Abstract

Soil erosion is a complex natural process that occurs by either individual or combined actions of wind, hydraulic currents, waves, and rain. This study comprehensively reviews biocementation-based soil stabilisation techniques for developing erosion-resilient landforms through an ecologically conscious strategy. The different pathways for biocementation occurring in nature are discussed with a focused view on the microbially induced carbonate precipitation (MICP) technique. MICP relies on biogenic calcium carbonate (CaCO3) precipitation via the urea hydrolysis route to bind the soil grains. The kinetics and factors affecting MICP are succinctly discussed to highlight the practical challenges associated with biocementation. This study emphasises the influence of MICP on erosion resistance (aeolian and hydraulic) and geotechnical properties of soils. The critical assessment of the previous studies revealed that aeolian and hydraulic erosion can be effectively controlled with a small to moderate quantity of biogenic CaCO3 (2% to 10% of soil weight). MICP marginally influences the hydraulic conductivity of soils with a substantial improvement in compressive strength, making it desirous over traditional soil cementation agents for erosion control due to the limited intervention to natural groundwater flow. However, the scientific design and findings of the previous laboratory-scale and pilot-scale research are still inconsistent for standardising biocementation techniques to transition towards upscaling. This study presents critical insights to the researchers of the environmental, geotechnical and geoenvironmental engineering domains to design their upcoming studies to tackle the challenges required for upscaling biocementation technology.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Preserving our terrestrial ecosystem against degradation and desertification is identified as one of the most challenging sustainable development goals (SDG15) by the United Nations (Economic and Social Council; United Nations 2022). Soil is one of the most vital resources for life in conjunction with air and water (García-Ruiz et al. 2015). A drastic soil loss of greater than 24 billion tonnes per year is reported around the globe (United Nations 2019). Aeolian, coastal and riverbank erosion are caused by natural and anthropogenic processes.

The majority of the deserts around the globe are vulnerable to aeolian erosion (D’Odorico et al. 2013). Around 12% of the dryland is found vulnerable to degradation, accounting for an area of around 5 million square kilometres (Burrell et al. 2020). The desert soil consists chiefly of dry and cohesionless loose sand and silts, which are subjected to surface erosion due to high-velocity winds. The aeolian processes are also liable to the formation of some of the majestic aeolian landforms such as crescent sand dunes and pinnacle Karst. In Fig. 1a, the pinnacle karst of Nambung National Park, Western Australia, is shown. The pinnacles have formed in the limestones due to cyclic aeolian erosion processes (Lipar and Webb 2015). However, the dust and sand particles released into the air due to the aeolian erosion adversely impact human health and essential infrastructural services such as transportation, telecommunication, and electricity.

On the other hand, around 40% of the global population is impacted by coastal erosion, and Mentaschi et al. (2017) recorded an overall surface loss of 28,000 square kilometres over a period of 32 years (1984–2015). The coasts are enduring severe erosion, leading to loss of land and infrastructure. One such coastal bank is situated near Eagle Bay, Rottnest Island, Australia. The photo of the beach is shown in Fig. 1b. The marks of erosion induced by the sea waves can be observed clearly in the photograph. Riverbank erosion also contributes significantly to global land degradation. The majority of the banks along the mega rivers lose substantial land due to erosion (Latrubesse 2008). One such mega river is the Brahmaputra, which has caused a land loss of around 2400 square kilometres in the Assam valley in eight decades (1912 to 1996) in India (Sarma 2005). The mega rivers around the world contribute significantly to land loss (Das et al. 2014).

Aeolian, riverbank, or coastal erosion initiates with the detachment of soil particles from the surface. Figure 2 demonstrates the micro-mechanics of surficial erosion initiation. The detached particles are entrained and transported by wind or water. Typically, the constitutive relationship between erosion rate (Ź) and shear stress (τ) is represented as illustrated in Eq. (1). Erosion at the soil surface initiates when the erosive stress (τ) applied on the soil–water or soil-air interface by flowing water or wind exceeds the critical stress, as illustrated in Eq. (2). Critical stress (τc) is the threshold stress that the granular material can withhold in its innate state. The critical stress of soil grains majorly depends on the interparticle electrical forces (fe), interparticle contact forces (fc), pore water pressure (-uw), and weight of the particles (Briaud 2008). Therefore, soil erosion can be controlled either by minimising the erosive stress or improving the critical stress of the soil particles.

The surficial detachment of soil grains can progress to different erosion modes depending upon the type of soil and angle of slope (bank or flat land) of the different terrestrial landforms (deserts, riverbanks, coasts and farmlands) against the erosive forces induced by rainfall, wind, river currents, coastal waves, or groundwater motion. The flatlands are expected to undergo scour (localised erosion), surficial erosion, internal erosion or piping and sinkhole formation. On the other hand, soil slopes, such as riverbanks and seashores near water bodies, can also undergo sudden collapse due to mass/slab failure caused by shear and tension apart from scour and surficial erosion (Nardi et al. 2012). The wet-dry cycle near water bodies leads to loss of matrix suction, resulting in erosion and collapse (Nardi et al. 2012). The different modes of soil erosion are illustrated in Fig. 3.

Consequently, erosion control measures can be classified broadly into two categories, including- 1. Deviating/attenuating the erosive stresses with rigid structures; or 2. Improving the soil erosion resistance by chemical binders/mechanical compaction. The existing erosion control engineering practices, including mechanical compaction, cement-based rigid structures, chemical-based synthetic binders and soil replenishment techniques, are barely viable in terms of their environmental impact and cost-effectiveness.

The attenuation of erosive forces such as wind, river currents and hydraulic waves is accomplished by means of cement-based rigid structures. These countermeasures are costly and counterproductive as they lead to sediment imbalance and harm the ecology (Florsheim et al. 2008; D’Odorico et al. 2013). The cement industry contributes more than 7% to global anthropogenic CO2 emissions, which are increasing rapidly (Ali et al. 2011). Around 0.92 tonnes of CO2 is emitted into the environment for each tonne of clinker produced in the cement-making process (Habert et al. 2010). With the target of controlling global warming, the United Nations has proposed a "net zero" carbon footprint by 2050 (Intergovernmental Panel on Climate Changes; United Nations 2018). Therefore, an alternative erosion mitigation strategy with an ecologically conscious approach is urgently required.

The other method to improve soil resilience includes chemical and cementitious binders that improve the critical stress of the sediments. However, it is to be noted that artificial grout materials, including lime, micro-fine cement, silicates, and epoxy, have been reported to be toxic to the geo-environment (Karol 2003; DeJong et al. 2010) and, hence, they can adversely impact the flora, fauna, and crop productivity of the soil. River embankments (artificial banks to prevent flooding-induced erosion) made with alternative materials such as slag to improve their strength and resilience against erosion can impart irretrievable damage to river ecology due to their hyperalkalinity (Dubey et al. 2022d). Therefore, there is a critical need to find next-gen sustainable materials that perform not only superior but also impart minimal ecological harm.

Extensive research is ongoing on different biostabilisation techniques in pursuit of sustainability, including biocementation, biopolymerisation, phytostabilisation and enzyme-induced cementation. Phytostabilisation (vegetation-based soil stabilisation) techniques are known to be the most appreciable sustainable erosion mitigation technique (Zhu and Zhang 2016; Bordoloi and Ng 2020). However, their influence on the erodibility of soil is too complex to predict due to its uncertain life cycle and dense root structures, which are dependent on the type of vegetation, available nutrition, and climatic conditions (van Dijk et al. 2013; Krzeminska et al. 2019). Enzyme-induced carbonate precipitation (EICP) and algae/cyanobacteria-based biocrust formation techniques are also getting attention due to their considerable potential in soil stabilisation with minimal environmental impact (Chandra and Ravi 2020; Fattahi et al. 2020; Patil et al. 2021, 2023). EICP is a comparatively convenient technique in terms of control over treatment strategy due to water-like consistency and straightforward application. However, purified enzyme (urease) is expensive and current research is extending towards finding cheaper sources from native plants (Rahman et al. 2023). Biocrust is a shallow (in millimetres) plant-promoting biological layer for antidesertification purposes; However, the biocrust formation has a slower growth rate and is easily disturbed with human intervention (Patil et al. 2023). Biopolymer treatment is not suitable for wet environment as the treated soils lose substantial strength upon moisture interaction due to the hydrophilic nature of biopolymers (Ramachandran 2022; Patwa et al. 2023).

