Abstract

The primary purpose of this paper is to present a novel algorithm for designing a family of variants. This platform base algorithm is utilized for designing suspension system for a family of Renault Logan cars. In this case, a gray penalty function is presented to minimize variations between suspension parameters and generate suspension variants which have most commonality between each other in different cars of the family. This study developed a nonlinear mathematical model in order to simulate the dynamic performance of suspension system. Therefore, a novel suspension model is presented based on combining vehicle vibration model and geometry suspension model which are subjected to a random vibration road profile excitation and gray family design algorithm. Geometry suspension model analyzes the effect of suspension parameters (i.e., hard points, length of arms, camber angle and caster angle) on the stability, ride and handling of the vehicle. Vehicle vibration model investigates the influence of seat location, damping and spring coefficients on the driver seat acceleration, roll angular and pitch angular acceleration, relative displacement and sprung mass acceleration. The results achieved by the simulation of the full vehicle in ADAMS/CAR and experimental test of Renault Logan car, which have been done in one of main Iranian automakers (SAIPA), demonstrate the accuracy of the novel model. Comparing the results of the family base suspension model and results of ADAMS/CAR simulation indicates the beneficial of this algorithm and its usage in designing suspension system.

Similar content being viewed by others

Abbreviations

- \(m_\mathrm{s}\) :

-

Sprung mass (kg)

- \(m_\mathrm{u1}\) :

-

Unsprung mass of front left suspension (kg)

- \(m_\mathrm{u2}\) :

-

Unsprung mass of rear left suspension (kg)

- \(m_\mathrm{u3}\) :

-

Unsprung mass of front right suspension (kg)

- \(m_\mathrm{u4}\) :

-

Unsprung mass of rear right suspension (kg)

- \(c_\mathrm{s1}\) :

-

Damping coefficient of front left suspension (N s/m)

- \(c_\mathrm{s2}\) :

-

Damping coefficient of rear left suspension (N s/m)

- \(c_\mathrm{s3}\) :

-

Damping coefficient of front right suspension (N s/m)

- \(c_\mathrm{s4}\) :

-

Damping coefficient of rear right suspension (N s/m)

- \(k_\mathrm{t1}\) :

-

Tire stiffness of front left tire (N/m)

- \(k_\mathrm{t2}\) :

-

Tire stiffness of rear left tire (N/m)

- \(k_\mathrm{t3}\) :

-

Tire stiffness of front right tire (N/m)

- \(k_\mathrm{t4}\) :

-

Tire stiffness of rear right tire (N/m)

- \(k_\mathrm{s1}\) :

-

Spring stiffness of front left suspension (N/m)

- \(k_\mathrm{s2}\) :

-

Spring stiffness of rear left suspension (N/m)

- \(k_\mathrm{s3}\) :

-

Spring stiffness of front right suspension (N/m)

- \(k_\mathrm{s4}\) :

-

Spring stiffness of rear right suspension (N/m)

- \(z_\mathrm{r1}\) :

-

Road profile excitation of front left tire (m)

- \(z_\mathrm{r2}\) :

-

Road profile excitation of rear left tire (m)

- \(z_\mathrm{r3}\) :

-

Road profile excitation of front right tire (m)

- \(z_\mathrm{r4}\) :

-

Road profile excitation of rear right tire (m)

- \(c_\mathrm{seat}\) :

-

Damping coefficient of driver seat (N s/m)

- \(k_\mathrm{seat}\) :

-

Spring stiffness of driver seat (N/m)

- \(\varphi \) :

-

Control arm rotation angle (deg)

- \(\varphi _{0}\) :

-

Initial control arm rotation angle (deg)

- \(z_\mathrm{s}\) :

-

Sprung mass displacement (m)

- \(z_\mathrm{u}\) :

-

Unsprung mass displacement (m)

- \(\xi _{a}\) :

-

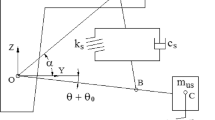

Length of suspension arm (m) (Fig. 4)

- \(\xi _{b}\) :

-

Length of suspension arm (m) (Fig. 4)

- \(\xi _{c}\) :

-

Length of control arm (m) (Fig. 4)

- \(\mathrm{acc.}_{zs}\) :

-

Sprung mass acceleration (\(\mathrm{m/s}^{2})\)

- \(\mathrm{acc.}_{\varphi }\) :

-

Control arm angular acceleration \((\mathrm{deg/s}^{2})\)

- \(\varphi \) :

-

Roll angle of control arm (deg)

- d :

