Abstract

In this study, flame-retardant poly(ethylene terephthalate) (PET) fibres were produced using a high-temperature bath method similar to dyeing fibres with disperse dyes. A mixture of aqueous solutions of silicon and phosphorus compounds was used as the flame retardant. Samples of the modified fibres were examined by thermogravimetric analysis. The residue left after limited oxygen index test was analysed by scanning electron microscopy. Effect of the flame retardant on changing the supermolecular structure of PET fibres was evaluated using wide-angle X-ray diffraction. Mechanical properties of the modified PET fibres as compared with standard fibres were also examined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Flame retardancy of PET fibres is of crucial importance because they are largely used to produce a variety of materials for finishing interiors of public buildings, means of transport, etc. These materials must meet very high standards of fire safety. Standard poly(ethylene terephthalate) fibres have good mechanical, chemical and dyeing properties. However, they are flammable (LOI = 21 %) and tend to drip when burning, which contributes to fire spread. There are three main methods of improving the resistance of PET fibres to ignition:

- 1.

-

2.

incorporation of retardant particles into the main chain of polymer macromolecule during polycondensation [5];

-

3.

melting a mixture of polymer and flame retardant in an extruder during fibre formation [6–13].

The first method, although fast and easy, has one major disadvantage in that it results in low durability and surface changes (roughness, etc.) of such fibres. The second method offers durable flame retardancy, but it is very costly. The third method requires large amounts of flame retardant, causing technological difficulties.

Flame-retardant compounds containing Cl and Br, which have been applied so far, are very effective but, as they release toxic gases (HCl, HBr) and corrosive fumes, their use is being limited to polymers [14–18]. In recent years, much research has been done to find flame retardants free of halogen atoms. These include organophosphorus compounds [1, 6, 7, 11, 19, 20] and silicon-containing compounds [3, 6, 7, 21].

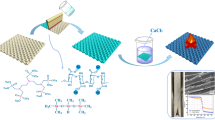

In this study, the first method of PET modification was adopted, but it was substantially modified. Silicon and phosphorus compounds were introduced into PET fibres the same way as disperse dyes are introduced during HT bath dyeing. Fakin et al. [22] used this method successfully, but their aim was to improve the hydrophilicity of polyester fabrics.

Very good results are achieved by modifying polymers with a mixture of flame retardants with different chemical structures, which yields synergistic effects [10, 13, 18, 19, 23, 24, 29]. Interaction between the flame retardant and polymer at high temperature changes the process of polymer decomposition. After burning it, a residue containing phosphorus and silicon is obtained in the condensed phase. This makes an effective barrier acting as the chief flame inhibitor. As a result, the barrier forms a trap for flammable gases, thereby reducing the amount of fuel feeding the flame [8, 13, 18–20, 25, 29].

The unquestionable novelty of in this study is the use of water glass as a silicon-containing compound for PET fibres.

Experimental

In this study, the first method of PET modification was adopted, i.e. surface treatment in a solution containing flame retardant. Retardant molecules were introduced into the fibre the same way as dye molecules are inserted during exhaustion dyeing [28].

Materials

The materials used in this work were all commercially available technical products. Two commercial flame-retardant modifiers were applied: water glass (WG) (aqueous sodium silicate—Na2O × nSiO2)—CAS 1344-09-8 supplied by Rudniki SA (Poland), and Pekoflam PES (PES) (cyclic organophosphates and phosphonates) supplied by Clariant (Switzerland).

Standard PET fibres were used, which were supplied by Elana SA Toruń (Poland). The finishing treatment was carried out in a laboratory dyeing device (Ahiba Turbomat, Switzerland) with liquid ratio of 1:50. The applied conditions were as follows: temperature—130 °C, treatment time—1 h, heating rate—2.5 °C min−1. Flame-retardant modifiers, mixed in the amounts of 0 % WG + 20 % PES, 4 % WG + 16 % PES; 8 % WG + 12 % PES, 12 %WG + 8 % PES, 16 % WG + 4 % PES and 20 % WG + 0 % PES, were added to the fibre mass.

