Abstract

Large-scale production of single-cell protein (SCP) has the potential not only to solve some of the food insecurity and water scarcity crises that plague a significant portion of our world today but also holds the promise to reduce the cost associated with the treatment of industrial and agricultural wastewater. Resource recovery of SCP from organic waste by microbes like yeast and microalgae is commonly documented. However, recently, a class of phototrophic bacteria, purple non-sulphur bacteria (PNSB), has emerged as a favourable option in terms of both wastewater treatment and resource recovery. PNSB are metabolically versatile and tolerant to a wide range of conditions, hence their ability to thrive in diverse waste streams. Besides its rich protein content, PNSB contains other nutritionally valuable bioproducts like carotenoids, coenzyme Q10, 5-aminolevulinic acid, and pantothenic acid. Recent evidence also indicates that PNSB-based aquafeed enhances growth and boosts immunity in certain aquaculture trials. It does not possess the same toxicity as most gram-negative bacteria due to its comparatively less potent lipopolysaccharide composition. With diverse promising prospects of PNSB-based SCP, it is critical to extensively examine the landscape from a holistic standpoint, highlighting the potential challenges large-scale SCP production may pose. Thus, this review explores the comparative advantages of utilizing PNSB for SCP production, essential components of PNSB-based SCP processing, and possible environmental and economic gains associated with the process. Current challenges with PNSB-based SCP production and future outlooks are also examined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Single-cell proteins (SCP) are commonly referred to as microbial proteins because they are derived from unicellular organisms like bacteria, yeast, fungi, protists, and microalgae (Upadhyaya et al. 2016; Jones et al. 2020). Some SCPs are also obtained from multicellular microbes like filamentous fungi and macroalgae (Ritala et al. 2017). These microbes are typically cultivated in organic carbon substrates, including fermented residues of industrial and agricultural wastewaters, wherein microbial biomass is produced, subsequently harvested, and processed. The dried or whole cells of some of these microbes have proven to be rich in protein and essential amino acids (AA), making SCPs a favourable protein substitute/supplement for humans and animals (Swetha et al. 2017; Nyyssölä et al. 2022). Sustainable SCP production is a promising branch of environmental and industrial biotechnology as it has the potential to utilize industrial waste streams from various sources to produce protein without having high demands on the limited resources (such as clean water and land) required by plants and animal production. Examples of past use of SCP for human consumption include bakers’ yeast and torula yeast grown in molasses and industrial hardwood liquors during World War I and II (Rose 1979; Goldberg 1985).

The widespread dependence of humans on crop and animal protein sources could be altered in the future if the comparative benefits of SCP production are objectively assessed and exploited. Besides the reduced pressure on finite natural resources like clean water, land, and minerals sustainable SCP production offers, the process promises to be more efficient. A protein-rich grain could take a year to be produced, while an equivalent yield from yeast and bacteria can be produced within a week and a day, respectively (Najafpour 2015). In addition, it has been estimated that for every unit of land utilized for cultivating staple crops, the protein and caloric yield of a corresponding SCP would be over ten-fold and two-fold higher, respectively (Leger et al. 2021). Moreover, microorganisms can be efficiently cultured independent of seasons, land area or soil type as opposed to crop protein. Land used for SCP production does not need to be arable land since the production is usually carried out in biochemical reaction vessels. These can even be orientated vertically for many types of SCP to provide greater footprint productivity. On the other hand, agricultural land use has reportedly contributed to around 80% of deforestation worldwide, significantly reducing biodiversity and negatively impacting the availability of terrestrial carbon sinks (Kissinger et al. 2012; Tanentzap et al. 2015). Other notable benefits are the relative ease of genetically modifying microbes to enhance protein production, the potential reduction in wastewater treatment cost by integrating the resource recovery component, and the ability of microbes to produce similar quality SCP in almost all regions globally. The utilization of waste streams as a carbon source for microbes in SCP production could make the process relatively cost-effective and suitable for both high-income and low-income societies (Hülsen et al. 2018a; Alloul et al. 2021c). The use of wastes allows valorisation from the treatment process while preventing environmental degradation from the waste discharge and the agricultural production offset through an integrated SCP process.

As with any conventional system, there are concerns related to SCP production. A primary concern is potential contaminants in the feedstock, such as xenobiotics and pathogens in municipal wastewaters, hydrocarbon carcinogens from petroleum wastes, persistent organic pollutants from agricultural wastes, and heavy metals in industrial wastewaters. This limits the SCP production to the utilization of relatively benign carbon substrates. Another concern is the public’s negative perception of terms like bacteria and wastewater. Social acceptance is crucial to the ability of SCPs to compete with mainstream protein sources. Other challenges include the rigid cell walls and the high nucleotide content of some microbes. Consumption of nucleic acid-rich SCP would result in a significantly higher level of uric acid in the body fluids, thereby leading to gout (Nasseri et al. 2011; Najafpour 2015). However, organisms with enzymes like urease and allantoicase can rapidly degrade uric acid, eventually released as NH4. These are reasons SCP is generally considered a substitute/supplement for certain animal feeds rather than human protein.

Moreover, post-treatment following the culturing stage can overcome some of these challenges. For example, the nucleotide content can be reduced by treating the SCP with NaOH solution. To improve digestibility, mechanical, chemical, and thermal treatment can promote cell wall lysis (Glencross et al. 2020). Even with possible digestibility challenges, SCP digestibility is comparable to protein-rich vegetables, with digestibility between 50 and 90% (Scrimshaw and Murray 2008). Another drawback with many SCP is their deficiency in sulphur-containing AA like methionine, cysteine, and cysteine, just like some leguminous crops. However, its rich lysine, threonine, and tryptophan content are advantageous over cereals. Many SCPs have been reported to have all essential AA values above the minimum requirements, making them somewhat nutritionally parallel to traditional protein sources like soybeans and fishmeal (Huang and Kinsella 1986; Kim and Lee 2000; Jones et al. 2020). A further nutritional benefit is that some SCPs are rich in lipids, vitamins, trace minerals, and biomolecules like carotenoids and coenzyme Q10.

Even though studies relating to protein production via SCP have spanned several decades, substantial progress has not been realised in devising a means to exploit this protein source on a large scale sustainably. Some of the prevalent challenges are the difficulty in harvesting biomass of small sizes and low densities, and the inability of SCP products to compete commercially with mainstream alternatives from a perceived health perspective (Zhou et al. 2019; Sui et al. 2020). With global social and environmental pressures like poverty, climate change, overpopulation, physical and economic water scarcity, increased industrialization, and a decrease in arable lands, exploring sustainable means of improving food security on a large scale is imperative. At the moment, some commercial industries present are Cellana (marine microalgae to biofuel and feed), Alltech (yeast to animal feed), ICC Brazil (yeast as nutritional additive), Calysta (aerobic heterotrophs to protein feed), KnipBio (leaf bacteria to aquafeed), Veramaris (marine algae to animal feed) and Unibio (methanotrophs to animal feed) using feedstocks like industrial CO2 waste, natural gas, molasses and processed wheat and corn (Jones et al. 2020). However, the commercialization of SCP via submerged (liquid) fermentation by utilizing organic-rich wastewater as a feedstock still poses a challenge. Integrating the resource recovery process into wastewater treatment processes will potentially broaden global efforts in our quest for sustainable protein production. Hence, this review explores how purple non-sulfur bacteria (PNSB), a class of organisms not widely explored for protein production, can be effectively exploited for SCP by utilizing diverse wastewaters as a carbon substrate. The comparative advantages of PNSB to other microbes used for SCP recovery and environmental and economic prospects are also reviewed.

2 Differences in common microbial SCP

The value placed on biomass derived for SCP production primarily depends on the biomass’ protein and AA content. Their vitamin and lipid content also contribute to the value of the product. For safe utilization, the nucleic acid contamination of SCP and potential toxicants present in the carbon substrate (such as heavy metals, pathogenic microbes, and persistent organic pollutants) are also of significant consideration (Ritala et al. 2017). The protein level derived from the production process mainly depends on the type of carbon substrate (feedstock) utilized and the type of microbes employed. Bacteria-based SCP has a comparatively higher crude protein content (frequently exceeding 70%) than SCP from yeast, fungi, or algae (Scrimshaw and Murray 2008; Zamani et al. 2020).

2.1 SCP from yeast

There are relatively more biomass production studies via yeast, as this was one of the earliest microbes discovered. Some advantages of yeast are that it is non-toxic, can grow in acidic conditions, and typically has high lysine content. Another advantage is that they are larger than bacterial cells, making biomass harvesting simpler. However, the multiplication rate is comparatively slower, and it has relatively lower methionine levels and a protein content that rarely surpasses 60% (Becker 2002; García-Garibay et al. 2014; Jach et al. 2022). The utilization of yeast in the production of everyday products like bread and beer enhances its social acceptance over less common SCP sources (García-Garibay et al. 2014).

