Abstract

The current study was performed to develop biodegradable films with matrix composed from gum Arabic (GA) and different concentrations from Alpinia officinarum phenolic extract (AOE). The color indices, physical properties, surface shape, crystallinity, mechanical properties and thermal stability of produced films were investigated. The incorporation of AOE extract (0.25 g/100 mL) inside GA films increased dark yellow color, reduced moisture, swelling, solubility and water vapor permeability (WVP) of films up to 10.29%, 21.05%, 14.15% and 4.20 × 10−10 g H2O/m s p.a., respectively. Furthermore, the scanning electron micrographs showed uniform structure with rough surface and turmoil spots in the structure by increasing AOE concentration inside films. The FT-IR analysis showed typically bands that proved physical interaction between AOE extract and GA polymer. The fabricated films showed satisfied thermal stability manners with declining trend by incorporation of AOE inside GA films. Furthermore, the developed films showed significant effects on reducing the changes of browning index from 17.20 to 24.54 and firmness from 33.98 to 22.65 N of Agaricus bisporus caps during storage days compared with commercial packaging materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The advances in petrochemical industry have led to the exploitation of fossil and non-renewable sources in production of poor biodegradation wrapping films with chemical residues in food products and significant effects on human health and the environment. This fact led to the increasing attention for biodegradable alternatives to reduce environmental problems and supporting the trend towards sustainability and environment-friendly natural biopolymer [1, 2]. Consequently, the researchers have tended to produce bio-multifunctional films of natural polymers as substitutes for synthetic plastic, such as polyvinyl dichloride, low-density polyethylene and polyvinyl chloride due to nontoxic, biodegradable and renewable nature [3, 4].

Many natural biopolymers such as chitosan, carboxy methyl cellulose, sodium alginate, gelatin and gum Arabic (GA) were utilized as basic material for production of edible films for different ecological food packaging purposes [5]. Especially, GA a type of carrier material extracted from Acacia species composed from salt of arabinogalactan-type of polysaccharide containing different ions and about 2% protein and still a good choice for bio-composite films forming [6]. Additionally, GA was considered as a natural and sustainable food-grade polysaccharide and the highly branched carbohydrate part makes it an ideal matrix with good emulsifying capacity and has been widely used in the food field [7, 8]. However, it requires providing the GA films with some additional characteristics such as modification of its permeability, solubility and increasing antioxidant properties to be suitable for specific functions for different food applications.

Supporting biopolymers with plant extracts is one of the most important ways to modify the composition of films and providing biological properties to them for different purposes such as antioxidant activity, enhancing water barrier properties and antibacterial agents for preservation of food products [1, 9,10,11].

The Galanga (Alpinia officinarum) is aromatic rhizomes, which is following ginger family (Zingiberaceae). The rhizomes are utilized as spicy traditional medicine and cultivated in Vietnam, India, Thailand and Southern China [12]. Three important bioactive groups (flavonoids, glycosides and diarylheptanoids) were detected in Galanga extracts and are involved in antioxidant and pharmacological properties of its extracts [13]. Additionally, the isolated diarylheptanoid from Galanga extracts showed strong inhibitory and antibacterial effects [14] and the methanolic extracts of rhizomes displayed antifungal activities [15]. Furthermore, the presence of bioactive components inside polymers were exploited previously to extend the shelf life during storage of grass carp fillets [16], preservation of chicken breast [17] and sliced Omega-3 rich mortadella [18]. This suggested its potential application directly to prolong the shelf life of food or presence inside polymer carries to enhance its properties as wrapping materials.

White mushrooms (Agaricus bisporus) are suitable fungi of commercial utilization because of their functional properties, high-protein, unique flavor and low-fat [19]. However, the caps are one of the most perishable fruits and tend to lose quality directly after harvest with 1 to 3 days shelf life at ambient temperature in marketing conditions and this largely due to their high respiration rate, high moisture content and microbial contamination [20] or due to the lack of suitable means of protection from physical or microbial attack [21]. On the basis of the above, this study was conducted to make comprehension between fabricated functional semi-permeable films and plastic commercial films for wrapping of white mushrooms to be considered as new approach to maintain the texture and quality instead of plastic materials.

Materials and Methods

Materials

The fresh Agaricus bisporus caps were purchased from Shaza company, Elgharbia, Egypt. The rhizomes of Alpinia officinarum were purchased in December 2021 from the local market in Cairo, Egypt. The utilized GA polymer and two radicals DPPH and ABTS were procured from Sigma Aldrich Co., Ltd. (St. Louis, MO, USA). The Glycerol was obtained from Solarbio Science & Technology Co., Ltd. (Beijing, China). The others reagents were of analytical grade.

Methods

Preparation of Alpinia officinarum Extract

A weight of 20 g from dried rhizomes was ground and extracted with 70% ethanol (200 mL) at room temperature (22 °C) for 48 h. The extraction process was repeated and the collected extracts were filtered and the filtrate was evaporated in a rotary evaporator. The remained residues were frozen at− 80 °C. Finally, the lyophilization process was done at− 40 °C for 48 h to get Alpinia officinarum extract (AOE) lyophilized powder and the powder was stored at -20 °C till use.

Characterization of AOE

The analysis of AOE bioactive components was conducted by utilizing LC-ESI-QTOFMS system (G2-XS QTOF Waters, Manchester, UK) as described previously [22] with suitable modifications. Briefly, diluted samples (2 mg/mL) of AOE were centrifuged at 5000 rpm for 20 min at 30 °C. After collecting supernatant, volumes of 1.5 mL were injected to HPLC vials for LC–MS detection. After that, 2 μL of extract was injected inside column ACQUITY UPLC BEH C18 with dimension of (2.1 × 100 mm) and the flow rate was adjusted to 0.4 mL/min. A concentration of 0.4% from formic acid was utilized as first mobile phase and the second was 0.3% formic acid in acetonitrile. The electrospray ionization unit was exploited to generate mass spectrum in ranges between 100 and 1600 with positive mode with temperature 800 °C at voltage 2.5 kV. The software of Masslynx version 4.1 was exploited to generate final results.

