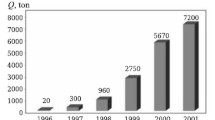

The main stages of development in the USSR and Russian Federation of technology and production of quartz steel-pouring refractories are considered. In the 1970s-1990s the main manufacturer of these refractories was the Podol’sk Refractory Products Plant (PRPP), and in the last 25 years it is the Pervouralsk Dinas Plant (PDZ, now OAO Dinur). This plant has developed and implemented technology for producing highly concentrated HCBS based on fused quartz produced by itself as a matrix system of ceramic concrete self-spreading mixes. A fundamentally new molding method has been implemented with their use, i.e., centrifugal casting in metal molds. The resulting products with a ceramic concrete structure have reduced porosity (up to 10 – 13 %) and increased service life. For some types of cast steels their durability is no worse than similar corundum-graphite products. Over the entire production period about 90 thousand tons of these refractories have been produced that at current prices is about 14 billion rubles of marketable products. Currently OAO Dinur is not only a monopoly manufacturer of quartz refractories in the Russian Federation, but also for over 30 years the only manufacturer of large quartz casings of furnace rollers for heat treating special grades of sheet steel. Development of quartz ceramic and refractory technology predetermines the birth of a new type of promising ceramic binders, i.e., HCBS as the basis for CFRC-ceramic concretes. Using this technology a whole series of oxide, silicate ceramic, and refractory materials has been created.

Similar content being viewed by others

References

Yu. E. Pivinskii and E. I. Suzdal’tsev (editor Yu. E. Pivinskii), Quartz Ceramic and Refractories. Vol. II. Material, Their Properties and Fields of Application [in Russian] Teploenergetik, Moscow (2008).

Yu. E. Pivinskii and F. T. Gorobets, “High-density fused-silica ceramics,” Refractories, 9(7/8), 509 – 516 (1968).

Yu. E. Pivinskii and A. G. Romashin, Quartz Ceramic [in Russian], Metallurgiya, Moscow (1974).

Yu. E. Pivinskii and E. I. Suzdal’tsev (editor Yu. E. Pivinskii), Quartz Ceramic and Refractories. Vol. I. Theoretical Bases of Production Processes [in Russian] Teploenergetik, Moscow (2008).

N. M. Frolovskii, M. G. Chigrinov, Yu. E. Pivinskii, et al., “Service of graphite-alumina and sense silica dispenser inserts during steel continuous casting,” Ogneupory, No. 10, 19 – 23 (1971).

K. A. Krasotin, D. A. Min’kov, T. S. Makarova, et al., “Quartz nozzle production,” Ogneupory, No. 11, 7 – 10 (1973).

D. I. Garshin, V. I. gromov, V. V. Kolomeitsev, et al., “Nozzle production from transparent quartz glass for CBCM,” Ogneupory, No. 9, 6 – 9 (1978).

Yu. E. Pivinskii, Quartz Ceramic HCBS and Ceramic Concretes. History of Technology Creation and Development [in Russian], Politekhnika-Print, St. Petersburg (2018).

E. M. Grishpun and Yu. E. Pivinskii, “Twenty year epoch of cooperation,” Novye Ogneupory, No. 1, 15 – 25 (2007).

E. M. Grishpun and Yu. E. Pivinskii, “HCBS and ceramic concretes – breakthrough in refractory technology of the 21st century,” Novye Ogneupory, No. 2, 28 – 33 (2020).

Yu. E. Pivinskii, “Half a century development of the domestic quartz ceramics industry. Part 2,” Refract. Ind. Ceram., 58(4), 357 – 363 (2017).

Yu. E. Pivinskii, “Half a century development of the domestic quartz ceramics industry. Part. 3,” Refract. Ind. Ceram., 58(5), 507 – 513 (2018).

Yu. E. Pivinskii, Ceramic and Refractory materials: sel. works, Vol. 2 [in Russian], Stroiizdat, St. Petersburg (2003).

Yu. E. Pivinskii, Rheology of Dispersed Systems, HCBS and Ceramic Concretes. Elements of Nanotechnology in Silicate Materials Science; in 3 vol. [in Russian], Politekhnika, St. Petersburg (2012).

Yu. E. Pivinskii, T. I. Litovskaya, O. N. Samarina, et al., “Centrifugal casting of ceramics. Main parameters and regularities of the process,” Refractories, 32(11), 551 – 558 (1991).

Yu. E. Pivinskii, T. I. Litovskaya, O. N. Samarina, and F. S. Kaplan, “Centrifugal casting of ceramics and properties of the castings,” Refractories. 33(3), 138 – 143 (1992).

Yu. E. Pivinskii, T. I. Litovskaya, O. N. Samarina, et al., “Development, introduction and service of unfired quartz refractories,” Refractories, 30(9), 572 – 578 (1989).

E. V. Rozhkov, Yu. E. Pivinskii, V. I. Khabarova, et al., “High-durability submerged fused silica nozzles for continuous steel casting machines: Design, fabrication and service,” Refract. Ind. Ceram., 38(11), 467 – 470 (1997).

Yu. E. Pivinskii, A. M. Gorokhovsky, and A. V. Makarov, “Record-breaking durability of quartz protecting tubes for steel teeming tested under service conditions,” Refract. Ind. Ceram., 46(1), 27, 28 (2005).