Dispersing agent: non-ionic dispersing agent NNO, which is an aqueous solution of sodium salts of naphthalenesulfonic acids of formaldehyde polycondensates, supplied by Organika-Rokita (Poland), was added into the modification bath in the amount of 1.5 g l−1.

In order to remove any flame retardant unbound with the fibres, the samples were washed. The washing process was carried out using the Ahiba Turbomat laboratory washing machine, in accordance with PN-EN 20105-CO3. The washing bath contained 5 g l−1 of Pretepon G soap (Organika-Rokita, Poland); initial temperature of the process: 20 °C; heating rate: 1.5 °C min−1; final temperature: 60 °C; time of washing: 30 min.

Methods of measurements

-

TG investigations were performed using thermogravimetric analyser TA Instruments Q500. Measurements were taken in a temperature range from 30 to 800 °C with the heating rate of 10 min−1 in air and nitrogen atmosphere (flow 40 mL min−1). At 800 °C, the analyser was switched and the inert gas was replaced with air (3 min) to burn the organic remains of the sample.

-

Wide-angle X-ray scattering (WAXS) investigations were performed with a URD-65 Seifert diffractometer. CuKα radiation was used at 40 kV and 30 mA. Monochromatization of the beam was obtained by means of a nickel filter and a pulse-height analyser. A scintillation counter was used as a detector. Investigations were performed in the range of angles 4°–60° with a 0.1° step. For the separation of an experimental diffraction pattern into two components connected with the scattering from crystalline and amorphous regions, the curve-fitting computer package WaxsFit [27] was used. Each peak was modelled using a Gaussian–Cauchy peak shape. The content of crystalline form of poly(ethylene terephthalate) was calculated as a ratio of the area under crystalline peaks, corresponding to that phase, to the total area of the scattering curve. To evaluate the variations of crystallite sizes of PET, the Scherrer equation was used. Crystallite sizes were calculated in the direction perpendicular to the (010), (100) and (101) planes.

For X-ray examination, fibre samples were powdered using a microtome.

-

The examinations of fibre flammability were carried out with the limited oxygen index (LOI) method using the equipment constructed originally by our team in accordance with PN ISO 4589 Standard.

-

Scanning electron microscopy (SEM) analyses were performed in conventional SEM mode using Joel JSM 5500LV instrument operating at 10 kV, after coating the samples with a thin layer of gold by sputter deposition. Surfaces of samples were observed up to × 1000 magnifications.

-

Tensile strength parameters of PET fibres were defined according to PN-EN ISO 5079 Standard by means of the tensile testing machine INSTRON 5544 Single Column [33, 34]. The samples were placed on the tensile testing machine in frames. The measurements were taken in normal climatic conditions for 20-mm-long samples. The tensile speed was 40 mm min−1, and 50 tests were done for each sample. Based on the measurements taken, the following values were determined: average breaking force of the fibres, relative elongation at break, and corresponding coefficients of variation.

Results and discussion

Determining fibre flammability—criteria for choosing the method

In order to determine flammability, limited oxygen index was chosen as the primary method. As there are many methods of determining flammability [12, 29–31], selecting the most adequate one is very difficult. It is the most difficult for items made of thermoplastic fibres including polyester. Determining flammability of products made of thermoplastic fibres by the so-called vertical positioning of samples results in errors for two reasons:

-

1.

when melting and shrinking, plastic fibres cause the sample to bend away from the pilot flame;

-

2.

burning drops of molten polymer separate from the sample, and the flame cannot encompass the molten material.

The method of limited oxygen index eliminates these drawbacks. It was also chosen for its simplicity and good reproducibility. LOI results for the fibres examined are shown in Table 1.

Analysis of the LOI results clearly demonstrates improved flame retardancy of the fibres. Following the treatment employed, LOI index increases from 21.2 % to almost 29 % for all variants of modification. Furthermore, when a mixture of water glass (WG) and PES flame retardants is used, the index is higher as compared with just one type of flame retardant. The most advantageous LOI value was achieved for a mixture containing 16 % PES and 4 % WG.

To verify the LOI results indicating improved flame retardancy, thermogravimetric analysis (TG) under an atmosphere of air was done.

