Abstract

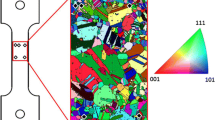

It is challenging to measure accurately and with high spatial resolution the local thermal strains in heterogeneous microstructures due of the complex nature of the thermal deformations and local boundary conditions. In the enclosed study, a digital image correlation (DIC) based, thermal strain mapping technique is described that is able to probe thermal deformations with sub-micron spatial resolution and sub-nanometer displacement accuracy for both homogeneous and heterogeneous materials, including cross-sections of IC packages. The full-field thermal deformation maps of different materials within a nanostructured IC chip cross-section are established from room temperature up to 160 °C, uncovering the heterogeneous nature of the specimen while accurately measuring the highly non-uniform displacement and strain fields across the multiple material constituents. As described in this work, the DIC-enabled technique is capable of high resolution mapping of local thermo-mechanical deformations in heterogeneous materials, providing a methodology that can improve our understanding of complex material systems under controlled thermal-environmental conditions.

Similar content being viewed by others

Notes

The authors also performed the refocusing process by temporarily increasing the SEM magnification by 10X to ensure that the Z-stage position provided optimal focus of the region. Once focus is confirmed, the SEM magnification is reset to the original value. Baseline results performed by the authors confirmed that this approach is effective and did not increase strain errors.

Correlated Solutions, Inc, 121 Dutchman Blvd, Irmo, SC 29063; www.correlatedsolutions.com

For the aluminum specimen, subset in the analysis is 21 × 21 pixel2, with a step size of 5 pixels between subsets and strain window of 25 × 25 pixel2. For the nickel specimen, which had a larger FOV and large gold particles, subset size is 37 × 37 pixel2, step size is 11 pixels and strain window is 55 × 55 pixel2. All analyses were performed with VIC2days using embedded image distortion correction.software.

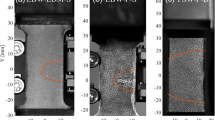

Software VIC-2D with distortion correction is used to map the strain field components εxx, εyy and εxy. For the Intel IC package. In addition, the temperature is measured using a K-type thermocouple mounted on the top surface of specimen (see center photograph in Fig. 5) comparing the thermocouple measurements to the heating stage temperature output.

Our mapping estimates for the thermal expansion of the polymers is 64*10−6m/m K, which is close to the literature value of 55*10−6m/m K for epoxy, castings resins & compounds and underfill material.

References

Sutton MA (2004) Recent developments and trends in measurements from the macro-scale to reduced length scales. In: Berthaud Y (ed) et al., Proc. Photomécanique, Albi, France, Ecole des Mines d’Albi, pp 1–8

Rastogi PK (2000) Photomechanics (topics in applied physics). Springer, Berlin

Peters WH, Ranson WF (1982) Digital imaging techniques in experimental stress analysis. Opt Eng 21:427–432

Sutton MA, Wolters WJ, Peters WH III, Ranson WF, McNeill SR (1983) Determination of displacements using an improved digital correlation method. Image Vis Comput 1(3):1333–1339

Chu TC, Ranson WF, Sutton MA, Peters WH III (1985) Application of digital image correlation techniques to experimental mechanics. Exp Mech 25(3):232–245

Sutton MA, Cheng M, Peters WH, Chao YJ, McNeil SR (1986) Applications of an optimized digital image correlation method to planar deformation analysis. Image Vis Comput 4:143–150

Sutton MA, McNeill SR, Jang JS, Babai M (1988) The effects of sub-pixel image restoration on digital correlation error estimates. Opt Eng 27(3):173–175

Sutton MA, Cheng M, McNeill SR, Chao YJ, Peters WH (1988) Application of an optimized digital correlation method to planar deformation analysis. Image Vis Comput 4(3):143–150

Bruck HA, McNeill SR, Sutton MA, Peters WH (1989) Digital image correlation using newton Raphson method of partial differential correction. Exp Mech 29:261–267

Yoneyama S, Kitagawa A, Iwata S, Tani K, Kikuta H (2007) Bridge deflection measurement using digital image correlation. Exp Tech 31:34–40

Kang J, Ososkov Y, Embury JD, Wilkinson DS (2007) Digital image correlation studies for microscopic strain distribution and damage in dual phase steels. Scr Mater 56:999–1002

