Abstract

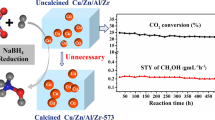

Cu/ZnO catalyst precursors for industrial methanol synthesis catalysts are traditionally synthesised by coprecipitation. In this study, a new precipitation route has been investigated based on anti-solvent precipitation using a switchable solvent system of triethylamine and water. This system forms a biphasic system under a nitrogen atmosphere and can be switched to an ionic liquid single phase under a carbon dioxide atmosphere. When metal nitrate solutions were precipitated from water using triethylamine–water as the anti-solvent a hydroxynitrate phase, gerhardite, was formed, rather than the hydroxycarbonate, malachite, formed by coprecipitation. When calcined and reduced, the gerhardite precursors formed Cu/ZnO catalysts which showed better productivity for methanol synthesis from CO2 hydrogenation than a traditional malachite precursor, despite their larger CuO crystallite size determined by X-ray diffraction. The solvents could be recovered by switching to the biphasic system after precipitation, to allow solvent recycling in the process, reducing waste associated with the catalyst synthesis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Copper–zinc oxide (Cu/ZnO) catalysts are widely used by industry for various reactions, most notably for methanol synthesis and low temperature water–gas shift reaction [1,2,3,4]. Despite having been used as the industrial standard catalyst for methanol synthesis since the 1960s [5], Cu/ZnO are still widely studied in academia and industry, with the focus on improvement in the performance of copper zinc catalysts through the preparation methods [3, 6]. The methanol synthesis reaction has had a resurgence of interest recently as a utilisation option for captured CO2 [7]. To reduce carbon based emissions in the atmosphere, this CO2 source can be used as a feedstock for different reactions, with methanol synthesis proposed as a possible route for CO2 utilisation and also as a vector for renewable hydrogen storage through this reaction. This has led to increased research into CO2 hydrogenation, rather than the more traditional syngas feedstocks, which could have a positive impact on climate change targets, particularly if renewable sources of H2 can be used in the reaction. Although alternative catalysts have been investigated for this reaction, Cu/ZnO is still one of the most promising catalysts for CO2 hydrogenation to methanol.

The most common method of preparing Cu/ZnO or Cu/ZnO/Al2O3 methanol synthesis and water–gas shift catalysts is coprecipitation [8]. The catalysts are usually precipitated form a nitrate solution using sodium carbonate and are precipitated as hydroxyl carbonate, most commonly as a zincian malachite or phases such as rosasite and aurichalcite [8, 9]. These hydroxyl carbonate precursors are then calcined to form CuO/ZnO and are reduced in situ to the active Cu/ZnO catalyst. Although the calcination and reduction steps are important, previous research has demonstrated that the precipitation and aging steps in the precursor synthesis are crucial in controlling the phases present and in the final performance of the catalysts.

Recently, it was demonstrated that a copper–zinc carbonate precursor, georgeite, could be prepared through supercritical anti-solvent precipitation8. Georgeite is naturally unstable and difficult to synthesise using conventional methods, ageing to zincian malachite during coprecipitation [10]. Copper–zinc oxide catalysts derived from supercritical anti-solvent precipitated georgeite were found to have highly dispersed Cu and a higher Cu surface area. This resulted in Cu/ZnO that were highly active for methanol synthesis from syngas [9, 11]. The supercritical anti-solvent process also avoided the use of sodium carbonate as a precipitating agent, thereby eliminating poisoning by sodium [3]. These publications by Spencer and co-workers on georgeite prepared by supercritical anti-solvent precipitation, demonstrates how alternative techniques can be used to make catalyst precursors that are, not only difficult to prepare, but also enhances the catalytic properties of the metal oxide catalyst compared to those derived from conventional methods.