Fabrication of Gum Arabic Alpinia officinarum Films

GA (3 g) was stirred on 900 rpm in 100 mL distilled water for 1 h at 70 °C. After that, 0.8 g of glycerol (as plasticizer) was added and another stirring with the same conditions was followed for 30 min. Then, different concentrations (0.05, 0.15 and 0.25 g) from lyophilized AOE were added to get mixtures of GA-AOE1, GA-AOE2 and GA-AOE3, respectively and stirred at 900 rpm with the previous solution for another 30 min on 45 °C. Finally, the solution was poured into special glass plates (20 cm × 30 cm) and dried for 6 h at 40 °C. After drying, the produced films were carefully peeled and stored between paper sheet in desiccator for further analysis.

Characterization of Produced GA-AOE Films

Color and Opacity Measurements

The color parameters of GA-AOE films were investigated by utilizing Minolta CR-A70 (Konica Minolta Co., Ltd, Tokyo, Japan) according to Sothornvit and Pitak [23]. The results were presented directly from the screen of machine as following; L* values indicated changes from darkness to lightness, a* values showed the color transference from green to red and b* values revealed changes of color from blue to yellow. The ΔE values were calculated from the subsequent equation;

where ΔE represents total color difference, ΔL* differences from darkness to lightness, Δa* differences from green to red and Δb* differences from blue to yellow.

The opacity parameter was recorded as described previously [24]. Briefly, the absorbance of ten repetition regions of produced films were recorded at 600 nm by using UV/Vis spectrophotometer and the opacity values were calculated depending on the subsequent equation;

where Abs600 absorbance at 600 nm and T values average thickness of samples (mm).

Determination of Moisture, Swelling Index and Solubility

The swelling index and solubility of the films were calculated as described by our previously report [25]. Briefly, ten equidistant pieces of samples were cut in dimension of 20 × 20 mm. After that, the wet weight was recorded (W0) and after drying at 105 °C, the dried weight was recorded (W1). A volume of 50 mL from distilled water was transferred to 100 mL beakers and the dried films were soaked carefully inside beakers and preserved for 24 h at 25 °C. After drying samples metaphorically by filter papers, the weight was recorded again (W2). Then, the resulted films were exposed to drying by air oven at 105 °C to get final drying weight (W3). The parameters were calculated according to the subsequent equations;

Determination of Film Thickness and Water Vapor Permeability

The method of Eltabakh et al. [22] was utilized to determine the thickness accurately with suitable modification. The samples were cut in dimension of 1 × 6 cm and the rectangle samples were extended between two microscopic slides. The micrometer was operated to define thickness ten times at various regions. After that, the rectangle films were pulled and the digital micrometer was operated again to define the thickness of two slides without films. Then the final thickness was calculated by difference.

The proficiency of the film to retard the permeability of water vapor was investigated as mentioned previously [26] with some modification. The glass cups were prepared and filled with calcium chloride and the tested films were fixed on top of cups and weighted. The prepared cups were transferred into dissector at 25 °C and 75% (RH). The changes in cups weight during storage were noticed every hour intervals for 10 h. The slope was drawn by noticing changes in weight and the WVP (gm−1 s−1 Pa−1) was calculated by using the following equation;

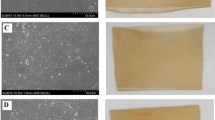

Scanning Electron Microscope Analysis

The surface cracks or wrinkles of the film samples were observed by using SEM (SU8010, Hitachi, Japan) machine. Square films shapes were cut into dimensions (10 × 10 mm) and fixed on aluminum surfaces in preparation for spraying it with golden spray to form the surface. The SEM photographs were captured with suitable magnification power to facilitate the study of film surface.

Analysis of FT-IR Spectra Wave Length

The spectra wave length of samples were recorded by (Nicolet iS-50, Thermo, USA) machine in different ranges between 4000 and 500 cm.−1 [27]

X-Ray Diffraction Analysis

The XRD patterns of films were generated according to previous work [28] by Bruker D8 Advance, USA X-ray diffractometer. The utilized voltage was 40 kV and 40 mA. The scattered radiation was performed in regular range 2θ = 5–35°.with a scanning rate of 5°/min.

DSC and TGA Analysis of Films

The DSC curves were generated by following the next method using DSC-60 plus SHIMADZU machine. The films samples were weighed (3 mg) and transferred accurately in aluminum pans and the pans were closed tightly with a piston. The closed pans were dropped carefully in machine filed and the empty pans were considered references in another side of field. Then the machine was adjusted to heat from 0 to 400 °C and 10 °C was considered as a stable rate for temperature increasing. Whilst for TGA analysis, the experiment was conducted by utilizing a TGA-50 thermogravimetric analyzer (Shimadzu, Tokyo, Japan). A weight of 10 mg of films samples was transferred to steel pan of machine that withstand high pressure and in contrast another empty pan was considered as reference. The machine was adjusted to raise temperature gradually to 600 °C at rate of 10 °C for minute.

Characterization of Mechanical Properties

The mechanical properties of films were characterized depending on determination of tensile strength (TS) and elongation at break (EB) of samples. Briefly, the texture analyzer (TA.XT Plus, Stable Micro Systems Ltd., Surrey, UK) was exploited to calculate both parameters. The samples were cut into rectangular shape with dimension of (20 × 100 mm) and were stabilized between the lower and upper grips. The machine was adjusted to move upper grip at speed of 100 mm/min and the tensile power was 100 N. The obtained data from stress and strain were calculated by utilizing software of Zwick (Test Expert V11.02).

