Abstract

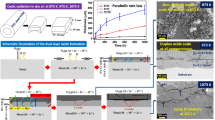

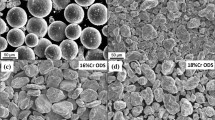

Oxide dispersion-strengthened (ODS) FeCrAl ferritic steels constitute a class of alloys with a combination of mechanical strength capabilities and environmental resistance that permits operation at temperatures significantly higher than available classes of wrought alloy. A significant issue for these ODS alloys is that, because of the extreme operating temperatures, unexpected failure of the protective scale in service could lead to catastrophic degradation of high-temperature, high-pressure components. In the absence of handbook data for quantification of their high-temperature environmental degradation, significant efforts have been made to develop approaches for predictive oxidation lifetime modeling. The main basis for such models is an aspect of oxidation behavior peculiar to these alloys at very high temperatures, specifically, their ability to maintain a protective alumina scale until practically all available Al in the alloy has been consumed. At the high temperatures involved the concentration profile for Al throughout the component remains flat while the alumina scale is intact, so that knowledge of the oxidation kinetics provides a basis for calculating the time to exhaustion of the alloy’s Al reservoir, hence service life. Difficulties arise when unanticipated gradients in the Al concentration profile are introduced following, for instance, premature local mechanical failure of the protective scale. The intent of this work was to consider if and how scale failures change with differences in surface shape, and how related mechanistic understanding of the actual oxidation behavior may be used to extend the utility of the modeling approaches. Experimental results for coupons of different shapes were very largely in agreement with the basic tenets of the lifetime modeling approaches, but a notable finding was that cylindrical shapes reproducibly exhibited a reduction in unexpected early scale failures, leading to more consistent oxidation-limited lifetimes.

Similar content being viewed by others

References

Note: commercial ODS-FeCrAl alloys of interest were: Incoloy® alloy MA956, Special Metals, Huntington, WV (Publication No. SMC-008, 2004); Alloy PM2000, Metallwerk Plansee, Reutte, Austria; and Alloy ODM751, Dour Metal Sro, Slovak Republic.

A. R. Jones, Historical Perspective—ODS alloy Development. Proceedings NETL-DOE ODS Materials Workshop, San Diego, CA, Nov 17–18, 2010.

G. J. Tatlock, E. G. Dyadko, S. N. Dryepondt, et al., Pulsed plasma-assisted diffusion bonding of ODS-FeCrAl alloys. Metallurgy and Materials Transactions A 38, 2007 (1663).

I. G. Wright, G. J. Tatlock, H. Al-Badairy, et al., Summary of Prior Work on Joining of Oxide Dispersion-Strengthened Alloys, ORNL/TM-2009/136, Aug 2009.

B.K. Kad, High-temperature performance of non-fusion joints, Proceedings. NETL-DOE ODS Materials Workshop, San Diego, CA, Nov 17–18, 2010.

F. Starr, A. W. White, and B. Kazimierzak, Pressurized heat exchangers for 1100 °C operation using ODS alloys. in Proceedings Conference on Materials for Advanced Power Engineering, eds. D. Coutsouradis, et al. (Kluwer Academic Publishers, Dordrecht, 1994), p. 1393.

N. J. Wood, J. Wonsowski, and Q. J. Mabbutt, The development of an externally-fired ODS closed-cycle demonstrator plant. in Proceedings Materials Issues in Heat Exchangers and Boilers Conference, eds. F. Starr and D. B. Meadowcroft (The Institute of Materials, London, 1997), p. 1.

F. Starr, ODS alloy high-temperature heat exchanger prototype development, Proceedings NETL-DOE ODS Materials Workshop, San Diego, CA, Nov 17–18, 2010.

J. R. Nicholls and M. J. Bennett, “Life extension of alumina-forming alloys: background, objectives, and achievements of the BRITE/EURAM programme LEAFA”. Lifetime modelling of high-temperature corrosion processes. Proceedings European Federation of Corrosion Workshop. eds. M. Schütze, W. J. Quadakkers and J. R. Nicholls, EFC Publication No. 34 Maney Publishing, (2001), paper No. 1, p. 3.

R. Newton, M.J. Bennett, J.P. Wilbur, et al., “The oxidation lifetime of commercial FeCrAl-(RE) alloys,” Lifetime Modelling of High-Temperature Corrosion Processes. Proceedings European Federation of Corrosion Workshop, eds. M. Schütze, W. J. Quadakkers, and J. R. Nicholls, EFC Publication No. 34 Maney Publishing, (2001), paper No. 2, p. 15.

W. J. Quadakkers, K. Schmidt, H. Grubmeier, et al., Composition, structure and protective properties of alumina scales on iron-base oxide dispersion-strengthened alloys. Materials at High Temperatures 10, (1), 1992 (23).

