Abstract

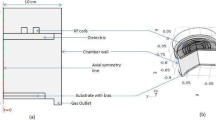

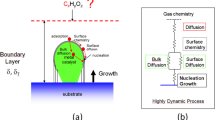

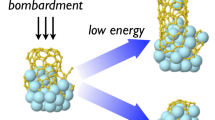

The aim of the present work is to develop a numerical model to understand and optimize the process parameters for the growth of carbon nanofibers (CNFs) inside the plasma enhanced chemical vapor deposition system containing acetylene, hydrogen, and argon gases. Two-dimensional axis-symmetrical inductive couple plasma module is implemented using COMSOL Multiphysics 5.2 simulation software to analyze the density profiles and temperatures of electrons, ions, and neutral species in the plasma at different gas pressures and input plasma powers. The outcomes of the COMSOL computational model show that the electron density in the plasma decreases with increase in gas pressure and increases with increase in plasma power. Other than the computational model, an analytical model is developed in the present paper that accounts the plasma sheath equations to study the fluxes and energies of the plasma species. The results obtained from the plasma sheath model at the catalyst-substrate surface boundary are fed as the input parameters to surface deposition model to investigate the growth characteristics of carbon nanofibers, i.e., poisoning of the catalyst nanoparticle, height, and diameter of carbon nanofiber at different gas pressures and input plasma powers. It is found that electron density decays at the faster rate when gas pressure is increased and decays at slower rate when input plasma power is raised. Moreover, it is also found that growth rate of CNFs increases with increase in gas pressure and plasma power. However, the significant drop in CNF growth rate is observed when the gas pressure is high enough (above and around 50 Torr). From the results obtained, it can be concluded that the CNFs having good growth characteristics can be obtained at some optimum pressure range, i.e., one order of the magnitude in the units of Torr. A good comparison between numerical simulation results and analytical results with each other and with existing experimental results confirms the adequacy of the computational and analytical approach.

Similar content being viewed by others

References

Choi WB, Jin YW, Kim HY, Lee SJ, Yun MJ, Kang JK, Coi YS, Park NS, Lee NS, Kim JM (2001) Appl Phys Lett 78:1547–1549

Niu C, Sichel EK, Hoch R, Moy D, Tennent H (1997) Appl Phys Lett 70:1480–1482

Saito R, Dresselhaus G, Dresslhaus MS (1998) Physical properties of carbon nanotubes. Imperial College Press, London

Darkrim FL, Malbrunot P, Tartaglia GP (2002) Int J Hydrog Energy 27:193–202

Guillorn MA, Melechko AV, Merkulov VI, Ellis ED, Simpson ML (2001) J Vac Sci Technol B 19:2598–2601

Merkulov VI, Melechko AV, Guillorn MA, Simpson ML, Lowndes DH, Whealton JH, Raridon RJ (2002) Appl Phys Lett 80:4816–4818

Wei HW, Leou LC, Wei MT, Lin YY, Tsai CH (2005) J Appl Phys 98:044313

Mehdipour H, Ostrikov K, Rider AE (2010) Nanotechnology 21:455605

Denysenko I, Azarenkov NA (2011) J Phys D Appl Phys 44:174031

Denysenko I, Ostrikov K (2009) J Phys D Appl Phys 42:015208

Denysenko I, Ostrikov K, Yu MY, Azarenkov NA (2007) J Appl Phys 102:074308

Chhowalla M, Teo KBK, Ducati C, Rupessinghe NL, Amaratunga GAJ, Ferrari AC, Roy D, Robertson J, Milne WI (2001) J Appl Phys 90:5308–5317

Catherine Y, Couderc P (1986) Thin Solid Films 144:265–280

Ganjipour B, Mohrajerzadeh S, Hesamzadeh H, Khodadadi A (2005) Fuller Nanotubes Carbon Nanostrcut 13:365–373

Delzeit L, McAninch I, Cruden BA, Hash D, Chen B, Han J, Meyyappan M (2002) J Appl Phys 91:6027–6033

Wang BB, Lee S, Xu XZ, Choi S, Yan H, Zhang B, Hao W (2004) Appl Surf Sci 236:6–12

