Abstract

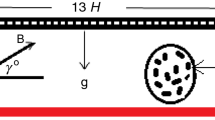

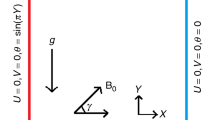

Entropy analysis is closely scrutinized for unsteady mixed convection in magneto-hybrid nanofluid (Cu–Fe\(_3\)O\(_4\)–water) flow over an inverted cone surrounded by a porous medium. The mathematical model comprises nonlinear, coupled partial differential equations. The numerical solutions of constitutive equations assisted by related initial boundary conditions are obtained by an effective finite difference method. The specified ranges for active parameters are: \(0\le \varphi _\mathrm{hnf}\le 0.04\), \(0\le M\le 5\), \(0.5\le K\le 3.5\), \(0.6\le \hbox {Gr}\le 1\) and \(0.1\le \hbox {Br}\Omega ^{-1} \le 0.4\). The impact of various parameters arising in the constitutive flow model on the virtual flow parameters is analyzed carefully, and the outcomes are illustrated graphically. Also, steady-state entropy production and Bejan lines are plotted for various active parameters. In addition, the physical quantities, i.e., heat transfer and momentum coefficient, are scrutinized for various parameters and the outcomes are displayed in the tabulated form. It is witnessed that heat transfer rates improved incredibly with growing estimates of hybrid nanoparticles volume fraction. The Nusselt number enhancement of Cu–Fe\(_3\)O\(_4\)–water hybrid nanofluid are 0.53%, 0.76%, 0.95% and 1.1% corresponding to volume concentration of 1%:4% with a difference of 1%, respectively. The theoretical measurement of skin friction showed a maximum enhancement of 0.25% at a volume concentration of 1% compared with Fe\(_3\)O\(_4\)–water nanofluid. Moreover, the momentum and heat transport coefficients are compared with those of natural convection and the result showed that heat transfer coefficient attains higher rates in mixed convectional flow compared with natural convection.

Similar content being viewed by others

Abbreviations

- (U, V):

-

Velocity components in (x, y) direction

- (x, y):

-

Cartesian coordinates

- B :

-

Magnetic field

- Be:

-

Bejan number

- Br:

-

Brinkman number

- \(C_\mathrm{p}\) :

-

Specific heat capacity

- g :

-

Gravitational acceleration

- Gr:

-

Thermal Grashof number

- K :

-

Dimensionless porosity parameter

- k :

-

Thermal conductivity

- \(k_{0}\) :

-

Permeability of porous medium

- L :

-

Reference length

- M :

-

Dimensionless magnetic parameter

- \(\hbox {Nu}_\mathrm{x}\) :

-

Local Nusselt number

- q :

-

Heat flux

- r :

-

Radius of the cone

- \(S_{0}\) :

-

Characteristic entropy generation

- \(S_\mathrm{GEN}\) :

-

Dimensionless entropy generation

- \(S_\mathrm{gen}\) :

-

Volumetric entropy generation

- T :

-

Temperature

- t :

-

Time

- Pr:

-

Prandtl number

- \(\alpha\) :

-

Half angle of the cone

- \(\beta\) :

-

Volumetric thermal expansion

- \(\Delta\) :

-

Grid/step size

- \(\mu\) :

-

Dynamic viscosity

- \(\nabla\) :

-

Gradient operator

- \(\nu\) :

-

Kinematic viscosity

- \(\rho\) :

-

Density

- \(\sigma\) :

-

Electrical conductivity

- \(\tau _\mathrm{x}\) :

-

Local skin friction

- \(\varphi\) :

-

Nanoparticles volume fraction

- \(\hbox {Br}\Omega ^{-1}\) :

-

Group parameter

- *:

-

Non-dimensional

- f:

-

Base fluid

- hnf:

-

Hybrid nanofluid

- i:

-

Grid point in the x direction

- j:

-

Grid point in the y direction

- k:

-

Time level

- nf:

-

Nanofluid

- s:

-

Nanoparticles

- w:

-

Wall

References

Choi SU, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. Tech. Rep.; Argonne National Lab., IL (United States); 1995. https://www.osti.gov/biblio/196525.