On the other hand, biocementation involves mimicking microbial mineralisation techniques that occur in nature (De Muynck et al. 2010; Dhami et al. 2013a). Biocementation technique has shown potential in their geotechnical applications because- 1. Soil is rich in microbial diversity (Mitchell and Santamarina 2005), 2. Biocementation solution has water-like consistency, ensuring easy and controllable in-depth penetration (Ivanov and Chu 2008), and 3. Biocementation has the healing capacity upon the availability of nutrients (Castro-Alonso et al. 2019; Kaur et al. 2023). The recent work has demonstrated the potential of biocementation in erosion control in diverse environments such as deserts, riverbanks, and seashores (Salifu et al. 2016; Bibi et al. 2018; Nayanthara et al. 2019; Zomorodian et al. 2019; Shahin et al. 2020; Behzadipour and Sadrekarimi 2021; Dubey et al. 2021b, 2022b). Moreover, biocementation is reported to be effective in mitigating various types of erosion, such as rainfall-induced erosion, internal erosion, and tangential-flow/current-induced erosion (Amin et al. 2017; Jiang and Soga 2017; Jiang et al. 2019; Devrani et al. 2021; Clarà Saracho et al. 2021a). Although extensive studies have been conducted, the upscaling and field-scale application is limitedly explored due to challenges such as difficulty in controlling the microbial viability/efficiency, uniformity of precipitation, by-product ammonia generation and cost. Therefore, this study is aimed to consolidate and critically assess the gained knowledge in erosion control via biocementation techniques and challenges to direct future research.

2 Biocementation as a potential erosion control solution

Nature has been forming biominerals and cemented aggregates for millions of years, as discovered by previous researchers in the case of anthills, cave speleothems, beach rocks and corals (Baskar et al. 2009; Dhami et al. 2013a). A few of such mesmerising nature-forming structures have been illustrated in Fig. 4. Figure 4a demonstrates a natural beach rock at Eagle-bay of the Rottenest Island, Western Australia, withstanding the wave-induced erosion forces. Figure 4b shows an anthill formed near the Department of Civil Engineering, which withholds against heavy rains, while Fig. 4c illustrates speleothems from Mawsmai Caves, Meghalaya, India.

Naturally formed karsts and beach rocks are observed to resist the erosive actions of wind and water up to a great extent when compared with naturally available loose soil. Emulating these techniques in the laboratory could provide the key to an eco-friendly technique for controlling soil erosion. Previous literature has discovered the biogenic and abiogenic cementation processes occurring in nature and mimicked them in the laboratory (van Paassen et al. 2010a; Gomez et al. 2017; Ramachandran et al. 2020).

The biominerals present in nature are classified as biologically induced mineralisation and biologically controlled mineralisation (Lowenstam 1981). The biologically induced minerals are developed extracellularly through the metabolic activities of the microorganisms, while the biologically controlled minerals are precipitated inside or around their cells. In nature, several chemical reactions govern the biologically induced mineralisation process that demonstrate potential for engineering applications, as illustrated in Table 1. The commonly observed natural biocementation pathways can be subdivided into autotrophic and heterotrophic pathways. Autotrophic microorganisms do not require external sources for their nutrition and energy, and these reactions are observed to be slow. Through one of such autotrophic pathways, i.e., photosynthesis, Nature has been forming stromatolites for billions of years using cyanobacteria (Arp et al. 1999; Altermann et al. 2006; Rodríguez-Martínez et al. 2012). On the other hand, the heterotrophic pathways require external sources for nutrition. It is to be noted that in Table 1, calcium sources have been considered for the precipitation. However, these chemical reactions can be harnessed to precipitate most of the divalent metal ions. Several studies have reported the application of biologically induced mineralisation for the bioremediation of soil by immobilising heavy metals such as Pb2+, Sr2+, and As2+(Fujita et al. 2010; Achal et al. 2012; Yang et al. 2017). It is critical to comprehend their advantages and limitations to select the most favourable biocementation pathway for engineering applications.

The autotrophic pathways are underexplored for engineering applications due to the challenges observed during the laboratory simulations. The major reason for the limited studies on photosynthesis pathway for biocementation can be attributed to the substantially slow rate of precipitation along with the continuous requirement of light and CO2 for the metabolic activity of cyanobacteria. However, it is to be noted that almost three-quarters (70%) of the carbonate rocks of the earth's crust are formed via photosynthesis (Altermann et al. 2006). On the other hand, in the methane oxidation pathway, complex microbial/enzymatic activity results in the production of formate (HCOO−), which eventually leads to the generation of CO32− in alkaline conditions (Ganendra et al. 2014; Caesar et al. 2019). The CO32− ions precipitate with Ca2+ and Mg2+. Further research in a controlled environment is required to determine the most suitable strategies for their emulation for in situ engineering applications.

The most common heterotrophic pathways, urea hydrolysis and denitrification, have particular advantages and limitations. Urea hydrolysis is quicker than the other heterotrophic biocementation pathways but leads to generation of harmful ammonia/ammonium (Keykha et al. 2019; Lee et al. 2019; Yu et al. 2022). The denitrification pathway is largely anaerobic, and therefore, it is viable for deep geotechnical applications; however, denitrification is a multi-step process utilising four kinds of enzymes, and the intermediate products such as nitric oxide (NO2−) and nitrous oxide (NO2) are toxic (DeJong et al. 2010; van Paassen et al. 2010a). Moreover, the accumulation of the intermediate products must be carefully managed by maintaining lower concentrations of reagents. In the case of denitrification, calcium acetate and calcium nitrate are considerably soluble and have a similar precipitation rate and yield in comparison to the urea hydrolysis pathway; however, there are only a few studies based on denitrification (van Paassen et al. 2010a; Gao et al. 2022). In a recent study by Gao et al. 2022, a large-volume circulation strategy was used following the denitrification pathway and the formation of cavities due to gas bubbles was reported. The other heterotrophic pathways, including Sulphate reduction, aerobic oxidation and ammonification, are not recommended for ground improvement due to the poor solubility of reagents (van Paassen et al. 2010a; Jain et al. 2021).

Therefore, the urea hydrolysis pathway is recommended as the most suitable candidate for erosion control applications, as oxygen availability is not a concern at shallow depths. In aerobic conditions, the urea hydrolysis path has been established for its high precipitation rate, carbonate yield and ease of control (DeJong et al. 2010; van Paassen et al. 2010a).

3 Biocementation via urea hydrolysis and its potential in erosion control

The principle of biocementation via urea hydrolysis is to catalyse calcium carbonate (CaCO3) precipitation with the help of microbial urease (Stocks-Fischer et al. 1999). Therefore, the urea-hydrolysis-based biocementation process is often termed microbially induced calcium carbonate precipitation (MICP). Over 5,000 microbial species are reported to possess urease enzyme and are capable of biocementation (Tamayo-Figueroa et al. 2019). Most of these microbes are abundantly available in the soil (Hammes et al. 2003; Burbank et al. 2011).

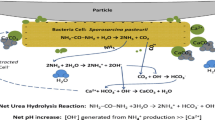

It is to be noted that for the engineering application of MICP, the strategy for employing exogenous ureolytic microbes in soil is termed bio-augmentation, while stimulating the indigenous microbial community for biocementation is known as bio-stimulation. One of the most popular bacteria used for bio-augmentation-based MICP is Sporosarcina pasteurii (SP).

The mechanism of soil binding is demonstrated in Fig. 5. The ureolytic microbes get attached to soil particles due to their surface-charge characteristics and extracellular polymeric substances (Jain and Arnepalli 2020; Datta et al. 2022). The attached microbes activate upon the availability of nutrients. In the presence of a cementation media (urea and calcium source), the microbes precipitate CaCO3 crystals on the surface of the soil or in the pores of the soil.

The binding of the soil usually occurs with surface coating, particle bonding/bridging and pore filling (Xiao et al. 2022). With surface coating, the interlocking and friction between soil particles improve, which provides resistance against movement and deformation. Apparent cohesion is induced with the grain bridging, and the soil densifies with pore filling, increasing the critical stress of the soil grains. Therefore, the erodibility of soil is expected to be controlled against the flow of the wind/water with biocementation treatment. Figure 6 demonstrates the micrographs from recent studies highlighting the microbes producing CaCO3 crystals and soil aggregation through MICP on a micro-scale.

The efficiency of the MICP process is assessed with- 1. The rate of urea hydrolysis (ku); 2. The rate of CaCO3 precipitation (Quantity) along with their quality; and 3. Urease activity of microbe. The rate of urea hydrolysis is evaluated with a first-order differential equation, assuming that the biomass (bacterial density) doesn’t vary during the urea hydrolysis as illustrated in Eq. (3) (Ferris et al. 2004; Mitchell et al. 2019).

Here [CO(NH2)2] implies the concentration of urea, ku denotes the first-order rate coefficient, and [B] is the concentration of biomass (bacterial density). It is necessary that the saturation index (SI) is greater than 1 for CaCO3 precipitation (Arp et al. 1999; Dhami et al. 2013a). The saturation index is defined in Eq. (4).

IAP stands for ionic activity product, and Ks stands for solubility product.

The rate of CaCO3 precipitation relies on the threshold activation energy required to move the chemical reaction forward. The rate and quantity of CaCO3 precipitation is evaluated with titration method, acid washing, thermogravimetric analysis, inductively coupled plasma (ICP), X-ray diffraction (XRD), thermogravimetric analysis (TGA) and ASTM method (Choi et al. 2017). The quality of precipitates implies their morphology, microstructure, and strength. Biogenic precipitation of calcite, vaterite and aragonite polymorphs is recorded (Cizer et al. 2012; Rodriguez-Navarro et al. 2012). Calcite is identified with rhombohedral shape and epitaxial growth (Hammes et al. 2003; Cizer et al. 2012; Cuthbert et al. 2012). Vaterite is often found in cauliflower-like spheroid and is a relatively less stable polymorph than calcite (Dubey et al. 2022c). In contrast, morning-star-shaped aragonite, identified with curved prismatic faces (Mayorga et al. 2019), is rarely reported with MICP.