2.2 SCP from fungi

For fungi, mycoproteins have been reported to be a good source of fibre and can also be a substitute for typical animal protein among vegetarians (Derbyshire and Ayoob 2019). However, they have a longer growth rate than yeast and bacteria, and the protein content is typically lower when compared to the other microbes (around 50%). Typically, fungi also lack optimal levels of sulphur-based AA, and their rigid cell walls reduce the digestibility of the potential feed (Boze et al. 2008; Nasseri et al. 2011). A significant disadvantage of using fungi for SCP is their ability to produce harmful secondary metabolites like aflatoxins, which are carcinogenic (Najafpour 2015). However, their larger size favours low-cost extraction/harvesting processes like basic filtration. They also have moderately low levels of nucleotides (between 3 and 10%), and they can utilize complex substrates like starch and cellulose (Boze et al. 2008; Nasseri et al. 2011; Ritala et al. 2017).

2.3 SCP from algae

The use of algae could be advantageous due to their ability to utilize carbon dioxide as the sole carbon substrate, the ability of a subgroup to utilize atmospheric nitrogen, their low nucleotide levels (around 4–6%), moderate protein content (40–60%), and their relative ease of harvesting especially when considering macroalgae (Janssen et al., 2022; Wang et al. 2020). However, algae also lack sufficient levels of sulphur-based AA. They have a relatively slower duplication rate and lower protein content than bacteria. Their setup is quite capital intensive as it may require closed photobioreactors to prevent cultures from breeding toxin-producing microalgae. The high energy requirement associated with providing artificial lightning is responsible for a significant portion of the cost. Also, algae tend to bioaccumulate heavy metals, and their cellulose-based cell wall, if present, makes digestibility an issue (Spain et al. 2021; Janssen et al. 2022).

2.4 SCP from bacteria

SCP production via bacteria biomass has been the least explored compared to the other microbial biomass, even though it has several key comparative advantages over the others (Swetha et al. 2017; Tlusty et al. 2017). The use of bacteria is particularly advantageous on an industrial scale due to their rapid growth rate, basic nutritional requirement, and ability to produce diverse products like food supplements, bioplastics, enzymes, solvents, and antibiotics (Kumara and Varma 2017). Bacteria commonly explored for SCP production include methylotrophic bacteria like Methylophilus methylotrophus and Methylococcus capsulatus, which utilize methanol/methane as a carbon source and Brevibacterium lactofermentum, which utilizes sugar as a carbon source (Windass et al. 1980; Rajoka et al. 2012; Nyyssölä et al. 2022). A disadvantage of employing these classes of bacteria for SCP production is the carbon substrate/feedstock limitation, implying that the process only applies to a narrow stream of industries.

In addition, a notable drawback with using bacteria is the widespread pathogenicity of bacteria, meaning only a limited subset can be considered for SCP production (Boze et al. 2008). For gram-negative bacteria, pathogenicity depends on the lipopolysaccharide (LPS) endotoxins on the cells’ outer membrane. Hence, exposure of humans and animals to high doses of LPS could lead to morbidity and mortality (Wang and Quinn 2010). The toxicity of LPS is dependent on its structure. For instance, the lipid A of the LPS in Rhodobacter sphaeroides is entirely non-toxic, while Rhodopseudomonas species lipid A has been shown to have little to no toxicity. However, certain species like Rhodocyclus gelatinosus synthesize endotoxic lipid A such as that from Escherichia coli (Weckesser and Mayer 1988).

PNSBs included within the Rhodovulum, Rhodopseudomonas, and Rhodobacter genera have been reported to exhibit probiotic effects in aquatics exposed to moderate doses. In one study, which included a 200-ton outdoor shrimp aquaria experiment, Rhodovulum sulfidophilum KKMI01 induced upregulation of a number of key genes in the shrimp and resulted in significant growth enhancement over a 145-day test (Koga et al. 2022a). These effects were attributed to LPS, given that the best effects were at relatively low cell density (103 CFU/mL) and were independent of feeding live or dead organisms. Another trial that provided fish with SCP from a mixed-culture dominated with Rhodopseudomonas sp. and Rhodobacter sp. at one-third, two-third, and complete bulk replacement of the fishmeal component (30%) reported no effects on variables like mortality and carcass composition (Delamare-Deboutteville et al. 2019). This provides further credence to the less toxic nature of lipid A in the highlighted PNSB genres. Hence, PNSB is one of the few groups of bacteria ideal for SCP production.

3 SCP from PNSB

3.1 Comparative benefits of PNSB-based SCP

The utilization of PNSB for wastewater treatment has been well appraised recently because it has proven effective in both the removal of wastewater pollutants and resource recovery (Lu et al. 2011). It has been utilized to treat diverse industrial wastewaters (Hülsen et al. 2014; Swetha et al. 2017; Zhi et al. 2019). For instance, R. sphaeroides cultivated in pharmaceutical wastewater containing recalcitrant organics like heptacosane, octadecane, and benzothiazole were able to degrade these compounds. The PNSB reduced the chemical oxygen demand (COD) load by over 80%, producing biomass with over 50% protein content (Madukasi et al. 2010). The ability of PNSB to utilize a range of metabolic modes, acclimatize to harsh and extreme conditions and their high biomass yields give this class of microbes an edge over other microbes used as SCP when considering the potential for wastewater resource recovery (George et al. 2020). PNSB are particularly well suited to growth under high-strength substrates (wastewater with > 2 g/L COD), removing the need for pre-dilution that may be required with microalgae or some other heterotrophic bacteria. This is also important when coupling SCP production with wastewater treatment systems and allows for high removal from complex streams (Lu et al. 2018). Compared to other microbes considered for SCP recovery, PNSB can thrive in unsterilized integrated systems. Due to their photoheterotrophic nature, a high level of PNSB selectivity can be guaranteed when exposed to visible light (absorbed via carotenoids) or near-infrared light (absorbed through bacteriochlorophylls), restricting the growth of other potentially unfavourable microbes (Hülsen et al. 2016b; Cerruti et al. 2020; Alloul et al. 2021c). The utilization of light as the energy source enhances PNSB’s carbon and nutrients assimilation resulting in biomass yields approaching unity (i.e. for each gram of COD consumed, an equivalent gram of biomass is formed), thereby facilitating maximum resource recovery from carbon and nutrient-rich wastewater (Capson-Tojo et al. 2020).

PNSB is known to have comparatively higher biomass production, growth rate, and protein yield than the other microbes used for SCP, with its protein content going as high as 70–90% (Bratosin et al., 2021; Yang et al., 2017a). They are also known to consist of a broader scope of AA, having relatively higher levels of lysine and sulphur-based AA. Methionine levels of 3% have been reported, while the average level for common plant-based and animal-based protein sources like soy, wheat, milk, and egg has been reported to be around 1% and 2.5%, respectively (Schulz and Oslage 1976; Boze et al. 2008; Ritala et al. 2017; Gorissen et al. 2018). Table 1 shows AA levels in diverse PNSB species compared to the AA content in mycoprotein from filamentous fungus Fusarium venenatum and the dietary requirement of penaeid shrimp (Penaeus monodon), a typical aquaculture organism for which SCP could be fed. Besides being rich in protein, PNSB-based feeds have a high nutritional quality due to the presence of macromolecules like lipids and carbohydrates and other biomolecules like carotenoids, coenzyme Q10, 5-aminolevulinic acid, and pantothenic acid in PNSB (George et al. 2020; Sali and Mackey 2021). In cases where the initial biomass is not utilised solely towards SCP in its intact state, the other biomolecules can be extracted and marketed separately (Lu et al. 2013).

Even though the nucleic acid levels in bacteria are typically high (between 10 and 16%), studies utilizing PNSB (Rhodopseudomonas sp.) have reported low nucleic acid contents ranging from 4.52 to 5.10% (Shipman et al. 1975; Boze et al. 2008; Patthawaro and Saejung 2019). However, animal-based and plant-based protein-rich food have even lower nucleic acid levels, ranging from 0.005 to 0.056%. For humans, the dietary limit for RNA has been reported to be 2 g/d because purines are not well metabolized by the digestive systems as opposed to animals (Imafidon and Sosulski 1990). Like humans, farmed mammals and birds also lack the ability to metabolize high nucleic acid levels, which is one of the drawbacks of utilizing SCP for animal feed (Carlberg et al. 2015, 2018). However, aquatic animals have been reported to have a higher liver urease activity, which enables the metabolism of higher concentrations of nucleic acid (Kinsella et al. 1985; Carlberg et al. 2018). This makes PNSB highly suitable for aquatic feed. Compared to SCP from algae, yeast, and fungi, PNSB-based SCP has been reported to have a more digestible cell wall which is an integral consideration for animal feed (Yang et al. 2017a). Moreover, unlike microalgae which have been widely reported to absorb heavy metal contaminants due to their high sorption capacity (Kaplan 2013; Leong and Chang 2020; Pavithra et al. 2020), PNSB has not been shown to share similar properties because they characteristically have low production of extracellular polymeric substances (Chen et al. 2020).

