Abstract

Two novel ternary and binary mono-oxovanadium(IV) complexes of acetylacetonate (ac) and 1,3-dipyridin-2-yl-urea are synthesized, as VO(acac)(L) (1:1) and VO(L)2 (1:2). They are characterized by various physico-chemical spectroscopic tools. The formation constants Kf are calculated from the spectrophotometric measurements. The catalytic potential of VO(acac)(L) and VO(L)2 has been examined in the (ep)oxidation of alkenes (cis-cyclooctene and 1-octene) by an aqueous hydrogen peroxide, H2O2, and tert-butyl hydroperoxide, TBHP. The effects of temperature, solvent and oxidant/alkene molar ratio are studied in order to get the optimized reaction conditions. Most of the catalytic (ep)oxidation products of cis-cyclooctene and 1-octene are determined qualitatively and quantitatively using gas chromatographic analysis. The increase of the catalyst amount to double time reduces the (ep)oxidation process time with improvement of the amount of the chemoselective epoxy product.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Oxovanadium complexes are very important class of high valent 3d transition metal complexes which attracted attention in therapeutic and medicinal immense [1], as anti-cancers [2], anti-diabetes [3] and speciation in human serum [4]. High progressed applicability of oxovanadium complexes is in the (ep)oxidation of organic substrates [5, 6]. They are high effective and selective catalysts for many homogeneous and heterogeneous oxidation processes of unsaturated hydrocarbons [7,8,9]. Indeed, vanadium ion features various oxidation states, especially accessible high oxidation states, i.e. oxovanadium(IV), with different coordination modes and a high affinity for oxygen, sulfur and nitrogen donation have been reported [10, 11].

The coordination chemical behavior of 1,3-dipyridin-2-yl-urea, and their derivatives with various first row of transition metals is of interest due to the presence of O,N-donor atoms [12] and/or participation in intramolecular hydrogen-bonding interactions [13, 14]. Kyriakidou et al. [15], studied the coordination behavior of 1,3-dipyridylurea with Ni2+ ion in molar ratios 1(metal):3 (ligand), whereas, Tiliakos et al. [16] reported the complexation of Ni2+ with 1,3-dipyridylurea was 1:2 with coordination of two nitrate ions to Ni2+ ion in the molecular structure. Furthermore, their possible behavior as polydentate deprotonated ligands also lead to dianionic ligands and forming polynuclear complexes as observed previously in the complexation of ruthenium with 1,3-dipyridylurea [12].

Therefore, due to the aforementioned importance and in continuation of our work [11], two novel VO-complexes of VO2+ ions with 1,3-dipyridin-2-yl-urea are synthesized and characterized. Additionally, their catalytic potential is examined in the (ep)oxidation of cis-cyclooctene and 1-octene by either an aqueous H2O2 or TBHP as terminal oxidants under various reaction conditions to establish their catalytic potentials and the optimized catalytic conditions.

Experimental

Instruments and reagents

All required reagents and materials are purchased from Sigma-Aldrich and Fluka, which directly used without any further purifications or treatment. Elemental analyses (C, H and N) were achieved with a GMBH VarioEl model V2.3 CHNS machine. Electronic spectra were measured using 10 mm silica cells in the thermostatted cell holder of a Jasco UV–Vis spectrophotometer (model V-570). Infrared spectra (as KBr discs) were recorded in the region of 4000–400 cm−1 using Shimadzu FTIR-8101 Fourier transform infrared spectrophotometer. Conductivity measurements were carried out using a Jenway conductivity meter model 4320, with an epoxy bodied conductivity cell (two electrodes, shiny) with cell constant calibration from 0.01 to 19.99 at 25 °C. Magnetic susceptibility of the studied complexes were measured on Gouy’s balance, the diamagnetic correction were made by Pascal’s contents and Hg[Co(SCN)4] as a calibrant. All experimental reactions were taken place with magnetic stirring and held at chosen temperatures using a thermostated oil bath.

Synthesis of 1,3-dipyridin-2-yl-urea, HL

1,3-Di-pyridin-2-yl-urea (HL) was synthesized according to the reported method with some modifications [15]. To a cooled solution (in ice-acetone bath) of nicotinic acid (0.12 g, 1.0 mmol) and anhydrous triethylamine (0.13 mL, 1.0 mmol) in absolute THF (20 mL) anhydrous ethylchloroformate (0.10 mL, 1.0 mmol) was added dropwise with stirring. Then, a cold solution of 2-aminopyridine (0.18 g, 2.0 mmol) in absolute THF (10 mL) was added and the solution was stirred at room temperature for 3 h. The reaction mixture was evaporated under vacuum. The solid residue was extracted with dichloromethane and a solution of 5% Na2CO3 was added under vigorous stirring. The organic phase was separated and dried over Na2SO4. The obtained residue after evaporation was recrystallized from ethanol to give the desired product as off white crystals in yield 60% (1HNMR, 13CNMR and dept-135, and mass spectra of HL are in Supplementary Information).

Synthesis of oxovanadium complexes

Synthesis of oxovanadium acetylacetonate 1,3-dipyridin-2-yl-urea complex, VO(acac)(L)

A methanolic solution (10 mL) of 1,3-dipyridin-2-yl-urea (0.21 g, 1.0 mmol) was added very slowly dropwisely to vanadyl acetylacetonate (0.26 g, 1.0 mmol) in methanol (10 mL) in ice bath with stirring. No change in color (blue) was observed after mixing. The resulted solution was heated at 60 °C for 6 h. The color of the solution changed gradually to pale green with no formation of any precipitate. After cooling, solvent was removed in vacuum and the residual washed further by cold methanol and diethyl ether and dried in vacuum. The pure complex was recrystallized from hot methanol to award 0.26 g (70%) yield of pale greenish brown powder.