Ureolytic microbes reduce the threshold energy barrier through the excreted “urease enzyme” out of their cell membrane or cytoplasm. The microbial activity increases the rate of reaction up to 1020 times by reducing the energy barrier (Mitchell and Santamarina 2005). The reduction in the energy barrier is primarily because of the (a). metabolic activity of microbes that secretes enzymes and catalyse the reaction, and (b). the negatively charged cell walls, leading the microbes to act as nucleation sites. Urease activity is defined as the quantity of enzyme hydrolysing unit micromole of urea per minute per millilitres (Dhami et al. 2013b; Dubey et al. 2022a). Urease activity is assessed by evaluating the quantity of generated ammonia by phenol-hypochlorite method, Nessler method and electric conductivity method (Whiffin 2004; Whiffin et al. 2007; Dhami et al. 2013b).

The factors influencing the MICP process in terms of the rate of urea hydrolysis, quantity and quality of precipitates are summarised in Table 2.

The key findings from the literature recommend that MICP has the potential to work well in coarse-grained soil (0.075 mm to 4.75 mm) in environments in a pH range varying from 6 to 10 and temperature 10 °C to 50 °C. The types of microbes and their specific urease must be assessed before their application in the soil to predict their efficiency in CaCO3 precipitation. However, the MICP application strategy can be strategised according to the type of soil, desired depth of penetration and rate of precipitation to overcome the limitation of geometric incompatibility of the soils with the microbes.

The majority of the proposed strategies for MICP application include injection/grouting and surface percolation/spraying for coarse-grained soils. Soon et al. (2014) investigated injection strategies with different pressures (0.2, 1.1 and 2 bar) for sandy soils and proposed a 1.1 bar pressure for 0.5 M cementation reagent flow for 48 h for uniform precipitation. At lower pressure, the precipitation is reported to occur close to the inlet and prohibits the flow of the reagents. Surface percolation is another method for the application of bacteria to the soil without disturbing the soil matrix. Cheng and Cord-Ruwisch (2014) reported with large-scale laboratory experiments that the surface percolation strategy is suitable for coarse-grained soil (D50 > 0.3 mm) due to its high permeability, which leads to uniform precipitation for shallow target depth. In contrast, there are limited studies on spraying strategies (Wang et al. 2018b; Zomorodian et al. 2019; Jiang et al. 2019; Chek et al. 2021) that have shown potential in mitigating the surficial erosion against wind and rainfall.

Contrarily, most of the studies on fine-clayey soil have considered a mixing strategy for the application of MICP. The field application of mixing techniques tends to be costly and non-feasible as the soil is disturbed. Cheng and Shahin (2016) utilised the bacterial suspension with urea and calcium sources and formed a bio-slurry. A high amount (more than 95%) of bio-slurry was reported to be retained in the soil, providing uniform precipitation. In a recent study, Won et al. (2021) demonstrated that a kaolinite suspension along with a biocementation solution facilitates uniform precipitation of CaCO3 as the kaolinite acts as a nucleation site. Similar observations were reported with bentonite-assisted MICP (Ma et al. 2021). It is to be noted that both of the above-mentioned studies have proposed injecting clay suspension along with bacterial and cementation solutions to enhance MICP; however, that will reduce the soil hydraulic conductivity continuously with treatment, leading to clogging in the upper layers. Moreover, it is to be noted that soil is heterogeneous in nature, containing different proportions of sand, clay, and gravel. Therefore, further studies on potential strategies of MICP on fine-grained soils are necessitated.

Extensive reviews capturing the key findings and processes involved in biocementation for engineering applications such as soil strength improvement, antidesertification, liquefaction control, recycling construction and demolition wastes aggregates, mine tailing stabilisation, and metal inhibition are available in the literature (Mitchell and Santamarina 2005; De Muynck et al. 2010; DeJong et al. 2010; Barkouki et al. 2011; Phillips et al. 2013; Dhami et al. 2013a; Anbu et al. 2016; Shashank et al. 2016; Mujah et al. 2017; Tamayo-Figueroa et al. 2019; Terzis and Laloui 2019a; Castro-Alonso et al. 2019; Mistri et al. 2020; Patil et al. 2021, 2023; Sharma et al. 2021a; Jain et al. 2021; Jha 2022; Jimenez-Martinez et al. 2022; Zúñiga-Barra et al. 2022; Xiao et al. 2022; Mahabub et al. 2023; Omoregie et al. 2023; Fu et al. 2023; Harran et al. 2023; Carter et al. 2023). These review papers are brilliant in capturing up-to-date information in the field of biocementation. However, a comprehensive review specifically focussing on soil erosion control is largely unexplored. In this paper, the key findings from recent studies on soil erosion control via biocementation techniques are discussed.

3.1 Influence of MICP on wind erosion resistance of soil

In the past few years, several studies have investigated the potential of biocementation to control aeolian erosion in the laboratory-scale wind tunnel (Maleki et al. 2016; Duo et al. 2018; Tian et al. 2018; Zomorodian et al. 2019; Devrani et al. 2021; Dubey et al. 2021a; Dagliya et al. 2022). One certain advantage of MICP over conventional cementation practices is easy permeation through soil media due to the water-like viscosity of the cementation solution (DeJong et al. 2010; Dhami et al. 2013a; Ivanov and Stabnikov 2017). The key findings on aeolian erosion mitigation with MICP in literature are summarised in Table 3.

The erosive stresses (\(\uptau\)) on the soil due to wind action can be calculated in Eq. (5) (Bagnold 1984)-

Here, ρa is the density of air, and vD is the drag velocity. The critical wind velocity (vc), often termed threshold wind velocity (in m/s), that induces stresses equivalent to Critical stresses (τc) can be estimated for cohesionless soils from Eq. (6) (Bagnold 1984; Ravi et al. 2006; Hamdan and Kavazanjian 2016).

For cohesive soil, the critical wind velocity (Ravi et al. 2006) is proposed as follows-

Here, ρs and ρa denote the density of sand particles and air (in kg/m3), g is the gravitational acceleration (9.81 m/s2), and "d" stands for the diameter of the particles in Eq. (7). A is a dimensionless parameter that depends on the shape factor, drag coefficient and ratio of the moment arm lengths to the soil grain diameter. Fc stands for interparticle cohesive forces, and B is a parameter depending on the shape factor of the particles. These equations can be useful to simulate the aeolian erosion in a wind tunnel and comprehend the mechanics of erosion control. With biocementation, the soil grains are bridged together, as illustrated in Figs. 5 and 6b. Therefore, the effective diameter of the soil grains enlarges, and the threshold detachment velocity improves. Apart from this, MICP treatment also imparts interparticle binding forces.

The threshold frictional velocity for fine desert sandy soil is reported to be around 20 km/h (Dubey et al. 2021a), which matches the theoretical value estimated from Eq. 5. Chen et al. (2016) reported that the desert soil from North Xinjiang, China, was able to withstand wind erosion even after 12-day exposure to freeze–thaw cycles. The existing studies have suggested that a low CaCO3 content of up to 4% can cease erosion against wind velocity of up to 45–55 km/h (Zomorodian et al. 2019; Dubey et al. 2021a). However, the threshold frictional velocity is difficult to determine for heavily biocemented soil due to the instrumental limitation of the generation of higher wind velocities (Dubey et al. 2021a). Nonetheless, there are several challenges associated with the filed-scale implementation and durability of MICP treatment for aeolian erosion mitigation.

With a large-scale experiment, Gomez et al. (2015) reported no deterioration after 44 days and moderate degradation after 298 days, withstanding a harsh winter season in the biocemented crust containing 2.1% CaCO3 content formed with low-concentration cementation solution (108 cells/litre SP, 15 g/l urea and 13.875 g/l CaCl2) in a mine site in dryland of the province of Saskatchewan, Canada. In other field-scale trials conducted in the Ulan Buh Desert of China, Meng et al. (2021a, b) reported that a soil crust of 1.25 cm and CaCO3 content of 0.57% withstood a wind velocity of 30 m/s and the depth of erosion was almost zero even after 30 days of exposure to the harsh local desert environment. They reported a 0.2 M equimolar urea and CaCl2 treatment with an application rate of 4 L/m2 for optimum plant growth. A deteriorating influence of higher concentration cementation media is observed, and therefore, plant-growth-promoting rhizobacteria (PGPR) must be investigated (Coban et al. 2022) for biocementation applications. However, it is to be noted that the water requirement for biocementation in deserts and drylands is a formidable concern apart from the harsh weather.

It is worth noting that the total water requirement for one cycle of 1 M biocementation treatment can be as high as 48 L/m2, resulting in 1.75% CaCO3 content and a 3.5 cm crust depth (Dubey et al. 2021a). The formed crust could withstand a wind velocity of up to 55 km/h without any detachment. Extensive future research is required to standardise the treatment procedures for design purposes considering these factors.

