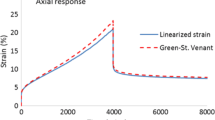

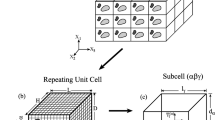

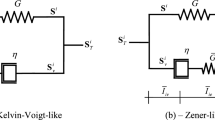

Usually, the viscoelastic (VE) response of polymers for applications in composites is obtained in uniaxial strainor stress-controlled tests. However, analyzing multimaterial structures by the Finite Element Method (FEM) or by other numerical or analytical tools, a material model in terms of a complete set of compliance functions and/or relaxation functions is required. In this paper, a methodology and exact analytical expressions for calculating the whole set of VE functions is presented based on the relaxation modulus E(t)and Poisson’s ratio v (t) determined in strain-controlled tests. The method is based on Laplace transforms, where an exact inversion is possible if a linear VE model with functions in Prony series is used. Results of the analytical model are compared with the FEM simulation, where specific boundary conditions to determine each particular VE function are used. Finally, the applicability of the so-called quasi-elastic method is investigated, where the expressions of elasticity theory are used to calculate a given viscoelastic function at an instant of time tk using the instant values of E(tk) and v(tk). For isotropic materials, the three approaches render almost coinciding results.

Similar content being viewed by others

References

A. V. Khokhlov, “Creep and long-term strength of a laminated thick-walled tube of nonlinear viscoelastic materials loaded by external and internal pressures,” Mech. Compos. Mater., 57, No. 6, 731-748 (2022).

S. Saseendran, M. Wysocki, and J. Varna, “Evolution of viscoelastic behavior of a curing LY5052 epoxy resin in the glassy state,” Advanced Manufacturing: Polymer & Composites Science, 2, No. 2, 74-82 (2016).

L. Pupure, R. Joffe, and J. Varna, “Methodology for macro-modeling of bio-based composites with inelastic constituents,” In: Composites Science and Technology, ISSN 0266-3538, 163, p. 41-48, (2018).

D. D. Vlasov and A. N. Polilov, “The possibility of creep prediction of viscoelastic polymer composites using frequency dependences of complex modulus components,” Mech. Compos. Mater., 58, No. 1, 31-42, (2022).

S. Saseendran, D. Berglund, and J. Varna,” Viscoelastic model with complex rheological behavior (VisCoR): incremental formulation,” Advanced Manufacturing: Polymer & Composites Science, 6, No. 1, 1-16 (2020)

E. N. Kablov and V. O. Startsev, “The influence of internal stresses on the aging of polymer composite materials: a Review,” Mech. Compos. Mater., 57, No. 5, 565-576 (2021).

ANSYS 2019, R3–Structural Analysis Guide, www.ansyshelp.ansys.com

E. H. Lee, “Stress analysis in viscoelastic bodies,” Q. Applied Math., 13, No. 2, 183-191 (1955).

R. A. Schapery, “Stress analysis of viscoelastic composite materials,” J. Composite Materials, 1, 228-267 (1967).

M. Hirsekorn, L. Marcin, and T. Godon, Multi-scale modeling of the viscoelastic behavior of 3D woven composites, Composites: Part A, 112, 539-548 (2018).

M. Levesque, M. D. Gilchrist, N. Bouleau, K. Derrien, and D. Baptiste, “Numerical inversion of the Laplace–Carson transform applied to homogenization of randomly reinforced linear viscoelastic media,” Computational Mechanics, 40, 771-789 (2007).

S. Beurthey and A. Zaoui, “Structural morphology and relaxation spectra of viscoelastic heterogeneous materials,” European Journal of Mechanics-A/Solids, 19, 1-16 (2000).

Yu. N. Rabotnov, “Elements of Hereditary Solid Mechanics”, Mir Publishers (1980).

S. G. Nunes, S. Saseendran, R. Joffe, S. C. Amico, P. Fernberg, and J. Varna, “On temperature-related shift factors and master curves in viscoelastic constitutive models for thermoset polymers,” Mech. Compos. Mater., 56, No. 5, 573-590 (2020).

E. A. Turi, “Thermal Analysis in Polymer Characterization,” in: Eastern Analytical Symposium, New York City, Heyden (1981).

J. M. Svanberg and J. A. Holmberg, “Prediction of shape distortions Part I. FE-implementation of a path dependent constitutive model,” Composites: Part A, 35, No. 6, 711-721 (2004).