Siavashi M, Joibary SMM. Numerical performance analysis of a counter-flow double-pipe heat exchanger with using nanofluid and both sides partly filled with porous media. J Therm Anal Calorim. 2019;135(2):1595–610. https://doi.org/10.1007/s10973-018-7829-z.

Izadi A, Siavashi M, Xiong Q. Impingement jet hydrogen, air and Cu–H\(_2\)O nanofluid cooling of a hot surface covered by porous media with non-uniform input jet velocity. Int J Hydrogen Energy. 2019;44(30):15933–48. https://doi.org/10.1016/j.ijhydene.2018.12.176.

Khanafer K, Vafai K. A review on the applications of nanofluids in solar energy field. Renew Energy. 2018;123:398–406. https://doi.org/10.1016/j.renene.2018.01.097.

Basha HT, Sivaraj R, Reddy AS, Chamkha A. SWCNH/diamond-ethylene glycol nanofluid flow over a wedge, plate and stagnation point with induced magnetic field and nonlinear radiation-solar energy application. Eur Phys J Spec Top. 2019a;228(12):2531–51. https://doi.org/10.1140/epjst/e2019-900048-x.

Li Z, Saleem S, Shafee A, Chamkha AJ, Du S. Analytical investigation of nanoparticle migration in a duct considering thermal radiation. J Therm Anal Calorim. 2019;135(3):1629–41. https://doi.org/10.1007/s10973-018-7517-z.

Reddy PS, Sreedevi P, Chamkha AJ. MHD boundary layer flow, heat and mass transfer analysis over a rotating disk through porous medium saturated by Cu-water and Ag-water nanofluid with chemical reaction. Powder Technol. 2017;307:46–55. https://doi.org/10.1016/j.powtec.2016.11.017.

Maleki H, Safaei MR, Togun H, Dahari M. Heat transfer and fluid flow of pseudo-plastic nanofluid over a moving permeable plate with viscous dissipation and heat absorption/generation. J Therm Anal Calorim. 2019a;135(3):1643–54. https://doi.org/10.1007/s10973-018-7559-2.

Reddy PS, Chamkha AJ. Soret and Dufour effects on MHD convective flow of Al\(_2\)O\(_3\)-water and TiO\(_2\)-water nanofluids past a stretching sheet in porous media with heat generation/absorption. Adv Powder Technol. 2016;27(4):1207–18. https://doi.org/10.1016/j.apt.2016.04.005.

Jabbari F, Rajabpour A, Saedodin S. Viscosity of carbon nanotube/water nanofluid. J Therm Anal Calorim. 2019;135(3):1787–96. https://doi.org/10.1007/s10973-018-7458-6.

Ghalambaz M, Behseresht A, Behseresht J, Chamkha A. Effects of nanoparticles diameter and concentration on natural convection of the Al\(_2\)O\(_3\)-water nanofluids considering variable thermal conductivity around a vertical cone in porous media. Adv Powder Technol. 2015;26(1):224–35. https://doi.org/10.1016/j.apt.2014.10.001.

Dogonchi A, Chamkha AJ, Hashemi-Tilehnoee M, Seyyedi S, Ganji D, et al. Effects of homogeneous-heterogeneous reactions and thermal radiation on magneto-hydrodynamic Cu-water nanofluid flow over an expanding flat plate with non-uniform heat source. J Cent South Univ. 2019a;26(5):1161–71. https://doi.org/10.1007/s11771-019-4078-7.

Chamkha A, Rashad A, EL-Zahar E, EL-Mky HA. Analytical and numerical investigation of Fe\(_3\)O\(_4\)-water nanofluid flow over a moveable plane in a parallel stream with high suction. Energies. 2019;12(1):198. https://doi.org/10.3390/en12010198.

Maghsoudi P, Siavashi M. Application of nanofluid and optimization of pore size arrangement of heterogeneous porous media to enhance mixed convection inside a two-sided lid-driven cavity. J Therm Anal Calorim. 2019;135(2):947–61. https://doi.org/10.1007/s10973-018-7335-3.

Shadloo MS, Mahian O. Recent advances in heat and mass transfer. J Therm Anal Calorim. 2019;135(3):1611–5. https://doi.org/10.1007/s10973-018-7718-5.