Jonnalagadda KN, Chasiotis I, Yagnamurthy S, Lambros J, Pulskamp J, Polcawich R, Dubey M (2010) Experimental investigation of strain rate dependence of nanocrystalline Pt films. Exp Mech 50:25–35

Tatschl A, Kolednik O (2003) A new tool for the experimental characterization of micro-plasticity. Mater Sci Eng A 339:265–280

Tanaka Y, Naito K, Kishimoto S, Kagawa Y (2011) Development of a pattern to measure multiscale deformation and strain distribution via in situ FE-SEM observations. Nanotechnology 22:115704

Sutton MA, Li N, Joy DC, Reynolds AP, Li X (2007) Scanning electron microscopy for quantitative small and large deformation measurements part I: SEM imaging at magnifications from 200 to 10,000. Exp Mech 47:775–787. doi:10.1007/s11340-007-9042-z

Sutton MA, Li N, Garcia D, Cornille N, Orteu JJ, McNeill SR, Schreier HW, Li X, Reynolds AP (2007) Scanning electron microscopy for quantitative small and large deformation measurements part II: experimental validation for magnifications from 200 to 10,000. Exp Mech 47:789–804. doi:10.1007/s11340-007-9041-0

Yamamoto Y, Shinohara K (2002) Application of X-ray microscopy in analysis of living hydrated cells. Anat Rec 269(5):217–223. doi:10.1002/ar.10166

Thibault P, Dierolf M, Menzel A, Bunk O, David C, Pfeiffer F (2008) High-resolution scanning X-ray diffraction microscopy. Science 321(5887):379–382. doi:10.1126/science.1158573

Sabate N et al (2006) Digital image correlation of nanoscale deformation fields for local stress measurement in thin films. Nanotechnology 17:5264–5270

Kang J et al (2005) Microscopic strain mapping using scanning electron microscopy topography image correlation at large strain. J Strain Anal Eng Des 40:559–570

Wang H et al (2006) Error analysis of digital speckle correlation method under scanning electron microscope. Exp Tech 30:42–45

Lagattu F et al (2006) In-plane strain measurements on a microscopic scale by coupling digital image correlation and an in situ SEM technique. Mater Charact 56:10–18

Sutton MA, Li N, Garcia D, Cornille N, Orteu JJ, McNeill SR, Schreier HW, Li X (2006) Metrology in a scanning electron microscope: theoretical developments and experimental validation. Meas Sci Technol 17:2613–2622

Davidson DL, Lankford J (1983) Fatigue crack tip strains in 7075-T6 aluminum alloy using stereo-imaging and the use in fatigue crack growth models, ASTM STP 801: Fatigue Mechanisms: Advances in Quantitative Measurement of Physical Damage, pp 371–399

Davidson DL, Williams DR, Buckingham JE (1983) Crack-tip stresses as computed from strains determined by stereoimaging. Exp Mech 23(2):242–248

Xu ZH, Jin H, Lu WY, Sutton MA, Li XD (2011) Influence of scanning rotation on nanoscale artificial strain in open loop AFM. Exp Mech 51(4):619–624

Xu ZH, Li XD, Sutton MA, Li N (2008) Drift and spatial distortion elimination in atomic force microscopy images by the digital image correlation technique. J Strain Anal Eng Des 43:729–743

Li N, Sutton MA, Li X, Schreier HW (2007) Full-field thermal deformation measurements in a scanning electron microscope by 2D digital image correlation. Exp Mech 48:635–646. doi:10.1007/s11340-007-9107-z

Sutton MA, Orteu J-J, Schreier HW (2009) Image correlation for shape, motion and deformation measurements. ISBN 978-0-387-78746-6 321pgs Springer

Berfield TA, Patel JK, Shimmin RG, Braun PV, Lambros J, Sottos NR (2006) Fluorescent image correlation for nanoscale deformation measurements. Small 2:631–635

Berfield TA, Patel JK, Shimmin RG, Braun PV, Lambros J, Sottos NR (2007) Micro- and nanoscale deformation measurement of surface and internal planes via digital image correlation. Exp Mech 47:51–62. doi:10.1007/s11340-006-0531-2