Determination of Antioxidant Activity of Films

The scavenging activity of films was investigated through testing ability to scavenge DPPH and ABTS radicals. For DPPH scavenging radical activity, the method of Siripatrawan and Harte [29] was conducted. Briefly, a weight of 100 g from films samples were immerged in to 10 mL of methanol 10% (v/v). After shaken at 120 rpm for 3 h, the samples were centrifuged and the supernatant was collected. Then, a volume of 0.5 mL from each supernatant was mixed with 4.5 mL of previously prepared methanolic DPPH solution (1 mM). To start the reactants, the mixture was vortexed for 30 min and the absorbance was recorded at 517 before and after mixing the samples and the parameter was calculated according to the next equation;

where Ab1 is the absorbance of DPPH solution and Ab2 is the absorbance of DPPH and sample.

For ABTS scavenging activity, the previously method was performed [30]. Briefly, the work solution was prepared by mixing concentration of 145 mM from potassium persulfate with 7 mM of ABTS reagent. After that, the work solution bottle was covered carefully and stored in dark for 12 h. Then, to adjust the absorbance of work solution to be not more than 0.8, the PBS (0.2 M, pH 7.4) was utilized to dilute the solution. After mixing 20 mL of films extract with 1980 µL of work solution, the absorbance was noticed at 734 nm and the scavenging activity was calculated according to the next equation;

where Ab0 describes the absorbance of the initial ABTS free radicals, A1 is the absorbance of sample, and A2 is absorbance of a standard organized as A1 whereas replacing ABTS radicals with PBS.

Determination of Biodegradation Ability

The films biodegradation ability was performed depending on the previous literature [31] with slight modifications. Briefly, a dimension of (4 × 4 cm) from films samples were weighed and buried at depth of 5 cm inside soil for 30 days. During storage, the soil was sprayed by water every 12 h. At the end of every 10 days, the samples were extracted and the weight loss was determined.

Characterization of Browning Index and Firmness of Mushrooms During Storage

The white mushrooms (Agaricus bisporus) samples were transported to laboratory and the wounded caps were discarded. The caps were cleared from traces of soil by soft dried tissues. After that, two pieces of different types from wrapped materials (stretch wrap, polyvinyl chloride and GA-AOE3) in dimension of 14 × 14 cm were folded to contain suitable number of mushrooms samples. The electronic impulse sealer machine was utilized carefully to close the package from the edges tightly. The packages were maintained on refrigerator at 5 °C for 21 days. The subsequent Measurements and analysis of the mushrooms were performed every 3 days. Concerning browning index, the colorimeter was exploited to measure L, a and b color indices of the middle of caps fruits as mentioned previously [20] and the values were generated from the subsequent equations;

The firmness was evaluated by using a texture analyzer (TA-XT2i, Stable Micro Systems Ltd., Godalming, UK) according to previous literature [32]. The machine was calibrated to achieve speed of prob 5.0 mms−1. The 2 mm diameter cylindrical probe was moved towards stabilized samples and penetrated to a depth of 10 mm. The measurements were investigated in triplicate and the mean was calculated.

Statistical Analysis

One-way anova with SPSS version 19.0 (Chicago, IL, USA) was used to analyze the data. Tukey’s honest (HSD) test was done to calculate the variances in relative abundance.

Results and Discussion

Analysis of AOE

The qualitative analysis of bioactive components in AOE was conducted by LC-ESC-QTOF/MS. Table 1 concluded the chromatographic list and the MS data for the eight experimentally identified compounds. The tentatively identified compounds were Apigenin, kaempferol, rutin, quercitin, pinocembrin, catechin, 5-caffeoylquinic acid and galangin. The previous literature proved the presence of apigenin, galangin and kaempferide in rhizomes extracts [33,34,35]. Furthermore, the galangin, a member of the flavonoids compounds, was present in high concentrations in galanga extracts [12, 13, 36]. The attendance of rutin and pinocembrin were proved previously in ethanolic extracts of rhizomes [37, 38].

Color Indices and Opacity

The surface color and opacity of fabricated films played a vital role in food application since they could affect directly on consumer sense and the stability of packed food products. The interaction between GA and AOE inside films created significant changes in color parameters as indicated in Table 2. The b* values that describe leaning towards yellow color were increased by increasing the concentration of AOE inside GA films to reach 22.13 in GA-AOE3 films. As a consequence, the L* values that describe sharpness or lightness of color were decreased with the presence of high concentrations of the extract. Additionally, the yellow color of the AOE led to an increase in the darkening of produced films and as a result, the total color difference ΔE increased significantly, reaching the highest level 27.13 in GA-AOE3 films. The previous changes in color parameters led to significant increase of opacity values to reach 5.87 in GA-AOE3 compared with GA films (1.98). The same manners were proved previously [39].

Physical Properties

The integration of active components inside GA films like AOE can impact on the physical manners of the films. Hence, this work illustrated these characteristics through determination of thickness, moisture content, solubility, swelling degree and WVP.

In the present study, the swelling index and solubility values of the films in water were reduced (p < 0.05) when the films were enriched with AOE as indicated in Fig. 1A. The physical interaction between molecules of phenolic extracts and polymers molecules could prevent the establishment of polymers-water hydrogen bonding. Furthermore, the hydrophobic properties of some plant extracts could reduce the swelling and solubility of prepared films by retarding absorption of water [40]. Notably, the moisture content of fabricated films followed the same reduction with the maximum addition of AOE inside GA films. The natural structure of GA films without AOE polyphenols showed the highest content of moisture due to the attendance of hydrophilic and protein part inside GA polymer that encourage interaction between water and these groups. However, the attendance of AOE with hydrophobic groups inside GA limiting the interaction between hydrophilic groups of GA and water molecules. The same characteristics were explained by using different polymers [41, 42]

As shown in Fig. 1B, the edible film thickness was increased significantly (p < 0.05) with increasing of AOE concentration inside GA films to reach its maximum value (0.145 mm) for GA-AOE3. The incorporation of extracts solution inside films matrix could create a disturb structure and reduce organize shape subsequent to of produce thicker films [43]. Similar trend has been reported previously [25].