Synthesis of oxovanadium bis-1,3-dipyridin-2-yl-urea complex, VO(L) 2

A methanolic solution (10 mL) of vanadyl acetylacetonate (0.26 g, 1.0 mmol) was added dropwise to a methanolic mixture (20 mL) of 1,3-dipyridin-2-yl-urea (0.46 g, 2.0 mmol) and KOH (0.11 g, 2 mmol) at room temperature with noticed no change in color (blue) after mixing. Then, the reaction mixture was refluxed with stirring at 80 °C for 2 h affording changing in color to green with no formation of any precipitate. The solvent was removed in vacuum and the residual was washed with cold methanol, water and diethyl ether. The obtained complex was recrystallized from hot methanol yielding 0.41 g (78%) of green powder.

Catalytic procedures

The catalytic oxidation of alkene (1.0 mmol, cis-cyclooctene or 1-octene) initiated by charging either 30% an aqueous H2O2 (3.0 mmol) or 70% in water of TBHP (1.5 mmol), as the oxygen source, using VO-complexes as catalysts (0.01 mmol) in 10 mL of acetonitrile or other organic solvent (chloroform, acetone, DMF or carbon tetrachloride), at various temperatures (45, 70 and 85 °C) in an oil bath under magnetic stirring for 16 h in an homogenous aerobic atmosphere. The catalytic processes were controlled by withdrawing samples (ca. 1 mL) at different time intervals during the catalytic process. Collected samples were treated with solid MnO2 (ca. 20 mg) to quench the excess amounts an aqueous H2O2 or TBHP and with anhydrous sodium sulfate (ca. 20 mg), under the same conditions for each catalytic run. The resulting slurry was filtered on Celite, and the filtrate was diluted by acetonitrile (1:3) mixed in vortex and then 1 µL of the sample was injected in the GC–MS.

The products of the catalytic processes were monitored and analyzed by Shimadzu gas chromatograph mass spectrometer (GC–MS) model QP2010 SE equipped with Rxi-5 Sil MS capillary column (30 m length × 0.25 mm ID × 025 um film thickness). The analysis was performed using the gas chromatography parameters as follow: injector temperature, 250 °C; initial oven temperature, 40 °C (held for 1 min), increased to 200 °C at a rate of 10 °C min−1. The total time required for one GC run was 17 min. The inlet was operated in the splitless mode. The MS transfer line was held at 200 °C. The carrier gas is high-purity helium with a flow rate 1 mL min−1. LabSolution software was used to control the system and to acquire the analytical data. Peaks identification were made by comparing the mass spectra of detected compounds with NIST mass spectral library.

Results and discussion

Synthesis and characterization of the oxovanadium complexes

The synthesis of the VO-complexes carried out by the reaction of 1,3-dipyridin-2-yl-urea (HL) with vanadyl acetylacetonate, VO(acac)2 in molar ratios 1:1 to afford VO(acac)(L) and 2:1 giving VO(L)2. They are soluble in DMSO and DMF. VO(acac)(L) is partial soluble in polar solvents, e.g. methanol, ethanol and acetone, whereas, VO(L)2 is insoluble in polar or less polar organic solvents, e.g. methanol, acetone, chloroform and dichloromethane. The pH stability range of VO-complexes solutions (1.0 × 10−3 mol dm−3 in DMSO) is in the region from pH ~ 4.2 to 9.4 using standard universal buffer solutions. They are unstable in strong basic and acidic media in which their color decays gradually. VO-complexes decompose at high temperatures (> 300 °C) as recorded in Table 1.

The characteristic values of the VO-complexes are compared with those of the corresponding reported for complexes of 1,3-dipyridin-2-yl-thiourea [11] in order to confirm the coordination mode between VO2+ ion and HL ligand. The elemental microanalysis data of the VO-complexes are in good agreement (± 0.4%) with their tentative molecular structures (Table 1). HL ligand in VO-complexes is acting as a chelating monobasic ligand in a monomeric structure with square pyramidal coordination geometry of the bis-binary complex, VO(L)2, and in the ternary complex, VO(acac)(L), as shown in Scheme 1.

The UV–Visible absorption spectra of HL and its corresponding VO-complexes are scanned at the wavelength range 700–200 nm at 25 °C (Fig. 1). The maximum absorption wavelengths (λmax) and the calculated molar absorptivity (ε) are given in Table 1. An intense band in the range at 248 and 232 nm are assigned to a π → π* transition originate in the aromatic moiety in VO(acac)(L) and VO(L)2, respectively. This band has been shifted in HL (251 nm) due to the effect of the presence of central metal ion due to the complexation. Additionally, an intense band at 275 and 277 nm for VO(acac)(L) and VO(L)2, respectively, is attributable for the n → π* transitions without any observable shift for that band in the free ligand HL (278 nm). A broad band shown at 409 and 400 nm for VO(acac)(L) and VO(L)2, respectively, could be attributed to the charge transfer from HL to VO2+ ion (Table 1). L → MCT transition might arise due to a charge transfer from a negative charge on oxygen of the deprotonated isomer of HL [16] to the empty 3d (dπ orbitals) of the vanadium ion (Fig. 1) [17].

