Abstract

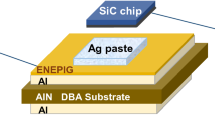

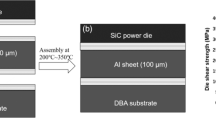

Low-stress design of bonding technology with a sandwich structure of sintered Ag and tungsten (W) thin film was developed for SiC power die-attached modules. The die-attached bonding layer was designed as sintered Ag/W/sintered Ag structure. Experiment results show that the initial bonding strength was larger than 65 MPa for this die-attached structure and larger than 35 MPa with a thermal shock test from − 50 to 250 °C for 1000 cycles. These results are largely better than that almost all sintering Ag technology reported in previous studies. Furthermore, the sandwich structure also compared with the sintered Ag structure which just using sintered Ag paste as bonding layer. The thickness of Ag paste is set as 100, 200 and 500 µm in the sintered Ag structure. The results show that the initial bonding strength of sintered Ag structure was about 60–70% of the value of W sandwich structure and about one-third of that after 1000 cycles. X-ray and SEM observation revealed that sandwich structure significantly decreased the size of crack extension in the sintered Ag layer during the thermal shock test. Finite element analysis reveal that the shear stress at the pore location of sandwich structure decreased to almost half values of the sintered Ag structure with the thickness of sintered Ag of 500 µm, and decreased almost 20% compared with the thickness of sintered Ag of 100 µm. The bonding technology with the W sandwich structure should be an attractive for low stress design in SiC power die-attached modules, which significantly increased its function for long-term high temperature applications.

Similar content being viewed by others

References

N. Kaminski, SiC and GaN devices-competition or coexistence, IEEE CIPS, (2012) pp 393–403

P.G. Neudeck, R.S. Okojie, L.-Y. Chen, High-temperature electronics—a role for wide bandgap Semiconductors, Proc. IEEE. 90 (2002) pp 1065–1076

H.S. Chin, K.Y. Cheong, A.B. Ismail, A review on die attach materials for SiC-based high-temperature power devices. Met. Mater. Trans. B 41, 824–832 (2010)

T. Funaki, J.C. Balda, J. Junghans, A.A. Kashyap, F.D. Barlow, H.A. Mantooth, T. Kimoto, T. Hikihara, SiC JFET dc characteristics under extremely high ambient temperatures. IEICE Electron. Express 1, 523–527 (2004)

L.N. Ramanathan, J.W. Jang, J.K. Lin, D.R. Frear, Solid-state annealing behavior of two high-Pb solders, 95Pb5Sn and 90Pb10Sn, on Cu under bump metallurgy. J. Electron. Mater. 34, 43–46 (2005)

K.S. Kim, C.H. Yu, N.H. Kim, H.J. Chang, E.G. Chang, Isothermal aging characteristics of Sn-Pb micro solder bumps. Microelectron. Reliab. 43, 757–763 (2003)

T. Laurila, V. Vuorinen, J.K. Kivilahti, Interfacial reactions between lead-free solders and common base materials. Mater. Sci. Eng. Rep. 49, 1–60 (2005)

E. Ide, S. Angata, A. Hirose, K.F. Kobayashi, Metal-metal bonding process using Ag metallo-organic nanoparticles. Acta Mater. 53, 2385–2393 (2005)

C. Chen, S. Nagao, K. Suganuma, J. Jiu, T. Sugahara, H. Zhang, T. Iwashige, K. Sugiura, K. Tsuruta, Macroscale and microscale fracture toughness of microporous sintered Ag for applications in power electronic devices. Acta Mater. 129, 41–51 (2017)

K.S. Siow, Are sintered silver joints ready for use as interconnect material in microelectronic packaging? J. Electron. Mater. 43, 947–961 (2014)

S.P. Chen, Z.K. Kao, J.L. Lin, Y.C. Liao, Silver conductive features on flexible substrates from a thermally accelerated chain reaction at low sintering temperatures. ACS Appl. Mater. Interfaces 4, 7064–7068 (2012)