Concerning WVP, it is one of the most determinations that can indicate the ability of fabricated films to retard moisture movement between product and surrounded environment to control the shelf life. Additionally, the moderate WVP values are favorable to organize the breath rate around wrapped plants. As indicated in Fig. 1C, the current results indicated that the addition of AOE to GA films caused significant decreasing (p < 0.05) effect on WVP of film samples except of the first concentration. The lowest value of WVP 4.132 (× 10–10 g H2O/m s P.a.) was achieved by thicker films (GA-AOE3). The thicker films could probably retard crossing water vapor through surface [44]. Nevertheless, the different components of fabricated films (GA, AOE and glycerol) may cause less connections between the water particles in the films and as a result decrease WVP [45]. The obtained results are in the same trend with those investigated previously [46].

SEM Photographs

SEM photographs were noticed to investigate the microstructure of films surface after incorporation by different concentrations from AOE. The changes on films surface play a principal role in the permeability of films [47]. The structure and homogeneity of GA-AOE films surface are shown in Fig. 2. The images of control films (GA) Fig. 2A showed homogeneous structure without aggregates or cracks. The attendance of AOE inside films caused disturbance and discontinuous in the matrix of GA polymer. However, at low percentage of AOE Fig. 2B, the surface appearance was uniformly without any obvious aggregation. The highest percentage of AOE Fig. 2D inside films caused rough surface and created turmoil spots in the structure. The heterogeneous surface of films after incorporation by polyphenolic extracts were observed previously [25, 48, 49]. Consequently, the wide area of aggregates on films surface could form rigid films with low mechanical properties [50] and this was in the same trend of the obtained results in “Antioxidant capacity of prepared films” section.

FT-IR Properties

As indicated in Fig. 3A, the functional groups and the nature of molecular interactions between the GA and AOE were noticed by using FT-IR spectroscopy. The FT-IR spectra of GA displayed principal points in wavenumber length around 1413.31, 1603.21 (symmetrical, asymmetric stretching vibration of –COO−), 2953.42 (C–H stretching) and 3287.12 (O–H stretching, characteristic of a glucosidic ring) [51, 52]. Concerning the addition of different concentrations from AOE to GA films, the resulted spectral analysis for GA-AOE films showed the same typically wavenumber length compared to GA films evidence for only physically interaction occurred between AOE extract and GA polymer [53]. The physically interaction is favorable to maintain the bioactivity of incorporated extracts by impeding the disappearance of their active groups by chemical bonding. The incorporation of different plant extracts inside polymers proved the physically interaction with small changes in wavenumber length [54, 55]

XRD Analysis

XRD analysis was investigated to compare the crystalline shape of control films without extracts with films incorporated by different AOE concentrations. As indicated in Fig. 3B, the XRD spectrum lines of GA, GA-AOE1, GA-AOE2 revealed almost the same crystalline manners with a broader and double peak appearance at 8.2° and 22.4°. The obtained results suggest that the existence of AOE with lower concentration inside GA films did not influence the internal structure and crystallinity of GA films. However, by continuous addition of AOE inside GA films; the x-ray spectrum showed one peak appearance at 22.8° with wider shape. Similar results have been illustrated previously [22, 56]. This phenomenon could be explained by the fact that a possible competitive interaction between AOE extract and GA decreased the formation of strong bonds inside GA films, and thus resulted changes in crystallinity. Consequently, this could explain the significant collapse of mechanical properties in “Antioxidant capacity of prepared films” section by changing the crystallinity properties of GA-AOE films at highly concentrations from extracts. The findings are in the same line with previous reports [22, 57]

DSC and TGA Analysis

The DSC curves of fabricated films are illustrated in Fig. 4A. All samples displayed exclusive peaks in shape of endothermic and exothermic curves. The endothermic shape explained the evaporation of water after heat absorption [58], whereas the exothermic shape of curves (from 260 to 300 °C) is related to collapse of GA polysaccharide [59]. The control GA films illustrated exothermic region in the range of 271.31 °C whilst, The GA-AOE3 exhibited exothermic region in the range of 255.41 °C. Thus, the increasing of AOE inside GA films caused declining trend in films thermal stability. The incorporation of plant extracts inside polymers resulting to decrease thermal stability of films [60].

A similar trend can be observed in Fig. 4B, which shows the thermal behavior of GA-AOE films using thermal gravity analysis. The natural composition of GA-AOE films created three manners of weight loss. Firstly, the degradation of hydrogen bonding by losing of water at (40 –120 °C). Secondly, the decomposition of provided glycerol during preparation of films at (130–250 °C) [61]. Lastly, the depolymerization stage of GA at (260–400 °C) could be ascribed to the degradation and carbonization of the residual products after thermal degradation during the first two stages. It is obvious from the findings that, the weight loss of GA films was significantly lower than that of GA-AOE films which proved that the incorporation of AOE into GA film decreased the thermal stability of the native film. The changes in structure and the crystallinity disturbance after adding AOE to GA films could explain that low energy is required to breakdown the polymer template [62, 63]. In addition, this result could be associated with the interaction weakening in the polymer chains when AOE was added, which assisted its decomposition at lower temperatures. The thermal stability analysis supports the results of SEM and XRD patterns.

Mechanical Properties of Films

The tested TS and EB properties of fabricated films are ideal parameters to describe the stretchability and strength during breakage. The results of mechanical characteristics for all the fabricated films are depicted in Fig. 5A. Noticed decreased trend (p < 0.05) in TS and EB was occurred of all films. It was obvious from the Figure that GA film showed the maximum values of mechanical properties 66.82 MPa and 56.83% of TS and EB, respectively. Whereas, the incorporation of AOE inside GA polymer decreased the mechanical properties. The polymers compositions, the internal molecular force and the crystallinity shape play very important role in influencing of the mechanical properties [64]. The results of SEM and XRD indicates formation of aggregates and disturbance of crystalline structure by continuous addition of AOE inside GA films that could lead to decreasing of mechanical properties. The obtained results were in the same trend of those explained previously [22, 25, 65] who proved that the incoroporation of plant phenolic extracts inside different polymes during formation of biocomposite films could change the crystaline shape of produced films and as a result decrease the mechanical properties.