The infrared spectral analysis of the studied complexes is presented in Table 2. HL exhibited significant bands diagnostic characteristic of the broad vibrations of the two N–H bonds (\(\bar{\nu }_{{{\text{N}}{-}{\text{H}}}}\)) at 3224 cm−1. This band is associated with that characteristic band in VO-complexes with little shifted towards the higher frequency (3259 and 3363 cm−1 in VO(acac)(L) and VO(L)2, respectively). Similarly, the N-pyridyl vibrational (\(\bar{\nu }_{\text{py}}\)) band has a remarkably shifted after the complexation from 1558 and 547 to 1602 and 624 cm−1 in VO(acac)(L) and to 1625 and 678 cm−1 in VO(L)2, respectively [11]. These corresponded shifts suggest coordination of the oxygen atom of the azomethine group of HL and the nitrogen atom of the N-pyridine ring to the VO2+ ion (Table 2). The carbonyl group was confirmed by presence of strong sharp bands at 1684 for HL and at 1699 cm−1 for VO(acac)(L), respectively. The C=O in VO(acac)(L) is corresponded to the coordinated acetylacetonate anion. On the other hand, the disappeared stretching vibrational band of C=O of the coordinated HL in VO(L)2 is due to the coordination of the O-atom of the carbonyl group with appearance of a new band at 1673 cm−1 characteristic for the azomethine group (C=N). The same behavior was noticed took place in coordination of HL to VO2+ ion in VO(acac)(L) with appearance of a new band at 1651 cm−1 [11]. IR spectra exhibit a new band \(\bar{\nu }_{{({\text{V}} = {\text{O}})}}\) at 987 or 879 cm−1 due to the presence of the V=O group and another new band \(\bar{\nu }_{{({\text{V}}{-}{\text{N}})}}\) at 516 or 504 cm−1 in VO(acac)(L) and VO(L)2, respectively (Scheme 1). Those stretching vibrational frequencies are well matched with the previously reported values of other oxido-vanadium(IV) complexes [2, 17]. The remarked difference between the two \(\bar{\nu }_{{({\text{V}} = {\text{O}})}}\) bands is probably due to the difference electron density or electronic nature of the two coordinated ligands (acac and HL) in VO(acac)(L) and VO(L)2. The high electron-withdrawing ligand (HL) reduces stretching vibrational band of V=O in VO(L)2 much more that in VO(acac)(L). This phenomenon could be observed also in the \(\bar{\nu }_{{({\text{V}}{-}{\text{N}})}}\) bands.

The conductivity measurements carried out in DMSO and DMF for VO(acac)(L) and VO(L)2 at [complex] = 1 × 10−4 mol dm−3 and 25 °C awarding very low conducting magnitudes as gathered in Table 3. The results demonstrate that VO(acac)(L) and VO(L)2 have non-electrolytic characters. Hence, the general formula of VO(acac)(L) and VO(L)2 were suggested that acetylacetonate (acac) and 1,3-dipyridin-2-yl-urea (HL) ligands act as monobasic bidentate ligands to form non-electrolytic complexes, as shown in Scheme 1.

Magnetic susceptibility measurements of VO(acac)(L) and VO(L)2, are measured and presented in Table 3. The results showed that, both VO(acac)(L) and VO(L)2 as binary and ternary complexes with highly spin and para-magnetic in a square pyramidal geometrical structures gave 1.24 and 1.76 B.M. values, respectively [18]. Therefore, based on these results and other previously reported literature [11], two points might be concluded: firstly, the vanadium ions in the VO-complexes have no ability for interaction. Secondly, the VO-complexes with the square pyramidal structures are closed system which greatly affects their solubility behavior. The molecular ion (M + 1) peak of all VO-complexes is shown in Figs. S1 and S2 (Supplementary Information). The relevant results confirmed that obtained and expected values of mass spectra matched appreciably indicating the mononuclearity of the VO-complexes without any interaction between VO2+ ions.

Determination of thermodynamic parameters of the oxovanadium complexes

The stoichiometry of the VO-complexes was estimated particularly by spectrophotometric continuous variation methods [19]. The spectral data confirm that the molar ratios of metal, VO2+, to ligand (HL) in VO(L)2 is 1:2, and is 1:1 in VO(acac)(L) as documented in Fig. S3 (Supplementary Information). The formation constants Kf of VO(acac)(L) and VO(L)2, are calculated by using Eq. 1 which derived from the continuous variation method:

where Ax is the absorbance at the complete formation of the VO-complex according to the continuous variation plot (Fig. S3), A is the absorbance of the complex at the despotic recognized concentration C of metal ion, VO2+. The calculated values (Table 4), showed that, all the prepared complexes exhibited high thermal stability characters [11].

The Kf values for the studied complexes considerably reflect the decrease of substitution reaction of HL with one of acetylacetonate ion (acac) in VO(acac)(L) or with two ions of ac in VO(L)2. The Kf values in Table 4 indicating that VO(L)2 is more stable than VO(acac)(L).

The thermodynamic parameters of the VO-complexes formation could be calculated from the determined equilibrium formation constant at different temperatures. The Gibbs–Helmholtz equation, via using Eq. 2, which could be applied to determine ∆fH and ∆fS from the slope and intercept, respectively, of the linear plotting relationship of ln Kf values as function of 1/T (Fig. 2). The calculated thermodynamic parameters are gathered in Table 4.

The negative values of ∆fG reflect that, the formation of the current VO-complexes under all the studied conditions is spontaneous process. As ∆fH is positive, this refers to, the complex formation was endothermic reaction, and the metal–ligand bonds are much stronger, especially for VO(L)2 [11]. Therefore, from the thermodynamic point of view and, the thermodynamic data indicating that, VO(acac)(L) is more reactive than VO(L)2 (Fig. 3).