Siavashi M, Karimi K, Xiong Q, Doranehgard MH. Numerical analysis of mixed convection of two-phase non-Newtonian nanofluid flow inside a partially porous square enclosure with a rotating cylinder. J Therm Anal Calorim. 2019a;137(1):267–87. https://doi.org/10.1007/s11242-018-1166-3.

Maleki H, Safaei MR, Alrashed AA, Kasaeian A. Flow and heat transfer in non-Newtonian nanofluids over porous surfaces. J Therm Anal Calorim. 2019b;135(3):1655–66. https://doi.org/10.1007/s10973-018-7277-9.

Parveen K, Banse V, Ledwani L. Green synthesis of nanoparticles: Their advantages and disadvantages. In: AIP Conference Proceedings; AIP Publishing; 2016;1724:020048. https://doi.org/10.1063/1.4945168.

Esfe MH, Esfandeh S, Rejvani M. Modeling of thermal conductivity of MWCNT-SiO\(_2\) (30: 70%)/EG hybrid nanofluid, sensitivity analyzing and cost performance for industrial applications. J Therm Anal Calorim. 2018a;131(2):1437–47. https://doi.org/10.1007/s10973-017-6680-y.

Moghadassi A, Ghomi E, Parvizian F. A numerical study of water based Al\(_2\)O\(_3\) and Al\(_2\)O\(_3\)–Cu hybrid nanofluid effect on forced convective heat transfer. Int J Therm Sci. 2015;92:50–7. https://doi.org/10.1016/j.ijthermalsci.2015.01.025.

Mohebbi R, Izadi M, Delouei AA, Sajjadi H. Effect of MWCNT-Fe\(_3\)O\(_4\)/water hybrid nanofluid on the thermal performance of ribbed channel with apart sections of heating and cooling. J Therm Anal Calorim. 2019;135(6):3029–42. https://doi.org/10.1007/s10973-018-7483-5.

Afrand M, Toghraie D, Ruhani B. Effects of temperature and nanoparticles concentration on rheological behavior of Fe\(_3\)O\(_4\)-Ag/EG hybrid nanofluid: an experimental study. Exp Thermal Fluid Sci. 2016;77:38–44. https://doi.org/10.1016/j.expthermflusci.2016.04.007.

Izadi M, Mohebbi R, Karimi D, Sheremet MA. Numerical simulation of natural convection heat transfer inside a \(\perp\) shaped cavity filled by a MWCNT-Fe\(_3\)O\(_4\)/water hybrid nanofluids using LBM. Chem Eng Process-Process Intensif. 2018;125:56–66. https://doi.org/10.1016/j.cep.2018.01.004.

Esfe MH, Arani AAA, Badi RS, Rejvani M. Ann modeling, cost performance and sensitivity analyzing of thermal conductivity of DWCNT-SiO\(_2\)/EG hybrid nanofluid for higher heat transfer. J Therm Anal Calorim. 2018b;131(3):2381–93. https://doi.org/10.1007/s10973-017-6744-z.

Asadi A, Asadi M, Rezaniakolaei A, Rosendahl LA, Afrand M, Wongwises S. Heat transfer efficiency of al\(_2\)o\(_3\)-MWCNT/thermal oil hybrid nanofluid as a cooling fluid in thermal and energy management applications: an experimental and theoretical investigation. Int J Heat Mass Transf. 2018;117:474–86. https://doi.org/10.1016/j.ijheatmasstransfer.2017.10.036.

Iqbal Z, Maraj E, Azhar E, Mehmood Z. A novel development of hybrid (MoS\(_2\)-SiO\(_2\)/H\(_2\)O) nanofluidic curvilinear transport and consequences for effectiveness of shape factors. J Taiwan Inst Chem Eng. 2017;81:150–8. https://doi.org/10.1016/j.jtice.2017.09.037.

Usman M, Hamid M, Zubair T, Haq RU, Wang W. Cu–Al\(_2\)O\(_3\)/water hybrid nanofluid through a permeable surface in the presence of nonlinear radiation and variable thermal conductivity via LSM. Int J Heat Mass Transf. 2018;126:1347–56. https://doi.org/10.1016/j.ijheatmasstransfer.2018.06.005.