W. J. Quadakkers and M. J. Bennett, Oxidation-induced lifetime limits of thin-walled, iron-based alumina-forming oxide dispersion-strengthened alloy components. Materials Science and Technology 10, 1994 (126).

W. J. Quadakkers and K. Bongartz, The prediction of breakaway oxidation for alumina-forming ODS alloys using Oxidation Diagrams. Werkstoffe u Korrosion 24, 1994 (232).

W. J. Quadakkers, K. Bongartz, and F. Schubert, The prediction of oxidation-limited life of thin-walled ODS heat exchangers for high-temperature applications, Materials for Advanced Power Engineering, COST 501, Liege 3-6 October 1994, p. 1535.

M. J. Bennett, Recent studies and current problems concerning the high-temperature oxidation behaviour of alumina-forming iron-base alloys. Solid State Phenomena 41, 1995 (235).

I. G. Wright, B. A. Pint, L. M. Hall, et al., “Oxidation lifetimes: experimental results and modelling,” Lifetime Modelling of High-Temperature Corrosion Processes. Proceedings European Federation of Corrosion Workshop, eds. M. Schütze, W. J. Quadakkers, and J. R. Nicholls, EFC Publication No. 34, Maney Publishing, (2001), paper No. 24, p. 339.

B. A. Pint and I. G. Wright, Long-term high-temperature oxidation behavior of ODS ferritics. Journal of Nuclear Materials 307–311, 2002 (763).

B. A. Pint, L. R. Walker, and I. G. Wright, Characterization of the breakaway Al content in alumina-forming alloys. Materials at High Temperatures 21, (3), 2004 (175).

W. J. Quadakkers, D. Naumenko, E. Wessel, et al., Growth rates of alumina scales on Fe–Cr–Al alloys. Oxidation of Metals 61, (1/2), 2004 (17).

I. G. Wright, R. Peraldi, and B. A. Pint, Influence of aluminium depletion effects on the calculation of the oxidation lifetimes of FeCrAl alloys. Materials Science Forum 461–464, 2004 (579).

B. A. Pint, L. R. Walker, and I. G. Wright, Factors affecting Al depletion during cyclic oxidation of Fe-base alumina-forming alloys. Materials at High Temperatures 26, (2), 2009 (211).

B. K. Kad, S. Dryepondt, A. R. Jones, et al., Progress in ODS alloys: a synopsis of a 2010 workshop on Fe-based ODS alloys, Proceedings at 8th International Charles Parsons Turbine Conference, (Portsmouth, England, 2011).

S. Dryepondt, J. C. Turan, D. Leonard, et al., Long-term oxidation testing and lifetime modeling of cast and ODS-FeCrAl alloys. Oxidation of Metals 87, 2017 (215).

H. E. Evans, A. T. Donaldson, and T. C. Gilmour, Mechanisms of breakaway oxidation and application to a chromia-forming steel. Oxidation of Metals 52, 1999 (379).

H. E. Evans and J. R. Nicholls, “Prediction of oxide spallation from an alumina-forming ferritic steel,” Lifetime Modelling of High-Temperature Corrosion Processes. Proceedings European Federation of Corrosion Workshop, eds. M. Schütze, W. J. Quadakkers, and J. R. Nicholls, EFC Publication No. 34, Maney Publishers, (2001), paper No. 3, p. 37.

A. S. Sabau and I. G. Wright, Influence of oxide growth and metal creep on strain development in the steam-side oxide in boiler tubes. Oxidation of Metals 73, 2010 (467).

A. M. Huntz, L. Marechal, and B. Lesage, Thermal expansion coefficient of alumina films developed by oxidation of a FeCrAl alloy determined by a deflection technique. Applied Surface Science 252, (22), 2006 (7781).

M. Schütze, Protective oxide scales and their breakdown, (Wiley, Chichester, 1997).

D. Renusch, G. Muralidharan, S. Uran, et al., Effect of edges and corners on stresses in thermally-grown alumina scales. Oxidation of Metals 53, (1), 2000 (171).

I. Gurrappa, S. Weinbruch, D. Naumenk, et al., Factors governing breakaway oxidation of FeCrAl-based alloys. Materials and Corrosion 51, 2000 (224).

W. J. Quadakkers, T. Malkow, and H. Nickel, The effect of major and minor alloying elements on the oxidation-limited life of FeCrAl-base alloys, Proceedings in 2nd International Conference on Heat-Resistant Materials, (Gatlinburg, Tennessee, 1995), p. 19.

G. J. Tatlock, Oxidation of alumina-forming ODS alloys, Proceedings in NETL-DOE ODS Materials Workshop, San Diego, CA, Nov 17–18, 2010.