The key learning from the literature on aeolian erosion control with biocementation is as follows-

-

A biocemented soil crust of 2 to 3 cm containing CaCO3 content in the range of 2% to 4% is capable of controlling soil erosion against wind velocity up to 55 km/h.

-

A major challenge in the desert environment for biocementation treatment is the harsh environment for microbes and water scarcity. Therefore, the local microbial community's adaptability to desert environments and protocols with low-water demands must be investigated.

-

The studies have not considered the disastrous case of dust storms where wind velocities can rise up to 150 km/h due to instrumental limitations of the wind tunnel. These events must be investigated in future studies in the field via pilot-scale investigations.

3.2 Influence of MICP on hydraulic-erosion resistance of soil

Similar to aeolian erosion, the detachment of soil particles with water occurs when the applied erosive stress exceeds the critical stress of the soil. Briaud (2008) proposed that the critical velocity of cohesionless soil is dependent on particle diameter and can be estimated from Eq. (8).

vc (m/s) stands for critical flow velocity, and D50 is the mean diameter of cohesionless soils (in mm). In the case of the cohesive soils of particle size lesser than 100 microns, the following Eqs. (9 and 10) are proposed by Briaud (2008) as lower and upper bounds-

The erosive stresses (τ) on the wall of an open channel, such as a flume, can be calculated from Eq. (11) (Briaud 2013; Clarà Saracho et al. 2021a).

Here, φ (friction factor) is a function of the flow regime and can be estimated with the help of pipe roughness, and Reynolds number and v is the velocity of the hydraulic flume. These equations can be used in designing the experimental flow velocity to simulate natural conditions in the hydraulic flume. Biocementation improves interparticle locking, and the effective particle diameter enlarges with bridging. Therefore, erosion can be controlled with biocementation. The key findings from the literature on hydraulic erosion mitigation via biocementation have been summarised in Table 4.

The soil erosion for riverlike tangential flow-induced erosion is usually investigated in an erosion function apparatus (EFA) or hydraulic flume. Amin et al. (2017) demonstrated the different injection strategies with and without aeration to ensure uniformity in calcium carbonate precipitation and reported that the critical shear stress increased five-fold upon MICP treatment with aeration in an EFA. Wang et al. (2018a, b) have investigated the efficiency of polyvinyl alcohol-modified MICP treatment and reported that the synthetic polymer is useful in anchoring the CaCO3 crystals and, thus, provides better control over erosion. Clarà Saracho et al. (2021a) reported that although biocementation can cease soil erosion against the tangential flow with ten cycles of 0.08 M cementation solution, the treated specimen cracks along with the tangential flow due to brittleness.

The above-discussed studies have considered the bio-augmentation approach for soil treatment. Transporting the microbes to the site following the proposed strategies might be a challenge. On the other hand, the bio-stimulation-based approach employing indigenous soil microbes can tackle the challenge of bacteria transport; however, this domain is relatively underexplored in the context of mitigating riverbank/coastal erosion. Behzadipour and Sadrekarimi (2021) have investigated the direct shear strength characteristics of the sand from the Karoon riverbank of southwest Iran upon biochar-assisted MICP via native strains without identification of the microbial diversity. In another study, six biocementation potent strains were isolated from the banks of the Brahmaputra River of Assam Valley of India (Dubey et al. 2021c, b). The strains shared significant genomics similar to the conventionally used microbe SP. The studies concluded that soil erosion could be reduced significantly with a biostimulation approach. The stimulation approach minimises the risk of biodiversity contamination with external microbes and can be helpful in reducing the transportation cost of microbes.

The coastal erosion scenario is often investigated in a hydraulic flume. The biocemented soil specimens are tested against hydraulic waves of a specific frequency and amplitude. Shahin et al. (2020) observed that less than 5% erosion occurs for a sample containing 1.52% CaCO3 content withstanding erosional waves of height 6.9 cm and wavelength 23 cm for two hours. Contrastingly, Kou et al. (2020) demonstrated erosion ceases for a soil specimen having 30.1% CaCO3 content against the waves of 4 cm amplitude and frequency of 1 cycle per minute for a 30-min test. Interestingly, Liu et al. (2021) reported that two cycles of MICP treatment were inefficient in preventing erosion for a 2-h test duration without quantifying the precipitated calcite content. Behzadipour and Sadrekarimi (2021) reported that negligible erosion occurred in a physical riverbank model treated with 20 cycles of biochar-assisted biocementation treatment against 600 strong waves. It is evident from these studies that the number of cycles of biocementation treatment, i.e., the quantity of CaCO3 precipitates, is one of the deciding factors in controlling erosion. Moreover, these studies have reported the erosion characteristics against the wave features such as dimension, frequency and test duration. In a recent study by Dubey et al. (2022a), it was determined that the tangential and perpendicular waves to the shoreline have different responses in terms of erosion. While a CaCO3 content of 98 mg/g-sand was sufficient to cease erosion against the wave energy density of 6 J/cm2, in the case of tangential waves, an equivalent biocemented sand eroded more than 40% at the wave energy density of 5.3 J/cm2. For upscaling the laboratory results to the field, further studies considering natural wave energy at coasts, temperatures and saline environement are needed.

Biocemented soil slopes have also been investigated in the case of rainfall-induced soil erosion (Jiang et al. 2019; Sun et al. 2022a; Chung et al. 2021; Wang et al. 2023). A rainfall simulator is used to investigate the resiliency of biocemented soil against erosion. Jiang et al. (2019) reported that a high concentration of cementation solution (2 M) could be detrimental to the CaCO3 precipitation. At the same time, Chung et al. (2021) demonstrated that in the presence of high organic content in soils, the MICP treatment for erosion mitigation is less effective compared to sandy soil with lower organic content. Although several attempts have been made to investigate the efficiency of biocementation in the mitigation of hydraulic-induced erosion, there is a large gap to fill to come up with datasets that can be useful for standardising the treatment process similar to concrete design standards.

The key learning from the literature on hydraulic-erosion control studies with biocementation can be encapsulated as follows-

-

The erosion tests on biocemented soils reveal notable improvements in the erodibility parameters (erosion rate and critical stress) with the biocementation treatment. A CaCO3 content in the range of 2–12% in the shallow depth of soils around 10 to 20 cm is suggested in the above-discussed studies to mitigate the hydraulic-induced erosion by different environmental events such as rain, tangential flow (rivers) and coastal waves.

-

However, the studies in the literature are broad and fundamental quantification and mechanism of erosion parameters for different types of soils, different erosive forces and different levels of biocementation are still obscure.

-

Application of biopolymer to assist biocementation is recommended to tackle the challenge of non-uniform CaCO3 precipitation in heterogeneous soil matrix to the desired depth. Moreover, the application of biocementation is only possible in dry conditions in the wetlands to avoid the dilution of bacteria and cementation media that could result in insufficient precipitation.

3.3 Influence of MICP on permeability and strength of soil

Although a direct relationship between the strength of soils and erosion resistance is not established, the erosion resistance of the soil is assumed to be improving with an increase in the strength of the soil, primarily because both the parameters improve with soil binding. Nevertheless, it is critical to assess the behaviour of soils upon biocementation in terms of the fundamental parameters such as permeability and strength for their geotechnical applications. The key findings from the literature have been summarised in Table 5.

It is to be noted that a one to two-order decrease in hydraulic conductivity of soil (specifically fine sand) has been reported in literature upon MICP treatment (Al Qabany and Soga 2013; Chu et al. 2014; Cheng and Shahin 2016; Ma et al. 2021). With a high calcite content of 14% and unconfined compressive strength of around 1000 kPa, the maximum reduction reported in the literature is less than one order (Cheng et al. 2013; Jain and Das 2023), indicating that biocementation treatment is capable of retaining the high permeability of granular material while imparting strength. It is an obvious advantage over the traditional soil stabilisation methods such as lime or cement-based soil improvement, which clog the pores, resulting in a minimum reduction of 2–3 orders of permeability (Karol 2003; Cheng et al. 2013). Enhancement in soil strength without clogging the soil pores is one of the desirous as allowing drainage of pore liquid (Mujah et al. 2017) limits the generation of excess pore water pressure and risks of soil and foundation failure.

Several studies have reported substantial improvement in soil strength via MICP, as mentioned in Table 5. Most of these studies have utilised injection strategy for treatment and evaluated soil strength via UCS and triaxial tests. An unconfined compressive strength in the range of 1 to 5 MPa is reported in the literature, with CaCO3 content in the range of 5–10%, with a few exceptions (Al Qabany and Soga 2013; Terzis and Laloui 2019a; Mori and Venkata Uday 2022). The disparity in the UCS findings is attributed to the location of CaCO3 precipitates, mineralogy of soils and precipitates, degree of saturation and the density of the soils. The maximum UCS strength is around 12 MPa with 27% CaCO3 content in fine sands of a mean diameter of 0.17 mm (van Paassen et al. 2010b). On the other hand, Terzis and Laloui (2018) reported a UCS strength of up to 11.3 MPa for fine sands of a mean diameter of 0.3 mm. Primarily, it was assumed that the strength of MICP-treated soil is dependent on the quantity and mineralogy of precipitates. However, Cheng and Shahin 2016 reported that the location of precipitate in the soil matrix plays a vital role in the development of strength. They reported that treating specimens with 30% pore volumes of biocementation treatment may result in optimum strength.