Esfe MH, Amiri MK, Alirezaie A. Thermal conductivity of a hybrid nanofluid. J Therm Anal Calorim. 2018c;134(2):1113–22. https://doi.org/10.1007/s10973-017-6836-9.

Toghraie D, Abdollah MMD, Pourfattah F, Akbari OA, Ruhani B. Numerical investigation of flow and heat transfer characteristics in smooth, sinusoidal and zigzag-shaped microchannel with and without nanofluid. J Therm Anal Calorim. 2018;131(2):1757–66. https://doi.org/10.1007/s10973-017-6624-6.

Moldoveanu GM, Minea AA, Huminic G, Huminic A. Al\(_2\)O\(_3\)/TiO\(_2\) hybrid nanofluids thermal conductivity. J Therm Anal Calorim. 2019;137(2):583–92. https://doi.org/10.1007/s10973-018-7974-4.

Sheikholeslami M, Jafaryar M, Shafee A, Li Z. Nanofluid heat transfer and entropy generation through a heat exchanger considering a new turbulator and CuO nanoparticles. J Therm Anal Calorim. 2018;134(3):2295–303. https://doi.org/10.1007/s10973-018-7866-7.

Shamsabadi H, Rashidi S, Esfahani JA. Entropy generation analysis for nanofluid flow inside a duct equipped with porous baffles. J Therm Anal Calorim. 2019;135(2):1009–19. https://doi.org/10.1007/s10973-018-7350-4.

Bozorg MV, Siavashi M. Two-phase mixed convection heat transfer and entropy generation analysis of a non-Newtonian nanofluid inside a cavity with internal rotating heater and cooler. Int J Mech Sci. 2019;151:842–57. https://doi.org/10.1016/j.ijmecsci.2018.12.036.

Hayat T, Khan MI, Qayyum S, Alsaedi A. Entropy generation in flow with silver and copper nanoparticles. Colloids Surf A. 2018;539:335–46. https://doi.org/10.1016/j.colsurfa.2017.12.021.

Ellahi R, Alamri SZ, Basit A, Majeed A. Effects of mhd and slip on heat transfer boundary layer flow over a moving plate based on specific entropy generation. J Taibah Univ Sci. 2018;12(4):476–82. https://doi.org/10.1080/16583655.2018.1483795.

Rashad A, Armaghani T, Chamkha A, Mansour M. Entropy generation and MHD natural convection of a nanofluid in an inclined square porous cavity: effects of a heat sink and source size and location. Chinese journal of physics. 2018;56(1):193–211. https://doi.org/10.1016/j.cjph.2017.11.026.

Shahriari A, Ashorynejad HR, Pop I. Entropy generation of MHD nanofluid inside an inclined wavy cavity by Lattice Boltzmann method. J Therm Anal Calorim. 2019;135(1):283–303. https://doi.org/10.1007/s10973-018-7061-x.

Chamkha A, Rashad A, Armaghani T, Mansour M. Effects of partial slip on entropy generation and MHD combined convection in a lid-driven porous enclosure saturated with a Cu-water nanofluid. J Therm Anal Calorim. 2018;132(2):1291–306. https://doi.org/10.1007/s10973-017-6918-8.

Afridi M, Qasim M, Khan I, Tlili I. Entropy generation in MHD mixed convection stagnation-point flow in the presence of joule and frictional heating. Case Stud Therm Eng. 2018;12:292–300. https://doi.org/10.1016/j.csite.2018.04.002.

Nguyen TK, Sheikholeslami M, Shehzad SA, Shafee A, Alghamdi M. Solidification entropy generation via fem through a porous storage unit with applying a magnetic field. Phys Scr. 2019;94(9):095207. https://doi.org/10.1088/1402-4896/ab19ea.

Alkanhal TA, Sheikholeslami M, Arabkoohsar A, Haq Ru, Shafee A, Li Z, et al. Simulation of convection heat transfer of magnetic nanoparticles including entropy generation using CVFEM. Int J Heat Mass Transf. 2019;136:146–56. https://doi.org/10.1016/j.ijheatmasstransfer.2019.02.095.

Ellahi R, Sait SM, Shehzad N, Ayaz Z. A hybrid investigation on numerical and analytical solutions of electro-magnetohydrodynamics flow of nanofluid through porous media with entropy generation. Int. J. Numer. Methods Heat Fluid Flow. 2019;. https://doi.org/10.1108/HFF-06-2019-0506.