However, the supercritical anti-solvent process is energy intensive, with CO2 cycled between 100 and 150 bar during the precipitation process and atmospheric pressure during the solvent and anti-solvent recovery. As such, the scale up to industrial level has not been applied for catalyst preparation, even if the resulting catalyst is more active than the conventional coprecipitated catalysts [12]. As a result, coprecipitation remains the most common industrial method for the preparation of Cu/ZnO catalysts [3, 13]. In this study we have investigated low pressure precipitation methods using a switchable solvent system as an alternative to the high pressure supercritical CO2 process.

Switchable solvents are a classification of ionic liquids whose properties can be changed by external stimuli [14, 15]. Early work on switchable solvents focused around DBU (1,8 diazobicyclo[5.4.0]-undec-7-ene) which forms a polar ionic liquid when combined with an alcohol under a carbon dioxide atmosphere [16].

When heated to 60 °C under nitrogen the carbon dioxide is removed and the ionic liquid reverts back to the alcohol and DBU, hence it can be changed back to its original non-polar state under a nitrogen or argon atmosphere. Subsequently other switchable polar solvent combinations have been discovered and the ability to switch between non-polar and polar characteristics has been used as a potential way of reducing the steps and solvents required for synthesis steps, thereby reducing waste [17, 18] Although widely used, DBU-alcohol and similar systems are very water sensitive with > 42 ppm of atmospheric water in the system resulting in the solid DBU carbonate. Consequently, many of the identified switchable solvents only work under ultra-dry conditions [19, 20]. The water sensitivity of these systems [21] makes them difficult to work with for the preparation of metal oxide precursors, especially if the initial metal salt contains water.

There are a wide variety of switchable systems that have been applied, using switchable hydrophilicity [18, 21], switchable surfactants [22] and switchable water [23]; where the additive increases its ionic strength under different atmospheres and can be used to precipitate out compounds. The switching of the solvent properties is relatively slow using low pressure gases, although in theory this could be used as a way of precipitating a dissolved component from solution.

In this study we have used a switchable hydrophilic–hydrophobic solvent system that has been previously applied for a range of applications including metal extraction [24] and recycling homogeneous catalysts [25]. This solvent system contains a mixture of triethylamine (TEA) and water that can be switched using low pressure (1 bar) N2 or CO2 as shown in Fig. 1. TEA was chosen due to the relatively broad switching range, commercial availability and cost, coupled with the compatibility with water.

The solvent switching allows the easy separation of the solvents after the reaction to enable reuse and recycling of the individual components. A material in aqueous solution can be precipitated using a switchable anti-solvent and then the water and anti-solvent can be recovered by adjusting the polarity of the switchable solvent.

The aim of this research was to develop the methodology for using the TEA–water system in green catalyst synthesis, using Cu/ZnO catalysts for the direct hydrogenation of CO2 as an exemplar process.

2 Experimental

2.1 Switchable Solvent System

Triethylamine and water (1:1 molar ratio) were added to a round bottom flask equipped with a gas adapter (Radleys). The flask was then filled with N2 (1 bar) for 30 min, while being degassed twice to remove trace amounts of CO2. This gave a biphasic system of water and TEA.

The solvent was switched by bubbling CO2 (1 bar) through the solution for around 30 min until a single-phase solvent had formed. The rate of switching could be increased using a stainless steel frit to reduce the size of the bubbles passing through the solvent.

This reaction was reversible, reverting to a biphasic system when exposed to a N2 atmosphere for around 30 min.

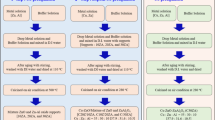

2.2 Copper/Zinc Oxide Synthesis Using Triethylamine–Water

Copper(II) nitrate hemi(pentahydrate) and zinc(II) nitrate hexahydrate were used to prepare solutions for the precipitation experiments. Different Cu:Zn ratios were used, with a total metal content of 50 mmol in 25 ml of water. The metal nitrate solution was then injected into the TEA–water (50 ml) under a carbon dioxide atmosphere and left for 1 h after the addition of the metal salt. The precipitated sample was then filtered under vacuum, washed and then dried in the oven overnight. The resultant materials were then calcined in a furnace under flowing air with a heating rate of 2 °C min−1 for 3 h.