Drained and undrained triaxial tests have also been conducted extensively for biocemented soils. Both friction angle and cohesion are reported to improve substantially with biocementation. In a recent study, Wu et al. (2021) proposed that the effective friction angle of the biocemented soil improves only up to 5% CaCO3 precipitation. While investigating fine sand in CaCO3 precipitation ranging from 0 to 14.25%, it was reported that the shear strength of biocemented sand above 5% CaCO3 content rises only due to enhancement in cohesion. The study also reported an increase in the dilatancy behaviour of sand with the increase in CaCO3 content. The improvement in the shear modulus of soil can also be measured non-destructively with bender elements, which could also be installed in triaxial instruments. In one of the studies, the shear wave velocity (vs) was found to improve from 107 to 395 m/s when CaCO3 content varies from 12 to 27% (van Paassen et al. 2010b). In another study, Montoya and DeJong (2015) reported that the shear wave velocity of MICP-treated fine sand improved from 190 to 1400 m/s for heavy cementation with 5.31% calcite content. The differences in their findings are influenced by the confinement conditions and type of soil. In a large-scale test on biocementation with stimulation and augmentation approaches, Gomez et al. (2017) reported that the shear wave velocity improved from 107 to 1028 m/s for MICP-treated sand and a maximum CaCO3 content of 5.3%. Although researchers have demonstrated that the MICP treatment can be monitored through bender elements, more insights are required for predicting the relationship between shear wave velocity, CaCO3 content, strength parameters and intrinsic properties of soil.

Another approach for measuring the magnitude of improvement in soil strength upon biocementation is determining the local strength at various points of the formed crust of soil is the needle penetration test (Ulusay et al. 2014; Dipova 2018; Sun et al. 2022b; Dubey et al. 2021c, 2021b, 2022b; Chung et al. 2021; Ramachandran et al. 2022). The benefit of using needle penetration tests is that they can be conducted on various points to measure the deviation in the improvement in soil properties upon biocementation, specifically in the case of spraying strategy. The existing studies established that the needle penetration index (NPI) improves to around 25 N/mm for 54.5 ± 3.6 mg CaCO3 per gram of sand before plateauing for 150–500 µm sand (Chung et al. 2021). However, a linear relationship between CaCO3 content and needle penetration index was observed up to 100 mg of CaCO3 per gram of 75–425 µm sand (Dubey et al. 2021c, 2022b). The disparity in the findings is expected due to the different gradation of soils and treatment strategies used. Bender elements are relatively costly alternatives for non-destructively evaluating soil strength. The needle penetrometer can provide a cheaper, non-destructive alternative for monitoring the soil strength of the developed crust. Therefore, further research to establish a correlation between needle penetration index and CaCO3 content is necessary.

The key findings from the literature on the permeability and strength of biocemented soils are as follows-

-

Biocementation treatment is capable of retaining the high permeability of granular materials while improving the strength substantially. This is a clear advantage as it minimally intervenes with the natural groundwater flow paths and allows easy release of excess pore pressure, limiting the risks of soil failure.

-

The UCS of soil is reported in the range of 1–5 MPa, corresponding to CaCO3 content in the range of 5–10%, with a small number of exceptions. The inconsistency in the UCS findings is attributed to the location of CaCO3 precipitates, mineralogy of soils and precipitates, degree of saturation and the density of the soils.

-

The cohesion and friction angle of soils improves substantially upon biocementation. Overall, the friction angle is reported to improve from 33° to 44° upon a 5% CaCO3 precipitation in fine sand (Montoya and DeJong 2015; Wu et al. 2021). The increase in the strength above 5% CaCO3 content is attributed to an increase in cohesion value only.

-

Other tools, such as bender elements and needle penetration tests, are found to be promising for the measurement of strength improvement of biocemented soils non-destructively. The transition of soils from granular materials (100 m/s < vs < 200 m/s and almost no needle penetration resistance) to a soft-rock-like behaviour (vs > 1000 m/s and NPI of 25 N/mm) can be captured with the real-time monitoring of biocementation treatment.

4 Challenges in upscaling and future perspective of biocementation technique

Extending laboratory knowledge of biocementation techniques to the field is the most formidable challenge. Many peers consider that biocementation can never replace the conventional grouting system (DeJong et al. 2013), which is rational as, in the current state of knowledge, there is uncertainty over its service life, monitoring tools and durability. The upscaling concerns are due to (a). The by-product ammonia/ammonium; (b). Non-uniform distribution; (c). Durability; (d). The possible interaction of biocementation media with pore fluid/organic matter; (e). Actual carbon footprint; and (f). High cost of MICP due to chemical grade pure reagents. The challenges with the upscaling of biocementation and the recent advances for tackling them are discussed in Table 6.

In summary, there is ongoing research to reduce ammonia by zeolites, struvite precipitation and urea replacement with asparaginase (Li et al. 2015; Keykha et al. 2019; Gowthaman et al. 2022). Non-uniform precipitation could be tackled with polymer composite treatment (Wang et al. 2018a; Dubey et al. 2021c, 2022b) and low-concentration cementation solutions (Al Qabany and Soga 2013; Cheng et al. 2019; Mujah et al. 2019). The existing pore liquid and organic matter present in the soil matrix can hinder the precipitation, and therefore, there might be a need to investigate and pump them out (Patil et al. 2021; Chung et al. 2021). A promising permanence of biocement treatment was reported through freeze–thaw and acid rain tests (Cheng et al. 2013; Sharma et al. 2021b); however, its service life has not been quantified yet. In addition, it is established that MICP is not a net-zero carbon footprint technique due to the inherent CO2 associated with the chemical-grade urea and CaCl2 in lab-scale investigations (Porter et al. 2021). Therefore, it is critical to investigate natural sources and waste resources as an alternative for chemical reagents that are used in MICP (Choi et al. 2016; Røyne et al. 2019; Gowthaman et al. 2021; Meng et al. 2021b).

Furthermore, the most obvious cause limiting the upscaling of MICP is the associated cost. Ivanov and Chu (2008) reported that the cost of materials for biocementation treatment could vary from 0.5 to 9 US$/m3, which is competitive with the cost of existing grout material (2–72 US$/m3) such as sodium silicates, polyurethane, and acrylamides. In contrast, the estimates are also reported in a wide range of 25–500 US$/m3 (DeJong et al. 2013). These estimated costs are in vast range due to the uncertainty in labour, electricity and transport costs. A recent study revealed that biopolymer-biocement composite material cost could vary from US$4.6 to US$9 for a 5 cm target depth depending upon the concentration of cementation reagents and biopolymer (Dubey et al. 2022b). The material cost could be further brought down by the recommended strategy in Table 6. However, to establish a fair estimation and optimisation of cost, a collaborative interdisciplinary field-scale investigation must be conducted.

Developing an end-user standard procedure is of critical importance for the unanimous acceptance of biocementation technique by policymakers and the public. Unlike the mixed design of concrete with the standard grades of cement used in retaining walls/abutment that prevents erosion, the proposed biocementation technique has many discords in application parameters and strategies such as (a). The ratio of the volume of bacterial solution to cementation solution, (b). The optimum concentration of bacterial solution/urease and cementation media, (c). The number of treatments, (d). The retention time for each cycle, and (e). Different application strategies. It must also be noted that proper safety training must be provided to the students and researchers working in the biostimulation field, as many pathogenic ureolytic microbes, such as Mycobacterium tuberculosis, are abundantly available in the soil (Velayati et al. 2015). Furthermore, it is recommended that the final end-user product for employing the biocementation technique should be designed in a non-hazardous powder or liquid form with conveniently transportable packaging to the end users.

In the context of erosion control with biocementation technique, there are several practical challenges against upscaling in different terrestrial environments such as deserts, riverbanks, and seashores, as illustrated in Fig. 7. They key aspects learnt from literature review to effectively mitigate erosion has also been captured in Fig. 7 in terms of cementation media concentration (Urea/Ca2+) and recommended CaCO3 content. Future studies must consider these challenges to devise a strategic approach for the different terrestrial environments.

The parameters such as suitable range of cementation media concentration, target depth of treatment, target range of CaCO3 content and number of treatment cycles have been summarised in Table 7. It is to be noted that the recommended range is based on previous literature, and they might be refined further based on future research. The common recommendation for all the landforms is to work with plant-promoting microbes, strategies for ammonia reduction, and cost optimisation for field application.