Thermogravimetric measurements

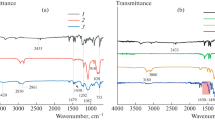

Figure 1 shows the TG curves and corresponding dTG curves (mass loss derivative as a function of temperature) for untreated PET fibres, wherein measurements were first taken under an atmosphere of nitrogen (green curves) and then of air. Analysis of the thermogravimetric curve recorded during heating in inert gas reveals only mass loss of the PET sample (above 80 %), related to thermal dissociation of the fibres. It is a one-step process, with the highest rate of mass loss at 458.8 °C (maximum of the dTG curve).

By contrast, analysis of the TG curve recorded during the heating of a sample of standard PET fibres under an atmosphere of air reveals, apart from mass loss related to thermal dissociation, an additional transformation related to the ignition and combustion of the sample in the thermogravimetric analyser. This process results in more than 15 % mass loss. The highest rate of combustion (and mass loss accompanying it) is obtained at 545.5 °C. Since combustion and thermal dissociation of the fibres examined, as depicted by the TG curves, are distinctly separated transformations (the dTG signal line between these transformations is near zero), it was decided to employ the thermogravimetric measurements under an atmosphere of air for a deeper analysis of the effectiveness of the flame retardants used [26].

Figure 2 shows the TG and dTG curves recorded for fibres modified with water glass, phosphorous flame retardant (Pekoflam PES) and a mixture of both retardants applied in a 4/16 % ratio. For comparison, the curves recorded for untreated fibres are also included. Analysis of the dTG curves for these samples reveals that the local maximum corresponding to the maximum speed of mass loss during combustion in air may occur at various temperatures. For the PES/WG (4/16 %) modification, being the most advantageous combination as proved earlier by its LOI index (LOI = 29.8 %), the mass loss maximum, and hence the rate of combustion, is most markedly shifted towards higher temperatures up to 560.6 °C. For standard fibres (not treated with any retardant), the difference in the position of the maximum on the dTG curve is as big as more than 15 °C. Unmodified fibres also reveal a significant shift of combustion initiation, or sample auto ignition, towards lower temperatures. Thus, thermogravimetric analysis fully confirmed the results of the LOI tests.

It should be noted here that while the use of thermogravimetric measurements under an atmosphere of air to monitor flammability properties draws on earlier studies by other authors [31, 32], the novelty of the approach proposed in this paper lies in the detailed interpretation of the course of the dTG signal line over a temperature range corresponding to the combustion of the sample.

Another issue addressed in this study was an attempt to explain why, among all the samples examined, modification using a mixture of phosphorous flame retardant and water glass in a 16/4 % ratio proved to be the most effective. It was attributed to a similar mechanism of binding the retardant with polyester as that of dyeing with disperse dyes, which excludes chemical interactions. The mechanism is based on the so-called “free volume model”, in which free spaces are formed in PET fibres during their thermal processing above the glass transition temperature [28]. Therefore, to answer the question of flame-retardant effectiveness, it was necessary to examine the structure of PET fibres at a supermolecular level.

Structural examination

The adopted method was wide-angle (4°–60°) X-ray scattering. The WAXS curves for selected variants of flame-retardant modification (corresponding to those presented in the thermogravimetric method) are depicted in Fig. 3.

Note that all these curves are very similar in nature. Based on the methodology described in the Experimental section, the obtained diffraction experimental curves were fitted with theoretical curves, which were then deconvoluted into individual peaks from scattering at different lattice planes of crystallites and from scattering in the amorphous areas [26].

Figure 4 is a representative example of a diffraction curve that has been resolved into individual scattering components using the peak-fitting software.

Based on the methodology adopted, basic parameters of the examined nanostructure were determined, i.e. the degree of crystallinity and the mean size of crystallites (Table 2).

The results of diffraction examination presented in the table demonstrate that, for all variants of flame-retardant modification, the determined mass degree of crystallinity is more than 6 % lower than that for standard fibres. However, it cannot be concluded that the lower the degree of crystallinity, the higher the LOI index, because for the most advantageous PES/WG combination (16/4 %), the degree of crystallinity is in fact slightly higher than for other variants. Similarly, analysis of the mean size of crystallites does not reveal any clear change trend.

