Abstract

The synthesis of nanosized phosphors by using the non-thermal plasma-driven method is presented. The method allows to control the average grain size of nanocrystals. The synthesis of Eu3+-doped Y2O3 nanocrystalline phosphors at water solution of nitrates is described. The average sizes of nanocrystals were controlled by sintering temperature. Their structure, morphology, and luminescent properties were investigated.

Similar content being viewed by others

Introduction

The Eu3+-doped yttria (Y2O3) is one of the most popular red phosphors commonly applied in different light-emitting devices (Hunt and Chakhovskoi 1997; Shea 1998). The type of light source determines the specific phosphor requirements. The Eu3+:Y2O3 phosphor is used for wide group of light sources and displays (Hunt and Chakhovskoi 1997; Shea 1998; Shionoya and Yen 1998; Srivastava and Ronda 2003; Vetrone et al. 2004; Wakefield et al. 2000; Waser 2003). There are a few methods for synthesis of nanocrystals (Barta et al. 2010; Chen et al. 2005; Hreniak et al. 2004; Jang et al. 2006; Lee and Choi 2005; Pechini 1967; Tang et al. 2003; Song et al. 2003; Vollath and Szabo 2006; Xu et al. 2005; Zhang et al. 2004). The simple one is modified Pechini method (Pechini 1967; Psuja et al. 2007a, b, 2009, 2012). It consists in crystallization of the compounds in violent combustion reaction. The synthesis connects advantages of sol–gel and thermal decomposition techniques. The disadvantage of this method is the necessity of sintering of resins which implicates the difficulties in the case of mass production. Those difficulties come off as a large amount of air contaminations—products of thermal decomposition of resins. Another drawback of this method is violence of reaction, which really influence and limit mass production application. Despite the above-mentioned methods (Hreniak et al. 2004; Lee and Choi 2005; Pechini 1967; Xu et al. 2005; Song et al. 2003) and the others presented elsewhere (Barta et al. 2010; Chen et al. 2005; Cuba et al. 2010a, b, 2011, 2012; Gbur et al. 2011; Jang et al. 2006; Tang et al. 2003; Vollath and Szabo 2006; Zhang et al. 2004) synthesis of nanocrystals using only water solutions of nitrates exposited for non-thermal plasma (NTP) is possible. The other method of synthesis of nanoparticles uses a plasma microwave reactor (Vollath and Szabo 2006), where the reaction of ionized gases takes place.

In the present work a new method of synthesis of Eu3+:Y2O3 nanocrystals using NTP reactor is described. This method allows fabrication of nanoparticles with narrow size distribution by using only water solutions of metal nitrates. The plasma treatment is necessary to change the crystallization mechanism of salts (nitrates) dispersed in the solution. Such a process of fabrication of nanostructures has been described earlier by (Tereshko et al. 2007a, b).

Experimental

Lanthanide oxides were purchased form Sigma-Aldrich company. The nitrides were prepared by dissolving the corresponding lanthanide oxides in a nitric acid solution and the water was evaporated from the solution. The structure of obtained powders samples was characterized by X-ray diffraction (XRD-a Stoe Powder Sensitive Detector; filtered CuKα1 radiation). For Eu3+:Y2O3 sample sintered at 600 °C TEM images was created using Philips CM 20 Super Twin Transmission Electron Microscope with resolution 0.025 nm. The photoluminescence spectra were registered at room temperature using CCD spectrophotometer Avantes 350–1,000 nm spectral range, ~0,35 nm resolution. The samples were excited using λ ex = 266 nm of Nd:YAG laser system (the forth harmonic of Nd:YAG laser, 10 ns in pulse, 50 Hz). The luminescence spectra of obtained materials were registered and compared.

The schematic diagram of NTP reactor is presented above (Fig. 1). The reaction dish contained the water solution of Eu,Y(NO3)3 was placed between two electrodes. The electrodes were connected to generator, and high-voltage power supply. The reaction dish and electrodes were placed in the vacuum chamber. The pressure in the reactor was decreased to c. a. 0.15 hPa. The voltage and the current were properly 2.5 kV and 30 mA. The process of plasma irradiation takes usually 2–3 h.

