Abstract

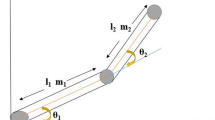

A major technical challenge in decentralized fault-tolerant control for a torque sensorless constrained reconfigurable manipulators is associated with decentralized control of the constraint force. This paper proposed a novel decentralized force/position control method based on the motor-side and link-side position measurements along with harmonic drive model for each joint module of constrained reconfigurable manipulators. In addition, a modified sliding mode controller is designed to guarantee force/position tracking performance, and the unknown non-affine actuator fault in independent subsystem can be compensated by adding an adaptive compensation term to the sliding mode controller. The stability of closed-loop system is analyzed using the Lyapunov method. Finally, simulations are performed to verify the advantages of the proposed method.

Similar content being viewed by others

References

Kumar, N., Panwar, V., Sukavanam, N., Sharma, S.P., Borm, J.H.: Neural network based hybrid force/position control for robot manipulators. Int. J. Precis. Eng. Manuf. 12(3), 419–426 (2011)

Gams, A., Nemec, B., Ijspeert, A.J., Ude, A.: Coupling movement primitives: interaction with the environment and bimanual tasks. IEEE Trans. Robot. 30(4), 816–830 (2014)

Li, Z., Cao, X., Tang, Y., Li, R., Ye, W.: Bilateral teleoperation of holonomic constrained robotic systems with time-varying delays. IEEE Trans. Instrum. Meas. 62(4), 752–765 (2013)

Rahman, S.M.M., Ikeura, R.: Weight-prediction-based predictive optimal position and force controls of a power assist robotic system for object manipulation. IEEE Trans. Ind. Electron. 63(9), 5964–5975 (2016)

Lee, C., Wang, W.: Robust adaptive position and force controller design of robot manipulator using fuzzy neural networks. Nonlinear Dyn. 85(1), 343–354 (2016)

Xu, Q.: Robust impedance control of a compliant microgripper for high-speed position/force regulation. IEEE Trans. Ind. Electron. 62(2), 1201–1209 (2015)

Singh, H.P., Sukavanam, N.: Stability analysis of robust adaptive hybrid position/force controller for robot manipulators using neural network with uncertainties. Neural Comput. Appl. 22(7), 1745–1755 (2013)

Xu, Q.: Adaptive discrete-time sliding mode impedance control of a piezoelectric microgripper. IEEE Trans. Robot. 19(3), 663–673 (2013)

Heck, D., Saccon, A., Wouw, N., Nijmeijer, H.: Guaranteeing stable tracking of hybrid positionCforce trajectories for a robot manipulator interacting with a stiff environment. Automatica. 63, 235–247 (2016)

Yip, M.C., Camarillo, D.B.: Model-less hybrid position/force control: a minimalist approach for continuum manipulators in unknown, constrained environments. IEEE Robot. Autom. Lett. 1(2), 844–851 (2016)

Abdul, S., Liu, G.: Decentralised fault tolerance and fault detection of modular and reconfigurable robots with joint torque sensing. In: IEEE International Conference on Robotics and Automation, Pasadena, pp. 19–23 (2008)

Zhao, B., Li, Y.C.: Local joint information based active fault tolerant control for reconfigurable manipulator. Nonlinear Dyn. 77(3), 859–876 (2014)

David, J.C., Ulrik, P.S., Kasper, S.: A distributed and morphology-independent strategy for adaptive locomotion in self-reconfigurable modular robots. Robot. Auton. Syst. 61(9), 1021–1035 (2013)

Ahmad, S., Zhang, H., Liu, G.: Distributed fault detection for modular and reconfigurable robots with joint torque sensing: a prediction error based approach. Mechatronics 23(6), 607–616 (2013)

Fumagalli, M., Ivaldi, S., Randazzo, M., Natale, L., Metta, G., Sandini, G., Nori, F.: Force feedback exploiting tactile and proximal force/torque sensing. Auton. Robot. 33(4), 381–398 (2012)