-

Relative displacement of sprung mass and unsprung mass (m)

- \(\tilde{V}\) :

-

Relative velocity of sprung mass and unsprung mass (m/s)

- \(\xi _{0}\) :

-

Dimension in reference frame \(\xi _{0}\tau _{0}\psi _{0}\)

- \(\xi _{1}\) :

-

Dimension in reference frame \(\xi _{1}\tau _{1}\psi _{1}\)

- \(\tau _{0}\) :

-

Dimension in reference frame \(\xi _{0}\tau _{0}\psi _{0}\)

- \(\tau _{1}\) :

-

Dimension in reference frame \(\xi _{1}\tau _{1}\psi _{1}\)

- \(\psi _{0}\) :

-

Dimension in reference frame \(\xi _{0}\tau _{0}\psi _{0}\)

- \(\psi _{1}\) :

-

Dimension in reference frame \(\xi _{1}\tau _{1}\psi _{1}\)

- u :

-

Value of point p in \(\xi \) direction

- v :

-

Value of point p in \(\tau \) direction

- w :

-

Value of point p in \(\psi \) direction

- \(z_{w}\) :

-

Value of point w in z direction (m) (Fig. 4)

- \(z_{p}\) :

-

Value of point p in z direction (m) (Fig. 4)

- \(z_{q}\) :

-

Value of point q in z direction (m) (Fig. 4)

- \(y_{w}\) :

-

Value of point w in y direction (m) (Fig. 4)

- \(y_{p}\) :

-

Value of point p in y direction (m) (Fig. 4)

- \(y_{q}\) :

-

Value of point q in y direction (m) (Fig. 4)

- \(\sigma \) :

-

Angle between ow and y-axis (deg) (see Fig. 4)

- \(F_{xk}\) :

-

The kth external force in x direction (N)

- \(F_{yk}\) :

-

The kth external force in y direction (N)

- \(F_{zk}\) :

-

The kth external force in z direction (N)

- \(q_{j}\) :

-

The jth general coordinate in Lagrange equation

- V :

-

Potential energy in Lagrange equation

- T :

-

Kinetic energy in Lagrange equation

- D :

-

Energy of damping in Lagrange equation

- \(Q_{j}(n)\) :

-

The general force corresponding to the general coordinate \(q_{j}\)

- t :

-

Time domain in Lagrange equation (s)

- \(\lambda (t)\) :

-

White noise function

- \(\psi \) :

-

Spectral density of white noise

- \(\sigma ^{2}\) :

-

Variance of road roughness

- \(\zeta _{0}\) :

-

Constant value in linear regression equation

- \(\zeta _{1}\) :

-

Constant value in linear regression equation

- \(\nu _{i}\) :

-

The regression coefficients in linear regression equation

References

Nariman-Zadeh, N., Salehpour, M., Jamali, A., Haghgoo, E.: a Pareto optimization of a five-degree of freedom vehicle vibration model using a multi-objective uniform-diversity genetic algorithm (MUGA). Eng. Appl. Artif. Intell. 23, 543–551 (2010)

Lopez, A., Olazagoitia, J.L., Moriano, C., Ortiz, A.: Nonlinear optimization of a new polynomial tyre model. Nonlinear Dyn. 78, 2941–2958 (2014)

Guclu, R.: Fuzzy logic control of seat vibrations of a non-linear full vehicle model. Nonlinear Dyn. 40, 21–34 (2005)

Fang, Z., Shu, W., Du, D., Xiang, B., He, Q., He, K.: Semi-active suspension of a full-vehicle model based on double-loop control. Procedia Eng. 16, 428–437 (2011)

Joao, P.C., Goncalves, J.A., Ambrosio, C.: Optimization of vehicle suspension systems for improved comfort of road vehicles using flexible multibody dynamics. Nonlinear Dyn. 34, 113–131 (2003)

Dangor, M., Dahunsi, O.A., Pedro, J.O., Ali, M.M.: Evolutionary algorithm-based PID controller tuning for nonlinear quarter-car electrohydraulic vehicle suspensions. Nonlinear Dyn. 78, 2795–2810 (2014)

Jin, Y., Luo, X.: Stochastic optimal active control of a half-car nonlinear suspension under random road excitation. Nonlinear Dyn. 72, 185–195 (2013)

Bouazara, M., Richard, M.J.: An optimization method designed to improve 3-D vehicle comfort and road holding capability through the use of active and semi-active suspensions. Eur. J. Mech. A Solids 20(3), 509–520 (2001)

