, Miyano M, Bloom J, Srivastava V, Stampfer M, Gartner Z, LaBarge M, Sohn L (2018) Characterizing cellular mechanical phenotypes with mechano-node-pore sensing. Microsyst Nanoeng 4(1):17091

Logan D (2017) A first course in the finite element method (6th ed). Cengage Learning

Acknowledgements

These authors acknowledge the support from National Natural Science Foundation of China (grant nos. 11772004, 11972001 and 91848201), Beijing Natural Science Foundation (grant no. Z200017), and National Key Research and Development Program of China (grant no. 2021YFA1000200).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix A: Shape Functions of Nodes

The shape functions of nodes used in the global DIC algorithms are normally the same as those in the classical finite elements [60]. For instance, the 3-node triangular element, usually referred to as T3 element, has the following shape function

where i=1,2,3 for the T3 element, \({a}_{1}={X}_{2}{Y}_{3}-{X}_{3}{Y}_{2}\),\({a}_{2}={X}_{3}{Y}_{1}-{X}_{1}{Y}_{3}\), \({a}_{3}={X}_{1}{Y}_{2}-{X}_{2}{Y}_{1}\), \({b}_{1}={Y}_{2}{-Y}_{3}\), \({b}_{2}={Y}_{3}-{Y}_{1}\), \({b}_{3}={Y}_{1}-{Y}_{2}\), \({c}_{1}={X}_{3}{-X}_{2}\), \({c}_{2}={X}_{1}{-X}_{3}\), \({c}_{3}={X}_{2}{-X}_{1}\), \(({X}_{i},{Y}_{i})\) denotes the node coordinates and A is the area of the element.

Appendix B: Discrete Form of Governing Equation in Equation (4)

To estimate the lower limit of bar length in the virtual truss structure, we first rewrote (equation (2)) as \(T\left({\mathbf{p}}_{t}\right)=F\left(X,Y\right)-G(x,y)\) in an arbitrary element with

For the well-adopted first-order triangular element with three nodes, \({\mathbf{p}}_{t}=[{p}_{t1},{p}_{t2},{p}_{t3},{p}_{t4},{p}_{t5},{p}_{t6}{]}^{T}=[{u}_{t1},{v}_{t1},{u}_{t2},{v}_{t2},{u}_{t3},{v}_{t3}{]}^{T}\). We subsequently expand \(G\left(x,y\right)\) as a first-order Taylor’s series approximately [31], i.e.,

in which \({G}_{x}=\partial G/\partial X\) and \({G}_{Y}=\partial G/\partial Y\). Substituting the above expression into \(T{(\mathbf{p}}_{t})\) yields

And

In this context, we have

Substituting the expression into (equation (4)) gives

where \({\mathbf{C}}_{A}\) and R are the corresponding coefficient matrix and residual vector, respectively, which have the following forms

And

Rights and permissions

About this article

Cite this article

Duan, X.C., Yuan, Y., Liu, X.Y. et al. Coupling Self-Adaptive Meshing-Based Regularization and Global Image Correlation for Spatially Heterogeneous Deformation Characterization. Exp Mech 62, 779–797 (2022). https://doi.org/10.1007/s11340-022-00826-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-022-00826-w