B. O. Bolasodun, O. Rufai, A. Nesbitt, and R. J. Day, “Comparison of the isothermal cure kinetics of araldite LY 5052/4 4’DDS epoxy system using a differential scanning calorimetry and a microwave heated calorimeter,” Int. J. of Mater. Eng, 4, 148-165 (2014).

E. L. Wilson, R. L. Taylor, W. P. Doherty, and J. Ghaboussi, “Incompatible Displacement Models,” in: S. J. Fenves, et al. (eds.), Numerical and Computer Methods in Structural Mechanics, Academic Press, 43-57 (1973).

J. C. Simo, “On a fully three-dimensional finite-strain viscoelastic damage model: Formulation and computational aspects,” Computer Methods in Applied Mechanics and Engineering, 60, No. 2, 153-173 (1987).

N. J. Al-Ramahi, R. Joffe, and J. Varna, “Investigation of end and edge effects on results of numerical simulation of single lap adhesive joint with non-linear materials,” International Journal of Adhesion and Adhesives, 87,191-204 (2018).

Acknowledgements

The authors would like to thank ERDF within the Activity 1.1.1.2 “Post-doctoral Research Aid” of the Specific Aid Objective of the Operational Programme “Growth and Employment” (project No. 1.1.1.2/VIAA/4/20/641), the Higher Education Improvement Coordination (CAPES/Brazil), and the Swedish Foundation for International Coopera- tion in Research and Higher Education (STINT).

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 58, No. 6, pp.1095-1124, November-December, 2022. Russian DOI: https://doi.org/10.22364/mkm.58.6.01.

Appendices

Appendix 1. Relaxation Functions C 11 (t) and C 12(t)

In the Laplace domain, the relationships between the compliance functions \( {\overline{S}}_{ij} \) and relaxation functions \( {\overline{C}}_{ij},i,j=1,2, \) for isotropic material can be obtained from Eqs. (40) and (42):

Substituting in (A1.1) and (A1.2) expressions (54) for \( {\overline{S}}_{11} \) and \( {\overline{S}}_{12} \), gives

The 2M +1 singular points of (A1.3) needed for inverse transformation are found numerically as roots of polynomials in the denominator \( \left({p}_k=0,-\frac{1}{r_1},-\frac{1}{r_2},-\frac{1}{r_3},\dots, -\frac{1}{r_{2M}}\right). \) Then, using the partial fraction decomposition, the constants \( {C}_{11}^k \) and \( {C}_{12}^k \) are found similarly as described in Sect. 5.2. The expressions in the time domain are

Appendix 2. Viscoelastic Shear Functions C 66 ( t ) = Q 66 (t) = G 12 ( t ) and S 66 ( t )

In the Laplace domain, the relations between shear stress and strain for isotropic materials can be written as

Inserting (54) into (A2.1), it is obtained that

The creep compliance in shear is

The singular points of (A2.2) are found numerically and denoted \( {p}_k=-\frac{1}{\rho_k},k=1,\dots, M. \) The singular points of (A2.3) are the same as for \( {\overline{S}}_{11},\kern0.5em {p}_k=-\frac{1}{\tau_k},\kern1em k=1,2,\dots, M. \)

Expressing, as described above, the rational functions in partial fractions, the following expressions were obtained:

where

Appendix 3. Stress Relaxation Functions Q 11 (t) and Q 12 (t)

The relationships between the stress relaxation functions and compliance functions in the Laplace domain are simplified for cases where the out-of-plane normal stress can be neglected (σ3 = 0 ), as it is assumed in the classical laminate theory (CLT) for composites. For isotropic plies (for example, polymers, aluminum etc.),

Inserting (54) into (A3.1) and (A3.2) gives

The singular points of \( {\overline{Q}}_{11} \) and \( {\overline{Q}}_{11} \) are found numerically as roots of polynomials in the denominator \( \left({p}_k=0,-\frac{1}{\theta_1},-\frac{1}{\theta_2},-\frac{1}{\theta_3},\dots, -\frac{1}{\theta_{2M}}\right). \) Then, using the partial fraction decomposition, the constants \( {Q}_{11}^k \) and \( {Q}_{1k}^k \) are found as described in Sect 5.2. The expressions after inversion are

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Freire, R.T.S., Nunes, S.G., Amico, S.C. et al. On Determination of the Linear Viscoelastic Compliance and Relaxation Functions for Polymers in One Tensile Test. Mech Compos Mater 58, 765–786 (2023). https://doi.org/10.1007/s11029-023-10067-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-023-10067-0