Antioxidant Capacity of Prepared Films

The antioxidant capacity of produced films was determined based on two different methods DPPH and ABTS. The mentioned methods were recorded as suitable for expressing the ability of films to scavenge free radicals [66]. The results of Fig. 5B revealed that the DPPH and ABTS radical scavenging values increased significantly (p ˂ 0.05) with the increase of AOE concentrations inside GA films in a dose-dependent manner. Comparatively, the GA-AOE3 displayed the maximum antioxidant activity. It reduced 78.23 and 84.21% of stable DPPH and ABTS radicals, respectively. From the foregoing, it can be concluded that the greatest effect of films as antioxidants is due to the presence of AOE between the folds of GA films. However, the GA films without extracts indicated aptitude to reduce the stable radicals and this might be described by the fact that GA considers polymer with satisfied antioxidant properties [67]. Similar trend of obtained results was explained previously [26] by using mango kernel extracts as functional components for enhancement of protein—based films.

Biodegradation Ability

The biodegradation test represents an ideal choice to evaluate the breakdown of fabricated films to measure its sustainability and environmental compatibility. The results of biodegradation test in Fig. 6 revealed that, the weight loss of all tested samples increased as the time of soil dumping was increased. However, GA-AOE3 films exhibited the highest weight loss of (45.81%) compared with GA (26.87%) after 30 days. The obtained results were in the same trend of those obtained by Alnadari et al. [68] who proved that the presence of Cinnamomum camphora seeds polyphenols inside carboxymethyl chitosan-gum Arabic films led to reduction of weight loss by increasing soil dumping time. Thus, the addition of AOE inside GA films improved its biodegradability to be suitable for environment by quick degradation. Also, the same manners were obtained previously by incorporation of phenolic extracts inside polymers [69].

Characterization the Ability of Films to Maintain Mushrooms Quality

Browning Retardation and Firmness Preservation

Mushrooms browning is a limit biochemical character for consumer usage after harvest. Therefore, the browning assumes a vital role in marketability and consumer satisfaction. The obtained data in Fig. 7A revealed that, the wrapping of samples by GA-AOE3 retarded the formation of brown color with non-significant differences until 12 days of storage. However, significant increasement with slow rate was noticed after 12 days of storage. Concerning the wrapping of samples by the stretch wrap and polyvinyl chloride, the browning color was densely accumulated on the surface of samples compared with GA-AOE3. The obtained results revealed that, the AOE3 bio-composite films are suitable choice to cover mushrooms during cold storage. It was noticed that, the wrapping by commercial films like shrinkable and polyvinyl chloride led to accumulation of internal moisture a round samples. The accumulation of water vapour in the package, allowing spoilage by promoting the microbial growth and causing formation of brown and spotted samples [70]. However, the AOE3 films are semi-permeable and might regulate the WVP and as a result retard the accumulation of moisture on samples. The semi-permeable gum Arabic films by incorporation with plant polyphenols were obtained previously [68].

Concerning the firmness of mushrooms Fig. 7B, the compared films followed the same manners of browning with descending trend. Comparatively, the GA-AOE3 films indicated an ideal matrix for preserving the samples firmness during cold storage. The wrapping by commercial shrinkable and polyvinyl chloride films showed obvious collapse in the ability to maintain the firmness [71] revealed that, the wrapping of mushrooms samples by biodegradable coatings lowered the maturity index and retard the changes of firmness compared with different types of commercial polyvinyl chloride. Likewise, the accumulation of moisture around samples may lead to promote decay by encouragement of microbial growth and as a result occurring changes in firmness during storage. On the other hand, the attendance of polyphenolic compounds inside bio-composite films may inhibit growth of Gram -positive and Gram-negative bacteria causing preserving on food quality [22]. In general, the tough conditions inside package encourage increasing of respiratory rates of mushrooms caps that induce β-glucanase to accelerate the decay by smashing the mushroom polymer structure to fragile monosaccharide composition [72].

The obtained results for browning index and firmness were in the same trend of those obtained by Chang et al. [20] who proved that, the utilizing of bio-polymers might introduce favorable choice to regulate respiratory rate inside package for persevering mushrooms quality during cold storage.

Conclusion

The phenolic extracts from Alpinia officinarum (AOE) rhizomes were exploited to produce GA functional based packaging films. The effects of AOE after incorporation into the GA based food packaging film were explored. Addition of AOE in GA films improved moisture content, swelling degree, water-solubility and thickness. WVP was decreased up to 4.20 × 10−10 g H2O/m s p.a., which showed the good barrier properties of GA-AOE films. Also, AG-AOE3 films represented good scavenging antioxidant activity up to 77.42% for DPPH and 85.47% for ABTS.

The produced packaging films (GA-AOE3) were tested compared with commercial plastic materials (stretch wrap and polyvinyl chloride) to wrap mushroom samples during cold storage. The wrapping of samples by the stretch wrap and polyvinyl chloride showed accumulation of the browning color on the surface of samples compared with GA-AOE3. Also, samples packaged with GA-AOE3 film showed more firmness than others packaged. It may be concluded that the AOE3 bio-composite films are suitable choice to cover mushrooms during cold storage instead of unsustainable plastic materials. Further analysis is required to test the effects of wrapping materials on the activation of enzymes that influence on mushrooms shelf life.

Data Availability

Data will be made available on reasonable request.