There is very limited literature on field-scale investigations based on biocementation. van Paassen (2011) reported the first pilot study for the stabilisation of gravel to support horizontal directional drilling for a gas pipeline in the Netherlands in collaboration with contractors Visser & Smit Hanab. Despite several flushes, the calcite precipitation was heterogeneous; however, improvement in shear strength was significant, and the horizontal drilling was successful. Fujita et al. (2010) and Smith et al. (2012) reported a successful bio-stimulation operation to immobilise heavy metals, strontium-90, along with calcium carbonate, in the field. In contrast, in a recent study, Zeng et al. (2021) reported no significant improvement in the cone penetration resistance upon MICP treatment of three plots, each of 125 m3 via injection strategy and reasoned it with the heterogenous profile of the soil and inhibition of urease activity due to high amount of natural calcium salts and low pH of the soil.

In a recent study, Ghasemi and Montoya (2022b) implemented MICP in the field to improve erosion resistance for shallow soil depths through three application strategies, including surface spraying, shallow trenches and prefabricated vertical drains (PVDs) employing lower-grade chemicals and pond water. They reported wider zones for treatment and maximum improvement in erosion resistance with surface spraying technique for a monitoring period of around 11 months. These studies have provided promising results but the possibility of profit-making with the MICP technique for field-scale applications is still uncertain. Currently, three business start-ups, namely, Medusoil, BioMason and Basilisk, based on biocementation techniques, are operational. Their projects could provide more insights into the commercialisation of biocementation techniques. Nonetheless, further studies are required addressing the cost–benefit, service life and durability of biocementation for field-scale applications and replacing existing erosion control and grouting techniques.

5 Concluding remarks

Soil erosion leads to the degradation of arable and habitable land around the globe. In this environmentally conscious era, it is necessary for researchers to devise sustainable alternatives to the current erosion mitigation practices that harm ecology. The current review revisits the recent studies based on laboratory and pilot-scale investigations on soil erosion control and strength improvement through biocementation, with the aim of consolidating the gained knowledge and highlighting the challenges that need to be addressed for upscaling and commercialisation of biocementation technique.

The critical evaluation of the literature outlines the general consensus that a small to moderate quantity of CaCO3 (4–10% of soil weight) is satisfactory for a notable strength improvement and erosion control. However, there are disparities in the reported findings due to differences in types of soils, their gradation, density, soil mineralogy, biocementation application strategy, microbial characteristics (urease activity), loading/erosion testing strategy and environmental conditions (pH, temperature, aeration). Moreover, the obvious concerns of MICP-based biocementation over non-uniform precipitation, durability, cost-effectiveness, and overall environmental impact (due to generated by-product ammonia) have not been addressed for devising a viable and affordable strategy for field-scale applications. Therefore, there is an urgent need to explore the technique further to address the above-mentioned aspects in future studies. A systematic interdisciplinary approach must be channelised for standardising the biocementation procedure for upscaling. Moreover, different pathways of biocementation must be explored for erosion control applications to find their suitability. The biocementation technique is still in a nascent state despite the magnanimous efforts of researchers worldwide. This review will be helpful for the early-stage researchers of geotechnical and geoenvironmental engineering domain, who intend to work on the facilitation of biocementation technique from laboratories to the field.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author upon reasonable request.

Code Availability

Not Applicable.

References

Achal V, Pan X, Fu Q, Zhang D (2012) Biomineralization based remediation of As(III) contaminated soil by Sporosarcina ginsengisoli. J Hazard Mater 201–202:178–184. https://doi.org/10.1016/j.jhazmat.2011.11.067

Al Qabany A, Soga K (2013) Effect of chemical treatment used in MICP on engineering properties of cemented soils. Géotechnique 63:331–339. https://doi.org/10.1680/geot.SIP13.P.022

Ali MB, Saidur R, Hossain MS (2011) A review on emission analysis in cement industries. Renew Sustain Energy Rev 15:2252–2261. https://doi.org/10.1016/j.rser.2011.02.014

Alshalif AF, Irwan JM, Othman N, Anneza LH (2016) Isolation of sulphate reduction bacteria (SRB) to Improve compress strength and water penetration of bio-concrete. MATEC Web Conf 47:01016. https://doi.org/10.1051/matecconf/20164701016

Altermann W, Kazmierczak J, Oren A, Wright DT (2006) Cyanobacterial calcification and its rock-building potential during 3.5 billion years of earth history. Geobiology 4:147–166. https://doi.org/10.1111/j.1472-4669.2006.00076.x

Amin M, Zomorodian SMA, O’Kelly BC (2017) Reducing the hydraulic erosion of sand using microbial-induced carbonate precipitation. Proc Inst Civ Eng Gr Improv 170:112–122. https://doi.org/10.1680/jgrim.16.00028

Anbu P, Kang CH, Shin YJ, So JS (2016) Formations of calcium carbonate minerals by bacteria and its multiple applications. Springerplus 5:1–26. https://doi.org/10.1186/s40064-016-1869-2

Arp G, Reimer A, Reitner J (1999) Calcification in cyanobacterial biofilms of alkaline salt lakes. Eur J Phycol 34:393–403. https://doi.org/10.1080/09670269910001736452

Bagnold RA (1984) The Physics of blown sand and desert dunes. Wiley, New York

Barkouki TH, Martinez BC, Mortensen BM et al (2011) Forward and inverse bio-geochemical modeling of microbially induced calcite precipitation in half-meter column experiments. Transp Porous Media 90:23–39. https://doi.org/10.1007/s11242-011-9804-z

Baskar S, Baskar R, Lee N, Theophilus PK (2009) Speleothems from Mawsmai and Krem Phyllut caves, Meghalaya, India: Some evidences on biogenic activities. Environ Geol 57:1169–1186. https://doi.org/10.1007/s00254-008-1413-y

Behzadipour H, Sadrekarimi A (2021) Biochar-assisted bio-cementation of a sand using native bacteria. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-021-02235-0

Ben CK, Rodri C, Teresa Gonza M et al (2004) Precipitation and growth morphology of calcium carbonate induced by myxococcus xanthus: implications for recognition of bacterial carbonates. J Sediment Res 74:1527–1404

Bibi S, Oualha M, Ashfaq MY et al (2018) Isolation, differentiation and biodiversity of ureolytic bacteria of Qatari soil and their potential in microbially induced calcite precipitation (MICP) for soil stabilization. RSC Adv 8:5854–5863. https://doi.org/10.1039/C7RA12758H

Bordoloi S, Ng CWW (2020) The effects of vegetation traits and their stability functions in bio-engineered slopes: a perspective review. Eng Geol. https://doi.org/10.1016/j.enggeo.2020.105742

Briaud J-L (2008) Case histories in soil and rock erosion: woodrow wilson bridge, brazos river meander, normandy cliffs, and new orleans levees. J Geotech Geoenviron Eng 134:1425–1447. https://doi.org/10.1061/(ASCE)1090-0241(2008)134:10(1425)

Briaud J-L (2013) Geotechnical engineering: unsaturated and saturated soils. Wiley, Hoboken

Burbank MB, Weaver TJ, Green TL et al (2011) Precipitation of calcite by indigenous microorganisms to strengthen liquefiable soils. Geomicrobiol J 28:301–312. https://doi.org/10.1080/01490451.2010.499929

Burrell AL, Evans JP, De Kauwe MG (2020) Anthropogenic climate change has driven over 5 million km2 of drylands towards desertification. Nat Commun 11:1–11. https://doi.org/10.1038/s41467-020-17710-7

Caesar KH, Kyle JR, Lyons TW et al (2019) Carbonate formation in salt dome cap rocks by microbial anaerobic oxidation of methane. Nat Commun. https://doi.org/10.1038/s41467-019-08687-z

Carter MS, Tuttle MJ, Mancini JA et al (2023) Microbially induced calcium carbonate precipitation by sporosarcina pasteurii : a case study in optimizing biological CaCO3 precipitation. Appl Environ Microbiol. https://doi.org/10.1128/aem.01794-22

Castro-Alonso MJ, Montañez-Hernandez LE, Sanchez-Muñoz MA et al (2019) Microbially induced calcium carbonate precipitation (MICP) and its potential in bioconcrete: microbiological and molecular concepts. Front Mater 6:1–15. https://doi.org/10.3389/fmats.2019.00126

Chandra A, Ravi K (2020) Effect of magnesium incorporation in enzyme-induced carbonate precipitation (EICP) to improve shear strength of soil. In: Lecture Notes in Civil Engineering. pp 333–346

Chek A, Crowley R, Ellis TN et al (2021) Evaluation of factors affecting erodibility improvement for MICP-treated beach sand. J Geotech Geoenviron Eng 147:04021001. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002481

Chen F, Deng C, Song W et al (2016) Biostabilization of desert sands using bacterially induced calcite precipitation. Geomicrobiol J 33:243–249. https://doi.org/10.1080/01490451.2015.1053584

Cheng L, Cord-Ruwisch R (2014) Upscaling effects of soil improvement by microbially induced calcite precipitation by surface percolation. Geomicrobiol J 31:396–406. https://doi.org/10.1080/01490451.2013.836579

Cheng L, Shahin MA (2016) Urease active bioslurry: a novel soil improvement approach based on microbially induced carbonate precipitation. Can Geotech J 53:1376–1385. https://doi.org/10.1139/cgj-2015-0635

Cheng L, Cord-Ruwisch R, Shahin MA (2013) Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can Geotech J 50:81–90. https://doi.org/10.1139/cgj-2012-0023

