Abstract

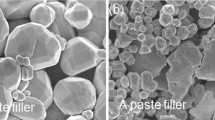

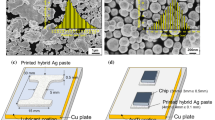

A rising variety of power devices based on wide-bandgap (WBG) semiconductors are employed in products that can service at high temperatures consistently for extending the working life. Traditional tin–lead and lead-free solders are no longer suitable for power device packaging. Recently, nano-Ag pressureless sintering technology has attracted widespread attention for high-temperature application. When commercial Ag powders are applied, satisfactory sintering quality is often not obtained due to unstable product batches, unknown surface cladding, and poor sintering performance. In this work, Ag nanoparticles are surface modified with tert-dodecyl mercaptan (TDM) to prevent agglomeration at room temperature for improving pressureless sintering performance. We systematically introduced the modification process of Ag nanoparticles and Ag paste preparation and sintering process and compared the changes in the sintering performance of modified Ag nanoparticles with different TDM contents. With a minor amount of TDM, 1.5% of the total weight of Ag, the sintering performance of the Ag paste can be effectively improved and the porosity reduced. The highest average shear strength of the bonded joints based on modified Ag nanoparticles is up to 46.82 MPa with only 6.1% porosity by pressureless and low-temperature sinter at 250 °C for 10 min in ambient air, and the sintering morphology is better than the joints without nanoparticle modification. At the same time, increasing the sintering time does not have much effect on the bond strength, which indicated that 10 min already formed a high-quality joint. The analysis reveals that TDM molecules can be absorbed on the surface of Ag nanoparticles by headgroups to form a coating layer. The mechanism of TDM modification to enhance the sintering performance is also proposed, which provides theoretical support for the practical application of the pressureless Ag sintering technology.

Graphical abstract

Similar content being viewed by others

References

Yang F, Zhu W, Wu W et al (2020) Microstructural evolution and degradation mechanism of SiC–Cu chip attachment using sintered nano-Ag paste during high-temperature ageing. J Alloy Compd 846:156442. https://doi.org/10.1016/j.jallcom.2020.156442

Yan J (2021) A review of sintering-bonding technology using Ag nanoparticles for electronic packaging. Nanomaterials 11:927. https://doi.org/10.3390/nano11040927

Zhang H, Wang W, Bai H et al (2019) Microstructural and mechanical evolution of silver sintering die attach for SiC power devices during high temperature applications. J Alloy Compd 774:487–494. https://doi.org/10.1016/j.jallcom.2018.10.067

Cheng S, Huang C-M, Pecht M (2017) A review of lead-free solders for electronics applications. Microelectron Reliab 75:77–95. https://doi.org/10.1016/j.microrel.2017.06.016

Wang Q, Zhang S, Lin T et al (2021) Highly mechanical and high-temperature properties of Cu–Cu joints using citrate-coated nanosized Ag paste in air. Progress in Natural Science: Materials International 31:129–140. https://doi.org/10.1016/j.pnsc.2020.12.004

Liu X, Liu L, Sun R, Li J (2021) Low temperature sintering of MOD assisted Ag paste for die-attach application. Materials Letters 305:130799. https://doi.org/10.1016/j.matlet.2021.130799

Zhao S-Y, Li X, Mei Y-H, Lu G-Q (2015) Study on high temperature bonding reliability of sintered nano-silver joint on bare copper plate. Microelectron Reliab 55:2524–2531. https://doi.org/10.1016/j.microrel.2015.10.017

Jiu J, Zhang H, Nagao S et al (2016) Die-attaching silver paste based on a novel solvent for high-power semiconductor devices. J Mater Sci 51:3422–3430. https://doi.org/10.1007/s10853-015-9659-8

Zhang H, Gao Y, Jiu J, Suganuma K (2017) In situ bridging effect of Ag2O on pressureless and low-temperature sintering of micron-scale silver paste. J Alloy Compd 696:123–129. https://doi.org/10.1016/j.jallcom.2016.11.225