Scrivens WA, Luo Y, Sutton MA, Collete SA, Myrick ML, Miney P, Colavita PE, Reynolds AP, Li X (2007) Development of patterns for digital image correlation measurements at reduced length scales. Exp Mech 47:63–77

Tschopp MA, Bartha BB, Porter WJ, Murray PT, Fairchild SB (2009) Microstructure-dependent local strain behavior in polycrystals through in situ scanning electron microscope tensile experiments. Metall Mater Trans A 40:2363–2368

Li N, Guo S, Sutton MA (2011) Recent progress in e-beam lithography for SEM patterning, MEMS and Nano., Conf. Proc. Soc. for Exp. Mech. Ser. 2, ed T Proulx. New York: Springer, pp 163–166

Kammers AD, Daly S (2011) Small-scale patterning methods for digital image correlation under scanning electron microscopy. Meas Sci Technol 22:125501

Kammers AD, Daly S (2013) Self-assembled nanoparticle surface patterning for improved digital image correlation in a scanning electron microscope. Exp Mech 53:1333–1341

Di Gioacchino F, Quinta da Fonseca J (2013) Plastic strain mapping with sub-micron resolution using digital image correlation. Exp Mech 53(5):743–754

Stinville JC, Vanderesse N, Bridier F, Bocher P, Pollock TM (2015) High resolution mapping of strain localization near twin boundaries in a nickel-based superalloy. Acta Mater 98(1):29–42

Stinville JC, Echlin MP, Texier D, Bridier F, Bocher P, Pollock TM (2015) Sub-grain scale digital image correlation by electron microscopy for polycrystalline materials during elastic and plastic deformation. Exp Mech. doi:10.1007/s11340-015-0083-4

Walley JL, Wheeler R, Uchic MD, Mills MJ (2012) In-situ mechanical testing for characterizing strain localization during deformation at elevated temperatures. Exp Mech 52(4):405–416. doi:10.1007/s11340-011-9499-7

Bridier F, Stinville JC, Vanderesse N, Villechaise P, Bocher P (2013) Microscopic strain and crystal rotation measurement within metallurgical grains. Key Eng Mater 592–593:493–496

Raabe D, Sachtleber M, Zhao Z, Roters F, Zaefferer S, Raabe D (2001) Micromechanical and macromechanical effects in grain scale polycrystal plasticity experimentation and simulation. Acta Mater 49(17):3433–3441

Delaire F, Raphanel JL, Rey C (2000) Plastic heterogeneities of a copper multicrystal deformed in uniaxial tension: experimental study and finite element simulations. Acta Mater 48(5):1075–1087

Collette SA, Sutton MA, Miney P, Reynolds AP, Xiaodong L, Colavita PE, Scrivens WA, Luo Y, Sudarshan T, Muzykov P, Myrick ML (2004) Development of patterns for nanoscale strain measurements: I. Fabrication of imprinted Au webs for polymeric materials. Nanotechnology 15:1812–1817

Instec, Inc. http://www.instec.com/

Sutton MA, Yan JH, Tiwari V, Schreier HW, Orteu JJ (2008) The effect of out-of-plane motion on 2D and 3D digital image correlation measurements. Opt Lasers Eng 46:746–757. doi:10.1007/s11340-013-9734-5

ASM International, Metals Handbook, Volume 2, 10th Edition, p 128

Zhu T, Sutton MA, Li N, Li X-D, Reynolds AP (2011) Quantitative stereovision in a scanning electron microscope. Exp Mech 51(1):97–109

Acknowledgments

The support of Semiconductor Research Corporation (SRC)/Intel Corporation via grant # 2011-IN-2171, the technical insight from Dr. Michael Mello at California Institute of Technology and the assistance provided by the University of South Carolina EM Center are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