Cheng L, Shahin MA, Cord-Ruwisch R (2014) Bio-cementation of sandy soil using microbially induced carbonate precipitation for marine environments. Geotechnique 64:1010–1013. https://doi.org/10.1680/geot.14.T.025

Cheng L, Shahin MA, Chu J (2019) Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech 14:615–626. https://doi.org/10.1007/s11440-018-0738-2

Choi S, Wu S, Chu J (2016) Biocementation for sand using an eggshell as calcium source. J Geotech Geoenviron Eng 142:2–5. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001534

Choi S-G, Park S-S, Wu S, Chu J (2017) Methods for calcium carbonate content measurement of biocemented soils. J Mater Civ Eng 29:1–4. https://doi.org/10.1061/(ASCE)

Chu J, Ivanov V, Naeimi M et al (2014) Optimization of calcium-based bioclogging and biocementation of sand. Acta Geotech 9:277–285. https://doi.org/10.1007/s11440-013-0278-8

Chung H, Kim SH, Nam K (2021) Application of microbially induced calcite precipitation to prevent soil loss by rainfall: effect of particle size and organic matter content. J Soils Sediments 21:2744–2754. https://doi.org/10.1007/s11368-020-02757-2

Cizer Ö, Rodriguez-Navarro C, Ruiz-Agudo E et al (2012) Phase and morphology evolution of calcium carbonate precipitated by carbonation of hydrated lime. J Mater Sci 47:6151–6165. https://doi.org/10.1007/s10853-012-6535-7

Clarà Saracho A, Haigh SK, Ehsan Jorat M (2021a) Flume study on the effects of microbial induced calcium carbonate precipitation (MICP) on the erosional behaviour of fine sand. Géotechnique 71:1135–1149. https://doi.org/10.1680/jgeot.19.P.350

Clarà Saracho A, Lucherini L, Hirsch M et al (2021b) Controlling the calcium carbonate microstructure of engineered living building materials. J Mater Chem A 9:24438–24451. https://doi.org/10.1039/d1ta03990c

Coban O, De Deyn GB, van der Ploeg M (2022) Soil microbiota as game-changers in restoration of degraded lands. Science 80(375):abe0725. https://doi.org/10.1126/science.abe0725

Colica G, Li H, Rossi F et al (2014) Microbial secreted exopolysaccharides affect the hydrological behavior of induced biological soil crusts in desert sandy soils. Soil Biol Biochem 68:62–70. https://doi.org/10.1016/j.soilbio.2013.09.017

Cuthbert MO, Riley MS, Handley-Sidhu S et al (2012) Controls on the rate of ureolysis and the morphology of carbonate precipitated by S. Pasteurii biofilms and limits due to bacterial encapsulation. Ecol Eng 41:32–40. https://doi.org/10.1016/j.ecoleng.2012.01.008

D’Odorico P, Bhattachan A, Davis KF et al (2013) Global desertification: drivers and feedbacks. Adv Water Resour 51:326–344. https://doi.org/10.1016/j.advwatres.2012.01.013

Dagliya M, Satyam N, Sharma M, Garg A (2022) Experimental study on mitigating wind erosion of calcareous desert sand using spray method for microbially induced calcium carbonate precipitation. J Rock Mech Geotech Eng. https://doi.org/10.1016/j.jrmge.2021.12.008

Das TK, Haldar SK, Das GI, Sen S (2014) River bank erosion induced human displacement and its consequences. Living Rev Landsc Res 8:1–35. https://doi.org/10.12942/lrlr-2014-3

Datta S, Manna S, Roy D (2022) Attachment of extracellular metabolic products of lysinibacillus sp. DRG3 on sand surface under variable flow velocities and bioprocesses. J Environ Eng 148:1–13. https://doi.org/10.1061/(asce)ee.1943-7870.0002072

De Muynck W, De Belie N, Verstraete W (2010) Microbial carbonate precipitation in construction materials: a review. Ecol Eng 36:118–136. https://doi.org/10.1016/j.ecoleng.2009.02.006

DeJong JT, Mortensen BM, Martinez BC, Nelson DC (2010) Bio-mediated soil improvement. Ecol Eng 36:197–210. https://doi.org/10.1016/j.ecoleng.2008.12.029

DeJong JT, Soga K, Kavazanjian E et al (2013) Biogeochemical processes and geotechnical applications: progress, opportunities and challenges. Géotechnique 63:287–301. https://doi.org/10.1680/geot.SIP13.P.017

Devrani R, Dubey AA, Ravi K, Sahoo L (2021) Applications of bio-cementation and bio-polymerization for aeolian erosion control. J Arid Environ 187:104433. https://doi.org/10.1016/j.jaridenv.2020.104433

Dhami NK, Reddy MS, Mukherjee A (2013a) Biomineralization of calcium carbonates and their engineered applications: a review. Front Microbiol 4:1–13. https://doi.org/10.3389/fmicb.2013.00314

Dhami NK, Reddy MS, Mukherjee A (2013b) Biomineralization of calcium carbonate polymorphs by the bacterial strains isolated from calcareous sites. J Microbiol Biotechnol 23:707–714. https://doi.org/10.4014/jmb.1212.11087

Dipova N (2018) Nondestructive testing of stabilized soils and soft rocks via needle penetration. Period Polytech Civ Eng. https://doi.org/10.3311/PPci.11874

Dubey AA, Devrani R, Ravi K et al (2021a) Experimental investigation to mitigate aeolian erosion via biocementation employed with a novel ureolytic soil isolate. Aeolian Res 52:100727. https://doi.org/10.1016/j.aeolia.2021.100727

Dubey AA, Ravi K, Mukherjee A et al (2021b) Biocementation mediated by native microbes from Brahmaputra riverbank for mitigation of soil erodibility. Sci Rep 11:15250. https://doi.org/10.1038/s41598-021-94614-6

Dubey AA, Ravi K, Shahin MA et al (2021c) Bio-composites treatment for mitigation of current-induced riverbank soil erosion. Sci Total Environ 800:149513. https://doi.org/10.1016/j.scitotenv.2021.149513

Dubey AA, Hooper-Lewis J, Ravi K et al (2022b) Biopolymer-biocement composite treatment for stabilisation of soil against both current and wave erosion. Acta Geotech. https://doi.org/10.1007/s11440-022-01536-2

Dubey AA, Murugan R, Ravi K et al (2022c) Investigation on the impact of cementation media concentration on properties of biocement under stimulation and augmentation approaches. J Hazardous Toxic Radioact Waste 26:1–13. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000662

Dubey AA, Rathore S, Devrani R et al (2022d) Geotechnical assessment of steel slag for river embankments. J Mater Civ Eng 34:1–9. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004494

Dubey AA, Devrani R, Ravi K, et al (2022a) Influence of Single-Dose Biocement Treatment on the Hydraulic Conductivity of the Riverbank Sand. In: Proceedings of the 7th world congress on civil, structural, and environmental engineering. pp 1–8

Duo L, Kan-liang T, Hui-li Z et al (2018) Experimental investigation of solidifying desert aeolian sand using microbially induced calcite precipitation. Constr Build Mater 172:251–262. https://doi.org/10.1016/j.conbuildmat.2018.03.255

Economic and Social Council; United Nations (2022) Progress towards the sustainable development goals

Erşan YÇ, de Belie N, Boon N (2015) Microbially induced CaCO3 precipitation through denitrification: an optimization study in minimal nutrient environment. Biochem Eng J 101:108–118. https://doi.org/10.1016/j.bej.2015.05.006

Fattahi SM, Soroush A, Huang N et al (2020) Laboratory study on biophysicochemical improvement of desert sand. CATENA 190:104531. https://doi.org/10.1016/j.catena.2020.104531

Feng Q, Song Y, Lu C et al (2023) Feasible utilization of waste limestone as a calcium source for microbially induced carbonate precipitation (MICP). Fermentation. https://doi.org/10.3390/fermentation9030307

Ferris FG, Phoenix V, Fujita Y, Smith RW (2004) Kinetics of calcite precipitation induced by ureolytic bacteria at 10 to 20 °C in artificial groundwater. Geochim Cosmochim Acta 68:1701–1710. https://doi.org/10.1016/S0016-7037(03)00503-9

Florsheim JL, Mount JF, Chin A (2008) Bank erosion as a desirable attribute of rivers. Bioscience 58:519–529. https://doi.org/10.1641/b580608

Fu T, Saracho AC, Haigh SK (2023) Microbially induced carbonate precipitation (MICP) for soil strengthening: a comprehensive review. Biogeotechnics 1:100002. https://doi.org/10.1016/j.bgtech.2023.100002

Fujita Y, Taylor JL, Wendt LM et al (2010) Evaluating the potential of native ureolytic microbes to remediate a 90Sr contaminated environment. Environ Sci Technol 44:7652–7658. https://doi.org/10.1021/es101752p

Ganendra G, De Muynck WD, Ho A et al (2014) Formate oxidation-driven calcium carbonate precipitation by methylocystis parvus OBBP. Appl Environ Microbiol 80:4659–4667. https://doi.org/10.1128/AEM.01349-14