References

Sady S, Błaszczyk A, Kozak W, Boryło P, Szindler M (2021) Quality assessment of innovative chitosan-based biopolymers for edible food packaging applications. Food Packag Shelf Life 30:100756

Yu Z, Jiang Q, Yu D, Dong J, Xu Y, Xia W (2022) Physical, antioxidant, and preservation properties of chitosan film doped with proanthocyanidins-loaded nanoparticles. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2022.107686

de Leis CM, Nogueira AR, Kulay L, Tadini CC (2017) Environmental and energy analysis of biopolymer film based on cassava starch in Brazil. J Clean Prod 143:76–89

Chang W, Liu F, Sharif HR, Huang Z, Goff HD, Zhong F (2019) Preparation of chitosan films by neutralization for improving their preservation effects on chilled meat. Food Hydrocoll 90:50–61

Haghighi H, Licciardello F, Fava P, Siesler HW, Pulvirenti A (2020) Recent advances on chitosan-based films for sustainable food packaging applications. Food Packag Shelf Life 26:100551

Erben M, Pérez AA, Osella CA, Alvarez VA, Santiago LG (2019) Impact of gum arabic and sodium alginate and their interactions with whey protein aggregates on bio-based films characteristics. Int J Biol Macromol 125:999–1007

Patel S, Goyal A (2015) Applications of natural polymer gum arabic: a review. Int J Food Prop 18(5):986–998

Idris O, Williams P, Phillips G (1998) Characterisation of gum from Acacia senegal trees of different age and location using multidetection gel permeation chromatography. Food Hydrocoll 12(4):379–388

Vidal OL, Santos MCB, Batista AP, Andrigo FF, Baréa B, Lecomte J et al (2022) Active packaging films containing antioxidant extracts from green coffee oil by-products to prevent lipid oxidation. J Food Eng 312:110744

Thivya P, Bhosale Y, Anandakumar S, Hema V, Sinija V (2021) Development of active packaging film from sodium alginate/carboxymethyl cellulose containing shallot waste extracts for anti-browning of fresh-cut produce. Int J Biol Macromol 188:790–799

Yuan D, Hao X, Liu G, Yue Y, Duan J (2022) A novel composite edible film fabricated by incorporating W/O/W emulsion into a chitosan film to improve the protection of fresh fish meat. Food Chem 385:132647

Köse LP, Gülcin I, Gören AC, Namiesnik J, Martinez-Ayala AL, Gorinstein S (2015) LC–MS/MS analysis, antioxidant and anticholinergic properties of galanga (Alpinia officinarum Hance) rhizomes. Ind Crops Prod 74:712–721

Eumkeb G, Sakdarat S, Siriwong S (2010) Reversing β-lactam antibiotic resistance of Staphylococcus aureus with galangin from Alpinia officinarum Hance and synergism with ceftazidime. Phytomedicine 18(1):40–45

Subramanian K, Selvakkumar C, Vinaykumar KS, Goswami N, Meenakshisundaram S, Balakrishnan A et al (2009) Tackling multiple antibiotic resistance in enteropathogenic Escherichia coli (EPEC) clinical isolates: a diarylheptanoid from Alpinia officinarum shows promising antibacterial and immunomodulatory activity against EPEC and its lipopolysaccharide-induced inflammation. Int J Antimicrob Agents 33(3):244–250

Liu Q, Luyten W, Pellens K, Wang Y, Wang W, Thevissen K et al (2012) Antifungal activity in plants from Chinese traditional and folk medicine. J Ethnopharmacol 143(3):772–778

Du H, Liu C, Unsalan O, Altunayar-Unsalan C, Xiong S, Manyande A et al (2021) Development and characterization of fish myofibrillar protein/chitosan/rosemary extract composite edible films and the improvement of lipid oxidation stability during the grass carp fillets storage. Int J Biol Macromol 184:463–475

Cui H, Cheng Q, Li C, Chen X, Lin L (2022) Improving packing performance of lily polysaccharide based edible films via combining with sodium alginate and cold plasma treatment. Int J Biol Macromol 206:750–758

Pérez-Córdoba LJ, Pinheiro AC, Núñez de Villavicencio-Ferrer M, Trindade MA, Sobral PJ (2022) Applying gelatine: chitosan film loaded with nanoemulsified garlic essential oil/α-tocopherol as active packaging of sliced Omega-3 rich mortadella. Int J Food Sci Technol. https://doi.org/10.1111/ijfs.15938

Zhang L, Liu Z, Sun Y, Wang X, Li L (2020) Combined antioxidant and sensory effects of active chitosan/zein film containing α-tocopherol on Agaricus bisporus. Food Packag Shelf Life 24:100470

Chang C-K, Cheng K-C, Hou C-Y, Wu Y-S, Hsieh C-W (2021) Development of active packaging to extend the shelf life of Agaricus bisporus by using plasma technology. Polymers 13(13):2120

Singh P, Langowski HC, Wani AA, Saengerlaub S (2010) Recent advances in extending the shelf life of fresh Agaricus mushrooms: a review. J Sci Food Agric 90(9):1393–1402

Eltabakh M, Kassab H, Badawy W, Abdin M, Abdelhady S (2021) Active bio-composite sodium alginate/maltodextrin packaging films for food containing Azolla pinnata leaves extract as natural antioxidant. J Polym Environ 30(4):1355–1365

Sothornvit R, Pitak N (2007) Oxygen permeability and mechanical properties of banana films. Food Res Int 40(3):365–370

Gómez-Estaca J, Giménez B, Montero P, Gómez-Guillén M (2009) Incorporation of antioxidant borage extract into edible films based on sole skin gelatin or a commercial fish gelatin. J Food Eng 92(1):78–85

Abdin M, El-Beltagy A, El-sayed M, Naeem MA (2021) Production and characterization of sodium alginate/gum arabic based films enriched with Syzygium cumini seeds extracts for food application. J Polym Environ 30(4):1615–1626