Catalytic studies

Catalytic (ep)oxidation of cis-cyclooctene and 1-octene

Mononuclear oxo-vanadium complexes are well known catalysts for various oxidation processes with moderate to high selectivity. Oxovanadium complexes are high effective catalysts for (ep)oxidation of alkenes [20], specifically cis-cyclooctene and 1-octene by an aqueous H2O2 or TBHP in various reaction conditions [5, 21, 22]. Particularly, the chemoselective and target product of cis-cyclooctene (ep)oxidation is epoxy-1,2-cyclooctane in high scale with contamination of other side products. Epoxy-1,2-octane is the target product of the 1-octene (ep)oxidation, which is also contaminated with other unwanted products. To the best of our knowledge, it is so far in literatures to explore all possible catalytic (ep)oxidation products of cis-cyclooctene [23] and 1-octene [11] qualitatively and quantitatively. So, the most advantage here is to report the ratios of the most possible products of the cis-cyclooctene or 1-octene (ep)oxidation using an aqueous H2O2 or TBHP catalyzed by VO(acac)(L) or VO(L)2 in various reaction conditions. Consequently, all possible molecular structure of the (ep)oxidation products of cis-cyclooctene and 1-octene, as representative unsaturated alkanes, using either an aqueous H2O2 or TBHP catalyzed by VO(acac)(L) or VO(L)2 at various reaction conditions are considerably identified and determined qualitatively and quantitatively by GC–MS. They are summarized and presented in Tables 5, 6 and 7. There was no observable conversion of cis-cyclooctene or 1,2-octene in absence of the current VO-complex catalysts.

The conversion and chemoselectivity of the alkene (ep)oxidation to the epoxy-product mainly depends on, the type of catalyst, type of oxidant, and the reaction conditions from solvents and temperature [8, 10]. Therefore, there are five unexpected side products have been identified for the (ep)oxidation of cis-cyclooctene namely: 4-cyclooctene-1-one (2), 2-cyclooctene-1-one (4), 2-hydroxy-cyclooctanone (5), cyclooctane-1,2-diol (6), and cyclooctanone (7) (Scheme 2, Tables 5 and 6) [24]. However, another 5 side products have been identified for (ep)oxidation of 1-octene namely: 7-octen-2-one (2′), 2-octenal (4′), 1-octanoic acid (5′), 1,2-octanediol (6′) and octanal (7′) (Scheme 3, Table 7). Some of those products are unexpected and not reported elsewhere. The conversion and chemoselectivity depend upon the ratio epoxy product in the catalytic process [8], they proceeded by the type of catalysts, type of oxidant and the catalytic reaction conditions [10].

By definition of the other formed side products at the end of each catalytic process at 45, 70 or 85 °C (Table 5), it is highly notable that the formed epoxide 3 experienced further oxidation to give 5, which underwent nucleophilic ring opening of 3 with aqueous hydrolysis forming 6 and 7 (Fig. 4) [23]. From Scheme 2, the amount of 5 and 6 depends upon the type of oxidant. Using an aqueous H2O2, ratios of 5 and 6 are high, while with TBHP, their amount ratios were reduced remarkably (Tables 5, 6). The presence of water with the molecular H2O2 could probably causes aqueous hydrolysis and so improves the production of both 2-hydroxy-cyclooctanone (5) and cyclooctane-1,2-diol (6) (nucleophilic ring opening reaction) in the catalytic process compared to that process with TBHP [25, 26]. This suggestion could be acceptable due to the absence of any amount of 5 as a side product using TBHP after 16 h at 45 °C (Table 6). GC–MS analyses detected two unexpected (ep)oxidation products which are 4-cyclooctene-1-one (2) and 2-cyclooctene-1-one (4). Carbon atoms C-3 or/and -8 and C-5 or/and -6 to the C=C group in cis-cyclooctene molecule are high reactive to be incorporated in the oxidation reaction by either H2O2 or TBHP with observable amounts of 2 and 4 especially at high temperature (85 °C) catalyzed by VO(acac)(L) or VO(L)2 (Table 5). Such work is similarly reported for the oxidation of cyclohexene previously by Maurya et al. [27] and Lashanizadegan et al. [28].

The catalytic (ep)oxidation of 1-octene is quite reactive with low regio- and chemoselecitivity compared to that redox process of cis-cyclooctene [5, 29, 30]. VO(acac)(L) and VO(L)2 have high catalytic potential for the (ep)oxidation of 1-octene using either an aqueous H2O2 or TBHP, in acetonitrile at low temperature (45 °C) after 16 h. The catalytic process products are shown in Scheme 3 and are listed with various ratios in Table 7. However, VO(acac)(L) and VO(L)2 show high quite high regio- and chemoselectivity for the (ep)oxidation of cis-cyclooctene, they have low regio- and chemoselective control for the same process of 1-octene. These results agree with the obtained previously by us of VO-complexes of 1,3-dipyridin-2-yl-thiourea and cumarin [11]. The further oxidation of 3′ is similar to that of 3 to give 5 which involved for further nucleophilic ring opening to afford 5′, which followed by aqueous hydrolysis of 5′ to give 6′ and 7′ (Scheme 3).

Effect of various reaction parameters, e.g. temperatures (45, 70 and 85 °C), type/ratio of catalyst (VO(acac)(L) or VO(L)2), solvent and type of oxidant (an aqueous H2O2 or TBHP) were studied to obtain the optimized (ep)oxidation reaction conditions of cis-cyclooctene in order to realize the highest amount of the target product, i.e. epoxy-product. Tables 5 and 6 show that VO(acac)(L) and VO(L)2 are effective catalysts and have high control chemoselectivity in the (ep)oxidation process (Scheme 2).

Effect of temperature in the cis-cyclooctene (ep)oxidation reaction

The catalytic processes initiated by injection of cis-cyclooctene (1.0 mmol) with either of VO(acac)(L) or VO(L)2 (0.01 mmol), as the catalyst, and an aqueous H2O2 (3.0 mmol) or TBHP (1.5 mmol), as the oxidant, at different reaction temperatures (45, 70 or 85 °C) in acetonitrile (10 mL). VO(acac)(L) and VO(L)2 exhibit moderate to excellent catalytic control and chemoselectivity for the conversion of cis-cyclooctene, as shown in Tables 5 and 6.

At low temperature, 45 °C, the conversion and chemoselectivity of cis-cyclooctene to epoxy target product catalyzed by either VO(acac)(L) or VO(L)2 was low even after long time (16 h), as observed in Table 6. After 16 h, the control chemoselectivity with both catalyst complexes to the target product was moderate at 70 °C and good at the highest reaction temperature (85 °C) compared to that at 45 °C.