Zhang H, Chen C, Jiu J et al (2018) High-temperature reliability of low-temperature and pressureless micron Ag sintered joints for die attachment in high-power device. J Mater Sci: Mater Electron 29:8854–8862. https://doi.org/10.1007/s10854-018-8903-9

Pei C, Chen C, Suganuma K, Fu G (2018) Thermal Stability of Silver Paste Sintering on Coated Copper and Aluminum Substrates. J Electron Mater 47:811–819. https://doi.org/10.1007/s11664-017-5857-2

Chen C, Suganuma K, Iwashige T et al (2018) High-temperature reliability of sintered microporous Ag on electroplated Ag, Au, and sputtered Ag metallization substrates. J Mater Sci: Mater Electron 29:1785–1797. https://doi.org/10.1007/s10854-017-8087-8

Chen C, Noh S, Zhang H et al (2018) Bonding technology based on solid porous Ag for large area chips. Scripta Mater 146:123–127. https://doi.org/10.1016/j.scriptamat.2017.11.035

Chen C, Choe C, Zhang Z et al (2018) Low-stress design of bonding structure and its thermal shock performance (− 50 to 250 °C) in SiC/DBC power die-attached modules. J Mater Sci: Mater Electron 29:14335–14346. https://doi.org/10.1007/s10854-018-9568-0

Ji H, Zhou J, Liang M et al (2018) Ultra-low temperature sintering of Cu@Ag core-shell nanop Microstructural studies and bonding article paste by ultrasonic in air for high-temperature power device packaging. Ultrason Sonochem 41:375–381. https://doi.org/10.1016/j.ultsonch.2017.10.003

Zabihzadeh S, Van Petegem S, Duarte LI et al (2015) Deformation behavior of sintered nanocrystalline silver layers. Acta Mater 97:116–123. https://doi.org/10.1016/j.actamat.2015.06.040

Gadaud P, Caccuri V, Bertheau D et al (2016) Ageing sintered silver: relationship between tensile behavior, mechanical properties and the nanoporous structure evolution. Mater Sci Eng, A 669:379–386. https://doi.org/10.1016/j.msea.2016.05.108

Chua ST, Siow KS (2016) Microstructural studies and bonding strength of pressureless sintered nano-silver joints on silver, direct bond copper (DBC) and copper substrates aged at 300 °C. J Alloys Compd 687:486–498. https://doi.org/10.1016/j.jallcom.2016.06.132

Siow KS, Lin YT (2016) Identifying the Development State of Sintered Silver (Ag) as a Bonding Material in the Microelectronic Packaging Via a Patent Landscape Study. J Electron Packag 138: https://doi.org/10.1115/1.4033069

Li S, Liu Y, Sun F, Fang H (2021) Multi-particle molecular dynamics simulation: shell thickness effects on sintering process of Cu-Ag core-shell nanoparticles. J Nanopart Res 23:1–14. https://doi.org/10.1007/s11051-021-05144-1

Qin G, Watanabe A (2014) Conductive network structure formed by laser sintering of silver nanoparticles. J Nanopart Res 16:1–12. https://doi.org/10.1007/s11051-014-2684-8

Mysliwiec M, Kisiel R, Pavlov K, Kruszewski MJ (2022) Pressureless Direct Bonding of Au Metallized Substrate with Si Chips by Micro-Ag Particles. In: 2022 45th International Spring Seminar on Electronics Technology (ISSE). IEEE, Vienna, Austria, pp 1–7

Jinendra U, Bilehal D, Nagabhushana BM et al (2019) Template-free hydrothermal synthesis of hexa ferrite nanoparticles and its adsorption capability for different organic dyes: Comparative adsorption studies, isotherms and kinetic studies. Materials Science for Energy Technologies 2:657–666. https://doi.org/10.1016/j.mset.2019.08.005