Barnoon P, Toghraie D, Dehkordi RB, Abed H. MHD mixed convection and entropy generation in a lid-driven cavity with rotating cylinders filled by a nanofluid using two phase mixture model. J Magn Magn Mater. 2019;483:224–48. https://doi.org/10.1016/j.jmmm.2019.03.108.

Zeeshan A, Shehzad N, Abbas T, Ellahi R. Effects of radiative electro-magnetohydrodynamics diminishing internal energy of pressure-driven flow of titanium dioxide-water nanofluid due to entropy generation. Entropy. 2019;21(3):236. https://doi.org/10.3390/e21030236.

Hosseini S, Ghasemian M, Sheikholeslami M, Shafee A, Li Z. Entropy analysis of nanofluid convection in a heated porous microchannel under MHD field considering solid heat generation. Powder Technol. 2019;344:914–25. https://doi.org/10.1016/j.powtec.2018.12.078.

Reddy PS, Chamkha A. Heat and mass transfer analysis in natural convection flow of nanofluid over a vertical cone with chemical reaction. Int J Numer Methods Heat Fluid Flow. 2017;27(1):2–22. https://doi.org/10.1108/HFF-10-2015-0412.

Reddy PS, Sreedevi P, Chamkha AJ. Magnetohydrodynamic (MHD) boundary layer heat and mass transfer characteristics of nanofluid over a vertical cone under convective boundary condition. Propuls Power Res. 2018;7(4):308–19. https://doi.org/10.1016/j.jppr.2018.11.004.

Patil P, Shashikant A, Hiremath P. Diffusion of liquid hydrogen and oxygen in nonlinear mixed convection nanofluid flow over vertical cone. Int J Hydrog Energy. 2019;44(31):17061–71. https://doi.org/10.1016/j.ijhydene.2019.04.193.

Sreedevi P, Reddy PS, Chamkha AJ. Magneto-hydrodynamics heat and mass transfer analysis of single and multi-wall carbon nanotubes over vertical cone with convective boundary condition. Int J Mech Sci. 2018;135:646–55. https://doi.org/10.1016/j.ijmecsci.2017.12.007.

Reddy PS, Chamkha AJ. Influence of size, shape, type of nanoparticles, type and temperature of the base fluid on natural convection MHD of nanofluids. Alex Eng J. 2016;55(1):331–41. https://doi.org/10.1016/j.aej.2016.01.027.

Basha HT, Animasaun I, Makinde O, Sivaraj R. Effect of electromagnetohydrodynamic on chemically reacting nanofluid flow over a cone and plate. In: Applied mathematics and scientific computing. Springer, Berlin; 2019b;99–107. https://doi.org/10.1007/978-3-030-01123-9_13.

Hanif H, Khan I, Shafie S. MHD natural convection in cadmium telluride nanofluid over a vertical cone embedded in a porous medium. Phys Scr. 2019;94(12):125208. https://doi.org/10.1088/1402-4896/ab36e1/meta.

Sujatha T, Reddy KJ, Kumar JG. Chemical reaction effect on nonlinear radiative MHD nanofluid flow over cone and wedge. In: Defect and diffusion forum; Trans Tech Publ; 2019;393:83–102. https://doi.org/10.4028/www.scientific.net/DDF.393.83.

Khan WA, Rashad A, Abdou M, Tlili I. Natural bioconvection flow of a nanofluid containing gyrotactic microorganisms about a truncated cone. Eur J Mech-B/Fluids. 2019;75:133–42. https://doi.org/10.1016/j.euromechflu.2019.01.002.

Ramzan M, Mohammad M, Howari F. Magnetized suspended carbon nanotubes based nanofluid flow with bio-convection and entropy generation past a vertical cone. Sci Rep. 2019a;9(1):1–15. https://doi.org/10.1038/s41598-019-48645-9.

Vijayalakshmi P, Gunakala SR, Animasaun I, Sivaraj R. Chemical reaction and nonuniform heat source/sink effects on casson fluid flow over a vertical cone and flat plate saturated with porous medium. In: Applied mathematics and scientific computing. Berlin: Springer; 2019; p. 117–127. https://doi.org/10.1007/978-3-030-01123-9_13.