Gao Y, Wang L, He J et al (2022) Denitrification-based MICP for cementation of soil: treatment process and mechanical performance. Acta Geotech. https://doi.org/10.1007/s11440-022-01489-6

García-Ruiz JM, Beguería S, Nadal-Romero E et al (2015) A meta-analysis of soil erosion rates across the world. Geomorphology 239:160–173. https://doi.org/10.1016/j.geomorph.2015.03.008

Ghasemi P, Montoya BM (2022a) Effect of treatment solution chemistry and soil engineering properties due to microbially induced carbonate precipitation treatments on vegetation health and growth. ACS ES&T Eng 2:2196–2205. https://doi.org/10.1021/acsestengg.2c00196

Ghasemi P, Montoya BM (2022b) Field implementation of microbially induced calcium carbonate precipitation for surface erosion reduction of a coastal plain sandy slope. J Geotech Geoenviron Eng. https://doi.org/10.1061/(asce)gt.1943-5606.0002836

Gomez MG, Martinez BC, Dejong JT et al (2015) Field-scale bio-cementation tests to improve sands. Proc Inst Civ Eng Gr Improv 168:206–216. https://doi.org/10.1680/grim.13.00052

Gomez MG, Anderson CM, Graddy CMR et al (2017) Large-scale comparison of bioaugmentation and biostimulation approaches for biocementation of sands. J Geotech Geoenviron Eng 143:04016124. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001640

Gowthaman S, Yamamoto M, Nakashima K et al (2021) Calcium phosphate biocement using bone meal and acid urease: an eco-friendly approach for soil improvement. J Clean Prod 319:128782. https://doi.org/10.1016/j.jclepro.2021.128782

Gowthaman S, Mohsenzadeh A, Nakashima K, Kawasaki S (2022) Removal of ammonium by-products from the effluent of bio-cementation system through struvite precipitation. Mater Today Proc 61:243–249. https://doi.org/10.1016/j.matpr.2021.09.013

Habert G, Billard C, Rossi P et al (2010) Cement production technology improvement compared to factor 4 objectives. Cem Concr Res 40:820–826. https://doi.org/10.1016/j.cemconres.2009.09.031

Hamdan N, Kavazanjian E (2016) Enzyme-induced carbonate mineral precipitation for fugitive dust control. Géotechnique 66:546–555. https://doi.org/10.1680/jgeot.15.P.168

Hammes F, Boon N, De Villiers J et al (2003) Strain-specific ureolytic microbial calcium carbonate precipitation. Appl Environ Microbiol 69:4901–4909. https://doi.org/10.1128/AEM.69.8.4901-4909.2003

Harkes MP, van Paassen LA, Booster JL et al (2010) Fixation and distribution of bacterial activity in sand to induce carbonate precipitation for ground reinforcement. Ecol Eng 36:112–117. https://doi.org/10.1016/j.ecoleng.2009.01.004

Harran R, Terzis D, Laloui L (2023) Adressing the challenges of homogeneity, quality control and waste handling in soil bio-cementation: a large-scale experiment. Soils Found 63:101332. https://doi.org/10.1016/j.sandf.2023.101332

Heveran CM, Liang L, Nagarajan A et al (2019) Engineered ureolytic microorganisms can tailor the morphology and nanomechanical properties of microbial-precipitated calcium carbonate. Sci Rep 9:1–13. https://doi.org/10.1038/s41598-019-51133-9

Heveran CM, Williams SL, Qiu J et al (2020) Biomineralization and Successive regeneration of engineered living building materials. Matter 2:481–494. https://doi.org/10.1016/j.matt.2019.11.016

Intergovernmental Panel on Climate Changes; United Nations (2018) Summary for policymakers of IPCC special report on global warming of 1.5°C approved by governments (available at https://www.ipcc.ch/2018/10/08/summary-for-policymakers-of-ipcc-special-report-on-global-warming-of-1-5c-approved-by-governments/). IPCC Secr 1–4

Ivanov V, Chu J (2008) Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev Environ Sci Bio/technol 7:139–153. https://doi.org/10.1007/s11157-007-9126-3

Ivanov V, Stabnikov V (2017) Construction biotechnology. Springer, Singapore

Jain S, Arnepalli DN (2020) Adhesion and deadhesion of ureolytic bacteria on sand under variable pore fluid chemistry. J Environ Eng 146:04020038. https://doi.org/10.1061/(asce)ee.1943-7870.0001708

Jain S, Das SK (2023) Influence of size and concentration of carbonate biomineral on biocementation and bioclogging for mitigating soil degradation. Biogeotechnics 1:100021. https://doi.org/10.1016/j.bgtech.2023.100021

Jain S, Fang C, Achal V (2021) A critical review on microbial carbonate precipitation via denitrification process in building materials. Bioengineered 12:7529–7551. https://doi.org/10.1080/21655979.2021.1979862

Jha AK (2022) Microbiological processes in improving the behavior of soils for civil engineering applications: a critical appraisal. J Hazardous Toxic Radioact Waste 26:1–28. https://doi.org/10.1061/(asce)hz.2153-5515.0000686

Jiang N-J, Soga K (2017) The applicability of microbially induced calcite precipitation (MICP) for internal erosion control in gravel–sand mixtures. Géotechnique 67:42–55. https://doi.org/10.1680/jgeot.15.P.182

Jiang N-J, Tang C-S, Yin L-Y et al (2019) Applicability of microbial calcification method for sandy-slope surface erosion control. J Mater Civ Eng 31:1–11. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002897

Jimenez-Martinez J, Nguyen J, Or D (2022) Controlling pore-scale processes to tame subsurface biomineralization. Rev Environ Sci Biotechnol 21:27–52. https://doi.org/10.1007/s11157-021-09603-y

Karol RH (2003) Chemical grouting and soil stabilization third. Marcel Dekker, New York

Kaur P, Joshi S, Shinde OA, Sudhakara Reddy M (2021) Utilization of biomineralized steel slag in cement mortar to improve its properties. J Mater Civ Eng 33:1–10. https://doi.org/10.1061/(asce)mt.1943-5533.0003749

Kaur NP, Wang Y, Dhami NK, Mukherjee A (2023) Long-term corrosion monitoring of bacterially healed concrete using electrochemical and ultrasonic techniques. J Mater Civ Eng 35:1–11. https://doi.org/10.1061/jmcee7.mteng-14160

Keykha HA, Mohamadzadeh H, Asadi A, Kawasaki S (2019) Ammonium-free carbonate-producing bacteria as an ecofriendly soil biostabilizer. Geotech Test J 42:20170353. https://doi.org/10.1520/GTJ20170353

Konhauser K (2007) Introduction to Geomicrobiology. Blackwell Science Ltd, Hoboken

Konstantinou C, Wang Y, Biscontin G, Soga K (2021) The role of bacterial urease activity on the uniformity of carbonate precipitation profiles of bio-treated coarse sand specimens. Sci Rep 11:1–17. https://doi.org/10.1038/s41598-021-85712-6

Kou H, Wu C, Ni P, Jang B (2020) Assessment of erosion resistance of biocemented sandy slope subjected to wave actions. Appl Ocean Res 105:102401. https://doi.org/10.1016/j.apor.2020.102401

Krzeminska D, Kerkhof T, Skaalsveen K, Stolte J (2019) Effect of riparian vegetation on stream bank stability in small agricultural catchments. CATENA 172:87–96. https://doi.org/10.1016/j.catena.2018.08.014

Lai HJ, Cui MJ, Wu SF et al (2021) Retarding effect of concentration of cementation solution on biocementation of soil. Acta Geotech 16:1457–1472. https://doi.org/10.1007/s11440-021-01149-1

Latrubesse EM (2008) Patterns of anabranching channels: the ultimate end-member adjustment of mega rivers. Geomorphology 101:130–145. https://doi.org/10.1016/j.geomorph.2008.05.035

Lee M, Gomez MG, San Pablo ACM et al (2019) Investigating ammonium by-product removal for ureolytic bio-cementation using meter-scale experiments. Sci Rep 9:18313. https://doi.org/10.1038/s41598-019-54666-1

Li M, Fu QL, Zhang Q et al (2015) Bio-grout based on microbially induced sand solidification by means of asparaginase activity. Sci Rep 5:1–9. https://doi.org/10.1038/srep16128

Li C, Yao D, Liu S et al (2018) Improvement of geomechanical properties of bio-remediated aeolian sand. Geomicrobiol J 35:132–140. https://doi.org/10.1080/01490451.2017.1338798

Lipar M, Webb JA (2015) The formation of the pinnacle karst in pleistocene aeolian calcarenites (Tamala Limestone) in southwestern Australia. Earth-Sci Rev 140:182–202. https://doi.org/10.1016/j.earscirev.2014.11.007

Liu K-W, Jiang N-J, Qin J-D et al (2021) An experimental study of mitigating coastal sand dune erosion by microbial- and enzymatic-induced carbonate precipitation. Acta Geotech 16:467–480. https://doi.org/10.1007/s11440-020-01046-z