3.2 Ameliorative properties of PNSB-based SCP on aquatic livestock

Several experimental studies on aquatic livestock have reported that SCP derived from PNSB has protective properties. A recent study using white leg shrimps as test subjects revealed that shrimps with diets consisting of R. palustris and Rhodobacter capsulatus had their individual weights significantly higher than those on the control diet. Shrimps with the PNSB formulated diet also had a more positive feed conversion ratio and a better tolerance against NH3 (Alloul et al. 2021c). Another study that fortified conventional fish feed with R. sulfidophilum biomass reported that the experimental group had a lower death rate and a significantly higher growth rate (Banerjee et al. 2000). A similar trend was reported by Chowdhury et al. utilizing the phototrophic purple bacteria Marichromatium sp. (Chowdhury et al. 2016). Other studies that examined the impact of PNSB-derived SCP on a fish with high dietary protein needs (juvenile Asian sea bass) revealed that fortification of the conventional fishmeal component of the feed (30%) with around 30% PNSB-derived SCP in no way affected the palatability and that there was no significant difference in the survival rate between the experimental and control groups. However, the group fed with feed where 100% of the fishmeal component was replaced with PNSB-derived SCP had the lowest weight and length gain and highest feed conversion ratio (Delamare-Deboutteville et al. 2019). This is most probably a consequence of SCP contamination with nucleic acid, as biomass pre-treatment was not performed. The exposure of aquatics to excess nucleic acid significantly increases ureagenesis (Oliva-Teles et al. 2006), which in turn can negatively impact growth parameters. Another possible reason for the lower growth experienced by the group fed with 100% dry PNSB biomass is the reduced digestibility of the feed. In contrast, another study, the experimental group had the highest feed conversion ratio and survival rate (Shapawi et al. 2012). In vivo and in vitro studies on PNSB biomass have also revealed that PNSB can be protective against the infectious shrimp pathogen Vibrio parahaemolyticus, thereby providing the possibility of reducing shrimp mortality attributed to acute hepatopancreatic necrosis disease (Chumpol et al. 2017). A more recent study reported that kuruma shrimp nurtured with aquafeed consisting of 0.01% fresh weight PNSB (R. sulfidophilum and R. sphaeroides) resulted in the increased expression of immunity genes like superoxide dismutase and antibacterial proteins (Koga et al. 2022a, b). Comparing the probiotic effects of SCP derived from PNSB with SCP derived from other common microbes, PNSB-based SCP has been reported to have a higher ameliorative effect. A trial that compared the survival and growth performance of shrimp larvae fed with SCP derived from algae (Chlorella vulgaris), yeast (Saccharomyces cerevisiae), and PNSB (R. faecalis) revealed that the trial group fed with PNSB-based SCP had the highest survival and growth rate (Saejung et al. 2018). In addition, similar benefits have also been reported in non-aquatic studies. A study on poultry birds reported a 10% increase in egg-laying rate and an enriched egg yolk quality after fortifying the poultry feed with R. capsulatus dry biomass (Kobayashi and Kurata 1978).

4 Processing of PNSB-based SCP

According to Ritala et al (2017), the integral steps in SCP production can be broadly categorized into (i) preparation of feedstock/nutrient medium; (ii) cultivation of microbes; (iii) harvesting and concentration of microbial biomass; (iv) processing of the biomass into SCP and potentially other valuable products. The medium and inoculum preparation phase of the SCP production are classified as upstream processes, while the harvesting and concentration of microbial biomass are components of the downstream processes (Kumara and Varma 2017). Another important step between both processes is identifying optimal environmental conditions in the fermenter/bioreactor essential for favourable microbial growth.

Figure 1 shows a chart describing the component of upstream and downstream operations of basic biotechnological microbial processes.

4.1 Upstream processing

4.1.1 Metabolism

To begin the upstream processing, it is important to ascertain how well the PNSB of choice will thrive under the intended setup. PNSB are physiologically robust anoxic organisms and the most metabolically versatile prokaryotes (Yang et al. 2017b). They can grow in both phototrophic and dark conditions and also autotrophically and heterotrophically. Unlike most phototrophs, PNSB prefer photoheterotrophy, but can also utilize other growth modes (Madigan and Jung 2009). Figure 2 shows some of their major routes of metabolism. There are around 20 genera identified, with Rhodobacter and Rhodopseudomonas species being the most explored so far (Madigan and Jung 2009). Photoheterotrophy is a more favourable growth mode for most PNSB (Kilby 1979; Yurkov and Beatty 1998; Madigan and Jung 2009). Their preference for photoheterotrophic conditions can be observed from their respective growth rates: 1.6–13 d−1 under heterotrophic conditions and 1–8 d−1 under autotrophic conditions (Madigan and Gest 1979; Colbeau et al. 1980; Rey et al. 2006; Sakarika et al. 2020). Even though PNSB is known to commonly utilize organic substrates consisting of low molecular carbon like volatile fatty acids under heterotrophic conditions, some species have been reported to degrade macromolecules without pretreatment (Lu et al. 2010, 2011).

4.1.2 PNSB strain

In addition, the strain of PNSB utilized could impact the protein yield obtained from the process. A study examining the yield of four different PNSB strains cultured under similar conditions revealed that R. sphaeroides SS15 had higher protein (54%) and photopigment yield than the other strains of R. sphaeroides S3W10, R. sphaeroides TKW17, and A. marina STW181 (Chumpol et al. 2018). However, its lipid yield was lower than the other groups. To date, most of the highest protein yields (74–90%) among PNSB-based SCP have been associated with R. palustris (Bratosin et al. 2021; Prasertsan et al., 1993b; Yang et al., 2017a), though it should be noted this is also the most commonly studied organism. Maintaining an axenic culture is highly preferable to obtain consistently high biomass yield and high protein content. However, under normal circumstances, it might be economically impractical to culture a single strain of PNSB in an industrial (large-scale) set-up, particularly if wastewater is used as carbon substrate or open pond/raceway reactors for cultivation. Hence, ensuring PNSB dominance in a non-axenic culture is one of the integral goals of upstream processing. Generally, two primary conditions that favour the selective growth and dominance of PNSB in a mixed culture are an anaerobic/microaerobic condition and a constant light condition (Sawada et al. 1977; Izu et al. 2001). Biomass from mixed cultures is also subjected to more scrutiny, as routine evaluations must ensure harmful organisms do not thrive in the culture. The utilization of mixed culture systems has its benefits, especially when the synergistic relationships between different strains are exploited. A notable synergistic association is that of fermentative chemoorganoheterotrophic bacteria and PNSB. When cultured together in glucose, acidogenic bacteria ferment the sugar into VFAs and alcohols, providing a degradable carbon substrate for PNSB (Honda et al. 2006; Cerruti 2022). Another study that co-cultivated PNSB and aerobic heterotrophs reported a higher biomass protein and fatty acid content compared to individual cultivation. The cocultivation group also derived a superior AA profile (Alloul et al. 2021b). Moreover, mixed cultures have also been reported to enhance pelletization, flocculation, and biofilm formation (Kapoore et al. 2022).

4.1.3 Feedstock

The source of the carbon substrate is also important from a financial perspective, as it can significantly increase the biomass production cost. It is economically and environmentally advantageous to utilize benign organic wastewater as the carbon substrate (Yang et al. 2017a). The carbon source utilized also influences how well photosynthetic bacteria would thrive in the culture. PNSB has been associated with favourable growth conditions when cultured in short carbon chain substrates like volatile fatty acids (VFAs). At the same time, species like R. palustris and R. capsulatus can utilize glucose as a carbon substrate (Honda et al. 2006; Alloul et al. 2021b). Culturing PNSB in different carbon substrates will result in varying biomass yield and protein content depending on the degradability of the organics. An experiment that examined the growth conditions of R. gelatinosus in tuna condensate wastewater, shrimp-blanching wastewater, and frozen seafood wastewater under similar anaerobic-light conditions reported the highest biomass yield (4.02 g/L) and COD removal (78%) with the tuna wastewater as opposed to shrimp (2.62 g/L and 36%) and frozen seafood wastewater (0.85 g/L and 27%) (Prasertsan et al. 1993a). In addition, the feedstock used also influences biomass protein content. An experiment that cultured Rhodopseudomonas in biogas slurry and brewery wastewater under similar conditions reported protein content of 90% and 55%, respectively (Yang et al. 2017a). However, a disadvantage of having a nitrogen-rich substrate like biogas slurry is the low C:N ratio resulting in low biomass yield (< 500 mg/L) (Yang et al. 2017a). Another factor to consider with the substrate is the strength of the wastewater. High-strength wastewater is often challenging to manage due to the substrate's high C:N ratio and/or potential inhibition. This results in low COD removal, low biomass growth and additional treatment requirements. Therefore, when high-strength wastewater is used as a carbon substrate, the feedstock might require dilution to attain maximum growth rate, biomass yield and protein content (Chen et al. 2020). Table 2 summarises the biomass productivity and protein content of different PNSB species cultured in diverse carbon substrates and reactors.