Adilah ZM, Jamilah B, Hanani ZN (2018) Functional and antioxidant properties of protein-based films incorporated with mango kernel extract for active packaging. Food Hydrocoll 74:207–218

Abdin M, Salama MA, Gawad R, Fathi MA, Alnadari F (2021) Two-steps of gelation system enhanced the stability of Syzygium cumini anthocyanins by encapsulation with sodium alginate, maltodextrin, chitosan and gum arabic. J Polym Environ 29(11):3679–3692

Nawab A, Alam F, Hadi A, Lutfi Z (2022) Development and characterization of edible film made from mango kernel starch. J Packag Technol Res 6(1):63–72

Siripatrawan U, Harte BR (2010) Physical properties and antioxidant activity of an active film from chitosan incorporated with green tea extract. Food Hydrocoll 24(8):770–775

Kim S, Baek S-K, Song KB (2018) Physical and antioxidant properties of alginate films prepared from Sargassum fulvellum with black chokeberry extract. Food Packag Shelf Life 18:157–163

Medina-Jaramillo C, Ochoa-Yepes O, Bernal C, Famá L (2017) Active and smart biodegradable packaging based on starch and natural extracts. Carbohyd Polym 176:187–194

Jiang T, Wang Q, Xu S, Jahangir MM, Ying T (2010) Structure and composition changes in the cell wall in relation to texture of shiitake mushrooms (Lentinula edodes) stored in modified atmosphere packaging. J Sci Food Agric 90(5):742–749

Fan G-j, Kang Y-H, Han YN, Han BH (2007) Platelet-activating factor (PAF) receptor binding antagonists from Alpinia officinarum. Bioorg med chem lett 17(24):6720–6722

Xin M, Guo S, Zhang W, Geng Z, Liang J, Du S et al (2017) Chemical constituents of supercritical extracts from Alpinia officinarum and the feeding deterrent activity against Tribolium castaneum. Molecules 22(4):647

Abubakar IB, Malami I, Yahaya Y, Sule SM (2018) A review on the ethnomedicinal uses, phytochemistry and pharmacology of Alpinia officinarum Hance. J Ethnopharmacol 224:45–62

Heo MY, Sohn SJ, Au WW (2001) Anti-genotoxicity of galangin as a cancer chemopreventive agent candidate. Mutat Res/Rev Mutat Res 488(2):135–150

Zhang J-Q, Wang Y, Li H-L, Wen Q, Yin H, Zeng N-K et al (2015) Simultaneous quantification of seventeen bioactive components in rhizome and aerial parts of Alpinia officinarum Hance using LC-MS/MS. Anal Methods 7(12):4919–4926

Zhang H, Xu L, Wu P, Wei X (2014) Flavonoids from the aerial parts of Alpinia officinarum. J Trop Subtrop Bot 22(1):89–92

Xie Q, Zheng X, Li L, Ma L, Zhao Q, Chang S et al (2021) Effect of curcumin addition on the properties of biodegradable pectin/chitosan films. Molecules 26(8):2152

Riaz A, Lagnika C, Abdin M, Hashim MM, Ahmed W (2020) Preparation and characterization of chitosan/gelatin-based active food packaging films containing apple peel nanoparticles. J Polym Environ 28(2):411–420

Leceta I, Guerrero P, De La Caba K (2013) Functional properties of chitosan-based films. Carbohyd Polym 93(1):339–346

Akhtar HMS, Riaz A, Hamed YS, Abdin M, Chen G, Wan P et al (2018) Production and characterization of CMC-based antioxidant and antimicrobial films enriched with chickpea hull polysaccharides. Int J Biol Macromol 118:469–477

Tongnuanchan P, Benjakul S, Prodpran T (2013) Physico-chemical properties, morphology and antioxidant activity of film from fish skin gelatin incorporated with root essential oils. J Food Eng 117(3):350–360

Mali S, Sakanaka LS, Yamashita F, Grossmann M (2005) Water sorption and mechanical properties of cassava starch films and their relation to plasticizing effect. Carbohyd Polym 60(3):283–289

Bitencourt C, Fávaro-Trindade C, Sobral PdA, Carvalho RA (2014) Gelatin-based films additivated with curcuma ethanol extract: Antioxidant activity and physical properties of films. Food Hydrocoll 40:145–152

Hosseini SF, Rezaei M, Zandi M, Ghavi FF (2013) Preparation and functional properties of fish gelatin–chitosan blend edible films. Food Chem 136(3–4):1490–1495

Hosseini SF, Rezaei M, Zandi M, Farahmandghavi F (2015) Fabrication of bio-nanocomposite films based on fish gelatin reinforced with chitosan nanoparticles. Food Hydrocoll 44:172–182

Sun X, Wang Z, Kadouh H, Zhou K (2014) The antimicrobial, mechanical, physical and structural properties of chitosan–gallic acid films. LWT-Food Sci Technol 57(1):83–89

Norajit K, Kim KM, Ryu GH (2010) Comparative studies on the characterization and antioxidant properties of biodegradable alginate films containing ginseng extract. J Food Eng 98(3):377–384

Riaz A, Lagnika C, Luo H, Nie M, Dai Z, Liu C et al (2020) Effect of Chinese chives (Allium tuberosum) addition to carboxymethyl cellulose based food packaging films. Carbohyd Polym 235:115944

Kanikireddy V, Kanny K, Padma Y, Velchuri R, Ravi G, Jagan Mohan Reddy B et al (2019) Development of alginate-gum acacia-Ag0 nanocomposites via green process for inactivation of foodborne bacteria and impact on shelf life of black grapes (Vitis vinifera). J Appl Polym Sci 136(15):47331

Ibekwe CA, Oyatogun GM, Esan TA, Oluwasegun KM (2017) Synthesis and characterization of chitosan/gum arabic nanoparticles for bone regeneration. Am J Mater Sci Eng 5(1):28–36