Liu, G., Abdul, S., Goldenberg, A.A.: Distributed control of modular and reconfigurable robot with torque sensing. Robotica 26(5), 75–84 (2008)

Benosman, B., Lum, K.Y.: Passive actuators fault-tolerant control for affine nonlinear systems. IEEE Trans. Control Syst. Technol. 18(1), 152–163 (2010)

Wang, W., Wen, C.: Adaptive compensation for infinite number of actuator failures or faults. Automatica 47(10), 2197–2210 (2011)

Huang, S.T., Davison, E.J., Kwong, R.: Decentralized robust servomechanism problem for large flexible space structures under sensor and actuator failures. IEEE Trans. Autom. Control 57(12), 3219–3224 (2012)

Yang, G.H., Ye, D.: Reliable control of linear systems with adaptive mechanism. IEEE Trans. Autom. Control 55(1), 242–247 (2010)

Wang, H., Ye, D., Yang, G.H.: Actuator fault diagnosis for uncertain TCS fuzzy systems with local nonlinear models. Nonlinear Dyn. 76(4), 1977–1988 (2014)

Yin, S., Luo, H., Ding, S.: Real-time implementation of fault tolerant control system with performance optimization. IEEE Trans. Ind. Electron. 61(5), 2402–2411 (2014)

Yin, C., Chen, Y.Q., Zhong, S.M.: Fractional-order sliding mode based extremum seeking control of a class of nonlinear systems. Automatica 50(12), 3173–3181 (2014)

Huang, P., Zhang, F., Meng, Z., Liu, Z.: Adaptive control for space debris removal with uncertain kinematics, dynamics and states. Acta Astronaut. 128, 416–430 (2016)

Yin, C., Cheng, Y., Chen, Y.Q., Stark, B., Zhong, S.: Adaptive fractional-order switching-type control method design for 3D fractional-order nonlinear systems. Nonlinear Dyn. 82(1), 39–52 (2015)

Wai, R.J., Muthusamy, R.: Fuzzy-neural-network inherited sliding-mode control for robot manipulator including actuator dynamics. IEEE Trans. Neural Netw. Learn. Syst. 24(2), 274–287 (2013)

Baek, J., Jin, M., Han, S.: A new adaptive sliding-mode control scheme for application to robot manipulators. IEEE Trans. Ind. Electron. 63(6), 3628–3637 (2016)

Huang, P., Wang, M., Meng, Z., Zhang, F., Liu, Z.: Attitude takeover control for post-capture of target spacecraft using space robot. Aerosp. Sci. Technol. 51, 171–180 (2016)

Huang, P., Wang, M., Meng, Z., Zhang, F., Liu, Z., Chang, H.: Reconfigurable spacecraft attitude takeover control in post-capture of target by space manipulators. J. Frankl. Inst. 353(9), 1985–2008 (2016)

Balasubramaniam, P., Muthukumar, P., Ratnavelu, K.: Theoretical and practical applications of fuzzy fractional integral sliding mode control for fractional-order dynamical system. Nonlinear Dyn. 80(1), 249–267 (2015)

Li, H., Yu, J., Hilton, C., Liu, H.: Adaptive sliding-Mode control for nonlinear active suspension vehicle systems using T–S fuzzy approach. IEEE Trans. Ind. Electron. 60(8), 3328–3338 (2013)

Chen, C.C., Xu, S.S.D., Liang, Y.W.: Study of nonlinear integral sliding mode fault-tolerant control. IEEE/ASME Trans. Mechatron. 21(2), 1160–1168 (2016)

Li, Y., Wang, G., Dong, B., Zhao, B.: Hybrid position-force control for constrained reconfigurable manipulators based on adaptive neural network. Adv. Mech. Eng. 7(9), 364–383 (2015)

Zhu, M., Li, Y.: Decentralized adaptive fuzzy sliding mode control for reconfigurable modular manipulators. Int. J. Robust Nonlinear Control 20(4), 472–488 (2010)