C. Chen, S. Nagao, H. Zhang, J. Jiu, T. Sugahara, K. Suganuma, T. Iwashige, K. Sugiura, K. Tsuruta, Mechanical deformation of sintered porous Ag die attach at high temperature and its size effect for wide-bandgap power device design. J. Electron. Mater. 46, 1576–1586 (2017)

C. Chen, S. Nagao, K. Suganuma, J. Jiu, H. Zhang, T. Sugahara, T. Iwashige, K. Sugiura, K. Tsuruta, Self-healing of cracks in Ag joining layer for die-attachment in power devices. Appl. Phys. Lett. 109, 093503 (2016)

S. Sakamoto, T. Sugahara, K. Suganuma, Microstructural stability of Ag sinter joining in thermal cycling. J. Mater. Sci. 24, 1332–1340 (2013)

C. Chen, S. Nagao, H. Zhang, J. Jiu, T. Sugahara, K. Suganuma, T. Iwashige, K. Sugiura, K. Tsuruta, Low-Stress Design for SiC Power Modules with Sintered Porous Ag Interconnection, Proceedings of 66th IEEE Electronic Components and Technology Conference (ECTC), (2016) pp 2058–2062

N. Heuck, S. Muller, G. Palm, A. Bakin, A. Waag, Swelling phenomena in sintered die-attached structure at high temperature: reliability problems and solutions for an operation above 350 °C. IMAPS International Conference and Exhibition on High Temperature Electronics (HITEC), (2010) pp 18–25

Y. Mei, G.-Q. Lu, X. Chen, G. Chen, S. Luo, D. Ibitayo, Investigation of post-etch copper residue on direct bonded copper (DBC) substrates. J. Electron. Mater. 40, 2119–2125 (2011)

Y. Mei, G.-Q. Lu, X. Chen, G. Chen, S. Luo, D. Ibitayo, Migration of sintered nanosilver die-attach material on alumina substrate between 250 °c and 400 °c in dry air. IEEE Trans. Device Mater. Reliab. 11, 316–322 (2011)

Y. Mei, Y. Cao, G. Chen, X. Li, G.-Q. Lu, X. Chen, Rapid sintering nanosilver joint by pulse current for power electronics packaging. IEEE Trans. Device Mater. Reliab. 13, 258–265 (2013)

J. Lia, C.M. Johnsona, C. Buttayb, W. Sabbahc, S. Azzopardi, Bonding strength of multiple SiC die attachment prepared by sintering of Ag nanoparticles. J. Mater. Process. Technol. 215, 299–308 (2015)

G.-Q. Lu, J.N. Calata, G. Lei, Low-temperature pressureless sintering technology for high-performance and high-temperature interconnection of semiconductor devices, IEEE 8th International Conference on Thermal, Mechanical and Multiphysics Simulation and Experiments in Micro-Electronics and Micro-Systems (2007) pp 609–613

Y. Moon, H. Kang, K. Kang, S. Moon, J. Hwang, Effect of thickness on surface morphology of silver nanoparticle layer during furnace sintering. J. Electron. Mater. 44, 1192–1199 (2015)

K. Sugiura, T. Iwashige, J. kawai, K. Tsuruta, C. Chen, S. Nagao, H. Zhang, T. sugahara, K. suganuma, S. kurosaka, Y. Sakuma, Y. Oda., Prominent interface structure and bonding material of power module for high temperature operation, The 19th international symposium on power semiconductor devices &ICs, (2017) pp 491–494

H. Zhang, S. Nagao, K. Suganuma, H. Albrecht, K. Wilke, Thermostable Ag die-attach structure for high-temperature power devices. J. Mater. Sci. 27, 1337–1344 (2016)

C. Chen, K. Suganuma, T. Iwashige, K. Sugiura, K. Tsuruta, High-temperature reliability of sintered microporous Ag on electroplated Ag, Au, and sputtered Ag metallization substrates. J. Mater. Sci. 29, 1785–1797 (2018)