2.3 Copper/Zinc Oxide Synthesis Using Coprecipitation

Copper(II) nitrate hemi(pentahydrate) (20.35 g, 350 mmol) and zinc(II) nitrate hexahydrate (11.16 g, 150 mmol) were dissolved in 250 ml of deionised water to create a mixed metal solution with a total molar concentration of 0.25 M. The coprecipitation was carried out using a Metrohm Titrando auto-titrator. 20 ml of the mixed metal nitrate solution was added to the reaction vessel under continuous stirring. The pH was adjusted to 6.5 by the addition of 1.5 M aqueous solution of Na2CO3. Subsequently, the mixed metal solution was added to the vessel at a rate of 5 ml min−1 with continuous stirring. The base solution was added at a sufficient rate to ensure that the reaction mixture maintained a constant pH of 6.5. Once all of the mixed metal solution was added, the pH was monitored and controlled for a further 10 min to ensure complete precipitation of the material. The precipitate was then allowed to age in solution at 65 °C for 3 h. The precipitate was filtered under suction and washed with hot water before being dried and calcined at 350 °C for 3 h under flowing air with a heating rate of 10 °C min−1.

2.4 Characterisation Methods

Powder X-ray diffraction (XRD) patterns were obtained using a PANalytical X’Pert Pro diffractometer equipped with a Cu Kα source with a voltage setting of 40 kV and current setting of 40 mA. The scans were taken at a scan rate of 2° min−1. PANalytical Highscore software was used to analyse the diffraction data and identify the phases present using the International Centre for Diffraction Data (ICDD) database.

Infra red spectra were recorded on a Bruker Vertex 70 spectrometer equipped with an ATR cell and a deuterated triglycine sulphate (DTGS) detector. A background of 16 scans was recorded prior to the sample scan. The sample was then placed on the ATR cell and pressed onto the crystal and exposed to the IR beam for 32 scans with an aperture setting of 6 cm−1.

Surface area analysis of the samples were performed by 5-point nitrogen adsorption at − 196 °C using a Micromeritics Gemini 2360 instrument. 100 mg of sample was degassed under nitrogen on a Flow-Prep 060 at 110 °C for 1 h for metal oxides and 60 °C for 16 h for precursor materials. The lower temperature for the metal precursors was to ensure that these materials did not degrade prematurely during the degassing stage.

Thermogravimetric analysis (TGA) was performed using a Perkin Elmer TGA 4000 instrument equipped with an auto sampler. The crucibles were weighed in the instrument prior to the addition of the sample (5–10 mg). Samples were held for 2 min at 30 °C to allow stabilisation before heating from 30 to 900 °C at a ramp rate of 5 °C min−1 under flowing air at 30 ml min−1.

Scanning electron microscopy (SEM) analysis was carried out using a Tescan Mira3 microscope with the electrons being generated by a tungsten tip, field emission gun. Imaging was carried out using an in-beam secondary electron detector and an electron beam with an accelerating voltage of 5–15 kV (depending on the sample). Samples were suspended on a carbon film and were coated with a 10 nm AuPd coating to reduce charging affects that occur due to electrostatic build up from the beam which can interfere with the imaging.

Energy dispersive X-ray (EDX) analysis was performed with using an Oxford Instruments X-MaxN 80 solid state detector and analysed using Oxford Instruments AZtec software.

2.5 Catalyst Testing

Methanol synthesis was performed on a fixed bed reactor. 0.1 g of the CuO/ZnO material was placed in a stainless-steel reactor tube, suspended by quartz wool, and reduced to form Cu/ZnO in situ under 5% H2/He (25 ml min−1) at 225 °C prior to testing.