4.1.4 Nutrients

The culture media used must be suitable or selective for the microorganisms of interest; the media's content and quality will influence the microbes' ability to grow optimally in the fastest time possible. Growth media typically consist of micro- and macro-elements, buffers, bacterial vitamins, minerals, metals, and cofactors (Bridson and Brecker 1970; Kumara and Varma 2017). Macroelements (like nitrogen, phosphorus, potassium, magnesium, and sulfur), trace elements (like iron, manganese, molybdenum, zinc, cobalt, nickel, boron, silicon, and vanadium), and vitamins (like folic acid, thiamine, p-aminobenzoic acid, nicotinic acid, biotin, riboflavin, and thiamine) have been identified as essential nutritional requirements for bacterial SCP production (Boze et al. 2008; Kumara and Varma 2017). Hence, it is essential to optimize the nutrient requirements of the PNSB before scaling up. Additionally, when wastewater is used as a substrate, the presence of individual nutrients needs to be assessed as wastewater often contains macro- and micro-elements.

4.1.5 Light conditions

Photosynthetic bacteria have been reported to thrive at intensities ranging from 2000 to 4000 lx and photoperiods with longer light phases (≥ 12 h) (Prasertsan et al. 1993a; Koku 2003; Nath and Das 2009; Al-Azad et al. 2013). The domination of PNSB during phototrophic growth does not imply they cannot also grow in the dark. Some PNSB like R. sphaeroides and R. palustris have been reported to grow under dark anaerobic conditions via chemotrophic mode of nutrition, while others like R. gelatinosus have been reported not to grow in such conditions (Uffen and Wolfe 1970; Prasertsan et al. 1993b). However, the biomass yield associated with chemotrophic growth is significantly less than that associated with phototrophic nutrition (Honda et al. 2006). It is important to note that the higher biomass yield of photoheterotrophy does not necessarily translate to higher protein content. A study that examined the impact of the light–dark cycle on PNSB biomass reported the highest biomass yields and lowest protein content (around 40%) in the 24-h light and 12-h light–dark cycles, while shorter cycles like 3 and 6-h light–dark had over 55% protein content (Zhi et al. 2019). Considering the light source, a mixed culture will be highly selective for PNSB when the light spectra are in the near-infrared light region. This is attributable to PNSB bacteriochlorophyll a and b’s preference for infrared light in the 800–900 nm range (Sawada et al. 1977). Other phototrophs like microalgae and cyanobacteria with a preference for visible light can potentially out-compete PNSB if the wavelength is ≤ 700 nm (Capson-Tojo et al. 2020).

4.1.6 Environmental factors

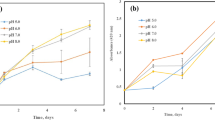

Factors like temperature, pH, and mixing also impact the recovery process. Concerning temperature, a range of 25–35 °C is effective for optimal PNSB biomass growth. However, biomass production can still be achieved at much lower temperatures (Chen et al. 2020). An experiment comparing the performance of PNSB cultured in domestic wastewater at 22 °C and 10 °C reported that optimal treatment and resource recovery were still feasible in both groups (Hülsen et al. 2016a). In addition, a pH range of 6.8–8.5 is considered to be suitable, with the neutral pH more conducive for biomass production (Chen et al. 2020). Considering mixing, the optimal stirring speed is negatively proportional to the size of the fermenter. Smaller fermenters (1–20 L) use a speed of around 250–350 rpm, while larger fermenters (over 400 L) use a reduced speed of around 60–120 rpm (Kumara and Varma 2017). For smaller fermenters, if the mixing speed is inefficient, cells are more likely to settle to the base. This will eventually limit their exposure to light and nutrients.

4.1.7 Reactor design

The functioning of the bioreactor can be categorized as suspended or immobilized depending on the state of the microbes in the reactor. The suspended growth bioreactors like continuous stirred tank reactors and flat-panel photobioreactors are commonly used because of their relative ease of fabricating and large illumination surface area. Due to the small sizes of PNSB, they disperse easily in the reactors, thereby efficiently capturing the light energy (Hülsen et al. 2016b; Chen et al. 2020). Another type of suspended growth bioreactor is the tubular flow-type photobioreactor (Lu et al. 2019b). The continuous mixing and movement of the cells imply constant exposure to the light source, thereby enhancing efficient energy capture. Lastly, outdoor systems like open ponds can be used. Recent studies have revealed the possibility of PNSB SCP production in raceways (Alloul et al. 2021a). The major advantage of such a setup is the energy and cost savings associated with using natural light for photosynthesis (Costa and de Morais 2014). A drawback to this type of reactor is the insufficient penetration of sunlight through the depth of the pond, as concentrated PNSB cultures reportedly permit 5 cm light penetration, negatively impacting biomass yields (Capson-Tojo et al. 2022). Also, there is the relative ease of contamination due to outdoor exposure and the requirement for a large area of land for largescale setup (Murthy 2011). A means of efficiently overcoming these challenges could be by utilising a flat-panel photobioreactor. A recent study by Hulsen et al. (2022) reported high levels of nutrient removal and SCP recovery from chicken and piggery wastewaters using naturally illuminated flat-plate photobioreactors.

4.2 Downstream processing

This stage comprises the extraction/harvesting and processing of the valuable product(s) of interest from the bioreactor. This phase hinges on how efficiently PNSB cells (biomass) can be extracted from the bioreactor. Harvesting employs a solid–liquid separation technique. One of the most significant challenges with utilizing PNSB for SCP production is the difficulty in harvesting due to the small cell size and density of PNSB. The size and width of PNSB have been reported to be around 0.85 µm and 1.9 µm, respectively, while the size of algae can range from 0.5 to 60 μm (Raven and Giordano 2014; Soon et al. 2014). The difficulty in harvesting the microbial biomass significantly increases the cost associated with the downstream processing (Nasseri et al. 2011). For this reason, the separation process consists of pre-treatment, biomass concentration/separation, and post-treatment (Kumara and Varma 2017). In laboratory-scale experiments, pre-treatment might not be required since biomass harvesting is done on a small scale, mostly with a centrifuge, as seen in numerous studies. However, on an industrial scale, the most available facilities used are industrial-scale centrifuges, filter presses, and membrane filters (Kumara and Varma 2017). Some of these methods are examined below.

4.2.1 Membrane separation

For suspended growth reactors, the most suitable harvesting medium is membrane separation (PSB-MBR). The main advantage is high biomass recovery without the addition of a flocculant. Compared to other bacteria, there is a lesser likelihood of membrane fouling due to the size of PNSB and reduced extracellular polymeric substance (EPS) formation, and the ability to efficiently recover a significant portion of the biomass (Chen et al. 2020). Another advantage of PSB-MBR is their ability to adsorb soluble substances like nutrients, thereby improving the quality of effluent released (Yan et al. 2018). Among membrane bioreactor technologies, forward osmosis (FO) is appraised for efficiently trapping microbial biomass and nutrients (Schneider et al. 2019; Valverde-Pérez et al. 2020). With the aid of a suitable draw solution, biomass and nutrients are retained in the semipermeable membrane due to an osmotic pressure gradient created within the reactor (Schneider et al. 2019). The pressure gradient causes the feed solution to move towards the draw solution, trapping the biomass on the membrane. Even though FO is advantageous for having little fouling tendency and fouling reversibility, salt flux reversal and reconcentration of draw solution are major demerits (Yan et al. 2018). An experiment that examined the use of FO to retain nutrients and dewater a methanotrophic culture for SCP processing reported that glycerol was more suitable as a draw solution compared to sodium and magnesium salts. Even during incidences of high reverse flux to the feed solution, microbial growth was not impaired (Valverde-Pérez et al. 2020). Glycerol also achieved the highest nutrient retention (Valverde-Pérez et al. 2020).

4.2.2 Biofilm reactors

Biofilm reactors are highly favourable because they guarantee high biomass density, which translates to an increased yield of valuable products like SCP (Ercan and Demirci 2015). Biofilm reactors typically provide consistent results in terms of pollutant degradation efficiency because the microbial community remains fairly constant. A study that cultured Rhodopseudomonas in a fish feed solution under aerobic conditions in both suspended and fixed reactors housed in a greenhouse reported that the genus dominated the suspended reactor by 23.8% and the biofilm reactor by 80% after 70 days (Wang et al. 2019). The dry cell weight of the suspended reactor was 0.056 g/L, while that of the biofilm was 7.5 g/L. In addition, biofilm reactors offer more flexibility in altering the flow rates of the reactor without risking biomass washout (Melo and Oliveira 2001). Also, the microbes do not need as many nutrients as required by microbes in a suspended bioreactor and are highly suitable for extended fermentation durations because the microbes can withstand more extreme conditions (Todhanakasem et al. 2019; Germec et al. 2020). Biofilm reactors have also been associated with enhanced quality of valuable products. Recent studies utilizing agricultural wastewaters reported significantly lower ash content and more consistent product quality over time in biofilm reactors than suspended growth (Hülsen et al. 2020, 2022). However, these facilities are typically capital and energy-intensive on a large scale, thereby reducing the economic and environmental benefit that accompanies the entire process. The expensive nature of these processes will also limit their viability in developing countries. Moreover, efficiently harvesting biomass from the biofilm substrata is a significant drawback, especially when biofilm is formed on irregularly shaped materials like the moving bed biofilm reactor rings. Even when flat surfaces are used, manually harvesting biomass via scraping will be challenging on a large scale. Hence, more efficient technologies like an automated spool harvester can be considered (Christenson and Sims 2012). Another drawback is the possibility of reduced nutrient diffusion since microbial layers are formed (Germec et al. 2020). The low EPS yield of PNSB may also significantly impede their ability to efficiently form biofilms at rates conducive for SCP production (Chen et al. 2020). A way around this challenge is by enriching the culture with other bacteria or microbes associated with high EPS yield.