Gundogdu, O.: Optimal seat and suspension design for a quarter car with driver model using genetic algorithms. Int. J. Ind. Ergon. 37(4), 327–332 (2007)

Attia, H.A.: Dynamic modelling of the double wishbone motor-vehicle suspension system. Eur. J. Mech. A Solids 21, 167–174 (2002)

Cao, D., Song, X., Ahmadian, M.: Vehicle system dynamics: international journal of vehicle mechanics and mobility. Veh. Syst. Dyn. 49(1–2), 3–28 (2011)

Chen, K., Beale, D.G.: Base dynamic parameter estimation of a Macpherson suspension mechanism. Veh. Syst. Dyn. 39(3), 227–244 (2003)

Hu, Y., Chen, M.Z.Q., Shu, Z.: Passive vehicle suspensions employing inerters with multiple performance requirements. J Sound Vib. 333, 2212–2225 (2014)

Nemeth, B., Gaspar, P.: Set-based analysis of the variable-geometry suspension system. In: 19th World Congress The International Federation of Automatic Control, Cape Town, South Africa (2014)

Yang, Q., Yu, S., Jiang, D.: A modular method of developing an eco-product family considering the reusability and recyclability of customer products. J. Clean. Prod. 64, 254–265 (2014)

Ramadan, K., ElMaraghy, W.: Product families and platforms diversification: customer expectations, product variations, or self-competition? Procedia Cirp. 16, 104–109 (2014)

Wei, W., Yixiong, F., Jianrong, T., Zhongkai, L.: Product platform two-stage quality optimization design based on multi-objective genetic algorithm. Comput. Math. Appl. 57, 1929–1937 (2009)

Shijia, L., Yunkai, T., Shijian, L.A.: Study of product family design dna based on product style. In: 2009 IEEE 10th international conference on computer-aided industrial design and conceptual design, pp. 377–38 (2009). doi:10.1109/CAIDCD.2009.5375436

Nayak, R.U., Chen, W., Simpson, T.W.: A variation-based method for product family design. Eng Optim. 34, 65–81 (2002)

Fallah, M.S., Bhat, R., Xie, W.F.: New model and simulation of Macpherson suspension system for ride control applications. Veh. Syst. Dyn. 47(2), 195–220 (2009)

Spong, M.W., Vidyasagar, M.: Robot Dynamics and Control. Wiely, London (2008)

Dai, Z., Scott, M.J.: Effective product family design using preference aggregation. J. Mech. Des. 128(4), 659–667 (2006). doi:10.1115/1.2197835

Simpson, T.W., Jiao, J., Siddique, Z., Hölttä-Otto, K.: Advances in Product Family and Product Platform Design Methods and Applications. Springer, Heidelberg (2014)

Raychaudhuri, S.: Introduction to Monte Carlo simulation. In: Proceedings of the 2008 Winter Simulation Conference Austin, Texas (2008)

Uys, P.E., Els, P.S., Thoresson, M.: Suspension settings for optimal ride comfort of off-road vehicles travelling on roads with different roughness and speeds. J. Terramech. 44, 163–175 (2007)

Jung, J.H., Kwon, W.T.: Optimization of EDM process for multiple performance characteristics using Taguchi method and Grey relational analysis. J. Mech. Sci. Technol. 24(5), 1083–1090 (2010)

Ning, X., Zhao, C., Shen, J.: Dynamic analysis of car suspension using ADAMS/car for development of a software interface for optimization. Procedia Eng. 16, 333–341 (2011)

Yang, Y., Ren, W., Chen, L., Jiang, M.: Study on ride comfort of tractor with tandem suspension based on multi-body system dynamics. Appl. Math. Model. 33, 11–33 (2009)

Tian, Q., Liu, C., Machado, M., Flores, P.: A new model for dry and lubricated cylindrical joints with clearance in spatial flexible multibody systems. Nonlinear Dyn. 64, 25–47 (2011)

Shojaeefard, M.H., Khalkhali, A., Yarmohammadisatri, S.: An efficient sensitivity analysis method for modified geometry of Macpherson suspension based on Pearson correlation coefficient. Veh. Syst. Dyn. 55(6), 827–852 (2017)

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

In Eq. (26):

In Eq. (47)

In Eq. (47)

Rights and permissions

About this article

Cite this article

Yarmohammadisatri, S., Shojaeefard, M.H. & Khalkhali, A. A family base optimization of a developed nonlinear vehicle suspension model using gray family design algorithm. Nonlinear Dyn 90, 649–669 (2017). https://doi.org/10.1007/s11071-017-3686-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-017-3686-8