After reduction, the reactor was then cooled down to room temperature and the gas flow was switched to a (20:60:20) CO2:H2:N2gas mixture and the pressure set to 20 bar using a back pressure regulator. The reactor was then heated to 200 °C, 225 °C and 250 °C. The reactor was held at each temperature interval for 200 min. Products were analysed on an Agilent 7890B gas chromatograph equipped with an FID and TCD with a gas sampling run time of 25 min.

3 Results and Discussion

The precipitation of Cu/ZnO catalysts was investigated as model system to investigate the feasibility of using switchable solvents to synthesise active mixed oxide catalysts. Initial experiments were carried out to determine whether the technique could be used to precipitate single metal oxide precursors with addition of the both copper and zinc nitrate solutions to the TEA–water instantly forming a precipitate. The X-ray diffraction pattern of the material precipitated from the copper nitrate solution (Fig. 2) indicates the formation of malachite [Cu(CO3)(OH)2] with the major reflections at 15.3°, 18.0° 24.5°, 31.7° and 36.1°. The XRD of the calcined material shows only the reflections of copper oxide with no other crystalline phase observed (Fig. 2).

This assignment is supported by the FTIR spectrum (Fig. 3) that confirms the presence of malachite with bands at 1625 cm−1,1475 cm−1, 1326 cm−1, 1315 cm−1, 816 cm−1 and 748 cm−1 associated with the carbonate features and bands at 1097 cm−1, 1038 cm−1 and 872 cm−1 associated with the OH stretching [26]. This is a promising result as zincian malachite is the industrial precursor to the most active Cu/ZnO catalysts. The material precipitated from the zinc nitrate solution was found to be zinc oxide by XRD (Fig. 2). This is likely to be due to the decomposition of a precipitated zinc carbonate based material during the drying step, which has been shown to occur at relatively low temperatures (< 150 °C) [27].

The precipitation mechanism for the single metal salts seems to be similar to the coprecipitation process, using the ionic liquid, triethyl ammonium hydrogen carbonate (Fig. 1) as the base. One advantage of using the switchable solvent system to precipitate the Cu/ZnO precursors is that it avoids the use of sodium based reagents (for example sodium carbonate or sodium hydroxide) which are commonly used in coprecipitation. Sodium is a known poison for the copper–zinc oxide methanol synthesis catalyst as it increases sintering and copper particle size during calcination [3], so the use of a system that avoids sodium is advantageous.

Following the precipitation of the individual components the methodology was investigated for precipitating solutions containing a mixture of copper and zinc nitrate. This was investigated with two different Cu:Zn ratios, an equimolar (1:1) solution and a molar ratio of 7:3, which is similar to the industrial catalysts for methanol synthesis. These were compared with a standard material synthesised by coprecipitation of copper and zinc nitrates with sodium carbonate (Cu:Zn = 7:3).

When the mixed solutions were precipitated using the TEA–water system there was a change in the phases produced, with XRD patterns that could be indexed to gerhardite, Cu2(OH)3NO3, with very small malachite reflections detected for some materials (Fig. 4). This suggests that using the mixed metal nitrate solution the precipitation mechanism has changed to an anti-solvent type process, with the TEA system reducing the nitrate solubility in water causing precipitation. This may be due to the methodology used with the nitrate solution being injected into the TEA. When the solutions are mixed, diffusion of the metal nitrate solution into an excess of TEA, or reaction of the water with CO2 and TEA to form a single phase, reduces the solvent power of the water, resulting in the precipitation of the nitrates. Previous studies showed that gerhardite could be produced by coprecipitation if the rate of addition of the reagents was fast but transformed into malachite on aging or with slower reagent addition [13]. The FTIR of the material precipitated from the mixed copper and zinc nitrates shows many of the features associated with malachite, although slightly shifted due to the inclusion of zinc [28], suggesting this is also a component of the precipitated material (Fig. 3).

Thermogravimetric analysis of the copper–zinc precursor (Fig. 5) showed three mass losses; a minor loss at 160 °C followed by a large mass loss at 220 °C and a minor mass loss at 400–450 °C.