Bi F, Zhang X, Bai R, Liu Y, Liu J, Liu J (2019) Preparation and characterization of antioxidant and antimicrobial packaging films based on chitosan and proanthocyanidins. Int J Biol Macromol 134:11–19

Wang L, Guo H, Wang J, Jiang G, Du F, Liu X (2019) Effects of Herba Lophatheri extract on the physicochemical properties and biological activities of the chitosan film. Int J Biol Macromol 133:51–57

Riaz A, Lagnika C, Luo H, Dai Z, Nie M, Hashim MM et al (2020) Chitosan-based biodegradable active food packaging film containing Chinese chive (Allium tuberosum) root extract for food application. Int J Biol Macromol 150:595–604

Amalraj A, Haponiuk JT, Thomas S, Gopi S (2020) Preparation, characterization and antimicrobial activity of polyvinyl alcohol/gum arabic/chitosan composite films incorporated with black pepper essential oil and ginger essential oil. Int J Biol Macromol 151:366–375

Hu D, Wang H, Wang L (2016) Physical properties and antibacterial activity of quaternized chitosan/carboxymethyl cellulose blend films. LWT-Food Sci Technol 65:398–405

Su J-F, Huang Z, Yuan X-Y, Wang X-Y, Li M (2010) Structure and properties of carboxymethyl cellulose/soy protein isolate blend edible films crosslinked by Maillard reactions. Carbohyd Polym 79(1):145–153

Martins JT, Cerqueira MA, Vicente AA (2012) Influence of α-tocopherol on physicochemical properties of chitosan-based films. Food Hydrocoll 27(1):220–227

Cruz-Gálvez A, Castro-Rosas J, Rodríguez-Marín M, Cadena-Ramírez A, Tellez-Jurado A, Tovar-Jiménez X et al (2018) Antimicrobial activity and physicochemical characterization of a potato starch-based film containing acetonic and methanolic extracts of Hibiscus sabdariffa for use in sausage. LWT 93:300–305

Oun AA, Rhim J-W (2015) Preparation and characterization of sodium carboxymethyl cellulose/cotton linter cellulose nanofibril composite films. Carbohyd Polym 127:101–109

Qiao C, Ma X, Zhang J, Yao J (2017) Molecular interactions in gelatin/chitosan composite films. Food Chem 235:45–50

Pankaj SK, Bueno-Ferrer C, Misra N, O’Neill L, Tiwari B, Bourke P et al (2014) Physicochemical characterization of plasma-treated sodium caseinate film. Food Res Int 66:438–444

Pastor C, Sánchez-González L, Chiralt A, Cháfer M, González-Martínez C (2013) Physical and antioxidant properties of chitosan and methylcellulose based films containing resveratrol. Food Hydrocoll 30(1):272–280

Fabra MJ, Falcó I, Randazzo W, Sánchez G, López-Rubio A (2018) Antiviral and antioxidant properties of active alginate edible films containing phenolic extracts. Food Hydrocoll 81:96–103

Genskowsky E, Puente L, Pérez-Álvarez J, Fernandez-Lopez J, Muñoz L, Viuda-Martos M (2015) Assessment of antibacterial and antioxidant properties of chitosan edible films incorporated with maqui berry (Aristotelia chilensis). LWT-Food Sci Technol 64(2):1057–1062

Al-Majed AA, Abd-Allah AR, Al-Rikabi AC, Al-Shabanah OA, Mostafa AM (2003) Effect of oral administration of arabic gum on cisplatin-induced nephrotoxicity in rats. J Biochem Mol Toxicol 17(3):146–153

Alnadari F, Bassey AP, Abdin M, Salama MA, Nasiru MM, Dai Z et al (2022) Development of hybrid film based on carboxymethyl chitosan-gum arabic incorporated citric acid and polyphenols from Cinnamomum camphora seeds for active food packaging. J Polym Environ. https://doi.org/10.1007/s10924-022-02453-x

Medina Jaramillo C, Gonzalez Seligra P, Goyanes S, Bernal C, Famá L (2015) Biofilms based on cassava starch containing extract of yerba mate as antioxidant and plasticizer. Starch-Stärke 67(9–10):780–789

Brennan M, Le Port G, Gormley R (2000) Post-harvest treatment with citric acid or hydrogen peroxide to extend the shelf life of fresh sliced mushrooms. LWT-Food Sci Technol 33(4):285–289

Kim KM, Ko JA, Lee JS, Park HJ, Hanna MA (2006) Effect of modified atmosphere packaging on the shelf-life of coated, whole and sliced mushrooms. LWT-Food Sci Technol 39(4):365–372

Liu J, Liu S, Zhang X, Kan J, Jin C (2019) Effect of gallic acid grafted chitosan film packaging on the postharvest quality of white button mushroom (Agaricus bisporus). Postharvest Biol Technol 147:39–47

Acknowledgements

This work was supported by project of funded by Food Technology Research Institute, Agriculture Research Center, Giza, Egypt. Also, the authors are most grateful for the technical support provided by Nano Microbiology Lab (NML)—Nano science and technology institution—Kafrelsheikh University.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). This manuscript will be supported for publication fees by Agricultural Research Center, Egypt depending on the agreement between Springer nature and our institute.

Author information

Authors and Affiliations

Contributions

MMG: Conceptualization, data curation, formal analysis, methodology, resources, software, supervision, writing—original draft. EEF: Conceptualization, data curation, formal analysis, methodology, resources, software, supervision, writing—original draft. MAS: Investigation, resources, software, supervision. MA: Conceptualization, data curation, formal analysis, methodology, resources, software, supervision, writing—original draft.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declared that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gomaa, M.M., Fadly, E.E., Salama, M.A. et al. Production of Bio-composite Films from Gum Arabic and Galangal Extract to Prolong the Shelf Life of Agaricus bisporus. J Polym Environ 30, 4787–4799 (2022). https://doi.org/10.1007/s10924-022-02551-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02551-w