H. Al-Badairy and G. J. Tatlock, The application of a wedge-shaped sample technique for the study of breakaway oxidation in Fe–20Cr–5Al-base alloys. Oxidation of Metals 53, (1), 2000 (157).

H. Al-Badairy, G. J. Tatlock, and M. J. Bennett, A comparison of breakaway oxidation in wedge-shaped and parallel-sided coupons of FeCrAlY alloys. Materials at High Temperatures 17, (1), 2000 (101).

G. Streihl, V. Guttmann, D. Naumenko, et al., “The influence of sample geometry of the oxidation and chemical failure of FeCrAl-(RE) alloys,” Lifetime Modelling of High-Temperature Corrosion Processes. Proc European Federation of Corrosion Workshop, eds. M. Schütze, W. J. Quadakkers, and J. R. Nicholls, EFC Publication No. 34 Maney Publishing, (2001), paper No. 7, p. 107.

J. P. Wilber, J. R. Nicholls, and M. J. Bennett, Assessment of defects in alumina scales formed on ferritic ODS alloys, in Microscopy of Oxidation-3, eds. S.B. Newcomb and J.A. Little, (The Institute of Materials, London, 1999), p. 207.

S. Dryepondt, J. C. Turan, M. J. Lance, et al., 3-D microscopy to assess the effect of high-temperature cyclic oxidation on the deformation of cast and ODS FeCrAlY Alloys. Oxidation of Metals 91, 2019 (327).

J. Jedlinski, The use of 18O2-exposure + SIMS-based approach to investigate the spallation mechanisms of alumina scales. Materials and Corrosion 57, (2), 2006 (185).

J. R. Nicholls, R. Newton, M. J. Bennett, et al., “Development of a life prediction model for the chemical failure of FeCrAl-(RE) alloys in oxidizing environments,” Lifetime Modelling of High-Temperature Corrosion Processes. Proceedings in European Federation of Corrosion Workshop, eds. M. Schütze, W. J. Quadakkers, and J. R. Nicholls, EFC Publication No. 34, Maney Publishing, (2001), paper No. 6, p. 83.

J. L. Smialek, A deterministic interfacial cyclic-oxidation spalling model. Acta Materialia 51, 2003 (469).

D. Poquillon and D. Monceau, Application of a simple statistical spalling model for the analysis of high-temperature, cyclic-oxidation kinetics data. Oxidation of Metals 59, 2003 (409).

D. Naumenko, W. J. Quadakkers, V. Guttmann, et al., “Critical role of minor element constituents on the lifetime behaviour of FeCrAl-(RE) alloys,” Lifetime Modelling of High-Temperature Corrosion Processes. Proceedings European Federation of Corrosion Workshop, eds. M. Schütze, W. J. Quadakkers, and J. R. Nicholls, EFC Publication No. 34 Maney Publishing, (2001), paper No. 5, p. 66.

B. A. Pint, Optimization of reactive-element additions to improve oxidation performance of alumina-forming alloys. Journal of the American Ceramic Society 86, (4), 2004 (686).

M. J. Bennett, J. R. Nicholls, N. J. Simms, et al., Lifetime extension of FeCrAl-RE alloys in air: potential roles of an enhanced Al-reservoir and surface pretreatment. Materials and Corrosion 56, (12), 2005 (854).

J. L. Smialek, Invited review paper in commemoration of over 50 years of Oxidation of Metals: Alumina scale adhesion mechanisms—a retrospective assessment. Oxidation of Metals 97, 2022 (1).

S. Dryepondt, B. P. Thiesing, G. J. Tatlock, et al., Void formation during cyclic oxidation of oxide dispersion-strengthened FeCrAl alloys. Materials at High Temperatures 2020. https://doi.org/10.1080/09603409.2020.1771657.

Acknowledgements

The experimental research reported was conducted while the authors worked at the Oak Ridge National Laboratory. We are extremely grateful to George Garner, Hu Longmire, and Larry Walker for their careful work in making the experimental measurements. The research was sponsored by the U.S. Department of Energy, Office of Fossil Energy, Advanced Research Materials Program, under Contract DE-AC05-00OR22725, and the Office of Energy Efficiency and Renewable Energy [DE-FC02-00CH11020], with UT-Battelle, LLC.

Author information

Authors and Affiliations

Contributions

IGW wrote the main manuscript text, and both authors reviewed and commented on it.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wright, I.G., Peraldi, R. Oxidation-Limited Lifetime of ODS-FeCrAl Alloys: Observations on Influence of Surface Shape. High Temperature Corrosion of mater. 99, 183–200 (2023). https://doi.org/10.1007/s11085-023-10150-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10150-w