Previous thermogravimetric studies on gerhardite have shown that it decomposes to the oxide at a lower temperature than malachite, so it is likely that following the removal of water at low temperature there is a large mass loss associated with the decomposition of the hydroxy nitrate, followed by a smaller mass loss associated with the hydroxy carbonate that is a minor component of the precipitated material.

The precursors were calcined at different temperatures (250 °C or 350 °C) to form the CuO/ZnO that could be reduced in situ to the final Cu/ZnO catalysts.

The XRD pattern of the samples (Fig. 6) after calcination showed the reflections for both copper oxide and zinc oxide. All of the precursors had very similar patterns, despite the different Cu:Zn ratios and calcination temperatures used in the synthesis although the reflections appeared much narrower compared to the precursor prepared by coprecipitation (Cu:Zn = 7:3, calcined at 350 °C). The ZnO phase could be assigned to hexagonal zincite with diffraction peaks at 2θ = 31.9°, 34.5° and 36.5° assigned to the (100), (002) and (101) planes respectively. These are close to the main CuO reflections corresponding to the (110), (002) and (111) planes at 2θ = 32.5°, 35.6° and 38.9° respectively, that are only visible as shoulders in the broad, asymmetrical reflections for the coprecipitated derived material. This suggests that the materials precipitated using the TEA–water process are more crystalline with a larger particle size. As methanol synthesis activity is commonly linked to copper particle size, which in turn is dependent on the CuO particle size before reduction, it could be expected that the coprecipitated catalyst would me more active. Particle sizes were determined for the catalysts precipitated using the switchable solvent (Table 1), although this could not be determined for the ZnO crystals in the coprecipitated material due to the overlap of the broad CuO and ZnO reflections.

XRD patterns of the calcined copper–zinc oxides: (a) coprecipitated, Cu:Zn = 7:3, calcined at 350 °C, (b) precipitated from TEA–water, Cu:Zn = 1:1, calcined at 250 °C, (c) precipitated from TEA–water, Cu:Zn = 1:1, calcined at 350 °C, and (d) precipitated from TEA–water, Cu:Zn = 7:3, calcined at 350 °C

Representative SEM images of the Cu:Zn 1:1 precipitated and calcined material is shown in Fig. 7. The precursor appeared to comprise of irregular platelets, which transformed into small rounded crystallites when calcined.

EDX mapping (Fig. 7) of the material calcined 350 °C showed that the copper and zinc were evenly distributed with no sign of isolated zinc or copper clusters. EDX determined that the target ratio of 1:1 had been achieved, although the sample was not completely homogeneous and the ratio varied between 1.16:1 and 0.92:1 when different areas were analysed.

3.1 Catalyst Testing

The equilibrium yield of methanol is greatly reduced when CO2 is used as the feed compared with the traditional syngas route [7, 29]. This necessitates the need to run the reaction at low temperature with recycling of the feedstock and hence, active catalysts are needed for the reaction. A second disadvantage of using CO2 as the feedstock is that water is formed as a byproduct, which can poison the surface of the catalyst causing deactivation. Copper is also a good water–gas shift (WGS) catalyst and in CO hydrogenation the WGS reaction can help to reduce the amount of water adsorbed on the catalyst. However, when CO2 is used as the feed the reverse WGS reaction is favoured which can produce more water, reducing the hydrogen available for the hydrogenation reaction, producing CO as a byproduct and further decreasing the yield of methanol.

The methanol synthesis activity was determined for the synthesised materials at 20 bar over a temperature range of 200–250 °C. Prior to testing, the CuO/ZnO materials were reduced in situ in 5% H2 in He to form the Cu/ZnO catalysts. The Cu/ZnO precipitated from switchable solvents were shown to be active for methanol synthesis from CO2 and H2 (Table 2). The only products observed were methanol and CO for all catalysts.