Procedure for Patterning with Gold Nanoparticles

In our studies, the AuNPs are produced using the following procedure, which is a slight modification of the process outlined by Kammers and Daly [31, 32]. First, gold (III) chloride trihydrate (HAuCl4•3H2O) and trisodium citrate dihydrate (C6H5Na3O7•2H2O) purchased from Sigma Aldrich are used to make stock solutions of 10 mM HAuCl4 and 38.8 mM Na3-citrate. Appendix Figure 14 shows a schematic of the process to synthesize AuNPs. Here, 400 mL of 1 mM HAuCl4 (diluted from 10 mM stock solution) is added to a beaker and brought to a boil while stirred with a magnetic stirring rod. Between 6.5 and 40 mL of 38.8 mM Na3-citrate is then added to the boiling solution to produce AuNPs with diameters of 136 nm, 48 nm, 32 nm and 15 nm, respectively. The authors produced smaller particles with the addition of more Na3-citrate, achieving a minimum particle size of 7 nm in the patterning experiments. The final particle size to be deposited is chosen according to the SEM magnification and spatial resolution that is needed for a given experiment. Generally speaking, a minimum of 3x3 pixels should be used to resolve each one gold particle in the final image to obtain accurate mapping using DIC. It is noted that, when viewing the resulting dispersion of discrete gold nanoparticles via colloidal suspension in transparent media by using white light illumination, the color of the scattered light depends upon the size of the suspended particles. The scattered colors in the bottles and the relative diameters of the gold nano-particles are shown in Appendix Figure 15 to illustrate this effect. After synthesis, the AuNPs are stored in dark glass bottles to protect them from UV rays that would reduce any remaining HAuCl4 until use. Our studies used the gold colloidal solutions within 1 week in all cases. Though longer storage time may also be acceptable, we have no data to confirm this.

To attach the AuNPs to a heterogeneous material surface, the specimen surface is first coated with a nano-layer of material to obtain a uniform material surface for consistent patterning. Once the nano-layer of deposited, the nano-layer surface is treated with organosilane molecules that possess a pendant functional group with a strong affinity for gold. In this work, the specimen that possesses reactive oxide/hydroxyl groups on their surface are immersed in (3-mercaptopropyl) methyldimethoxysilane (MPMDMS) to bond the silane molecules.

The specimen is then rinsed with deionized water, placed in fresh acetone, and agitated in an ultrasonic cleaner to remove residual contaminants; if left on the surface, the contaminants will darken the solution and affect the production of AuNPs. Once initial cleaning is completed, the specimen is transferred to amethanol bath and agitated in an ultrasonic cleaner for approximately 5 min. After the methanol cleaning is complete, the specimen is rinsed in deionized water, dried with compressed air, and stored in a sealed, container that is cleaned using acetone, then ethanol and finally deionized water. When ready to complete the process, the specimen is placed in boiling water for ~2 min to create a thick pseudo-boehmite layer and maximize the number of hydroxyl groups on the specimen surface in order to achieve dense AuNP surface coverage that is needed for local mapping throughout the region of interest. The specimens is then rinsed with deionized water and gently dried with compressed air. It is emphasized that the surface treatment described above should be performed immediately prior to patterning to ensure there is no degradation of the prepared surface. If patterning is immediately performed after air drying, all of our experiments show that this will result in a reproducible, hydrophilic surface for pattern application.

The specimens are silanized by soaking in vials filled with one part APTMS or MPMDMS to four parts methanol for 24 h as soon after hydroxylation as possible. In our studies, the entire specimen is immersed in the solution, but only those surfaces to be patterned have to be immersed. After soaking each specimen, the specimen is removed and immediately immersed in a beaker filled with 100 mL of methanol. The methanol is stirred with a magnetic stirrer such that it flows over the surface of the specimens for 30 min. The specimen is then transferred to a beaker of fresh methanol and rinsed for an additional 30 min. Following the methanol rinse, the specimens are rinsed with deionized water and placed in a vial that is subsequently filled with AuNPs of the desired diameter. As noted earlier, if darkening of the AuNP solution is observed when the specimen is placed in the solution, this is an indication of contamination that will induce AuNP aggregation or flocculation. In such case, the specimen should be immediately removed from the solution, thoroughly cleaned again using methanol and deionized water. Once this is done, the specimen can then be placed into a new vial to which the AuNP solution is added. The specimen should be soaked in the solution for a time that ranges between 24 h and 5 days, with larger particle sizes requiring less soaking time.

Rights and permissions

About this article

Cite this article

Guo, S.M., Sutton, M.A., Li, N. et al. Measurement of Local Thermal Deformations in Heterogeneous Microstructures via SEM Imaging with Digital Image Correlation. Exp Mech 57, 41–56 (2017). https://doi.org/10.1007/s11340-016-0206-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-016-0206-6