Therefore, given the above considerations, it can be stated that the crystal structure of PET fibres is not responsible for the varying effectiveness of the flame retardants used, and explanation should be sought elsewhere. Here, scanning electron microscopy comes in handy.

Scanning electron microscopy

SEM was used to obtain micrographs of cross sections of the remnants of the PET fibres burnt during the LOI tests (Fig. 5a–c).

Analysis of the images leads to the conclusion that, as earlier suggested [8], interaction between the retardant and polymer at high temperature changes the process of polymer decomposition. After burning it, a residue (scale) containing phosphorus and silicon is left in the condensed phase. This scale makes an effective barrier preventing the flame from spreading. It is a trap for flammable decomposition gases feeding the flame zone. Its cohesion (compactness) was the highest for the mixture of PES and WG (16/4 %), as was the effectiveness of this barrier. The LOI index was also the highest: 29.8 %. This conclusion is strongly supported by the morphology of the scale shown in Fig. 5c.

Mechanical tests

Various modifications of polymeric materials (including fibres) often lead to some deterioration of their mechanical parameters. For this reason, in addition to the above-described examinations, basic strength tests of the modified flame-retardant PET fibres were also conducted. The key mechanical parameters are presented statistically in Table 3, while examples of stress–strain curves are shown in Fig. 6.

Based on the data presented in Table 3, a decrease in specific strength was observed, from 53.7 cN tex−1 for unmodified PET fibres to less than 45 cN tex−1 for all the varieties of fibres modified at 130 °C. (Tex is a non-SI unit used in textile industry to describe the so-called fibre linear density; 1 tex = 10−6 kg m−1.) Thus, the strength of the flame-retardant PET fibres obtained in this study places them virtually in the middle of a wide range of strength values (from 30 to 70 cN tex−1) demonstrated by PET fibres [35, 36] depending on their applications. Table 3 also reveals a small scatter of average values, for both specific strength and elongation at break, which only slightly increases for the modified fibres.

By comparing the respective stress–strain curves (Fig. 6), it can be said that, for the modified flame-retardant PET fibres, the angle between the curves and the axis of stress is enlarged in the area of elastic deformation of the fibres.

Conclusions

As a result of the modification described above, standard PET fibres were provided with effective and durable flame-retardant properties without detracting from their mechanical properties. Average breaking tenacity was changed from 53.7 cN tex−1 for standard PET fibres to 44.0 cN tex−1 for PET + 16 % PES/4 % WG fibres—the best variant of the modification applied. However, average value of elongation at break equalled 23.1 and 18.7 %, respectively. It should be emphasized that this effect was achieved by utilizing equipment commonly used in industrial practice for finishing polyester fibres. Also noteworthy is the relatively low cost and simplicity of applying the proposed technology.

The method of limited oxygen index proved that a relatively high level of flame retardancy (LOI = 29.8 %) was achieved for the most advantageous combination of Pekoflam PES and WG modifiers (16/4 %); using these flame retardants yields synergistic effects. The results obtained by the method of critical oxygen index were fully confirmed by thermogravimetric analysis under an atmosphere of air. Therefore, both methods of evaluating flammability properties were found in a way to be complementary.

The study determined the cause of the varying effectiveness of flame retardants, probably stemming from the specific morphology of the scale formed during combustion (SEM; Fig. 5c). Following the diffraction examination, the influence of PET structure matrix at the supermolecular level was found to be negligible.

References

Chen DQ, Wang YZ, Hu XP, Wang DY, Qu MH, Yang B. Flame retardant and anti-dripping effects of a novel char-forming flame retardant for the treatment of poly(ethylene terephthalate) fabrics. Polym Degrad Stab. 2005;88:349–56. doi:10.1016/j.polymdegradstab.2004.11.010.

Liang S, Neisius NM, Gaan S. Recent developments in flame retardant polymeric coatings. Prog Org Coat. 2013;76:1642–65. doi:10.1016/j.porgcoat.2013.07.014.

Carosio F, Laufer G, Alongi J, Camino G, Grunlan JC. Layer-by-layer assembly of silica-based flame retardant thin film on PET fabric. Polym Degrad Stab. 2011;96:745–50. doi:10.1016/j.polymdegradstab.2011.02.019.