It is interesting to note that, despite the smaller CuO particle sizes observed in the coprecipitated materials, the Cu/ZnO catalysts derived from the switchable solvent route had activities that were very similar to the coprecipitated material. The coprecipitated catalyst, that had smaller CuO particle size and a higher BET surface area, had a higher activity than the switchable solvent derived catalysts. However, the catalysts precipitated from the TEA–water system had a higher selectivity which could be beneficial in reactors where reactant recycling is used to increase yields of methanol.

It should be noted that the Cu/ZnO catalysts synthesised in this study did not contain alumina which is added as a structural promotor to the industrial catalyst. However, despite this the catalysts did not show any deactivation over the relatively short testing regime where catalysts were held at each temperature for 200 min, giving an overall time-on-line of around 10 h.

4 Conclusions

Although catalytic reactions are generally thought of as green chemistry, catalyst synthesis can often produce water streams that are difficult or expensive to treat. For the last few years, we have been investigating anti-solvent processes for the synthesis of metal oxide catalysts, supports and precursors with the potential for solvent recycling to minimise waste. Recently, we have explored different ionic liquid based systems in anti-solvent processes, where low vapour pressures and tuneable properties, could be used to reduce the environmental impact of catalysts synthesis methods.

In this study we have shown that CuO/ZnO materials can be synthesised with promising activity for CO2 hydrogenation to methanol using a switchable solvent system with TEA–water that could be switched between a biphasic system and a single phase ionic liquid which could be used to aid solvent recycling in the process. This proof of concept demonstrates that the methodology could be used to synthesise a range of different metal oxide materials with improved performance.

There is considerable room for improvement in understanding the process parameters in this synthetic methodology and further investigations should enable catalysts with smaller particle sizes and larger surface areas to be produced in the future. However, even as a non-optimised synthetic route, catalysts that give promising yields of methanol with good selectivity have been produced. The methanol synthesis yield was found to be higher when compared with a standard coprecipitated material with a smaller copper particle size, suggesting the new methodology has produced a material with more active sites. This is likely to be due to the absence of sodium containing reagents in the anti-solvent process, which has been shown to poison copper–zinc oxide catalysts prepared by coprecipitation.

Data Availability

The catalyst testing and characterisation datasets generated during the current study are available free of charge through the Cardiff University Research Portal https://doi.org/10.17035/d.2021.0133683358.

References

Smith PJ, Kondrat SA, Carter JH, Chater PA, Bartley JK, Taylor SH, Spencer MS, Hutchings GJ (2017) ChemCatChem 9:1621–1631

Kowalik P, Antoniak-Jurak K, Prochniak W, Wiercioch P, Konkol M, Bicki R, Michalska K, Walczak M (2017) Catal Lett 147:1422–1433

Kondrat SA, Smith PJ, Carter JH, Hayward JS, Pudge GJ, Shaw G, Spencer MS, Bartley JK, Taylor SH, Hutchings GJ (2017) Faraday Discuss 197:287–307

Dang SS, Yang HY, Gao P, Wang H, Li XP, Wei W, Sun YH (2019) Catal Today 330:61–75

Gines MJL, Amadeo N, Laborde M, Apesteguia CR (1995) Appl Catal A 131:283–296

Behrens M (2014) Angew Chem Int Ed 53:12022–12024

Bowker M (2019) ChemCatChem 11:4238–4246

Prieto G, de Jong KP, de Jongh PE (2013) Catal Today 215:142–151

Kondrat SA, Smith PJ, Wells PP, Chater PA, Carter JH, Morgan DJ, Fiordaliso EM, Wagner JB, Davies TE, Lu L, Bartley JK, Taylor SH, Spencer MS, Kiely CJ, Kelly GJ, Park CW, Rosseinsky MJ, Hutchings GJ (2016) Nature 531:83–87