Preparation of Eu3+:Y2O3 nanocrystals

The stoichiometric amounts of yttrium nitride and europium nitride were dissolved using ultrasounds in 10 ml of deionized water. The concentration of europium was established for 5 %. Then the transparent, uniform solution was placed in NTP reactor (Fig. 1). The sample was held in plasma environment at special setup for 2 h. After that solution was divided for 5 samples dried separately at 90 °C and sintered for 8 h at temperatures: 425, 450, 500, 600, 700, 800, 850, and 950 °C. The samples with different Eu3+ concentrations (10, 5, 2, 1, and 0.5 %) were also prepared. The scheme of synthesis process is shown in Fig. 2.

Results and discussion

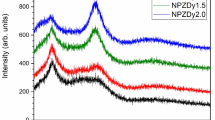

The XRD spectra of synthesized materials are presented in Figs. 3, 4, and 5. The XRD curves correspond well with the Y2O3 pattern (JCPDS# 430661). The average grain sizes of the obtained nanopowders were determined using Scherrer formula from bordering of diffraction peaks.

The solution was divided into two parts. The first was hold in NTP reactor for 3 h and the second was kept as a reference sample. Then the samples were held at temperature 70 °C for 24 h and then sintered at 450 and 425 °C. The XRD curves of samples sintered at 450 and 425 °C were compared. It is seen that sample treated by plasma and sintered at 450 °C was more phase homogenous.

It is seen that with increasing sintering temperature (Figs. 3, 4, and 6) the average grain size increased. This effect allowed to control the size of the obtained nanoparticles by adjusting temperature. The curve for sample synthesized at 500 °C has shown a quite weak crystallization rate. For the samples synthesized at 600, 700, and 800 °C the size differences were very small—14.1 nm at 600 °C and 17.8 nm at 800 °C. However, at 900 °C the average grain size was 29.4 nm. The temperature dependence of average grain size of the obtained nanocrystals at measured temperature range can be approximated as a linear function. It is seen that solution is more temperature sensitive at the range from 800 to 900 °C than from 600 to 800 °C. Hence, the full crystallization of sample appears above 800 °C. The confirmation of this statement is the average grain size of nanocrystals sintered at 850 °C, 27.5 nm. However, as it is shown from TEM image (Fig. 8) of sample sintered at 600 °C the obtained material is crystalline.

The XRD curves of samples sintered at 900 °C with different Eu3+ concentrations are presented in Fig. 4. It is seen that average grain size calculated using Scherrer formula decrease with Eu3+ concentration.

The dependence of average grain size on Eu3+ concentration is shown in Fig. 7. One can see that the average grain size decreases with concentration of Eu3+ ions.

Such behavior was also observed earlier for other rare earth ions in Y2O3, YAG, SnO2, and BaTiO3 nanocrystals. The most probable explanation is mismatching of ionic and atomic radius of europium and yttrium appearing in strong lattice strength influenced by this difference.

The TEM images of Eu:Y2O3 nanocrystals sintered at 600 °C are presented in Fig. 8.

It is seen that size and shape of the obtained nanocrystals is not uniform. The crystals are strongly aggregated. The average grain size estimated from the TEM images is similar to the size calculated from Scherrer’s formula.

The luminescence spectra of nanocrystals sintered at 425 and 450 °C obtained by using NTP method and the reference one are presented in Fig. 9. It is seen that only samples obtained by plasma treatment showed spectra attributed to Eu3+ emission at Y2O3 host. The spectra of reference samples are typical for Eu3+ in amorphous phase. The photoluminescence of the examined materials is well in correlation with their XRD data and leads to conclusion that fabrication of Eu3+:Y2O3 at 450 °C and even at 425 °C in the most simple way from water solution of nitrides is possible only by using NTP reactor.