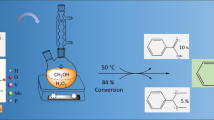

At 70 °C, the conversion was improved remarkably with VO(acac)(L) (84.68 and 91.52% using either H2O2 or TBHP, respectively) to afford good percentage of the chemoselective product (49.09 and 74.38% using either H2O2 or TBHP, respectively). With VO(L)2, the conversion was excellent (84.68 and 91.52% using either H2O2 or TBHP, respectively) with moderate to low amount of chemoselective product depending upon the type of oxidant (45.57 and 20.88% using either H2O2 or TBHP, respectively). The highest effective catalytic potentials VO(acac)(L) and VO(L)2 catalysts could be observed at 85 °C (~ boiling point of acetonitrile) after 16 h. The uncontrol conversion was excellent with VO(acac)(L) (98.96 and 98.92% using either H2O2 or TBHP, respectively) and the chemoselectivity was also remarkably excellent to afford epoxy-1,2-cyclooctane (69.95 and 84.08% using either H2O2 or TBHP, respectively) (Table 5). On the other hand, the conversion was good to excellent with VO(L)2 (94.50 and 79.28% using either H2O2 or TBHP, respectively) and the chemoselectivity was good (70.03 and 49.49% using either H2O2 or TBHP, respectively) (Table 5).

In particular, the effect of temperature is high effective parameter for determination of the optimized catalytic reaction condition of the (ep)oxidation of cis-cyclooctene using either an aqueous H2O2 or TBHP catalyzed by VO(acac)(L) or VO(L)2 (Fig. 3). So, the optimized reaction temperature for the (ep)oxidation of cis-cyclooctene catalyzed by either VO(acac)(L) or VO(L)2 using an aqueous H2O2 or TBHP is 85 °C for 16 h. It could be observed from the chromatograph that the intensities of cis-cyclooctene peaks are dramatically decreased, while the intensities of epoxy, 1,2-cyclooctene peaks are increased by prolongation of the oxidation time from 1 to 16 h. These observations are true for the (ep)oxidation of cis-cyclooctene catalyzed by either VO(acac)(L) using an aqueous H2O2 (Fig. 3a) and TBHP (Fig. 3b), or VO(L)2 using an aqueous H2O2 (Fig. 3c) and TBHP (Fig. 3d).

The percentages of the other side products, as listed in Table 5, are low in both VO(acac)(L) and VO(L)2, 29.01 or 24.47% using H2O2 and 14.84 or 29.79%, using TBHP, respectively. The ratios of the side products are also depending upon the reaction temperatures which increased by increasing the temperature.

In significant, the catalytic process could be performed by increasing the reaction temperature depending upon the catalyst solubility and hydrolytic stability which resulted from the thermodynamic parameters (Table 4, Fig. 2). The solubility and hydrolytic stability of the VO-catalysts could be an effective parameter in the performance of the catalytic process [20]. At low temperature (45 °C), VO(acac)(L) or VO(L)2 have low catalytic potential using an aqueous H2O2 or TBHP. This could refer to the heterogeneous nature and less reactivity of the catalyst, as observed experimentally and in previous studies for MoIVO2-dihydrazone catalysts [31]. At high temperature (85 °C), both VO-complexes are highly dissolved and more hydrolytic reactive in the reaction media and so both exhibit high catalytic activity for the (ep)oxidation of cis-cyclooctene, homogeneously. Conclusively, the optimized catalytic conditions are obtained at 85 °C after 16 h with 0.01 mmol of VO(acac)(L) and VO(L)2.

Effect of type of catalysts and catalyst/substrate ratios

Table 8 shows the effect of the catalyst amount ratio to the substrate (0.01:1, 0.05:1 and 0.10:1) in the proceeding of the catalytic (ep)oxidation. It is observed that the increase of the catalyst ratio reduces the (ep)oxidation time of cis-cyclooctene at 85 °C from 16 h (optimum reaction conditions) using 0.01 mmol to 4 h using 0.05 mmol and to ~ 1.5 h using 0.1 mmol of either VO(acac)(L) or VO(L)2 with remarkable improvement in the amount of the chemoselective product.

The electronic and steric effects [32,33,34] of the coordinated ligands and their substituents to VO2+ ion have subtle influence on the catalytic potential of the VO-complex catalyst [8]. It seems that the coordinated ligands acac or HL has a remarkable effect on the catalytic potential of VO(acac)(L) and VO(L)2, sterically and electronically, as observed in previous work by our group [21]. Both effects could be remarked in the electrophilic character of the central VO2+ ion by the attach of the nucleophiles, i.e. H2O2 or TBHP to the central metal ion [30], especially after formation of the active VO+ intermediate (I) see the mechanistic pathway.

Electronically, however, the coordination of VO2+ ion to one HL ligand through N- and O-atoms and with two O-atoms of acetylacetonate anion (acac), in VO(acac)(L) could probably form more reactive due to the high reactivity of the acetylacetonate group (acac), than its chelating to the two HL ligands, VO(L)2, as observed for vanadyl complexes by Rayati et al. [32] and by Maurya et al. [33]. Sterically, the more steric ligands decrease the catalytic activity of the catalyst [8], hence, the steric effect is remarked in VO(L)2 compared to VO(acac)(L). Consequently, VO(acac)(L) is more reactive and sufficient catalyst than VO(L)2 in such redox process, Table 8. This also could be elucidated by the thermodynamic parameters and formation constants (Table 4 and Fig. 2), VO(L)2 is little less stable than VO(acac)(L). The electronic and steric effects [32,33,34] could be remarked in the catalytic potentials of the VO-complexes by the electron transfer to the central metal ion and the oxygen transfer step in the catalytic processes (mechanistic pathway [30]).