Varesano A, Tonin C, Ferrero F, Stringhetta M. Thermal stability and flame resistance of polypyrrole—coated PET fibres. J Therm Anal Calorim. 2008;94(2):559–65. doi:10.1007/s10973-007-8639-x.

Zhang J, Ji Q, Ping Zhang, Xia Y, Kong Q. Thermal stability and flame retardancy mechanism of poly(ethylene terephthalate)/boehmite nanocomposites. Polym Degrad Stab. 2010;95:1211–8. doi:10.1016/j.polymdegradstab.2010.04.001.

Didane N, Giraud S, Devaux E, Lemort G. Development of fire resistant PET fibrous structures based on phosphinate-POSS blends. Polym Degrad Stab. 2012;97:879–85. doi:10.1016/j.polymdegradstab.2012.03.038.

Didane N, Giraud S, Devaux E, Lemort G, Capon G. Thermal and fire resistance of fibrous materials made by PET containing flame retardant agents. Polym Degrad Stab. 2012;97:2545–51. doi:10.1016/j.polymdegradstab.2012.07.006.

Didane N, Giraud S, Devaux E. Fire performances comparison of back coating and melt spinning approaches for PET covering textiles. Polym Degrad Stab. 2012;97:1083–9. doi:10.1016/j.polymdegradstab.2012.04.010.

Zhang X, Zhong Y, Mao ZP. The flame retardancy and thermal stability properties of poly (ethylene terephthalate)/hexakis (4-nitrophenoxy) cyclotriphosphazene systems. Polym Degrad Stab. 2012; 97:1504–10. doi:10.1016/j.polymdegradstab.2012.05.006.

Alongi J. Investigation on flame retardancy of Poly(ethylene terephthalate) for plastics and textiles by combination of an organo-modified sepiolite and Zn phosphinate. Fibers and Polymers. 2011;12(2):166–73. doi:10.1007/s12221-011-0166-5.

Zhang X, Zhong Y, Mao ZP. The flame retardancy and thermal stability properties of poly(ethylene terephthalate)/hexakis(4-nitrophenoxy) cyclotriphosphazene systems. Polym Degrad Stab. 2012;97:1504–10. doi:10.1016/j.polymdegradstab.2012.05.006.

Borysiak S. The thermo-oxidative stability and flammability of wood/polypropylene composites. J Therm Anal Calorim. 2015;119:1955–62. doi:10.1007/s10973-014-4341-y.

Doğan M, Erdoğan S, Bayramli E. Mechanical, thermal, and fire retardant properties of poly(ethylene terephthalate) fiber containing zinc phosphinate and organo-modified clay. J Therm Anal Calorim. 2013;112:871–6. doi:10.1007/s10973-012-2682-y.

Horrocks AR. Flame retardant challenges for textiles and fibres: new chemistry versus innovatory solutions. Polym Degrad Stab. 2011;96:377–92. doi:10.1016/j.polymdegradstab.2010.03.036.

Lu SY, Hamerton I. Recent developments in the chemistry of halogen-free flame retardant polymers. Prog Polym Sci. 2002;27:1661–712.

Dasaria A, Yub ZZ, Caic GP, Mai YW. Recent developments in the fire retardancy of polymeric materials. Prog Polym Sci. 2013;38:1357–87. doi:10.1016/j.progpolymsci.2013.06.006.

Malucelli G, Carosio F, Alongi J, Fina A, Frache A, Camino G. Materials engineering for surface-confined flame retardancy. Mater Sci Eng, R. 2014;84:1–20. doi:10.1016/j.mser.2014.08.001.

Chen X, Song W, Liu J, Jiao Ch, Qian Y. Synergistic flame-retardant effects between aluminum hypophosphite and expandable graphite in silicone rubber composites. J Therm Anal Calorim. 2015;120:1819–26. doi:10.1007/s10973-015-4428-0.

Chen Y, Peng H, Li J, Xia Z, Tan H. A novel flame retardant containing phosphorus, nitrogen and sulfur. Synthesis and application in thermoplastic polyurethane. J Therm Anal Calorim. 2014;115:1639–49. doi:10.1007/s10973-013-3461-0.