The photoluminescence spectra under λ exc = 266 nm of Eu3+:Y2O3 nanocrystallites with different average grain sizes are presented in Fig. 10. The sizes of samples were controlled using sintering temperature. Any significant differences were observed between spectra sintered above 500 °C. The registered spectra are typical for Eu3+ ions in Y2O3 host. The most intensive are peaks connected with the 5 D 0 → 7 F 2 transition. The peaks attributed to the 5 D 0 → 7 F 1 transition are assigned to the magnetic dipole transition and are not affected significantly by the size effect. The second one is electric dipole-allowed transition and is hypersensitive for local crystal field (Morais et al. 2008).

The relative intensities of both the transitions

and

were determined for the samples sintered at different temperatures (see Table 1). Here I total is the total intensity of all luminescent transition bands integrated from 450 to 750 nm.

A different behavior is observed for Eu3+ concentration influence on β 0→2/β 0→1. Here, the β 0→2 to β 0→1 ratio increase with concentration (Figs. 11 and 12). The results presented in Fig. 12 are well correlated with the dependence presented in Fig. 7. The observed situation suggests that with increasing of concentration interaction between Eu3+ ions and that of crystalline field as in Fig. 7, the size of the obtained nanocrystals decrease with Eu3+ concentration. So in single nanograin there is more and more Eu3+ ions interacting with local crystalline lattice. However, in the case of 10 % Eu3+:Y2O3 where average grain size of nanocrystals, calculated from Scherrer’s formula is only 31 nm, concentration quenching also plays some role. The same behavior is observed in Fig. 12.

The luminescence studies confirm a good crystallization of Eu3+:Y2O3 crystals obtained by NTP method.

Conclusion

The Eu3+:Y2O3 nanocrystallites were synthesized by new, simple, and efficient method using NTP reactor. It should be emphasized that only the water solutions of yttrium nitride and europium nitride were used as a substrate of the reaction. The average grain size of the obtained nanocrystals increased with sintering temperature and decreased with Eu3+ concentration. It was shown that using NTP reactor the synthesis of efficient Eu3+:Y2O3 is possible even at 425 °C, while reference sample synthesized in the same conditions and even at 450 °C was amorphous to a great extent. The proposed new method allows successful synthesis of RE-doped nanocrystalline phosphors. The resulting Eu3+:Y2O3 nanophophors show sufficient red luminescence upon UV excitation. The examinations over optimal synthesis conditions and size dependence on luminescence features of different nanocrystals will be a subject of our further studies.

References

Barta J, Pospisil M, Cuba V (2010) Photo- and radiation-induced preparation of nanocrystalline copper and cuprous oxide catalysts. J Radioanal Nucl Chem 286:611–618

Chen S-G, Li C-H, Xiong W-H, Liu L-M, Wang H (2005) Preparation of indium-tin oxide (ITO) nano-aciculae by a simple precipitation near boiling point and post-calcination method. Mater Lett 59:1342–1346

Cuba V, Gbur T, Mucka V, Nikl M, Kucerkova R, Pospisil M, Jakubec I (2010a) Properties of ZnO nanocrystals prepared by radiation method. Radiat Phys Chem 79:27–32

Cuba V, Nemec M, Gbur T, John J, Pospisil M, Mucka V (2010b) Radiation formation of colloidal silver particles in aqueous systems. Appl Radiat Isot 68:676–678

Cuba V, Indrei J, Mucka V, Nikl M, Beitlerova A, Pospisil M, Jakubec I (2011) Radiation induced synthesis of powder yttrium aluminum garnet. Radiat Phys Chem 80:957–962

Cuba V, Pavelkova T, Barta J, Jary V, Nikl M, Jakubec I (2012) Photo- and radiation induced preparation of Y2O3:Ce(Eu) nanocrystals. J Nanopart Res 14:794–801

Gbur T, Cuba V, Mucka V, Nikl M, Knizek K, Pospisil M, Jakubec I (2011) Photochemical preparation of ZnO nanoparticles. J Nanopart Res. doi:10.1007/s11051-011-0407-y

Hreniak D, Strek W, Mazur P, Pazik R, Zabkowska-Wacławek M (2004) Luminescence properties of Tb3+: Y3Al5O12 nanocrystallites prepared by the sol-gel method. Opt Mater 26:117–121

Hunt CE, Chakhovskoi AG (1997) Phosphor challenge for field-emission flat-panel displays. J Vac Sci Technol B 15:516–518