Effect of solvents and type of oxidants

The catalytic potential of oxovanadium complexes has been remarkably influenced by the nature of the solvent on (ep)oxidation processes, as reported recently [35,36,37,38]. The effect of different organic solvents in nature, i.e. acetone, dichloromethane, chloroform and DMF (N,N′-dimethylformamide), on the (ep)oxidation of cis-cyclooctene by either an aqueous H2O2 or TBHP catalyzed by VO(acac)(L) and VO(L)2 was investigated and summarized in Table 9. Under the optimized reaction conditions, chloroform, acetone, DMF (N,N′-dimethylformamide) or carbon tetrachloride was subjected to cis-cyclooctene and an aqueous H2O2 (3.0 mmol) or TBHP. The results in Table 9 illustrate that the conversion and control chemoselectivity are high influenced by the nature of solvent. With an aqueous H2O2, acetonitrile is the most effective solvent (70% catalyzed by VO(acac)(L) or VO(L)2), whereas, with TBHP, carbon tetrachloride and chloroform afforded the highest amount of epoxy product (Table 9) (87 and 68% catalyzed by VO(acac)(L) or VO(L)2, respectively). In other solvents (DMF and acetone), the epoxidation yields were low for both oxidants and catalysts.

Although, the high coordination ability of acetonitrile [5, 35, 38, 39], it is still the best solvent for the epoxidation processes due to its high resistant for oxidation. The high dielectric constant of acetonitrile could improve the catalytic potential of H2O2 [22, 31,32,33], this is why acetonitrile is the best solvent for the epoxidation reaction using an aqueous H2O2, as resulted in Table 9.

Oppositely, the most effective solvent for using TBHP as the oxidant is carbon tetrachloride and chloroform as reported previously [11, 35, 38,39,40,41] (Table 9). The inability of carbon tetrachloride and chloroform with low dielectric constant to coordinate to the central metal ion could be the reason to improve the catalytic yield of the epoxidation process.

The mechanistic aspects

Several mechanistic pathways have been proposed for the (ep)oxidation of alkenes catalyzed by oxovanadium complexes with alternative visions [22, 42]. Here we try to summarize the most convenient mechanism of the catalytic (ep)oxidation of alkenes. Despite, V4+=O species are relatively stable toward oxidation, they may be easily oxidized to V5+=O species, as active species [20, 22], in the presence of a suitable oxidant homogeneously and heterogeneously [41]. Therefore, the mechanism of (ep)oxidation catalytic reactions are performed by the type of oxovanadium(IV) complexes [5] and is strongly depending upon the oxidant, e.g. H2O2, via formation of a peroxide intermediate complex with the VO-catalyst, or through coordination of ROO− anion of alkylhydroperoxides ROOH to the central metal ion [26, 42]. The effect of the oxidant on the catalytic potentials of the VO-complexes has been evaluated by monitoring their UV–Vis. spectral changes, cyclic voltammeteries [43] or the electrochemical behavior of VO-catalysts in the catalytic processes [17, 25, 32, 33]. The treatment of either an aqueous H2O2 or TBHP to the VO-complex solution in acetonitrile in presence of cis-cyclooctene causes an observable shift of the characteristic maximum absorption band of the L-MCT band [33] (Fig. 4).

Such shift could be observed from 409 to 388 nm and from 400 to 352 nm for VO(acac)(L) and VO(L)2, respectively. These shifts are accompanied with changing in color from greenish brown to dark yellow and from green to yellow for VO(L)2 and VO(acac)(L), respectively (Figs. 5, 6) without no observable changes in the absorption bands at 248 and 232 nm (π → π*) and 275 and 277 nm (n → π*) of VO(L)2 and VO(acac)(L), respectively (Fig. 4). This change could be due to the oxidation of the central metal ion from V4+=O to V5+=O [42, 43] in agreement with the most previous reported studies [32, 33, 44,45,46] affording V5+ with d0 electronic configuration, i.e. high electrophile. Particularly, the resulted band decays in the (ep)oxidation proceeded by time, as shown in Figs. 5 and 6. Fig. 6 shows an isosbestic point at 419 nm for the pseudo first order reaction.

The first oxidation step in the tentative mechanism (Scheme 4) was suggested by the interaction of peroxo group of the oxidant, H2O2 or TBHP with the V4+=O central metal to give an active V5+=O intermediate complex through an electron transfer [47] from the catalyst to the oxidant (species I), as reported by Monfared et al. [11] and by Maurya et al. [33] This causes an observable shift of the characteristic maximum absorption band of the L-MCT band, as mentioned above, which is followed by an interaction between the active V5+=O intermediate species, as electrophiles. Then, another H2O2 or TBHP molecule to give an oxo-peroxo intermediate complex (species II), as suggested by Rayati et al. [32] and Bisht et al. [33]. The oxo-peroxo intermediate complex (species II) could be formed due to coordination of an oxidant molecule, as a nucleophile (with high electron density on the oxygen atom), to the active V5+=O oxo-peroxo intermediate (species I), as well reported elsewhere [30, 42]. It followed by an approach of the substrate (cis-cyclooctene or 1-octene) to the coordinated oxidant giving a new oxo-peroxo intermediate (species III A) resulted from the interaction of the V5+=O with the coordinated oxidant, V5+=O–H [48], as suggested by Grivani et al. [26, 33, 35] and Rayati et al. [43]. However, with mass spectroscopic detection by Bortolini et al. [42], another proposed pathway for the reactivity of species II was suggested by removal of a water or tert-butyl alcohol (tBuOH) molecule to give a new peroxo intermediate complex (species III B) [30, 49]. The peroxo intermediate species III B could be in an equilibrium with dioxovanadium intermediate complex (III B’) [21, 30, 42]. Both intermediates (III B and III B’) could be formed due to oxygen transfer step [20]. The presence of III B’ could be more acceptable for VO(acac)(L) due to the presence of a high reactive acetylacetonate ligand [20, 50]. The presence of III B could be more acceptable for VO(acac)(L) due to the presence of a high reactive acetylacetonate ligand [20, 50]. This suggestion has been studied by Nunes et al. [41] in the epoxidation of styrene by H2O2. DFT calculations suggest that an intermediate of [VO(H-BIAN)(MeOO)]+ contains active VIV species in two proposed competitive mechanisms. Furthermore, the donor atom electrochemical contribution to redox potentials (DEC) of the Oac (acetylacetonate-enolic oxygen) compared to Npy (pyridine nitrogen) in the square pyramidal vanadyl complexes is an important study to measure the VO-complexes reactivity toward catalytic oxidation processes as reported by Keramidas et al. [51] and by our previous work [52, 53]. This could be a highly acceptable reason for the higher catalytic activity of VO(acac)(L) compared to VO(L)2 in the (ep)oxidation processes of cis-cyclooctene or 1,2-octene homogeneously.

