Abstract

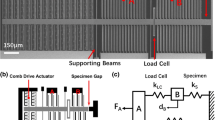

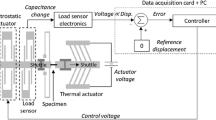

Microelectromechanical system (MEMS) devices based on electro-thermal actuation have been used over the past few years to perform tensile tests on nanomaterials. However, previous MEMS designs only allowed small (e.g., <100 nm) total displacement range without a significant increase in temperature near the nanospecimens (<20°C), thereby limiting the design of the load sensor or the range of nanomaterials to test. Here we characterize the thermo-mechanical behavior of three MEMS devices, using optical displacement measurements, micro-Raman temperature measurements, and finite element modeling. We observe the increase in temperature near the nanospecimen gap per displacement of thermal actuator to linearly decrease with the distance between nanospecimen gap and thermal actuator. We also present a MEMS device that can provide up to 1.6 μm of total displacement with less than 10°C increase in temperature near the nanospecimens, more than one order of magnitude improvement with respect to previously published MEMS material testing setups. This MEMS device can be used for accurate, temperature-controlled tensile testing of nanocrystalline metallic nanobeams.

Similar content being viewed by others

Notes

The beams were added to allow the resistance measurement of a nanospecimen during a test (via a 2 terminal setup).

Given the large area of the epoxy link, and the expected elastic modulus of several GPa, the stiffness of the epoxy should be 2 to 3 orders of magnitude larger than the stiffness of the load sensor or nanospecimen. Hence the epoxy links do not affect the overall mechanics of the MEMS device.

We have not observed any permanent deformation or slippage of the Pt clamps (see Fig. 9) during tensile tests of nanobeams with applied forces up to 0.3–0.4 mN.

References

Agrawal R, Peng B, Espinosa HD (2009) Experimental-computational investigation of ZnO nanowires strength and fracture. Nano Lett 9(12):4177–4183

Agrawal R, Peng B, Gdoutos EE, Espinosa HD (2008) Elasticity size effects in ZnO nanowires-A combined experimental-computational approach. Nano Lett 8(11):3668–3674

Peng B, Locascio M, Zapol P, Li SY, Mielke SL, Schatz GC, Espinosa HD (2008) Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements. Nat Nanotechnol 3(10):626–631

Richter G, Hillerich K, Gianola DS, Monig R, Kraft O, Volkert CA (2009) Ultrahigh Strength Single Crystalline Nanowhiskers Grown by Physical Vapor Deposition. Nano Lett 9(8):3048–3052

Desai AV, Haque MA Mechanical properties of ZnO nanowires. In, 2007. Elsevier Science Sa, pp 169–176.

Zhang DF, Breguet JM, Clavel R, Philippe L, Utke I, Michler J (2009) In situ tensile testing of individual Co nanowires inside a scanning electron microscope. Nanotechnology 20(36):365706

Zhang DF, Breguet JM, Clavel R, Sivakov V, Christiansen S, Michler J (2010) Electron microscopy mechanical testing of silicon nanowires using electrostatically actuated tensile stages. J Microelectromech Sys 19(3):663–674

Greer JR, Nix WD (2005) Size dependence of mechanical properties of gold at the sub-micron scale. Appl Phys a-Mater Sci Process 80(8):1625–1629

Greer JR, Nix WD (2006) Nanoscale gold pillars strengthened through dislocation starvation. Physical Review B 73(24)

Greer JR, Oliver WC, Nix WD (2005) Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Materialia 53(6):1821–1830

Kim J-Y, Greer JR (2009) Tensile and compressive behavior of gold and molybdenum single crystals at the nano-scale. Acta Materialia 57(17):5245–5253

Kim J-Y, Jang D, Greer JR (2009) Insight into the deformation behavior of niobium single crystals under uniaxial compression and tension at the nanoscale. Scr Mater 61(3):300–303

Philippe L, Wang Z, Peyrot I, Hassel AW, Michler J (2009) Nanomechanics of rhenium wires: elastic modulus, yield strength and strain hardening. Acta Materialia 57(14):4032–4035

Brown JJ, Suk JW, Singh G, Baca AI, Dikin DA, Ruoff RS, Bright VM (2009) Microsystem for nanofiber electromechanical measurements. Sens Actuator A-Phys 155(1):1–7

Wu B, Heidelberg A, Boland JJ (2005) Mechanical properties of ultrahigh-strength gold nanowires. Nat Mater 4(7):525–529