Shanmugan S, Gorjian S, Elsheikh AH, et al (2021) Investigation into the effects of Sio2/Tio2 nanolayer on the thermal performance of solar box type cooker. null 43:2724–2737. https://doi.org/10.1080/15567036.2020.1859018

Das A, Mohanty S, Kuanr BK (2022) Introducing longitudinal oxidation reaction for ultrarapid and single-step synthesis of thiol-mediated end-to-end assembly of gold nanorods. J Nanopart Res 24:1–15. https://doi.org/10.1007/s11051-022-05551-y

Paknejad SA, Dumas G, West G et al (2014) Microstructure evolution during 300 °C storage of sintered Ag nanoparticles on Ag and Au substrates. J Alloys Compd 617:994–1001. https://doi.org/10.1016/j.jallcom.2014.08.062

Chen C, Zhang Z, Choe C et al (2019) Improvement of the bond strength of Ag sinter-joining on electroless Ni/Au plated substrate by a one-step preheating treatment. Journal of Elec Materi 48:1106–1115. https://doi.org/10.1007/s11664-018-06842-8

Wang X, Mei Y, Li X et al (2019) Pressureless sintering of nanosilver paste as die attachment on substrates with ENIG finish for semiconductor applications. J Alloy Compd 777:578–585. https://doi.org/10.1016/j.jallcom.2018.10.294

Liu W, Mei Y, Xie Y et al (2019) Design and characterizations of a planar multichip half-bridge power module by pressureless sintering of nanosilver paste. IEEE Journal of Emerging and Selected Topics in Power Electronics 7:1627–1636. https://doi.org/10.1109/JESTPE.2019.2905773

Mo L, Liu D, Li W et al (2011) Effects of dodecylamine and dodecanethiol on the conductive properties of nano-Ag films. Appl Surf Sci 257:5746–5753. https://doi.org/10.1016/j.apsusc.2011.01.090

Shao C, Xiong S, Cao X et al (2021) Dithiothreitol-capped red emitting copper nanoclusters as highly effective fluorescent nanoprobe for cobalt (II) ions sensing. Microchem J 163:105922. https://doi.org/10.1016/j.microc.2021.105922

Kwon S, Lee T-I, Lee H-J, Yoo S (2020) Improved sinterability of micro-scale copper paste with a reducing agent. Mater Lett 269:127656. https://doi.org/10.1016/j.matlet.2020.127656

Yoon J-W, Back J-H, Jung S-B (2018) Effect of surface finish metallization on mechanical strength of Ag sintered joint. Microelectron Eng 198:15–21. https://doi.org/10.1016/j.mee.2018.06.009

Chen C, Zhang Z, Zhang B, Suganuma K (2020) Micron-sized Ag flake particles direct die bonding on electroless Ni–P-finished DBC substrate: low-temperature pressure-free sintering, bonding mechanism and high-temperature aging reliability. J Mater Sci: Mater Electron 31:1247–1256. https://doi.org/10.1007/s10854-019-02636-8

Caccuri V, Milhet X, Gadaud P et al (2014) Mechanical properties of sintered Ag as a new material for die bonding: influence of the density. J Electron Mater 43:4510–4514. https://doi.org/10.1007/s11664-014-3458-x

Carr J, Milhet X, Gadaud P et al (2015) Quantitative characterization of porosity and determination of elastic modulus for sintered micro-silver joints. J Mater Process Technol 225:19–23. https://doi.org/10.1016/j.jmatprotec.2015.03.037

Funding

This work is financially supported by National Natural Science Foundation of China with the grant number of 51805197.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shen, X., Xi, S., Xu, L. et al. Pressureless sintering performance enhancement of Ag pastes by surface modification of Ag nanoparticles with tert-dodecyl mercaptan. J Nanopart Res 24, 213 (2022). https://doi.org/10.1007/s11051-022-05591-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-022-05591-4