4.2.3 Bioflocculation

An emerging environmentally friendly process to reduce the cost associated with biomass harvesting is the use of bioflocculants. This class of flocculants are favoured compared to the conventional chemical agents like ferric chloride and alum, because of the environmental and economic burden involved in their production and use. Just like PNSB, similar challenges with biomass harvesting have been reported in other biotechnological processes. For example, the microalgae C. vulgaris, whose biomass is valuable for biofuel production, has a small cell size ranging from 2 µm to 10 µm (Vander Wiel et al. 2017), thus making large-scale processing difficult. Microalgae and photosynthetic bacteria both have high electronegativity, implying that both types of organisms can have similar flocculation properties. Flocculation has facilitated easy biomass harvesting in several microalgae studies (de Godos et al. 2011; Lei et al. 2015; Li et al. 2018a). Bioflocculants are more favoured than chemical flocculants because of their degradability and environmentally friendly characteristics (Awolusi et al. 2020). Their production from low-cost, readily available, and biodegradable materials like starch and crustacean shells and from several non-pathogenic organisms like Bacillus subtilis enhances the practicability of large-scale application.

Microbial-based flocculants have been extensively explored for algae studies and have shown promising results. The EPS-producing microbes are efficiently exploited to promote flocculation by extracting and applying their EPS directly to cultures or co-cultivation with the organisms of interest. An experiment that employed bioflocculant from the marine bacterium Cobetia marina reported a flotation activity of over 90% for C. vulgaris upon applying 20 mg/L bioflocculant and 5 mM CaCl2 in the reactor (Lei et al. 2015). The gram-negative bacteria Citrobacter freundii has also been reported to produce bioflocculant using acetate as a carbon source efficiently. Organics like fumarate, citrate and malate were shown to have a negative impact on bioflocculant production (Kimura et al. 2014). Other microalgae studies have reported high flocculation efficiencies by co-cultivating microalgae with other green algae species like Tetraselmis suecica, Ankistrodesmus falcatus and Scenedesmus obliquus (Salim et al. 2011). Furthermore, fungal organisms have also been reported to induce bioflocculation in algal systems (Muradov et al. 2015). In one study, their utilization was reported to enhance the aggregation of microalgae and increased the overall biomass and lipid yields (Muradov et al. 2015). Another study that co-cultured Mucor circinelloides with Chlorella pyrenoidosa (1:250) with 1.25 g/L of glucose reported a harvest efficiency of around 91% (Qiong et al. 2017). Moreover, a flocculation efficiency of over 99% was obtained when pellets of Aspergillus niger were inoculated in the microalgal culture (Pei et al. 2021). However, in the case of SCP biomass production, co-cultivation with flocculation-inducing organisms is only feasible with non-pathogenic microbes. In cases where non-axenic cultures are used and PNSB is enriched under their natural niche growing conditions, co-culture is unlikely to be viable, and dosing previously extracted EPS bioflocculants from suitable organisms is more favourable.

Biological flocculants of plant and animal origins have also been highly efficient in inducing flocculation. Commonly explored flocculants like chitosan and cationic starch are polymers with a net positive charge. Thus, their prominent mechanism of action is via charge neutralization, polymer bridging, and adsorption (Kurniawan et al. 2020). A study that incorporated both a biosurfactant (saponin) and bioflocculant (chitosan) into a microalgae culture reported a flocculation efficiency of over 93% (Kurniawati et al. 2014). Other flocculants like cationic starch, Moringa oleifera, clearing nut, and tannin have also been utilized (Abdul Hamid et al. 2014; Abdul Razack et al. 2015; Bracharz et al. 2018; Wang et al. 2020). The dosage and flocculation efficiency of these compounds depend on a wide range of factors like the pH of the culture, the net negative charge of the cells, settling time, stirring speed, temperature, and biomass concentration. A direct comparison of operational cost per m3 under similar conditions revealed that the utilization of alum for palm oil mill effluent treatment costs 19 USD compared to 1–1.25 USD when utilizing chitosan, verifying significant cost savings can be achieved by employing bioflocculants that would be suitable for SCP purposes (Kurniawan et al. 2020). For PNSB application, extensive experimentation is required to determine the optimal culture conditions required to drive high flocculation efficiency. Table 3 provides data about three classes of bioflocculants used for microalgae studies and their varying degrees of efficiency.

5 Environmental and economic perspectives of PNSB-based SCP production

The use of SCP as a protein supplement for aquaculture feed has the potential to be both environmentally and economically beneficial. Soybean, the conventional protein source for animal feed and a common component of aquaculture feed, has been reported to be quite inefficient, as it burdens available water, land, and other material resources (LaTurner et al. 2020). For instance, it has been estimated that for each unit of nitrogen utilized for crop farming processes, around 59% is attributed to environmental losses through runoff and volatilization (Matassa et al. 2015; LaTurner et al. 2020). A net nitrogen efficiency of just 16% has also been reported, with the losses primarily attributed to plant farming which included additional processes like leaching and denitrification (Matassa et al. 2015). The utilization of phototrophic bacteria in upcycling nitrogen in organic wastewater through direct assimilation to feed has been reported to significantly reduce the extensive nitrogen losses associated with the conventional treatment and plant farming application processes (Matassa et al. 2015; Alloul et al. 2019). The release of the greenhouse gas N2O is also curbed in the process since it is completely anaerobic. Furthermore, a study that compared the human and environmental impact of producing PNSB-based microbial protein (from potato wastewater in an outdoor tubular photobioreactor) to soybean meal using life cycle assessment revealed that PNSB-based SCP had a lesser impact. The endpoint health impact (disability-adjusted life years or DALY) and endpoint ecosystems impact (species per year) of microbial protein production were lower than soybean meal production by 52% and 75%, respectively (Spiller et al. 2020). At midpoint, the human health (climate change, particulate matter formation, and human toxicity) and ecosystems (natural land transformation, agricultural land occupation, and climate change) impact of soybean meal was greater than that of PNSB SCP by over 50%. Still, PNSB SCP production had a much higher fossil depletion (79%) compared to soybean meal. The heavy energy demand was attributed to the electricity required for the production phase and downstream processes like biomass harvesting and drying. Culturing PNSB in open race ponds for production, using renewable energy sources, and using settling tanks to harvest some biomass will go a long way in reducing energy demands (Spiller et al. 2020).

A different study examined the possible gains derived from using landfill-bound food waste for SCP production. Environmental gains were recorded when PNSB-derived SCP offset soybean meal production instead of the waste being treated via landfilling or anaerobic digestion (LaTurner et al. 2020). Gains were specifically derived from impacts associated with eutrophication and land and water use. However, no economic gains were achieved in this case due to the low cost of soybean. Global warming-associated gains were dependent on the electricity requirement of the SCP production process. Processes that employed natural light or a hybrid of both natural and artificial light significantly reduced the global warming potential of the PNSB production process compared to the soymeal production process. When solely SCP production was considered, the process was not economical. Economic gains were only achieved when the carotenoid-rich SCP fishmeal offset regular fishmeal. The SCP production process was economically beneficial when converted to fishmeal, while the reverse was estimated with soybean meal. A net gain of 0.041 USD per kg of treated food waste was derived, while a loss of 0.21 USD per kg of treated food waste was obtained when offsetting soybean meal. The scenario where high-value carotenoid-rich SCP fishmeal was derived from the process was also reported to be more profitable than anaerobic digestion and landfilling due to the inexpensive nature of biogas (LaTurner et al. 2020). Carotenoid content is an essential constituent of fish feed, as it maintains the integrity of some aquatic organisms' immune systems and enhances their fertility (Koller et al. 2014; Panis and Carreon 2016).