Shivkumar G, Tholeti SS, Alrefae MA, Fisher TS, Alexeenko AA (2016) J Appl Phys 119:113301

Cruden BA, Cassell AM, Hash DB, Meyyappan M (2004) J Appl Phys 96:5284–5292

Mao M, Bogaerts A (2010) J Phys D Appl Phys 43:205201

Harilal SS, Bindhu CV, Issac RC, Nampoori VPN, Vallabhan CPG (1997) J Appl Phys 82:2140–2146

Collison WZ, Ni TQ, Barnes MS (1998) J Vac Sci Technol A 16:100–107

Melechko AV, Merkulov VI, McKnight TE, Guillorn MA, Klein KL, Lowndes DH, Simpson ML (2005) J Appl Phys 97:041301

Li WZ, Wen JG, Tu Y, Ren ZF (2001) Appl Phys A 73:259–264

Pint CL, Nicholas N, Pheasant ST, Duque JG, Vasquez ANGP, Eres G, Pasquali M, Hauge RH (2008) J Phys Chem C 112:14041–14051

Tsakadze ZL, Ostrikov K, Sow CH, Mhaisalkar SG, Boey YC (2010) J Nanosci Nanotechnol 10:6575–6579

Tanemura M, Iwata K, Takahashi K, Fujimoto Y, Okuyama Y, Sugie H, Filip V (2001) J Appl Phys 90:1529–1533

Hinkov I, Farhat S, Scott CD (2005) Carbon 43:2453–2462

Chang SC, Lin TC, Pai CY (2007) Microelectron J 38:657–662

Merkulov VI, Hensely DK, Melechko AV, Guillorn MA, Lowndes DH, Simpson ML (2002) J Phys Chem B 106:10570–10577

Gupta R, Sharma SC, Sharma R (2017) Plasma Sources Sci Technol 26:024006

Gupta R, Gupta N, Sharma SC (2018) Phys Plasmas 25:043504

Gupta R, Sharma SC (2018) Contrib Plasma Phys. https://doi.org/10.1002/ctpp.201700138

Gupta R, Sharma SC (2017) Phys Plasma 24:073504

Dagel DJ, Mallouris CM, Doyle JR (1996) J Appl Phys 79:8735–8747

Denysenko IB, Xu S, Long JD, Rutkevych PP, Azarenkov NA, Ostrikov K (2004) J Appl Phys 95:2713–2724

Deschenaux C, Affolter A, Magni D, Hollenstein C, Fayet P (1999) J Phys D Appl Phys 32:1876

Benedikt J (2010) J Phys D Appl Phys 43:043001

Doyle JR (1997) J Appl Phys 82:4763–4771

Ostrikov K, Yoona HJ, Rider AE, Vladimirov SV (2007) Plasma Process Polym 4:27–40

Mehdipour H, Ostrikov K, Rider AE, Han Z (2011) Plasma Process Polym 8:386–400

Marvi Z, Xu S, Foroutan G, Ostrikov K (2015) Phys Plasmas 22:013504

Cantoro M, Hofmann S, Pisana S, Ducati C, Parvez A, Ferrari AC, Robertson J (2006) Diam Relat Mater 15:1029–1035

Hofmann S, Cantoro M, Kleinsorge B, Casiraghi C, Parvez A, Robertson J, Ducati C (2005) J Appl Phys 98:034308

Louchev OA, Laude T, Sato Y, Kanda H (2003) J Chem Phys 118:7622–7634

Yudasaka M, Kikuchi R, Matsui T, Ohki Y, Yoshimura S, Ota E (1995) Appl Phys Lett 67:2477–2479

See (http://matter.org.uk/matscicdrom/manual/df.html) for metal atom diffusion coefficient

Sodha MS, Misra S, Mishra SK (2010) Phys Plasmas 17:113705

Sodha MS, Misra S, Misra SK, Srivastava S (2010) J Appl Phys 107:103307

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gupta, R., Sharma, S.C. Parametric Study of Plasma Characteristics and Carbon Nanofibers Growth in PECVD System: Numerical Modeling. Plasma Chem Plasma Process 40, 1331–1350 (2020). https://doi.org/10.1007/s11090-020-10090-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-020-10090-2