Spencer MS (2000) Catal Lett 66:255–257

Kondrat SA, Smith PJ, Lu L, Bartley JK, Taylor SH, Spencer MS, Kelly GJ, Park CW, Kiely CJ, Hutchings GJ (2018) Catal Today 317:12–20

Kowalik P, Antoniak-Jurak K, Bicki R, Prochniak Wiercioch WP, Michalska K (2000) Int J Hydrog Energy 44:913–922

Behrens M, Brennecke D, Girgsdies F, Kissner S, Trunschke A, Nasrudin N, Zakaria S, Idris NF, Abd Hamid SB, Kniep B, Fischer R, Busser W, Muhler M, Schlogl R (2011) Appl Catal A 392:93–102

Jessop PG, Heldebrant DJ, Li XW, Lu J, Hallett JP, Jones RS, Pollet P, Thomas CA, Eckert CA, Liotta CL (2011) Abstr Pap Am Chem Soc 229:U971

Jessop PG, Heldebrant DJ, Li XW, Eckert CA, Liotta CL (2005) Nature 436:1102

Heldebrant DJ, Jessop PG, Thomas CA, Eckert CA, Liotta CL (2005) J Org Chem 70:5335–5338

Yamada T, Lukac PJ, George M, Weiss RG (2007) Chem Mater 19:967–969

Vanderveen JR, Durelle J, Jessop PG (2014) Green Chem 16:1187–1197

Jessop PG, Mercer SM, Heldebrant DJ (2012) Energy Environ Sci 5:7240–7253

Phan L, Andreatta JR, Horvey LK, Edie CF, Luco AL, Mirchandani A, Darensbourg DJ, Jessop PG (2008) J Org Chem 73:127–132

Yang ZQ, He CQ, Sui H, He L, Li XG (2019) J CO2 Util 30:79–99

Bryant K, Ibrahim G, Saunders SR (2017) Langmuir 33:12982–12988

Jessop PG (2015) Aldrichimica Acta 48:18–21

Yilmaz E, Soylak M (2011) Anal Chim Acta 2015(886):75–78

Mercer SM, Robert T, Dixon DV, Jessop PG (2011) Catal Sci Technol 2:1315–1318

Baltes C, Vukojevic S, Schuth F (2008) J Catal 258:334–344

Kanari N, Mishra D, Gaballah I, Dupré B (2004) Thermochim Acta 410:93–100

Behrens M, Girgsdies F, Trunschke A, Schlögl R (2009) Eur J Inorg Chem 2009:1347–1357

Behrens M (2015) Recycl Catal 2:78–86

Acknowledgements

UK Catalysis Hub is kindly thanked for resources and support provided via our membership of the UK Catalysis Hub Consortium and funded by EPSRC Grant EP/K014854/1.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Mike Spencer

I first came across Mike when I took over lecturing first year thermodynamics from him in the School of Chemistry, Cardiff University and was grateful to be given his very detailed notes to use as the basis for my lectures. Mike was always generous with his time and keen to pass on his knowledge, to both undergraduates and research students—something I discovered when we subsequently worked together on copper–zinc oxide (Cu/ZnO) catalysts, one of his specialist subjects. Mike would often bring along long forgotten papers or patents to meetings to help explain results and had an encyclopaedic knowledge of the field. As well as his scientific knowledge, I was also taken with Mike’s sense of style as he stepped out of his sports car dressed in a polo necked jumper. I am not sure if I was subconsciously influenced by him when I got an Alfa Romeo, although rather than his sporty Spider I had to settle for a more practical estate car which was not quite as impressive. Here we present the next stage of our studies into Cu/ZnO catalysts, following on from the work carried out with Mike.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wallace, W.T., Hayward, J.S., Ho, CY. et al. Triethylamine–Water as a Switchable Solvent for the Synthesis of Cu/ZnO Catalysts for Carbon Dioxide Hydrogenation to Methanol. Top Catal 64, 984–991 (2021). https://doi.org/10.1007/s11244-021-01457-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-021-01457-6