Alvarez-Ramirez, J., Espinosa-Paredes, G., Puebla, H.: Chaos control using small amplitude damping signals. Phys. Lett. A 316(3–4), 196–205 (2003)

Zhang, H., Ahmad, S., Liu, G.: Modeling of torsional compliance and hysteresis behaviors in harmonic drives. IEEE/ASME Trans. Mechatron. 20(1), 178–185 (2015)

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (61374051 and 60974010) and Scientific and Technological Development Plan Project in Jilin Province of China (20160414033GH and 20160520013JH).

Author information

Authors and Affiliations

Corresponding authors

Appendix: Joint torque estimation

Appendix: Joint torque estimation

Considering the constrained reconfigurable module manipulators that consists of n-modules, each module provides an independently rotating joint with harmonic drive transmission. The graph in Fig. 13 [36] depicts the main components of harmonic drives. The wave generator (WG) is connected to a motor, the circular spline (CS) is connected to the joint base, and the flexspline (FS) is sandwiched in between CS and WG and connected to the joint output.

Owing to flexibility of FS and WG, a kinematic representation of a harmonic drive is illustrated in Fig. 14. Therefore, FS and WG torsion are defined as follows:

where \({\theta _{fsi}}\) and \({\theta _{foi}}\) refer to the angular position at the FS gearside (gear-toothed circumference) and the FS angular position at the load side which is measured using the link-side encoder, respectively. \({\theta _{ goi}}\) and \({\theta _{gsi}}\) denote the positions of the WG outside part (ball bearing outer rim) and the center part (WG plug), respectively.

The total torsional angle of harmonic drive can be described by:

By adding and subtracting the terms \({\theta _{fsi}}\) and \({\theta _{ goi}} \) to (55), one obtains:

where \({\theta _{\mathrm{err}i}}\) denotes the kinematic error of harmonic drive transmission. Based on the assumption that the relative motion between the WG output and the FS input can be ignored, we can conclude that \({\theta _{\mathrm{err}i}} = 0\) [36]. The FS and WG torque can be modeled as:

where \({L_f}\) and \({L_g}\) are the stiffness of FS and WG, respectively.

Because the torsional angle is described a function of the torque, the local elastic coefficient increases as \({\tau _{fi}}\) increases. Therefore, one can define the local elastic coefficient \({L_{fk}}\) as:

where \({L_{fo}}\) and \({a_f}\) are constants to be determined. If \({L_{fo}} \ne 0\) , then the FS torsion can be counted as:

Note that the harmonic drive deformation deformation range drops down to zero sharply at rated torque, which implies that the stiffness of WG increase sharply. In order to replicate the hysteresis shape of this stiffness property, the local elastic coefficient of WG can be modeled as:

where \({L_{ go}}\) and \({a_{g}}\) are constants to be determined. If \({L_{go}} \ne 0\) , then the WG torsional angle can be calculated using the following relation:

Finally, by substituting the FS and WG deformation given in (60) and (62) into (56), the total deformation of the harmonic drive can be expressed as:

Then,

where the WG torque \({\tau _{gi}}\) can be approximated by the motor torque command.

By the following formula, one can get the constrained torque, which is obtained by the constrained force on the end-effector of manipulator:

where \(\tau _{fio}\) denotes the joint torque which is obtained in free space, \(\tau _{fie}\) denotes the total joint torque in the constrained space. The total joint torque \(\tau _{fie}\) and/or joint torque in free space \(\tau _{fio}\) is directly obtained from formula (64) under the condition of constrained space and free space, respectively.

Rights and permissions

About this article

Cite this article

Zhou, F., Li, Y. & Liu, G. Robust decentralized force/position fault-tolerant control for constrained reconfigurable manipulators without torque sensing. Nonlinear Dyn 89, 955–969 (2017). https://doi.org/10.1007/s11071-017-3494-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-017-3494-1