Siavashi M, Rasam H, Izadi A. Similarity solution of air and nanofluid impingement cooling of a cylindrical porous heat sink. J Therm Anal Calorim. 2019b;135(2):1399–415. https://doi.org/10.1007/s10973-018-7540-0.

Yazdi M, Aghamajidi M, Dinarvand S, Pop I. Tiwari-Das nanofluid model for magnetohydrodynamics (MHD) natural-convective flow of a nanofluid adjacent to a spinning down-pointing vertical cone. Propuls Power Res. 2018;7(1):78–90. https://doi.org/10.1016/j.jppr.2018.02.002.

Hayat T, Nadeem S. Heat transfer enhancement with Ag–CuO/water hybrid nanofluid. Results Phys. 2017;7:2317–24. https://doi.org/10.1016/j.rinp.2017.06.034.

Brinkman H. The viscosity of concentrated suspensions and solutions. J Chem Phys. 1952;20(4):571–81. https://doi.org/10.1063/1.1700493.

Devi SA, Devi SSU. Numerical investigation of hydromagnetic hybrid Cu–Al\(_2\)O\(_3\)/water nanofluid flow over a permeable stretching sheet with suction. Int J Nonlinear Sci Numer Simul. 2016;17(5):249–57. https://doi.org/10.1515/ijnsns-2016-0037.

Dogonchi A, Ismael MA, Chamkha AJ, Ganji D. Numerical analysis of natural convection of Cu-water nanofluid filling triangular cavity with semicircular bottom wall. J Therm Anal Calorim. 2019b;135(6):3485–97. https://doi.org/10.1007/s10973-018-7520-4.

Ghadikolaei S, Yassari M, Sadeghi H, Hosseinzadeh K, Ganji D. Investigation on thermophysical properties of TiO\(_2\)-Cu/H\(_2\)O hybrid nanofluid transport dependent on shape factor in MHD stagnation point flow. Powder Technol. 2017;322:428–38. https://doi.org/10.1016/j.powtec.2017.09.006.

Maxwell JC. A treatise on electricity and magnetism; vol. 1. Oxford: Clarendon Press; 1873. https://scholar.google.com/scholar?hl=en&as_sdt=1%2C5&as_vis=1&q=A+treatise+on+electricity+and+magnetism+maxwell&btnG=.

Selimefendigil F, Chamkha AJ. Magnetohydrodynamics mixed convection in a power law nanofluid-filled triangular cavity with an opening using Tiwari and Das’ nanofluid model. J Therm Anal Calorim. 2019;135(1):419–36. https://doi.org/10.1007/s10973-018-7037-x.

Sheikholeslami M, Arabkoohsar A, Khan I, Shafee A, Li Z. Impact of Lorentz forces on Fe\(_3\)O\(_4\)-water ferrofluid entropy and exergy treatment within a permeable semi annulus. J Clean Prod. 2019;221:885–98. https://doi.org/10.1016/j.jclepro.2019.02.075.

Soomro FA, Zaib A, Haq RU, Sheikholeslami M. Dual nature solution of water functionalized copper nanoparticles along a permeable shrinking cylinder: FDM approach. Int J Heat Mass Transf. 2019;129:1242–9. https://doi.org/10.1016/j.ijheatmasstransfer.2018.10.051.

Ramzan M, Mohammad M, Howari F, Chung JD. Entropy analysis of carbon nanotubes based nanofluid flow past a vertical cone with thermal radiation. Entropy. 2019b;21(7):642. https://doi.org/10.3390/e21070642.

Sambath P, Pullepu B, Hussain T, Shehzad SA. Radiated chemical reaction impacts on natural convective mhd mass transfer flow induced by a vertical cone. Results Phys. 2018;8:304–15. https://doi.org/10.1016/j.rinp.2017.12.005.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hanif, H., Khan, I. & Shafie, S. Heat transfer exaggeration and entropy analysis in magneto-hybrid nanofluid flow over a vertical cone: a numerical study. J Therm Anal Calorim 141, 2001–2017 (2020). https://doi.org/10.1007/s10973-020-09256-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09256-z