One involves an external attack of the olefin at the coordinated peroxide, and the second involves an inner sphere mechanism by coordination of the olefin to VO2+ ion. This suggested mechanism involves replacement of acetylacetonate ligand by the nucleophilic oxidant, i.e. H2O2 with coordination to the central metal ion. The decay in the intensity of the characteristic maximum absorption band could be resulted from the oxygen transfer [22, 54], i.e. oxygenation, from the species IV to the approached substrate in order to be oxidized forming the chemoselective product (epoxy-1,2-cyclooctane or epoxy-1,2-octane) and other products with regeneration of the active species I (Scheme 4). Finally, the probability for the replacement of the reactive acac ligand by the oxidant molecule could be not supported here as detected elsewhere [33, 54], because the small difference in the reactivity and catalytic sufficiency between VO(acac)(L) and VO(L)2 is not high remarkable.

Conclusion

1,3-Dipyridin-2-yl-urea as a ligand reacts with VO(acac)2 forming two novel ternary and binary mono-oxovanadium(IV) complexes depending upon the ratios of ligand to metal, 1:1 in VO(acac)(L) and 1:2 in VO(L)2. They are characterized by EA, IR and UV–Vis Spectra, conductivity and magnetic measurements. The calculated formation constants Kf from the spectrophotometric measurements show that VO(acac)(L) is less stable than VO(L)2. The catalytic (ep)oxidation of cis-cyclooctene and 1-octene by an aqueous hydrogen peroxide, H2O2, and tert-butyl hydroperoxide, TBHP, as oxygen sources, is studied in the presence of either VO(acac)(L) or VO(L)2, as a homogeneous catalyst, within effects of temperature, solvent and oxidant/alkene molar ratio are studied in order to get the optimized reaction conditions. The chemoselective product of cis-cyclooctene (ep)oxidation is epoxy-1,2-cyclooctane and for 1-octene, the chemoselective product is epoxy-1,2-octane. The side products of the catalytic (ep)oxidation of cis-cyclooctene determined qualitatively and quantitatively by GC-Mass which are 4-cyclooctene-1-one, cyclooctanone, cyclooctane-1,2-diol, 2-cyclooctene-1-one and 2-hydroxy-cyclooctanone, a side products. For 1-octene, the side products are 7-octen-2-one, 2-octenal, 1-octanoic acid, 1,2-octanediol and octanal. The increase of the catalyst amount to double time reduces the (ep)oxidation process time with improvement of the amount of the chemoselective epoxy product. The electronic effect of the coordinated ligands in VO(acac)(L) and VO(L)2 has an impact on their catalytic potentials by the yield of the chemoselective products of the (ep)oxidation of cis-cyclooctene and 1-octene. The type of oxidant, an aqueous H2O2 and TBHP, effects on the amount of the (ep)oxidation yield of the chemoselective products, in which TBHP is more reactive than an aqueous H2O2 due to the aqueous hydrolysis ring opening reaction. The mechanistic pathway is suggested and shows an electron transfer from the oxidant to the catalyst forming an active intermediate of V5+O-species which is detected spectroscopically.

References

Pessoa JC, Etcheverry S, Gambino D (2015) Coord Chem Rev 301–302:24–48

Kioseoglou E, Petanidis S, Gabriel C, Salifoglou A (2015) Coord Chem Rev 301–302:87–105

Willsky GR, Chi L-H, Godzala M, Kostyniak PJ, Smee JJ, Trujillo AM, Alfano JA, Ding W, Hu Z, Crans DC (2011) Coord Chem Rev 255:2258–2269

Jakusch T, Pessoa JC, Kiss T (2011) Coord Chem Rev 255:2218

da Silva JAL, da Silva JJRF, Pombeiro AJL (2011) Coord Chem Rev 255:2232–2248

Pessoa JC (2015) J Inorg Biochem 147:4–24

Pourkhosravani M, Dehghanpour S, Farzaneh F, Sohrabi S (2017) Reac Kinet Mech Cat 122:961–981

Adam MSS, Youssef MM, Aboelghar MF, Hafez AM, El-Ayaan U (2017) Appl Organomet Chem. https://doi.org/10.1002/aoc.3650

Bezaatpour A (2014) Reac Kinet Mech Cat 112:453–465

Back DF, de Oliveira GM, Roman D, Ballin MA, Kober R, Piquini PC (2014) Inorg Chim Acta 412:6–14

Hosseini-Monfared H, Bikas R, Mayer P (2010) Inorg Chim Acta 363:2574–2583

Cabeza JA, del Rio I, Martinez-Mendeza L, Miguel D (2007) J Organomet Chem 692:4407–4410