Lighting is a key component influencing the economics of the photoheterotrophic culturing of PNSB. An experimental survey that examined PNSB production from brewery wastewater reported that the overall PNSB production cost could reduce from around 10 EUR per kg dry weight to around 9 EUR per kg of dry weight if sunlight were used for the process. Artificial light energy accounted for between 13 and 28% of the operational expenditure (Alloul et al. 2019). The possibility of utilizing natural light for PNSB production has been reported in a past study using R. palustris (Carlozzi et al. 2006). A recent study also reported a high biomass yield that cultivated PNSB in brewery wastewater outdoors using a plexiglass cylindrical bioreactor (Lu et al. 2019a).

Operational lighting mode can also strongly affect the overall economics. Although not with PNSB, a study exploring microalgae biomass production reported that the optimal production process utilizes a natural light and darkness cycle, with biomass harvested at the late exponential phase. In the scenario with continuous light, the cultivation phase accounted for 57% of the major equipment expenditure, out of which 55% was attributed to lighting investment costs. The cultivation phase also accounted for 93% of major utility expenditure, out of which 90% was attributed to lighting. However, when natural light/dark cycles were used, the harvest and dehydration phase accounted for 53% of the major equipment expenditure. In comparison, the cultivation phase accounted for 55% of the major utility expenditure (with 81% of the cost attributed to CO2 usage) (Sui et al. 2020). Compared with artificial light, the lower cost has been associated with microalgae biomass production in raceway ponds. However, demerits like large environmental footprints, increased risk of contamination, and evaporation losses are factors that need to be considered (Capson-Tojo et al. 2020). A critical trade-off that needs to be considered for SCP production processes is whether artificial lighting will significantly enhance productivity, increasing overall profit. However, even though this could be economically favourable, fossil fuel-derived electricity production processes would eventually lead to increased environmental damage (Sui et al. 2020). When artificial lighting is required, LED lights are recommended due to their relatively lower energy cost and ability to provide only the necessary wavelengths. LEDs were also associated with significantly higher biomass productivity when compared with other light sources (Capson-Tojo et al. 2020).

Economic gains are also achieved when PNSB production is incorporated with conventional wastewater treatment. The incorporation of PNSB production in the brewery wastewater treatment relieved the treatment cost by 29,000–68,000 EUR/year due to the COD concentration removed by the process (Alloul et al. 2019). According to Lu et al. (2019a), recovery of SCP, polysaccharides, carotenoids, bacteriochlorophyll and coenzyme Q10 from China’s brewery, beverage and tea manufacturing process wastewater could generate an income close to 400 million USD/year. Another study examined the economic benefits of recovering SCP via the solid fermentation of orange residue from a local industry with a waste output of 100 t/d. They estimated a yearly profit of 48,500 USD. Meanwhile, the routine disposal methods cost the industry over 7,500 USD (Zhou et al. 2019).

6 Overcoming health and safety concerns with PNSB-based SCP

As earlier stated, there are several health and safety concerns about SCP from microbial sources. These include concerns about nucleic acid content, pathogenic microbes, and feedstock toxicants like heavy metals and polycyclic aromatic hydrocarbons. Overcoming safety concerns could be quite delicate as food/feed regulations vary between countries and regions, so the extent of difficulties faced in overcoming safety regulations will differ based on the local perspective. Thus, this section of the paper examines possible ways to overcome this bottleneck. Beforehand, it is important to note that overcoming the hurdles of safety and regulatory concerns is feasible as there are a number of established SCP industries (such as Earthrise, Lallemand Inc, Unibo, Calysta, and Alltech Inc). In fact, recent data reveals that the global SCP market value (for animal feed, food and beverages, dietary supplements, pharmaceuticals, and cosmetics) was around 115 billion USD in 2021 and is expected to be over 194 billion USD in 2027 (MMR 2021). However, to our knowledge, none of the established companies produces PNSB-derived SCP.

6.1 Nucleic acid concerns

In cases when biomass nucleic acid content is beyond permissible limits, a pre-treatment phase can be included downstream to regulate this. Some of the methods identified in literature are heat shock, sodium chloride treatment, alkaline treatment, and alcoholic mineral acid treatment (Akin and Chao 1971; Hedenskog and Ebbinghaus 1972; Yang et al. 1979; Alvarez and Enriquez 1988; Abou-Zeid et al. 1995).

6.2 Microbial pathogenicity concerns

Safety concerns related to microbial pathogenicity are usually overcome by utilizing biomass from axenic cultures. Most established microbial-based SCP companies utilize a microbial strain consistently tested to be safe under optimized culturing conditions (Ritala et al. 2017). However, with recent considerations of PNSB-based SCP production from mixed cultures, microbial pathogenicity screening will need to be performed at a much higher frequency, possibly at the end of each batch. Microbial competency is determined by screening for toxic genes and ensuring all microbes detected are classified as biosafety level 1 microorganisms (Groenewald et al. 2014).

6.3 Concerns about feedstock toxicant

Safety concerns about feedstock toxicants accumulation in microbial biomass are commonly addressed by using benign feedstock. For example, the established and globally marketed Quorn mycoprotein is produced using a glucose-ammonia-biotin-mineral salts medium (Trinci 1992), while current bacteria-based SCP companies like Unibo and Calysta use methylotrophs (Calysta 2022; Unibio 2022). However, with PNSB’s proposed integration into wastewater treatment, only benign organic-rich wastewater can be considered. This would prove difficult as agro-industrial wastewaters are often contaminated with toxicants like heavy metals. However, a recent study reported the possibility of utilizing fuel synthesis process water for PNSB-based SCP recovery. The industrial wastewater and PNSB biomass were characterized to be void of harmful heavy metals (Wada et al. 2022). Hence, wastewaters considered for resource recovery of SCP should be free of toxins like heavy metals, pathogenic microbes, and organics.

6.4 Safety regulations

Overcoming food safety regulations is probably the greatest hurdle faced by SCP establishments. Before Quron mycoprotein received approval for sales for human consumption in 1980, the parent company had been through a 10-year evaluation which included trials with 11 animal species and 2,500 human volunteers (Trinci 1992). However, with the pressing need to reduce the burden on scarce environmental resources and manage environmental degradation, food regulatory agencies are tasked to encourage the production of alternate protein, broadly classified as “novel food”. To this end, a few countries/regions (including Singapore, Japan, Australia, New Zealand, China, India, Thailand, United States of America, the European Union, Israel, United Kingdom, Canada, and Brazil) have made notable progress in developing regulatory frameworks (GFI-APAC 2022). A common theme across all regulations is the ensure consumer safety is guaranteed. However, there are diverse alternate protein sources, so there is no singular approach to conducting safety assessments. Hence, companies are advised to implement “effective testing strategies based on their understanding of the hazards that may be present in their novel food” using internationally validated methodologies (Singapore Food Agency 2022).

Therefore, before approaching regulation agencies, it is suggested that PNSB-based SCP recovered from wastewater should undergo the following assessments: wastewater characterization (which must include heavy metal, metagenomics, and organic screening), microbial culture assays (which must consist of metagenomics, genotoxicity, and endotoxicity), and PNSB biomass characterization (heavy metal screening, organics screening, and toxicity screening via in vitro assays and animal models).

7 Challenges and outlook

-

1.

High energy demands associated with artificial lighting.v Photobioreactors guarantee optimal biomass productivity but also come with significant energy demands. This has adverse economic and environmental implications on the sustainability of the process. Potential solutions that should be explored are the usage of optimal use of natural light, including enhanced light distribution devices and reactor designs; as well as energy-efficient light sources combined with renewable energy sources.

-

2.

High energy demands associated with biomass harvesting and drying. The difficulty in biomass harvesting is attributed to PNSB’s low density. Environmentally friendly harvesting techniques like bioflocculation need to be explored. Future research also needs to examine ways of subsidising the energy burden associated with biomass drying.

-

3.

Risk assessment. Extensive risk assessment studies need to be conducted to verify the safety of PNSB-based SCP, particularly those produced from waste streams. Assessments like heavy metal analysis, animal toxicity assessments, genotoxicity and mutagenicity studies need to be conducted based on substrate. Subsequent research can also consider comprehensive toxicity studies that would allay public concerns about the feed’s safety.

-

4.

Public perception about consuming bacteria and products from waste streams. The social acceptance of bacteria and wastewater-based SCP is still unclear. As arduous efforts are being put into optimizing largescale SCP production, the public perception of potential end-users needs to be gauged and properly managed. Subsequent studies need to examine this social aspect.

-

5.

Policy regulation challenges. In order for innovative green solutions to thrive, they need to be backed by local and international policies. Provision of incentives, infrastructural support, public sector support, and access to funds are necessary for the success of such novel ventures. Extensive reviews on the current state of local and international policies with respect to green technologies in the animal feed sector are required as these currently limit development.

-

6.

Competition with mainstream alternatives. Competition of PNSB-based SCP feeds with mainstream soybean feed and fishmeal mostly hinges on our ability to overcome the challenges outlined earlier successfully. For example, policies that back environmentally cleaner alternatives would need to be promoted and enforced. A key means of achieving this will be by providing comprehensive life cycle assessment and life cycle costing data comparing optimal production of PNSB-based SCP and mainstream processes.