Shan ZW, Mishra RK, Asif SAS, Warren OL, Minor AM (2008) Mechanical annealing and source-limited deformation in submicrometre-diameter Ni crystals. Nat Mater 7(2):115–119

Haque MA, Saif MTA (2004) Deformation mechanisms in free-standing nanoscale thin films: a quantitative in situ transmission electron microscope study. Proc Natl Acad Sci United States America 101(17):6335–6340

Lu SN, Guo ZY, Ding WQ, Dikin DA, Lee J, Ruoff RS (2006) In situ mechanical testing of templated carbon nanotubes. Rev Sci Instrum 77(12):125101

Ostlund F, Rzepiejewska-Malyska K, Leifer K, Hale LM, Tang YY, Ballarini R, Gerberich WW, Michler J (2009) Brittle-to-ductile transition in uniaxial compression of silicon pillars at room temperature. Adv Funct Mater 19(15):2439–2444

Espinosa HD, Zhu Y, Moldovan N (2007) Design and operation of a MEMS-based material testing system for nanomechanical characterization. J Microelectromech Sys 16(5):1219–1231

Zhu Y, Corigliano A, Espinosa HD (2006) A thermal actuator for nanoscale in situ microscopy testing: design and characterization. J Micromech Microeng 16(2):242

Zhu Y, Espinosa HD (2005) An electromechanical material testing system for in situ electron microscopy and applications. Proc Natl Acad Sci United States America 102(41):14503–14508

Zhu Y, Moldovan N, Espinosa HD (2005) A microelectromechanical load sensor for in situ electron and X-ray microscopy tensile testing of nanostructures. Appl Phys Let 86(1):013506–013501

Ganesan Y, Lu Y, Peng C, Lu H, Ballarini R, Lou J (2010) Development and application of a novel microfabricated device for the in situ tensile testing of 1-D nanomaterials. J Microelectromech Sys 19(3):675–682

Lu Y, Ganesan Y, Lou J (2010) A multi-step method for in situ mechanical characterization of 1-D nanostructures using a novel micromechanical device. Exper Mech 50(1):47–54

Zhang DF, Drissen W, Breguet JM, Clavel R, Michler J (2009) A high-sensitivity and quasi-linear capacitive sensor for nanomechanical testing applications. J Micromech Microeng 19:075003

Lu SB, Guo ZY, Ding WQ, Ruoff RS (2006) Analysis of a microelectromechanical system testing stage for tensile loading of nanostructures. Rev Sci Instrum 77(5):056103

Lu SN, Dikin DA, Zhang SL, Fisher FT, Lee J, Ruoff RS (2004) Realization of nanoscale resolution with a micromachined thermally actuated testing stage. Rev Sci Instrum 75(6):2154–2162. doi:10.1063/1.1710703

Haque MA, Espinosa HD, Lee HJ (2010) MEMS for in situ testing-handling, actuation, loading, and displacement measurements. MRS Bull 35(5):375–381

Zhu T, Li J, Samanta A, Leach A, Gall K (2008) Temperature and strain-rate dependence of surface dislocation nucleation. Phys Rev Lett 100:025502

http://www.memscap.com/en_mumps.html (2010). www.memscap.com/memsrus/crmumps.html.

Pant B, Allen BL, Zhu T, Gall K, Pierron ON (2011) A versatile microelectromechanical system for nanomechanical testing. Appl Phys Let 98(5):053506

Beechem T, Graham S, Kearney SP, Phinney LM, Serrano JR (2007) Invited article: simultaneous mapping of temperature and stress in microdevices using micro-Raman spectroscopy. Rev Sci Instrum 78(6)

Huang QA, Lees NKS (1999) Analysis and design of polysilicon thermal flexure actuator. J Micromech Microeng 9(1):64–70

Mankame ND, Ananthasuresh GK (2001) Comprehensive thermal modelling and characterization of an electro-thermal-compliant microactuator. J Micromech Microeng 11(5):452–462

Brantley WA (1973) Calculated elastic constants for stress problems associated with semiconductors devices. J Appl Phys 44(1):534–535

Acknowledgments

The authors acknowledge the NSF Grant Nos. CMMI-0758554 (BP, KG, and OP), CMMI-0825435 (BA, KG, and OP), and DMR-0952641 (EB and OP).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pant, B., Choi, S., Baumert, E.K. et al. MEMS-Based Nanomechanics: Influence of MEMS Design on Test Temperature. Exp Mech 52, 607–617 (2012). https://doi.org/10.1007/s11340-011-9526-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-011-9526-8