Barboiu M, van der Lee A (2003) Acta Crystallgr C C59:m366–m368

Meng S, Tang Y, Yin Y, Yin X, Xie J (2013) RSC Adv 3:18115–18127

Kyriakidou F, Panagiotopoulos A, Perlepes SP, Maessi-Zoupa E (1996) Polyhedron 15:1031–1034

Tiliakos M, Cordopatis P, Terzis A, Raptopoulou CP, Perlepes SP, Manessi-Zoupa E (2001) Polyhedron 20:2203–2214

Mandal M, Nagaraju V, Karunakar GV, Sarma B, Borah BJ, Bania KK (2015) J Phys Chem C 119:28854–28870

Thompson KH, Bohmerle K, Polishchuk E, Martins C, Toleikis P, Tse J, Yuen V, McNeill JH, Orvig C (2004) J Inorg Biochem 98:2063–2070

Job P (1928) Ann Chem 9:113–203

Adão P, Pessoa JC, Henriques RT, Kuznetsov ML, Avecilla F, Maurya MR, Kumar U, Correia I (2009) Inorg Chem 48:3542–3561

Sutradhar M, Martins LMDRS, da Silva MFCG, Pombeiro AJL (2015) Coord Chem Rev 301–302:200–239

Licini G, Conte V, Coletti A, Mba M, Zonta C (2001) Coord Chem Rev 255:2345–2357

Santos ICMS, Gamelas JAF, Duarte TAG, Simoes MMQ, Neves MGPMS, Cavaleiro JAS, Cavaeiro AMV (2017) J Mol Catal A 426:593–599

Lal RA, Chakrabarty M, Choudhury S, Ahmed A, Borthakur R, Kumar A (2010) J Coord Chem 63:163–175

Sedighipoor M, Kianfar AH, Mahmood WAK, Azarian MH (2017) Inorg Chim Acta 457:116–121

Schoenfeldt NJ, Ni Z, Korinda AW, Meyer RJ, Notestein JM (2011) J Am Chem Soc 133:18684–18695

Maurya MR, Bisht M, Avecilla F (2011) J Mol Catal A 344:18–27

Lashanizadegan M, Rayati S, Zeinab DD (2011) Chin J Chem 29:2439–2444

Yuan LS, Razali R, Efendi J, Buang NA, Nur H (2013) Appl Catal A 460–461:21–25

Conte V, Coletti A, Floris B, Licini G, Zonta C (2011) Coord Chem Rev 255:2165–2177

Adam MSS (2015) Monatsh Chem 146:1823–1836

Rayati S, Ghaemi A, Sadeghzadeh N (2010) Catal Commun 11:792–796

Bisht MRM, Kumar A, Kuznetsov ML, Avecilla F, Pessoa JC (2011) Dalton Trans 40:6968–6983

Coletti A, Galloni P, Sartorel A, Conte V, Floris B (2012) Catal Today 192:44–55

Grivani G, Tahmasebi V, Khalaji AD, Fejfarova K, Dušek M (2013) Polyhedron 51:54–60

Asadi Z, Zeinali A, Dusek M, Eigner V (2014) Int J Chem Kinet 46:718–729

Abdel-Rahman LH, Abu-Dief AM, Adam MSS, Hamdan SK (2016) Catal Lett 146:1373–1396

Grivani G, Khalaji AD, Tahmasebi V, Gotoh K, Ishida H (2012) Polyhedron 31:265–271

Grivani G, Bruno G, Rudbari HA, Khalaji AD, Pourteimouri P (2012) Inorg Chem Commun 18:15–20

Ghaffari A, Behzad M, Dutkiewicz G, Kubick M, Salehi M (2012) J Coord Chem 65:840–855

Nunes CD, Vaz PD, Felix V, Veiros LF, Moniz T, Rangel M, Realista S, Mourato AC, Calhorda MJ (2015) Dalton Trans 44:5125–5138

Bortolini O, Conte V (2006) Mass Spectrom Rev 25:724–740

Rayati S, Ashouri F (2012) C R Chim 15:679–687

Joseph T, Srinivas D, Gopinath CS, Halligudi SB (2002) Catal Lett 83:209–214

Maurya MR, Chandrakar AK, Chand S (2007) J Mol Catal A 270:225–235

Maurya MR, Kumar A (2006) J Mol Catal A 250:190–198

Hamstra BJ, Colpas GJ, Pecoraro VL (1998) Inorg Chem 37:949–955

Rayati S, Koliaei M, Ashouri F, Mohebbi S, Wojtczak A, Kozakiewicz A (2008) App Catal A 346:65–71

Mirzaee M, Bahramian B, Gholizadeh J, Feizi A, Gholami R (2017) Chem Eng J 308:160–168

Vlasiou M, Drouza C, Kabanos TA, Keramidas AD (2015) J Inorg Biochem 147:39–43

Aschi M, Crucianelli M, Giuseppea AD, Nicola CD, Marchetti F (2012) Catal Today 192:56–65

Adam MSS, Abd El-Lateef HM, Soliman KM (2018) J Mol Liq 250:307–322

Adam MSS (2018) Appl Organometal Chem. https://doi.org/10.1002/aoc.4234

Cussó O, Serrano-Plana J, Costas M (2017) ACS Catal 7:5046–5053

Acknowledgements

The authors greatly thank Prof. Dr. Usama El-Ayaan, Professor of Inorganic Chemistry, Chemistry Department, Faculty of Science, Mansoura University, Mansoura-35516, Egypt his continued and precious advice and encouragement to produce this work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Adam, M.S.S., Hafez, A.M. & El-Ghamry, I. Catalytic performance of binary and ternary oxovanadium complexes of dipyridinyl-urea in (ep)oxidation of cis-cyclooctene and 1-octene. Reac Kinet Mech Cat 124, 779–805 (2018). https://doi.org/10.1007/s11144-018-1399-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-018-1399-8