Yu. E. Pivinskii, E. M. Grishpun, and A. M. Gorokhovskii, “Engineering, manufacturing, and servicing of shaped and highly concentrated ceramic binding suspensions,” Refract. Ind. Ceram., 56(3), 245 – 253 (2015).

Yu. E. Pivinskii and P. V. Dyakin, “Research in the area of preparing materials based on fused quartz HCBS. Part 1. Comparative evaluation and distinguishing features of quartz ceramic and refractory,” Refract. Ind. Ceram., 58(4), 311 – 317 (2014).

Yu. E. Pivinskii, “Research in the area of preparing materials based on fused quartz HCBS. Part 2. Quartz steel-pouring refractories,” Refract. Ind. Ceram., 56(1), 20 – 25 (2015).

Yu. E. Pivinskii, “Research in the area of preparing materials based on fused quartz HCBS. Part 3. Study and improvement of centrifugal casting,” Refract. Ind. Ceram., 56(2), 126 – 135 (2015).

P. P. Budnikov and Yu. E. Pivinskii, “Quartz ceramics,” Russian Chemical Reviews, 36(3), 210 – 227 (1967).

Yu. E. Pivinskii and F. T. Gorobets, “Some features of slip casting quartz glass ceramics,” Glass and Ceramics, 25(5), 285 – 290 (1968).

Yu. E. Pivinskii, “Increase in powder particle layering density during molding a ceramic semiproduct,” Steklo Keramika, No. 9, 25 – 29 (1969).

M. Yu. Rusin, “From an engineering task to cone development for export,” Nauka Proizvodstvu, No. 22, 14 – 16 (1999).

A. G. Romashin, E. I. Suzdal’tsev, and M. Yu. Rusin, “Scientific and practical aspects of preparing large complexly-shaped quartz ceramic objects,” Novye Ogneupory, No. 9, 34 – 40 (2004).

Yu. E. Pivinskii, “Fundamentals of the technology of ceramoconcrete,” Refractories, 19(1/2), 102 – 107 (1978).

P. L. Mityakin and Yu. E. Pivinskii, “Properties of quartz-ceramic concrete,” Refractories, 21(9/10), 501 – 505 (1980).

Yu. E. Pivinskii, Ceramic Binders and Ceramic Concretes [in Russian] Metallurgiya, Moscow (1990).

Yu. E. Pivinskii, “HCBS ceramic concretes in the XXI century — problems and prospects for applying technology in the field of silicate materials science. Part.1,” Refract. Ind. Ceram., 52(2), 107 – 116 (2011).

Yu. E. Pivinskii, “Cement-free refractory concretes. Part 1. General information. HCBS and ceramic concretes,” Refract. Ind. Ceram., 60(5), 430 – 438 (2020).

Yu. E. Pivinskii, P. V. Dyakin, E. M. Grishpun, and A. M. Gorokhovsky, “Cement-free refractory concretes. Part 2. High-alumina and corundum ceramic concretes,” Refract. Ind. Ceram., 60(6), 566 – 573 (2020).

Yu. E. Pivinskii, “Cement-free refractory concretes. Part 3. Very fine forms of silica as effective refractory concrete components,” Refract. Ind. Ceram., 61(7), 31 – 39 (2020).

E. M. Grishpun, Yu. E. Pivinskii, and E. V. Rozhkov, “Production process and service of quartz steel-casting refractories. Part 1. Features of the process,” Refract. Ind. Ceram., 40(3/4), 170 – 173 (1999).

E. M. Grishpun, Yu. E. Pivinskii, and E. V. Rozhkov, “Production process and service of quartz steel-casting refractories. Part 2. Some properties and special features of service,” Refract. Ind. Ceram., 40(5/6), 264 – 268 (1999).

Yu. E. Pivinskii, “Nanodispersed silica and same aspects nanotechnologies in the field of silicate science. Part 3,” Refract. Ind. Ceram., 49(1), 38 – 49 (2008).

Yu. E. Pivinskii, P. V. Dyakin, A. D. Buravov, et al., “Research in the area of preparing materials based on fused quartz HCBS. Part 11. Tests for implementing new unfired quartz refractory technology,” Refract. Ind. Ceram., 57(4), 373 – 37 (2016).

Yu. E. Pivinskii, P. V. Dyakin, and A. Yu. Kolobov, “Research in the area of preparing materials based on fused quartz HCBS. Part 10. Some properties of cristobalite-containing materials,” Refract. Ind. Ceram., 57(3), 252 – 257 (2016).

Yu. E. Pivinskii, Theoretical Aspects of Ceramic and Refractory Technology [in Russian], Stroiizdat, St. Petersburg (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No.10, pp. 14 – 24, September, 2021.

Continuation. Parts 1 – 10 of the article published in Novye Ogneupory Nos. 9 and 11 (2019), Nos. 1, 3, 7 and 9 (2020), and Nos. 1, 5, 6, 8 and 9 (2021)

Rights and permissions

About this article

Cite this article

Pivinskii, Y.E., Grishpun, E.M. & Gorokhovskii, A.M. Cement-Free Refractory Concretes. Part 12-1. Siliceous Composition HCBS and Ceramic Concretes. Refract Ind Ceram 62, 526–534 (2022). https://doi.org/10.1007/s11148-022-00637-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-022-00637-5