Jang HD, Song CM, Chang HK, Kim HC (2006) Synthesis and characterization of indium–tin oxide (ITO) nanoparticles. Curr Appl Phys 6:1044–1047

Lee J-S, Choi S-Ch (2005) Solvent effect on synthesis of indium tin oxide nano-powders by a solvothermal process. J Eur Ceram Soc 25:3307–3314

Morais EA, Scalvi LV, Tabata A, Oliveira JBB, Ribeiro SJL (2008) Photoluminescence of Eu3+ ion in SnO2 obtained by sol-gel. J Mater Sci 43:345

Pechini MP (1967) Method of preparing lead and alkaline earth titanates and niobates and coating method using the same to form capacitor. US Patent US 3330697 form, 11 July 1967

Psuja P, Strek W (2012) Influence of concentration and sintering temperature on luminescence properties of Eu3+:SnO2 nanocrystallites. J Rare Earth 30:627–631

Psuja P, Hreniak D, Strek W (2007) Fabrication, properties and possible applications of pure and Eu3+ doped SnO2 and In2O3/SnO2 (ITO) nanocrystallites. In: Proceedings of IEEE International Students and Young Scientists Workshop “Photonic and Microsystems” Dresden IEEE Cat. No. 07EX1824:66–69

Psuja P, Hreniak D, Strek W (2007b) Rare earth doped nanocrystalline phosphors for field emission displays. J Nanomater 2007:7

Psuja P, Hreniak D, Stręk W (2009) Synthesis and characterization of indium-tin oxide nanostructures. J Phys 146:012033 10 pages

Shea LE (1998) Low-voltage cathodoluminescent phosphors. Electrochem Soc Interface 7:24–27

Shionoya S, Yen WM (1998) Phosphors handbook. CRC Press, New York, pp 561–580

Song K-H, Park S-C, Nam J-G (2003) Indium oxide powder, method for preparing the same, and method for manufacturing high-density indium tin oxide target. US Patent No. US 2003/0178752 A1

Srivastava AM, Ronda CR (2003) Phosphors. Electrochem Soc Interface 12:48–51

Tang S, Yao J, Chen J, Luo J (2003) Preparation of indium tin oxide (ITO) with single-phase structure. J Mater Process Technol 137:82–85

Tereshko I, Abidzina V, Elkin I (2007a) Formation of nanostructures in metals by low-energy ion irradiation. Surf Coat Technol 201:8552–8556

Tereshko I, Abidzina V, Tereshko A, Elkin I (2007b) Nanostructural evolution of steel and titanium alloys exposed to glow-discharge plasma. Nucl Instrum Methods Phys Res B 261:678–681

Vetrone F, Boyer J-Ch, Capobianco JA, Nalva HS (2004) Yttrium oxide nanocrystals: luminescent properties and application. In: Nalva HS (ed) Encyclopedia of nanoscience and nanotechnology, vol 10. American Scientific Publishers, New York, pp 725–765

Vollath D, Szabo V (2006) The microwave plasma process—a versatile process to synthesis nanoparticulate materials. J Nanopart Res 8:417–428

Wakefield G, Williams DM, Harris CG, Dobson PJ (2000) Nanocrystalline phosphors for low voltage excitation applications, SID’00 Tech Dig, LP-5

Waser R (2003) Nanoelectronics and information technology Chap. 39, Wiley KGaA, Weinheim 935–957

Xu H, Zhu G, Zhou H (2005) Preparation of monodispersed tin-doped indium oxide powders by hydrothermal method. J Am Ceram Soc 88:986–988

Zhang J, Au KH, Zhu ZQ, O’Shea S (2004) Sol–gel preparation of poly(ethylene glycol) doped indium tin oxide thin films for sensing application. Opt Mater 26:47–55

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Psuja, P., Strek, W. & Yelkin, I. Non-thermal plasma-driven synthesis of Eu3+:Y2O3 nanosized phosphors. J Nanopart Res 16, 2176 (2014). https://doi.org/10.1007/s11051-013-2176-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-013-2176-2