T.G. Lei, J.N. Calata, G.-Q. Lu, X. Chen, S.F. Luo, Low-temperature sintering of nanoscale silver paste for attaching large-area (> 100 mm2) chips. IEEE Trans. Compon. Packag. Technol. 33, 98–104 (2010)

J.G. Bai, G.-Q. Lu, Thermomechanical reliability of low-temperature sintered silver die attached SiC power device assembly. IEEE Trans. Device Mater. Reliab. 6, 436–441 (2006)

R. Khazaka, L. Mendizabal, D. Henry, Review on joint shear strength of nano-silver paste and its long-term high temperature reliability. J. Electron. Mater. 43, 2459–2466 (2014)

M. Knoerr, S. Kraft, A. Schletz, Reliability Assessment of Sintered Nano-Silver Die Attachment for Power Semiconductors, 12th IEEE Electronics Packaging Technology Conference (EPTC), (2010) pp 56–61

D.A. Shnawah, M.F. MohdSabri, I.A. Badruddin, A review on thermal cycling and drop impact reliability of SAC solder joint in portable electronic products. Microelectron. Reliab. 52, 90–99 (2012)

K. Siow, Are sintered silver joints ready for use as interconnect material in microelectronic packaging? J. Electron. Mater. 43, 947–961 (2014)

H. Zhang, C. Chen, S. Nagao, K. Suganuma, Thermal fatigue behavior of silicon-carbide-doped silver microflake sinter joints for die attachment in silicon/silicon carbide power devices. J. Electron. Mater. 46, 1055–1060 (2017)

S. Egelkraut, L. Frey, M. Knoerr, A. Schletz, Evolution of shear strength and microstructure of die bonding technologies for high temperature applications during thermal aging, Proc. 12th Electron. Package Tech. Conf., (2010) pp 660–667

T. Wang, X. Chen, G.Q. Lu, G. Lei, Low-Temperature sintering with nano-silver paste in die-attached interconnection. J. Electron. Mater. 36, 1333–1340 (2007)

S. Zabihzadeh, S. Van Petegem, L.I. Duarte, R. Mokso, A. Cervellino, H. Van Swygenhoven, Deformation behavior of sintered nanocrystalline silver layers. Acta Mater. 97, 116–123 (2015)

S.T. Chua, K.S. Siow, Microstructural studies and bonding strength of pressureless sintered nano-silver joints on silver, direct bond copper (DBC) and copper substrates aged at 300 °C. J. Alloy. Compd. 687, 486–498 (2016)

P. Gadaud, V. Caccuri, D. Bertheau, J. Carr, X. Milhet, Ageing sintered silver: relationship between tensile behavior, mechanical properties and the nanoporous structure evolution. Mater. Sci. Eng. A 669, 379–386 (2016)

H. Vijayakumar, A.H. Sriramamurthy, S.V. Nagender Naidu, Calculated phase diagrams of Cu-W, Ag-W and Au-W binary systems, Calphad 12, 177–184 (1988)

G.W. Jones, J.A. Venables, Observation of surface diffusion by biassed secondary electron imaging: the case of Ag/W (110). Ultramicroscopy 18, 439–444 (1985)

H. Zhang, C. Chen, J. Jiu, S. Nagao, K. Suganuma, High-temperature reliability of low-temperature and pressureless micron Ag sintered joints for die attachment in high-power device. J. Mater. Sci. 29, 8854–8862 (2018)

Acknowledgements

This work was supported by the JST Advanced Low Carbon Technology Research and Development Program (ALCA) project “Development of a high frequency GaN power module package technology” (Grant No. JPMJAL1610). The authors thank Mr. Aiji Suetake for his help in the experiment and also thankful to the Network Joint Research Centre for Materials and Devices, Dynamic Alliance for Open Innovation Bridging Human, Environment and Materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, C., Choe, C., Zhang, Z. et al. Low-stress design of bonding structure and its thermal shock performance (− 50 to 250 °C) in SiC/DBC power die-attached modules. J Mater Sci: Mater Electron 29, 14335–14346 (2018). https://doi.org/10.1007/s10854-018-9568-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9568-0