Conclusions

Using HCBS of fused quartz, we studied and analyzed the main regularities of the centrifugal casting process of ceramic products.

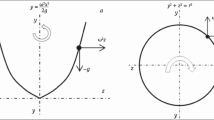

The procedure for calculating the magnitude of the centrifugal pressure during the molding process and a nomogram establishing the relationship between the rotational frequency of the mold, the diameter of the product being molded, and the circumferential velocity of centrifugal forming were presented. Based on the integral curves of grain size distribution of the castings, the degree of layering in their solid phase was characterized.

The volume fraction of HCBS, the circumferential velocity and the temperature maintained during the molding process, and the coefficient of excess solid phase form the most important and decisive technological parameters of the process of centrifugal forming.

The method of centrifugal casting makes it possible to accelerate the molding process by several tens of times as compared to slip casting. In this case, the porosity of the castings amounts to 12–20%.

Similar content being viewed by others

Literature cited

Yu. E. Pivinskii and A. G. Romashin, Quartz Ceramics [in Russian], Metallurgiya, Moscow (1974).

A. Majdic and G. Rontschka, Keram. Zeitschr.,38, No. 9, 495–503 (1986).

Yu. E. Pivinskii, N. G. Kotova, and F. S. Kaplan, Ogneupory, No. 6, 14–19 (1986).

Yu. E. Pivinskii, Ceramic Binders and Ceramic Concretes (Keramobetons) [in Russian], Metallurgiya, Moscow (1990).

Yu. E. Pivinskii, T. I. Litovskaya, O. N. Samarina, et al., Ogneupory, No. 9, 40–44 (1989).

I. N. Akhverdov, Centrifugally Cast Ferro-Concrete Force Pipes [in Russian], Stroiizdat, Moscow (1967).

I. N. Akhverdov, Physical Principles of Concrete [in Russian], Stroiizdat, Moscow (1981).

S. B. Yudin, M. M. Levin, and S. E. Rozenfel'd, Centrifugal Casting [in Russian], Mashinostroenie, Moscow (1972).

Yu. E. Pivinskii, Ogneupory, No. 9, 18–24 (1987).

R. Ya. Popil'skii and Yu. E. Pivinskii, Compaction of Particulate Ceramic Bodies [in Russian], Metallurgiya, Moscow (1983).

Yu. E. Pivinskii, S. G. Semikova, F. S. Kaplan, et al., Ogneupory, No. 5, 11–16 (1989).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 11, pp. 2–6, November, 1991.

Rights and permissions

About this article

Cite this article

Pivinskii, Y.E., Litovskaya, T.I., Samarina, O.N. et al. Centrifugal casting of ceramics. Main parameters and the regularities of the process. Refractories 32, 551–558 (1991). https://doi.org/10.1007/BF01280846

Issue Date:

DOI: https://doi.org/10.1007/BF01280846