8 Conclusion

The use of PNSB for SCP production holds great promise in offsetting the pressure on animal and plant protein sources for feed production. PNSB-based SCP has proven to be of high quality as it contains an amino acid profile comparable to mainstream protein sources like soybean, relatively low nucleic acid content, and various other valuable macromolecules like lipids and carbohydrates and biomolecules including carotenoids, coenzyme Q10, and 5-aminolevulinic acid. Such properties have led to very promising outcomes in aquaculture and poultry testing. Moreover, the process is highly suited to integration with wastewater treatment for combined pollution management and resource recovery. PNSB’s unique metabolism and versatility allow easy enrichment under anaerobic/microaerobic-illuminated conditions in a wide array of wastewater sources.

References

Abdul Hamid SH, Lananan F, Din WNS et al (2014) Harvesting microalgae, Chlorella sp. by bio-flocculation of Moringa oleifera seed derivatives from aquaculture wastewater phytoremediation. Int Biodeterior Biodegrad 95:270–275. https://doi.org/10.1016/j.ibiod.2014.06.021

Abdul Razack S, Duraiarasan S, Santhalin Shellomith AS, Muralikrishnan K (2015) Statistical optimization of harvesting Chlorella vulgaris using a novel bio-source, Strychnos potatorum. Biotechnol Rep 7:150–156. https://doi.org/10.1016/j.btre.2015.06.006

Abou-Zeid A-ZA, Khan JA, Abulnaja KO (1995) On methods for reduction of nucleic acids content in a single-cell protein from gas oil. Bioresour Technol 52:21–24. https://doi.org/10.1016/0960-8524(95)99782-Q

Ahmad AL, Mat Yasin NH, Derek CJC, Lim JK (2011) Optimization of microalgae coagulation process using chitosan. Chem Eng J 173:879–882. https://doi.org/10.1016/j.cej.2011.07.070

Akin C, Chao K (1971) Process for reducing the nucleic acid content of single cell protein affording microorganisms

Al-Azad S, Soon TK, Ransangan J (2013) Effects of light intensities and photoperiods on growth and proteolytic activity in purple non-sulfur marine bacterium, Afifella marina strain ME (KC205142). Adv Biosci Biotechnol 04:919–924. https://doi.org/10.4236/abb.2013.410120

Alloul A, Wuyts S, Lebeer S, Vlaeminck SE (2019) Volatile fatty acids impacting phototrophic growth kinetics of purple bacteria: paving the way for protein production on fermented wastewater. Water Res 152:138–147. https://doi.org/10.1016/j.watres.2018.12.025

Alloul A, Cerruti M, Adamczyk D et al (2021a) Operational strategies to selectively produce purple bacteria for microbial protein in raceway reactors. Environ Sci Technol 55:8278–8286. https://doi.org/10.1021/acs.est.0c08204

Alloul A, Muys M, Hertoghs N et al (2021b) Cocultivating aerobic heterotrophs and purple bacteria for microbial protein in sequential photo- and chemotrophic reactors. Bioresour Technol 319:124192. https://doi.org/10.1016/j.biortech.2020.124192

Alloul R et al (2021c) Purple bacteria as added-value protein ingredient in shrimp feed: Penaeus vannamei growth performance, and tolerance against Vibrio and ammonia stress. Aquaculture 530:735788. https://doi.org/10.1016/j.aquaculture.2020.735788

Alvarez R, Enriquez A (1988) Nucleic acid reduction in yeast. Appl Microbiol Biotechnol 29:208–210. https://doi.org/10.1007/BF01982903

Anupama A, Ravindra P (2000) Value-added food. Biotechnol Adv 18:459–479. https://doi.org/10.1016/S0734-9750(00)00045-8

Awolusi OO, Ademakinwa AN, Ojo A et al (2020) Marine actinobacteria bioflocculant: a storehouse of unique biotechnological resources for wastewater treatment and other applications. Appl Sci 10:7671. https://doi.org/10.3390/app10217671

Banerjee S, Azad SA, Vikineswary S et al (2000) Phototrophic bacteria as fish feed supplement. Asian-Australas J Anim Sci 13:991–994. https://doi.org/10.5713/ajas.2000.991

Becker PM (2002) Single cell proteins in diets for weanling pigs. Animal Sciences Group-Nutrition & Food

Boze H, Moulin G, Galzy P (2008) Production of microbial biomass. In: Biotechnology. Wiley, Germany, pp 166–220

Bracharz F, Helmdach D, Aschenbrenner I et al (2018) Harvest of the oleaginous microalgae Scenedesmus obtusiusculus by flocculation from culture based on natural water sources. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2018.00200

Bratosin BC, Darjan S, Vodnar DC (2021) Single cell protein: a potential substitute in human and animal nutrition. Sustainability 13:9284. https://doi.org/10.3390/su13169284

Bridson E, Brecker A (1970) Design and formulation of microbiological culture media. In: Ribbons JR, Norris DW (eds) Methods in microbiology, 1st edn, vol 3A. Academic Press, London, p 504

Calysta (2022) Circular cellular agriculture. https://calysta.com/our-process/. Accessed 1 Aug 2022

Capson-Tojo G, Batstone DJ, Grassino M et al (2020) Purple phototrophic bacteria for resource recovery: challenges and opportunities. Biotechnol Adv 43:107567. https://doi.org/10.1016/j.biotechadv.2020.107567

Capson-Tojo G, Batstone DJ, Grassino M, Hülsen T (2022) Light attenuation in enriched purple phototrophic bacteria cultures: implications for modelling and reactor design. Water Res 219:118572. https://doi.org/10.1016/j.watres.2022.118572

Carlberg H, Cheng K, Lundh T, Brännäs E (2015) Using self-selection to evaluate the acceptance of a new diet formulation by farmed fish. Appl Anim Behav Sci 171:226–232. https://doi.org/10.1016/j.applanim.2015.08.016

Carlberg H, Lundh T, Cheng K et al (2018) In search for protein sources: evaluating an alternative to the traditional fish feed for Arctic charr (Salvelinus alpinus L.). Aquaculture 486:253–260. https://doi.org/10.1016/j.aquaculture.2017.12.027

Carlozzi P, Pushparaj B, Degl’Innocenti A, Capperucci A (2006) Growth characteristics of Rhodopseudomonas palustris cultured outdoors, in an underwater tubular photobioreactor, and investigation on photosynthetic efficiency. Appl Microbiol Biotechnol 73:789–795. https://doi.org/10.1007/s00253-006-0550-z

Castrillo M, Lucas-Salas LM, Rodríguez-Gil C, Martínez D (2013) High pH-induced flocculation–sedimentation and effect of supernatant reuse on growth rate and lipid productivity of Scenedesmus obliquus and Chlorella vulgaris. Bioresour Technol 128:324–329. https://doi.org/10.1016/j.biortech.2012.10.114

Cerruti M, Stevens B, Ebrahimi S et al (2020) Enrichment and aggregation of purple non-sulfur bacteria in a mixed-culture sequencing-batch photobioreactor for biological nutrient removal from wastewater. Front Bioeng Biotechnol 8:557234. https://doi.org/10.3389/fbioe.2020.557234

Cerruti M (2022) Harnessing the metabolic versatility of purple non-sulfur bacteria. Thesis, Delft University of Technology

Chen J, Wei J, Ma C et al (2020) Photosynthetic bacteria-based technology is a potential alternative to meet sustainable wastewater treatment requirement? Environ Int 137:105417. https://doi.org/10.1016/j.envint.2019.105417

Chitapornpan S, Chiemchaisri C, Chiemchaisri W et al (2013) Organic carbon recovery and photosynthetic bacteria population in an anaerobic membrane photo-bioreactor treating food processing wastewater. Bioresour Technol 141:65–74. https://doi.org/10.1016/j.biortech.2013.02.048

Chowdhury Z, Khan AJ et al (2016) Phototrophic purple bacteria as feed supplement on the growth, feed utilization and body compositions of Malaysian mahseer, Tor tambroides juveniles. Sains Malays 45:135–140

Christenson LB, Sims RC (2012) Rotating algal biofilm reactor and spool harvester for wastewater treatment with biofuels by-products. Biotechnol Bioeng 109:1674–1684. https://doi.org/10.1002/bit.24451

Chumpol S, Kantachote D, Rattanachuay P et al (2017) In vitro and in vivo selection of probiotic purple nonsulphur bacteria with an ability to inhibit shrimp pathogens: acute hepatopancreatic necrosis disease-causing Vibrio parahaemolyticus and other vibrios. Aquac Res 48:3182–3197. https://doi.org/10.1111/are.13149

Chumpol S, Kantachote D, Nitoda T, Kanzaki H (2018) Administration of purple nonsulfur bacteria as single cell protein by mixing with shrimp feed to enhance growth, immune response and survival in white shrimp (Litopenaeus vannamei) cultivation. Aquaculture 489:85–95. https://doi.org/10.1016/j.aquaculture.2018.02.009