Wang Y, Zhang L, Yang Y, Cai X. The investigation of flammability, thermal stability, heat resistance and mechanical properties of unsaturated polyester resin using AlPi as flame retardant. J Therm Anal Calorim. doi:10.1007/s10973-015-4875-7.

Ji Q, Wang X, Zhang Y, Kong Q, Xia Y. Characterization of poly(ethylene terephthalate)/SiO2 nanocomposites prepared by Sol–Gel method. Compos A. 2009;40:878–82. doi:10.1016/j.compositesa.2009.04.010.

Fakin D, Kleinschek KS, Kurečič M, Ojstršek A. Effects of nanoTiO2–SiO2 on the hydrophilicity/dyeability of polyester fabric and photostability of disperse dyes under UV irradiation. Surf Coat Technol. 2014;253:185–93. doi:10.1016/j.surfcoat.2014.05.035.

Fei G, Liu Y, Wang Q. Synergistic effects of novolac-based char former with magnesium hydroxide in flame retardant polyamide-6. Polym Degrad Stab. 2008;93:1351–6. doi:10.1016/j.polymdegradstab.2008.03.031.

Lewin M. Flame retarding polymer nanocomposites: synergism, cooperation, antagonism. Polym Degrad Stab. 2011;96:256–69. doi:10.1016/j.polymdegradstab.2010.12.006.

Horrocks AR. Developments in flame retardants for heat and fire resistant textiles—the role of char formation and intumescence. Polym Degrad Stab. 1996;54:143–54.

Lyon RE, Walters RN, Stoliarov SI. Thermal analysis of flammability. J Therm Anal Calorim. 2007;89(2):441–8. doi:10.1007/s10973-006-8257-z.

Rabiej M. Application of the genetic algorithms and multi-objective optimisation to the resolution of X-ray diffraction curves of semicrystalline polymers. Fibres Text East Eur. 2003;11(5):83–5.

Toda T, Yoshida H, Fukunishi K. Amorphous structure changes in poly(ethylene terephthalate) induced by annealing under dry and wet conditions and its dye uptake properties. Polymer. 1997;38(21):5463–9.

Lewin M. Unsolved problems and unanswered questions in flame retardance of polymers. Polym Degrad Stab. 2005;88:13–9. doi:10.1016/j.polymdegradstab.2003.12.011.

Fabia J, Gawłowski A, Graczyk T, Ślusarczyk C. Changes of crystalline structure of poly(ethylene terephthalate) fibers in flame retardant finishing process. Polimery. 2014;7–8:557–61.

Janowska G, Rybiński P, Jantas R. Effect of the modification of silica on thermal properties and flammability of cross-linked butadiene-acrylonitrile rubbers. J Therm Anal Cal. 2007;87(2):511–7. doi:10.1007/s10973-006-7796-7.

Rybiński P, Janowska G, Antkowicz W, Krauze S. Thermal stability and flammability of butadiene-acrylonitrile rubber cross-linked with iodoform. J Therm Anal Cal. 2005;81:9–13. doi:10.1007/s10973-005-6414-4.

Technical-motion documentation of a resistance machine INSTRON—model 5544.

Textiles—Fibres—Determination of breaking force and elongation at break of individual fibres (ISO 5079:1995).

Bunsell AR (ed). Handbook of tensile properties of textile and technical fibres. Woodhead Publishing Series in Textiles. Cambridge: Elsevier Science; 2009. p. 288. ISBN:9781845696801.

Idemat. Mechanical properties of polyethyleneterephthalate fiber [Online]. 2003. Available at: http://www.matbase.com/material-categories/natural-and-synthetic-polymers/polymer-fibers/synthetic-fibers/material-properties-of-polyethyleneterephthalate-fiber.html. Accessed 24 Jan 2016.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Gawłowski, A., Fabia, J., Graczyk, T. et al. Study of PET fibres modified with phosphorus–silicon retardants. J Therm Anal Calorim 125, 1327–1334 (2016). https://doi.org/10.1007/s10973-016-5498-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5498-3