Colbeau A, Kelley BC, Vignais PM (1980) Hydrogenase activity in Rhodopseudomonas capsulata: relationship with nitrogenase activity. J Bacteriol 144:141–148. https://doi.org/10.1128/JB.144.1.141-148.1980

Costa JAV, de Morais MG (2014) An open pond system for microalgal cultivation. In: Biofuels from algae. Elsevier, pp 1–22

de Godos I, Guzman HO, Soto R et al (2011) Coagulation/flocculation-based removal of algal–bacterial biomass from piggery wastewater treatment. Bioresour Technol 102:923–927. https://doi.org/10.1016/j.biortech.2010.09.036

Delamare-Deboutteville J, Batstone DJ, Kawasaki M et al (2019) Mixed culture purple phototrophic bacteria is an effective fishmeal replacement in aquaculture. Water Res X 4:100031. https://doi.org/10.1016/j.wroa.2019.100031

Derbyshire E, Ayoob K-T (2019) Mycoprotein. Nutr Today 54:7–15. https://doi.org/10.1097/NT.0000000000000316

Ercan D, Demirci A (2015) Current and future trends for biofilm reactors for fermentation processes. Crit Rev Biotechnol 35:1–14. https://doi.org/10.3109/07388551.2013.793170

Finnigan T, Needham L, Abbott C (2017) Mycoprotein. In: Sustainable protein sources. Elsevier, pp 305–325

García-Garibay M, Gómez-Ruiz L, Cruz-Guerrero AE, Bárzana E (2014) Single cell protein: yeasts and bacteria. In: Encyclopedia of food microbiology. Elsevier, pp 431–438

George DM, Vincent AS, Mackey HR (2020) An overview of anoxygenic phototrophic bacteria and their applications in environmental biotechnology for sustainable resource recovery. Biotechnol Rep 28:e00563. https://doi.org/10.1016/j.btre.2020.e00563

Germec M, Demirci A, Turhan I (2020) Biofilm reactors for value-added products production: an in-depth review. Biocatal Agric Biotechnol 27:101662. https://doi.org/10.1016/j.bcab.2020.101662

GFI-APAC (2022) Novel food regulations around the world. https://gfi-apac.org/novel-food-regulations-around-the-world/. Accessed 1 Aug 2022

Glencross BD, Huyben D, Schrama JW (2020) The application of single-cell ingredients in aquaculture feeds—a review. Fishes 5:22. https://doi.org/10.3390/fishes5030022

Goldberg I (1985) Single cell protein. Springer, Berlin

Gorissen SHM, Crombag JJR, Senden JMG et al (2018) Protein content and amino acid composition of commercially available plant-based protein isolates. Amino Acids 50:1685–1695. https://doi.org/10.1007/s00726-018-2640-5

Groenewald M, Boekhout T, Neuvéglise C et al (2014) Yarrowia lipolytica safety assessment of an oleaginous yeast with a great industrial potential. Crit Rev Microbiol 40:187–206. https://doi.org/10.3109/1040841X.2013.770386

Hedenskog G, Ebbinghaus L (1972) Reduction of the nucleic acid content of single-cell protein concentrates. Biotechnol Bioeng 14:447–457. https://doi.org/10.1002/bit.260140313

Honda R, Fukushi K, Yamamoto K (2006) Optimization of wastewater feeding for single-cell protein production in an anaerobic wastewater treatment process utilizing purple non-sulfur bacteria in mixed culture condition. J Biotechnol 125:565–573. https://doi.org/10.1016/j.jbiotec.2006.03.022

Huang YuT, Kinsella JE (1986) Functional properties of phosphorylated yeast protein: solubility, water-holding capacity, and viscosity. J Agric Food Chem 34:670–674. https://doi.org/10.1021/jf00070a020

Hülsen T, Batstone DJ, Keller J (2014) Phototrophic bacteria for nutrient recovery from domestic wastewater. Water Res 50:18–26. https://doi.org/10.1016/j.watres.2013.10.051

Hülsen et al (2016a) Low temperature treatment of domestic wastewater by purple phototrophic bacteria: Performance, activity, and community. Water Res 100:537–545. https://doi.org/10.1016/j.watres.2016.05.054

Hülsen T, Barry EM, Lu Y et al (2016b) Domestic wastewater treatment with purple phototrophic bacteria using a novel continuous photo anaerobic membrane bioreactor. Water Res 100:486–495. https://doi.org/10.1016/j.watres.2016.04.061

Hülsen R et al (2018a) Simultaneous treatment and single cell protein production from agri-industrial wastewaters using purple phototrophic bacteria or microalgae—a comparison. Bioresour Technol 254:214–223. https://doi.org/10.1016/j.biortech.2018.01.032

Hülsen T, Hsieh K, Tait S et al (2018b) White and infrared light continuous photobioreactors for resource recovery from poultry processing wastewater—a comparison. Water Res 144:665–676. https://doi.org/10.1016/j.watres.2018.07.040

Hülsen T, Sander EM, Jensen PD, Batstone DJ (2020) Application of purple phototrophic bacteria in a biofilm photobioreactor for single cell protein production: biofilm vs suspended growth. Water Res 181:115909. https://doi.org/10.1016/j.watres.2020.115909

Hülsen T, Stegman S, Batstone DJ, Capson-Tojo G (2022) Naturally illuminated photobioreactors for resource recovery from piggery and chicken-processing wastewaters utilising purple phototrophic bacteria. Water Res 214:118194. https://doi.org/10.1016/j.watres.2022.118194

Igwegbe CA, Ighalo JO, Onukwuli OD et al (2021) Coagulation-flocculation of aquaculture wastewater using green coagulant from Garcinia kola seeds: parametric studies. Kinet Model Cost Anal Sustain 13:9177. https://doi.org/10.3390/su13169177

Imafidon GI, Sosulski FW (1990) Nucleic acid nitrogen of animal and plant foods. J Agric Food Chem 38:118–120. https://doi.org/10.1021/jf00091a024

Izu K, Nakajima F, Yamamoto K, Kurisu F (2001) Aeration conditions affecting growth of purple nonsulfur bacteria in an organic wastewater treatment process. Syst Appl Microbiol 24:294–302. https://doi.org/10.1078/0723-2020-00027

Jach ME, Serefko A, Ziaja M, Kieliszek M (2022) Yeast protein as an easily accessible food source. Metabolites. https://doi.org/10.3390/metabo12010063

Janssen M, Wijffels RH, Barbosa MJ (2022) Microalgae based production of single-cell protein. Curr Opin Biotechnol 75:102705. https://doi.org/10.1016/j.copbio.2022.102705

Jones KA, Friedman S et al (2020) Recent advances in single cell protein use as a feed ingredient in aquaculture. Curr Opin Biotechnol 61:189–197. https://doi.org/10.1016/j.copbio.2019.12.026

Kantachote D, Torpee S, Umsakul K (2005) The potential use of anoxygenic phototrophic bacteria for treating latex rubber sheet wastewater. Electron J Biotechnol 8:314–323. https://doi.org/10.2225/vol8-issue3-fulltext-8

Kaplan D (2013) Absorption and adsorption of heavy metals by microalgae. In: Handbook of microalgal culture. Wiley, Oxford, pp 602–611

Kapoore RV, Padmaperuma G, Maneein S, Vaidyanathan S (2022) Co-culturing microbial consortia: approaches for applications in biomanufacturing and bioprocessing. Crit Rev Biotechnol 42:46–72. https://doi.org/10.1080/07388551.2021.1921691

Kilby B (1979) The photosynthetic bacteria. Biochem Educ 7:73. https://doi.org/10.1016/0307-4412(79)90054-2

Kim JK, Lee B-K (2000) Mass production of Rhodopseudomonas palustris as diet for aquaculture. Aquac Eng 23:281–293. https://doi.org/10.1016/S0144-8609(00)00057-1

Kimura K, Inoue T, Nagayama N et al (2014) Effects of organic acids and amino acids on the flocculation activity of chitosan-like bioflocculant-producing Citrobacter freundii IFO 13545. Jpn J Water Treat Biol 50:23–31. https://doi.org/10.2521/jswtb.50.23

Kinsella JE, German B, Shetty J (1985) Uricase from fish liver: Isolation and some properties. Comp Biochem Physiol B Comp Biochem 82:621–624. https://doi.org/10.1016/0305-0491(85)90498-5

Kissinger G, Herold M, de Sy V (2012) Drivers of deforestation and forest degradation: a synthesis report for REDD+ policymakers. Vancouver

Kobayashi M, Kurata S (1978) Mass culture and cell utilization of photosynthetic bacteria. Process Biochem 13:27–30

Koga A, Goto M, Hayashi S et al (2022a) Probiotic effects of a marine purple non-sulfur bacterium, Rhodovulum sulfidophilum KKMI01, on kuruma shrimp (Marsupenaeus japonicus). Microorganisms 10:244. https://doi.org/10.3390/microorganisms10020244